Stiffness test bench device of debugging engine hood and use method thereof

A technology of test bench and engine cover, which is applied in the field of vehicle testing to achieve the effect of simple operation and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

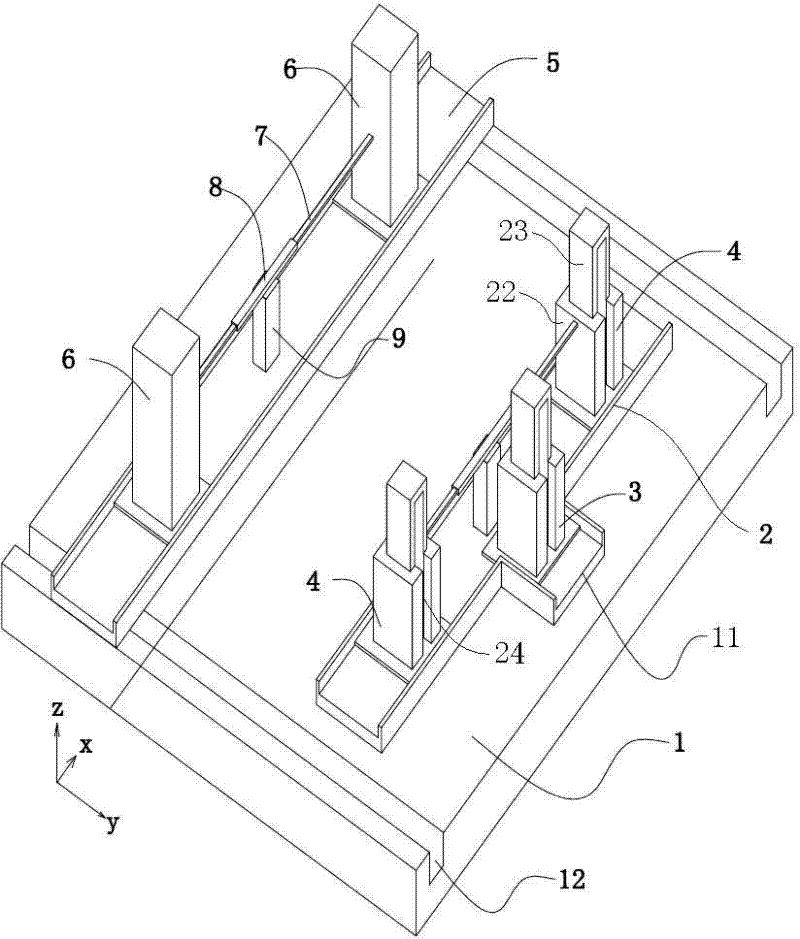

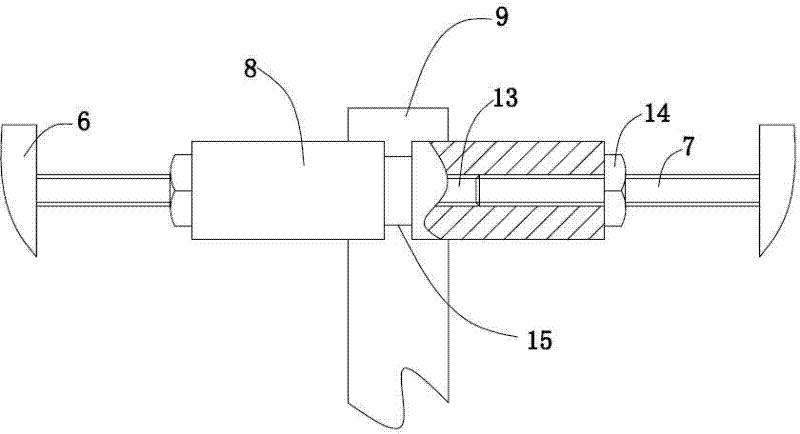

[0033] Embodiment 1: A kind of adjustable hood stiffness test bench device (see attached figure 1 ), including a platform base 1, rectangular concave base guide rails 12 are arranged on both sides of the platform base, and fixed guide rails 2 and movable guide rails are arranged on the platform base in a direction perpendicular to the base guide rails 5. The fixed guide rail is parallel to the movable guide rail, the fixed guide rail is fixed to the base of the bench, the two ends of the movable guide rail straddle the base guide rail, and a lead screw 20 is placed in the base guide rail, and the two ends of the lead screw pass through the bearing 18 is fixed on the base guide rail, the end of the lead screw is connected with a stepping motor 21, the lower surface of the two ends of the movable guide rail is fixed with a lead screw nut 19, the position of the lead screw nut is aligned with the base guide rail, and the lead screw penetrates into the wire inside the lever nut (s...

Embodiment 2

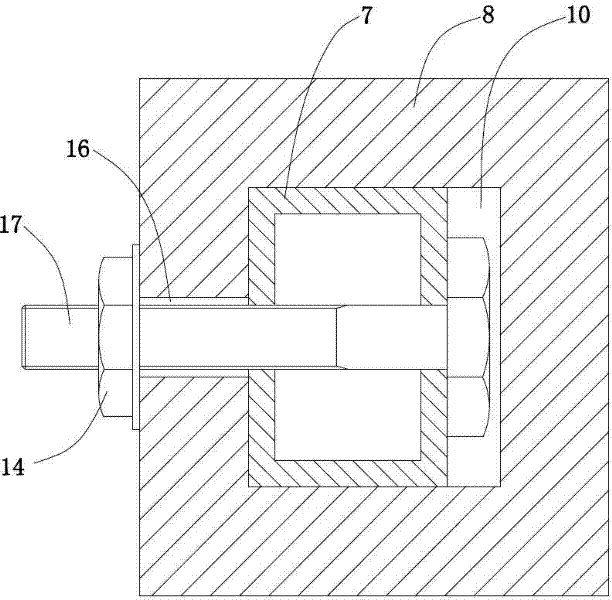

[0038] Embodiment 2: A kind of adjustable hood rigidity test bench device (see attached figure 1 ), the hood hinge connection column and the buffer block connection column are respectively provided with a sleeve fixing bracket and a support rod. The sleeve and the bracket in the sleeve fixing bracket are fixedly connected, and a square through hole 10 is arranged in the sleeve. The side wall midline position of sleeve is provided with slot 16, and support bar is the square bar that matches with through hole, and the end of support bar is fixed with locking screw 17, and the end of locking screw stretches in the slot, locks Lock nut 14 is screwed on the tightening screw, and lock nut tightens and fixes the support rod. Refer to Example 1 for all the other structures.

[0039] A method for using an adjustable engine hood stiffness test bench device, comprising the following steps: (1) measuring the X-direction distance between the two left and right hood hinges of the engine ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com