Ball-point pen

A technology for ballpoint pens and nibs, applied in the direction of ballpoint pens, nibs, printing, etc., to achieve the effect of inhibiting scratches and stains and preventing scratches and stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The manner in which the present invention is carried out is described below with reference to the accompanying drawings.

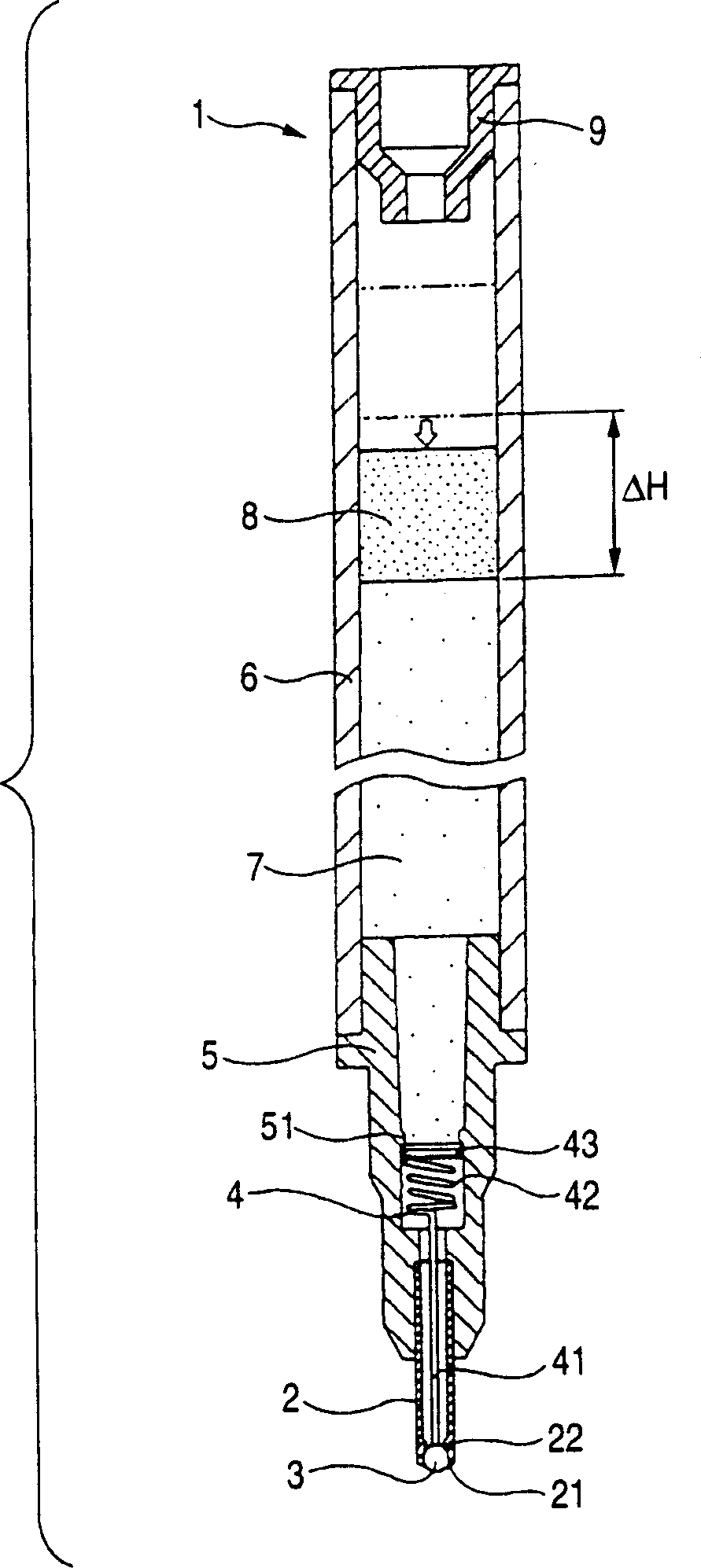

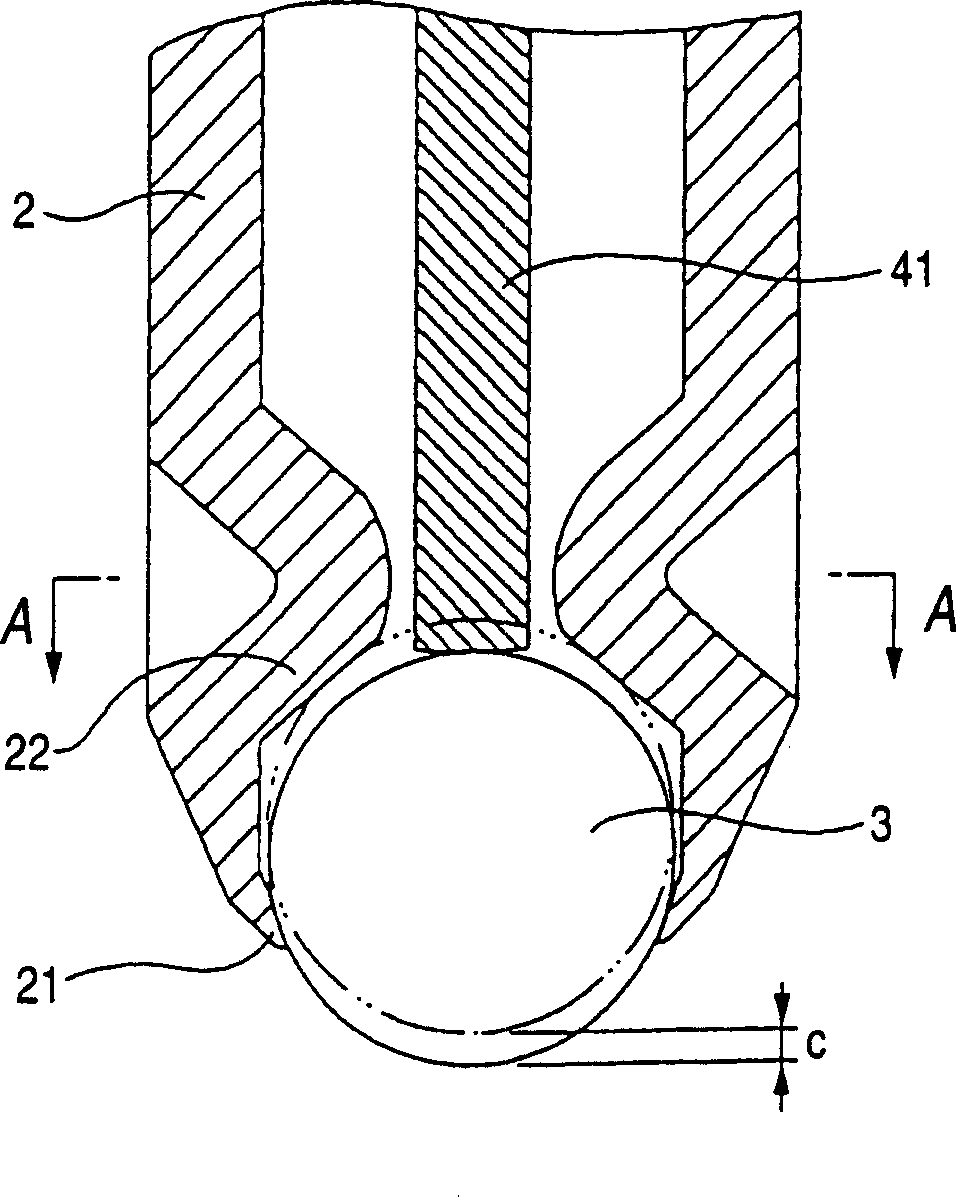

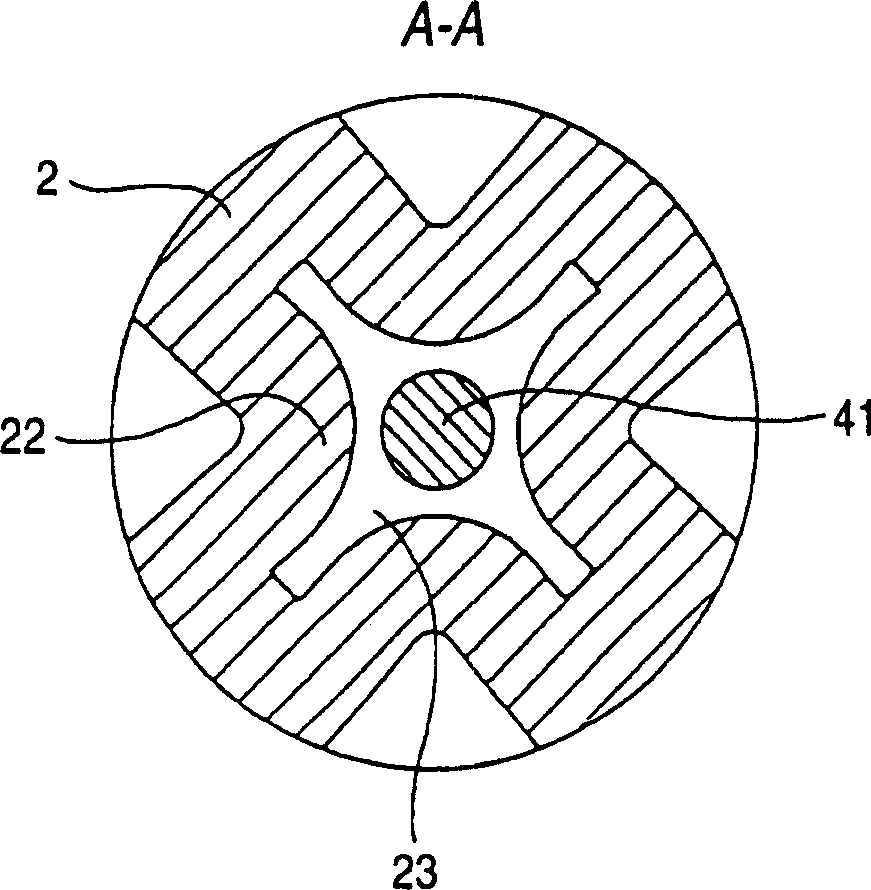

[0039] Figure 1 to Figure 5 A first embodiment of the invention is shown.

[0040] In this embodiment, the ballpoint pen 1 includes: a nib body 2 formed so that a ball 3 is rotatably retained at the front end portion of the nib body 2; a holder 5 formed so that the rear of the nib body 2 is pressed Into and fixed in the front of the holder 5; ink tube 6, the ink tube 6 is formed so that the rear of the holder 5 is pressed into and fixed in the front opening of the ink tube 6; the ink stored in the ink tube 6; An ink follower 8 accommodated in the ink tube 6; an elastic member 4 (spring) located inside the nib body 2 and inside the holder 5; and a tail plug 9 pressed into and fixed in the opening portion of the rear end of the ink tube 6 .

[0041] The ink tube 6 is shaped like a right cylinder having opposite open ends, and is formed by extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com