Preparation method of antibacterial hydrophobic ZnO nanorod

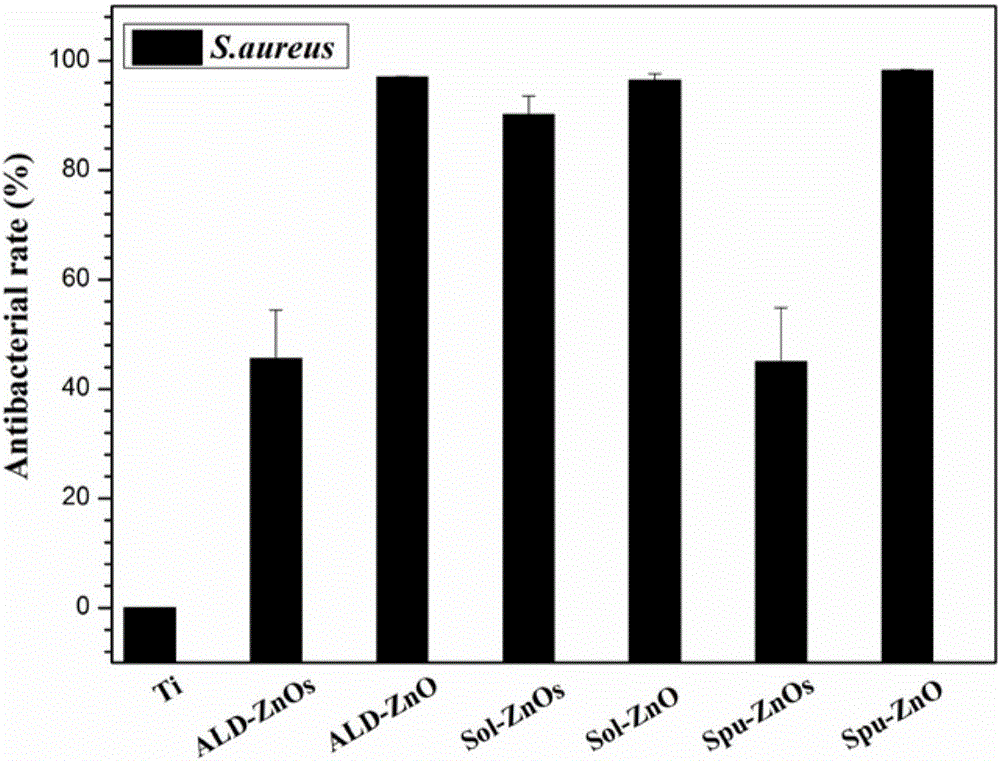

A nanorod, hydrophobic technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of increasing patient hospitalization time and medical expenses, threatening the life safety of patients, and failure of implant surgery and other problems, to achieve the effect of preventing scaling and bacterial biofilm formation, the preparation method is simple and easy, and the implementation is less difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

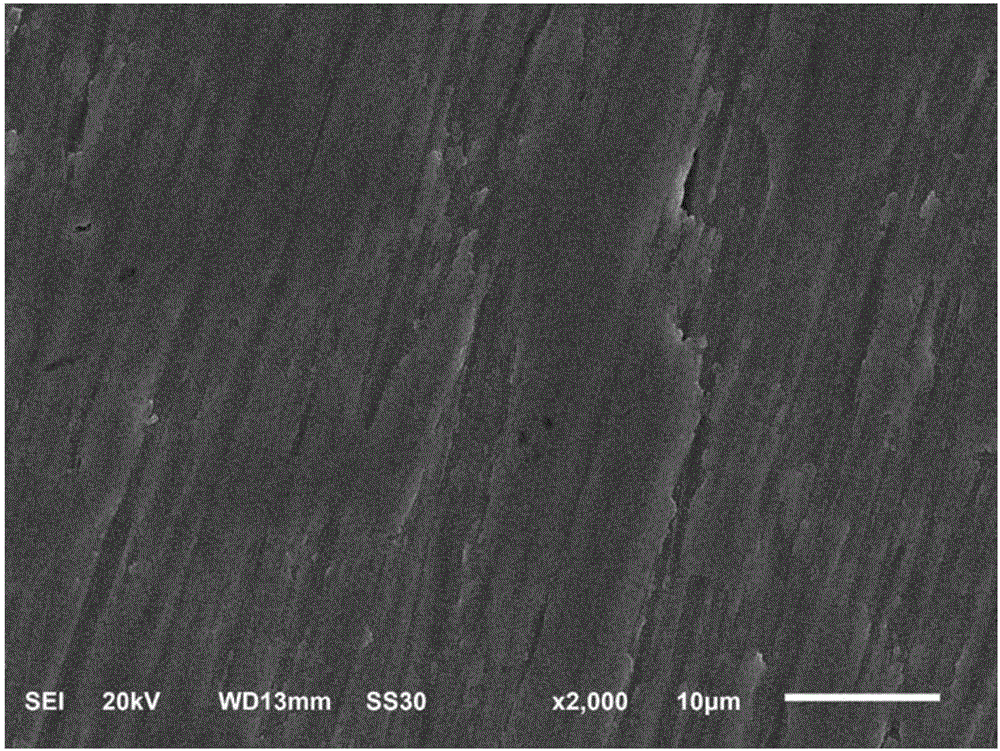

[0050] (1) Mechanical polishing of titanium sheet (diameter 6mm, thickness 2mm): Polish the titanium sheet with 240, 600, 1200 and 2400 mesh emery on the polishing machine in turn, until the surface is smooth, then place the polished titanium sheet in acetone, no Ultrasonic cleaning for 15 minutes each in water ethanol and deionized water, and natural drying at room temperature for use;

