Method for locally softening automotive thermal forming part

A local softening, thermoforming technology, applied in furnace type, heat treatment furnace, heat treatment equipment, etc., to achieve the effect of optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

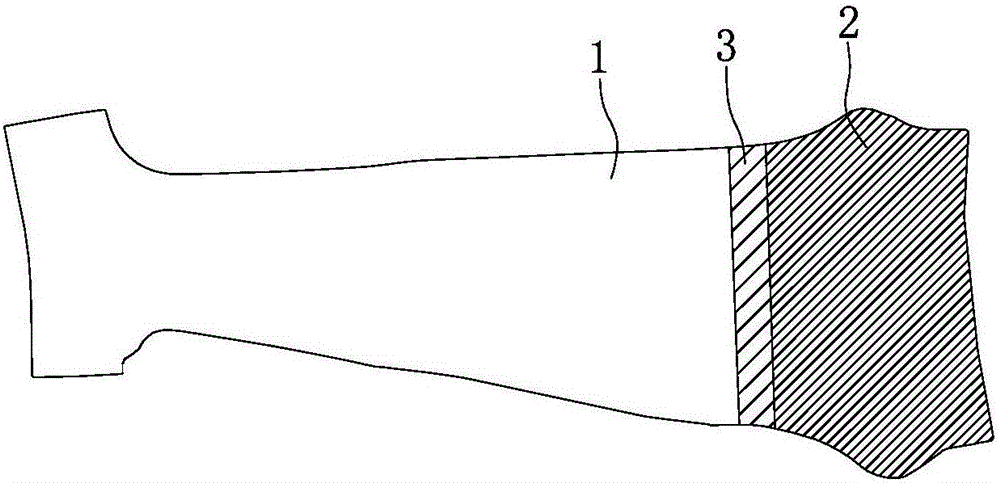

[0022] Such as figure 1 As shown, the local softening method of the automobile B-pillar comprises the following steps:

[0023] 1) Heating: put the B-pillar material into the heating furnace for zone heating, only one part of the material needs to be softened, this part is soft zone 2, and the rest of the material is hard zone 1, and hard zone 1 is also one. The temperature of the hard zone of the blank is heated to any value or range of values in 860-960° C., and the blank is kept at this temperature for 3-5 minutes until the hard zone is completely austenitic. Heating the soft area of the web to any value or range of values in the range of 500-650°C, and maintaining this temperature, a transition area 3 is naturally formed between the hard area 1 and the soft area 2 of the web;

[0024] 2) Molding cooling: take the blank out of the heating furnace, and then stamp it on the press through the mold clamping. When the mold is clamping, the circulating cooling water in the...

Embodiment 2

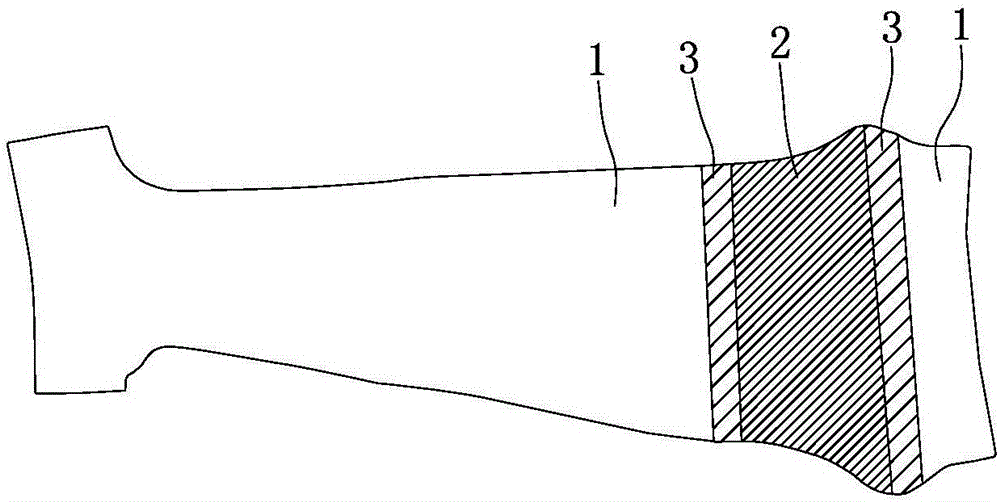

[0026] Such as figure 2 As shown, the local softening method of the automobile B-pillar comprises the following steps:

