Carbon fiber automobile bumper beam and manufacturing method thereof

A manufacturing method, carbon fiber technology, applied to vehicle parts, vehicle safety arrangements, bumpers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

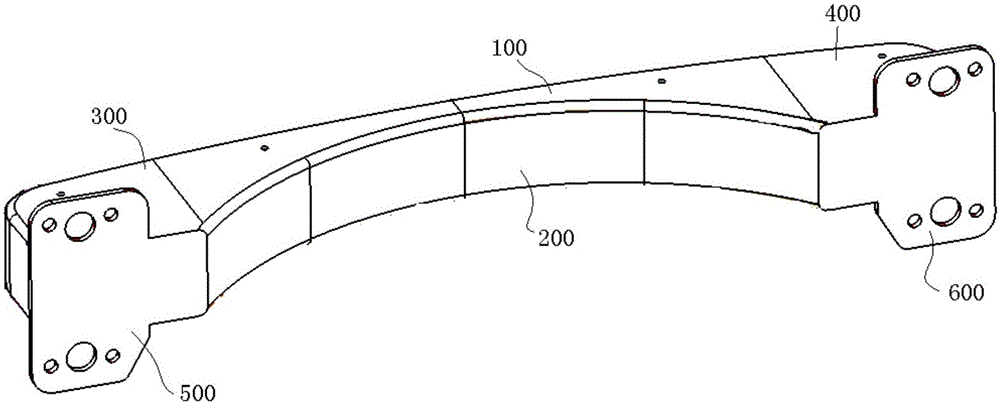

[0033] see figure 1 , the carbon fiber automobile bumper shown in the figure includes a foam sandwich and embedded parts, and the carbon fiber cloth reinforced resin matrix composite material is covered on the foam sandwich and embedded parts.

[0034] The carbon fiber automobile bumper includes a first anti-deformation area 100, a second anti-deformation area 200, a first low-speed collision energy-absorbing area 300, a second low-speed collision energy-absorbing area 400, a first back plate installation area 500, and a second back plate The installation area 600, wherein the second anti-deformation area 200 is located at the back of the first anti-deformation area 100, the first low-speed collision energy-absorbing area 300 and the second low-speed impact energy-absorbing area 400 are located at both ends of the first anti-deformation area 100, the second A back panel installation area 500 and a second back panel installation area 600 are located at both ends of the second a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com