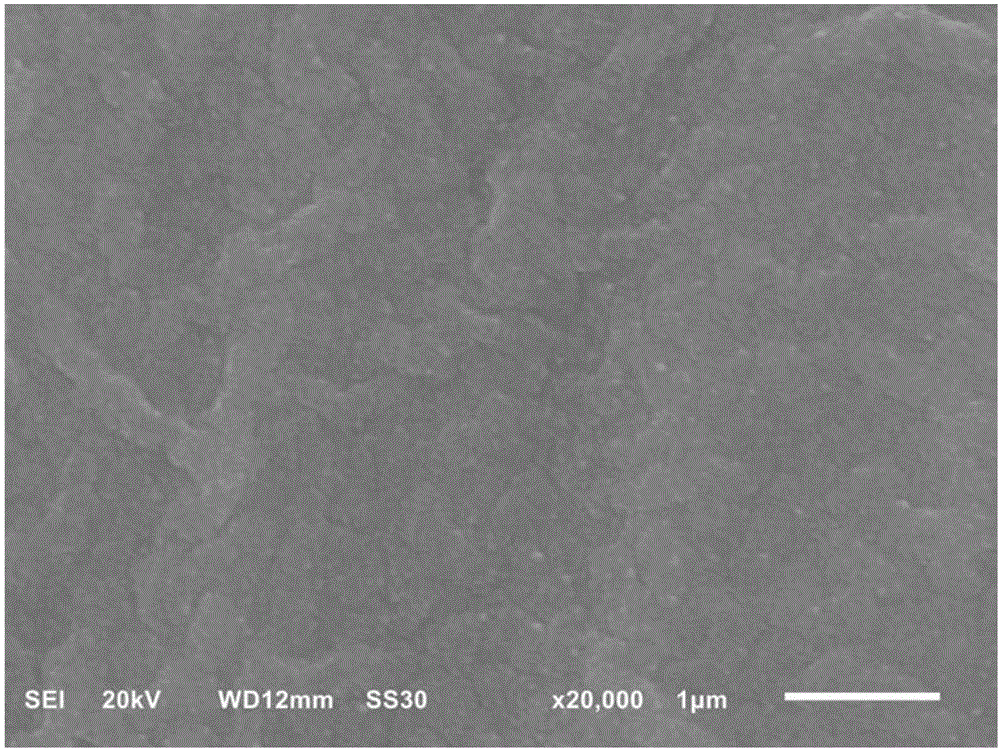

[0051](2) Using the obtained polished titanium sheet as a substrate, a uniform ZnO seed layer is plated by a sol-gel method; the specific method is to prepare an ethanol solution of 0.75mol / L zinc acetate dihydrate and 0.75mol / L ethanolamine, Then continue stirring for 4 hours to obtain a colorless transparent colloid and store it at room temperature for 24 hours. After the sol is fully aged, the precursor solution is obtained. Use a spin coater to coat 30 μL of the precursor solution on the titanium sheet. 15 seconds, 5000 rpm for 30 seconds in the later stage, then blow dry with nitrogen ga...

Embodiment 2

[0054] (1) Mechanical polishing of titanium sheet (diameter 6mm, thickness 2mm): use 240, 600, 1200 and 2400 mesh emery on a polishing machine to polish the titanium sheet to a smooth surface, and then place the polished titanium sheet in acetone and anhydrous ethanol. Ultrasonic cleaning with deionized water for 15 minutes each, natural drying at room temperature, for use;

[0055] (2) Using the obtained polished titanium sheet as a substrate, a uniform ZnO seed layer is plated by atomic layer deposition, specifically: preparing a zinc oxide solution with diethyl zinc (DEZ) and water as a zinc source and an oxygen source As the precursor, the substrate is then deposited. Under the conditions of the deposition temperature of 100 °C, the deposition pressure of 40 Pa, and the deposition flow of 20 , high-purity nitrogen cleaning for 20s as a cycle for deposition (H 2 O / N 2 / DEZ / N 2 =0.1:20:0.1:20s), the number of cycles is 300, and a ZnO seed layer is obtained on the substrat...

Embodiment 3

[0058] (1) Mechanical polishing of titanium sheet (diameter 6mm, thickness 2mm): use 240, 600, 1200 and 2400 mesh emery on a polishing machine to polish the titanium sheet to a smooth surface, and then place the polished titanium sheet in acetone and anhydrous ethanol. Ultrasonic cleaning with deionized water for 15 minutes each, natural drying at room temperature, for use;

[0059] (2) Using the obtained polished titanium sheet as a substrate, a uniform ZnO seed layer is plated by a high vacuum magnetron sputtering method; specifically, by using radio frequency magnetron sputtering, the pressure is first reduced to below 6.0×10-4Pa , and then pass high-purity argon as the working gas until the pressure is 3.0Pa, the sputtering temperature is 25°C, the sputtering power is 120W, and the sputtering time is 120s;

[0060] (3) First prepare 0.025mol / L zinc nitrate hexahydrate (Zn(NO) 3 )2) 6H 2 O) and 0.025mol / L hexamethylenetetramine (C6H 12 N 4 ) of the aqueous solution 60ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com