[0027] 1) Heating: put the B-pillar material into the heating furnace for zone heating, only one part of the material needs to be softened, this part is soft zone 2, the rest of the material is hard zone 1, and hard zone 1 is two, Heat the temperature in the high temperature zone of the blank to 910-960°C, keep the temperature for 3 minutes until the hard zone is completely austenitized, heat the soft zone of the blank to 700-860°C, and keep this temperature range. A transition zone 3 is naturally formed between the hard zone 1 and the soft zone 2;

[0028] 2) Molding cooling: Take the tablet out of the heating furnace, and then stamp it on the press through the mold clamping. When the mold is closed, the circulating cooling water in the mold is quickly cooled, so that all the hard areas 1 of the tablet form high-strength quenching Martensite, the soft ar...

Embodiment 3

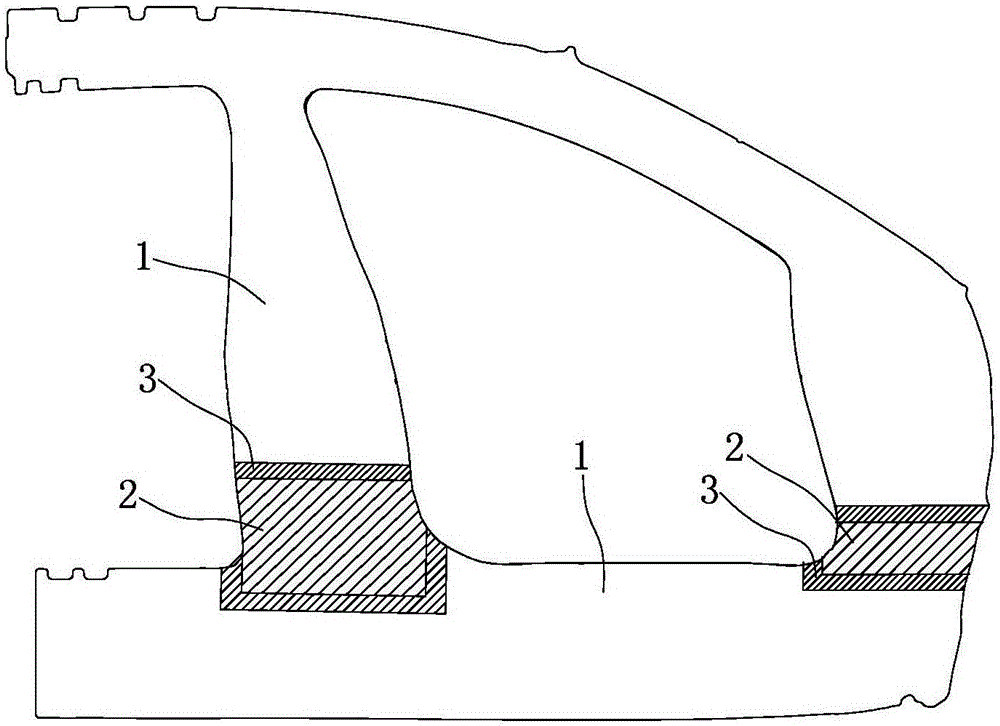

[0030] Such as image 3 As shown, the local softening method of the integral door knocker includes the following steps:

[0031] 1) Heating: put the overall door ring piece sheet into the heating furnace for heating, heat the temperature in the furnace to any value or value range in the range of 860-960°C, keep the sheet at this temperature for 3-5 minutes, so that The blank is completely austenitized;

[0032] 2) Molding and cooling: take the tablet out of the heating furnace, and then press the mold on the press for 10-15 seconds. When closing the mold, the part of the blank that needs to be softened is the soft zone 2, there are two soft zones 2, the rest of the blank is the hard zone 1, and there are three hard zones 1. The mold insert corresponding to the soft zone 2 of the blank has a built-in heating system, and the temperature is maintained at 500°C-550°C, while the mold insert corresponding to the hard zone 1 of the blank is circulated with cooling water to achieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com