Pull-type high-speed train crash test bench

A technology for high-speed trains and collision tests is applied in the field of rail vehicle collision tests to achieve the effects of low use cost, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

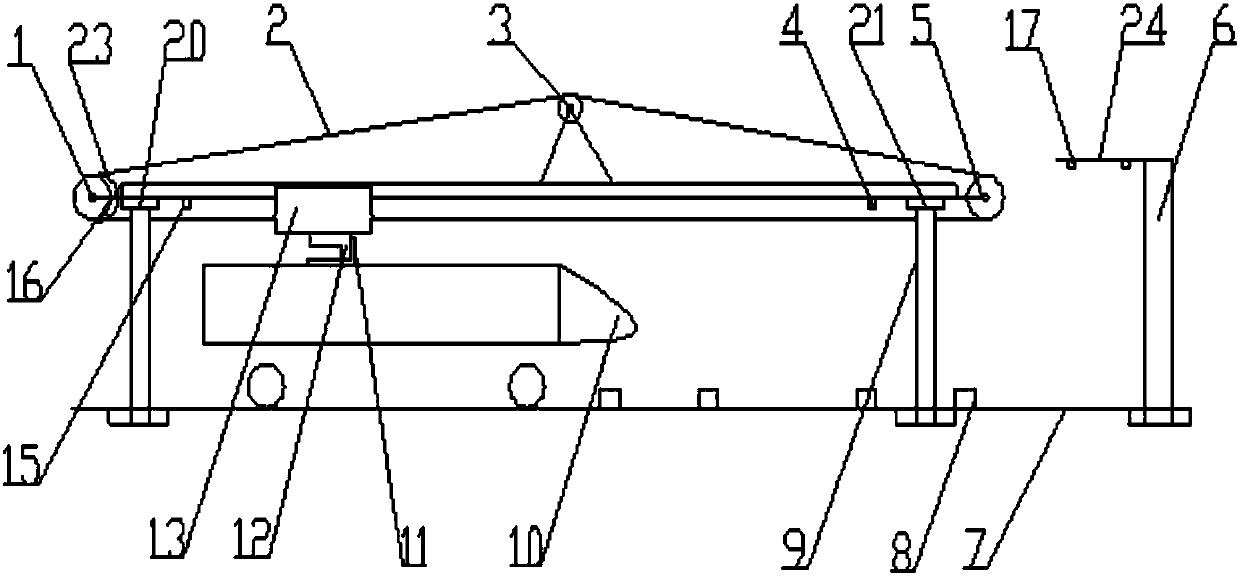

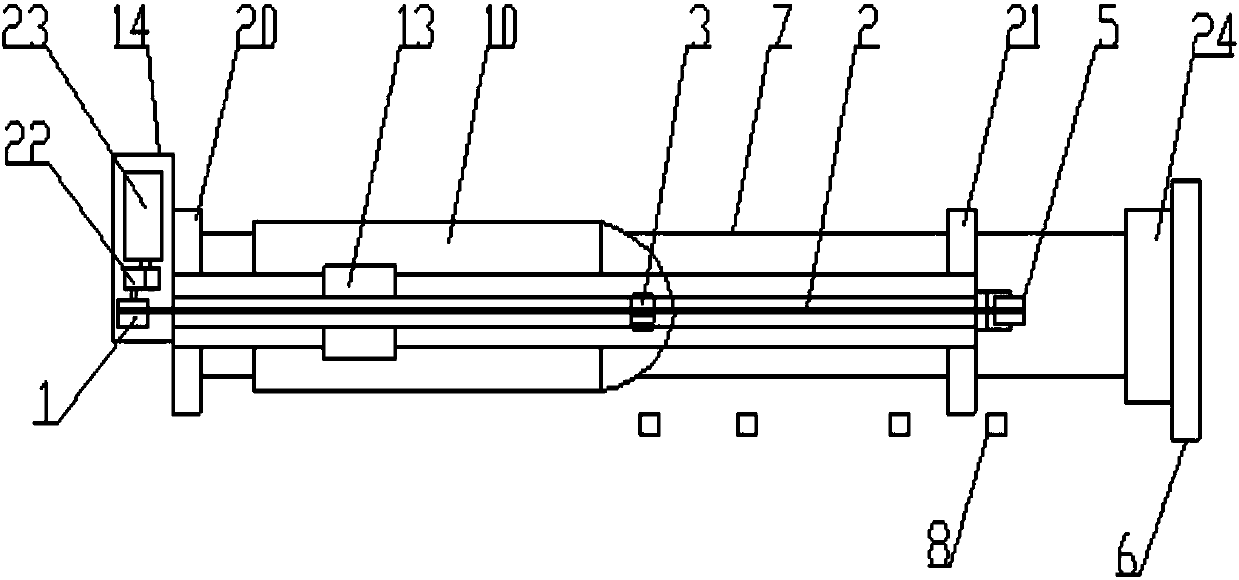

[0015] The present invention is a kind of traction type high-speed train collision test bench, such as figure 1 as shown,

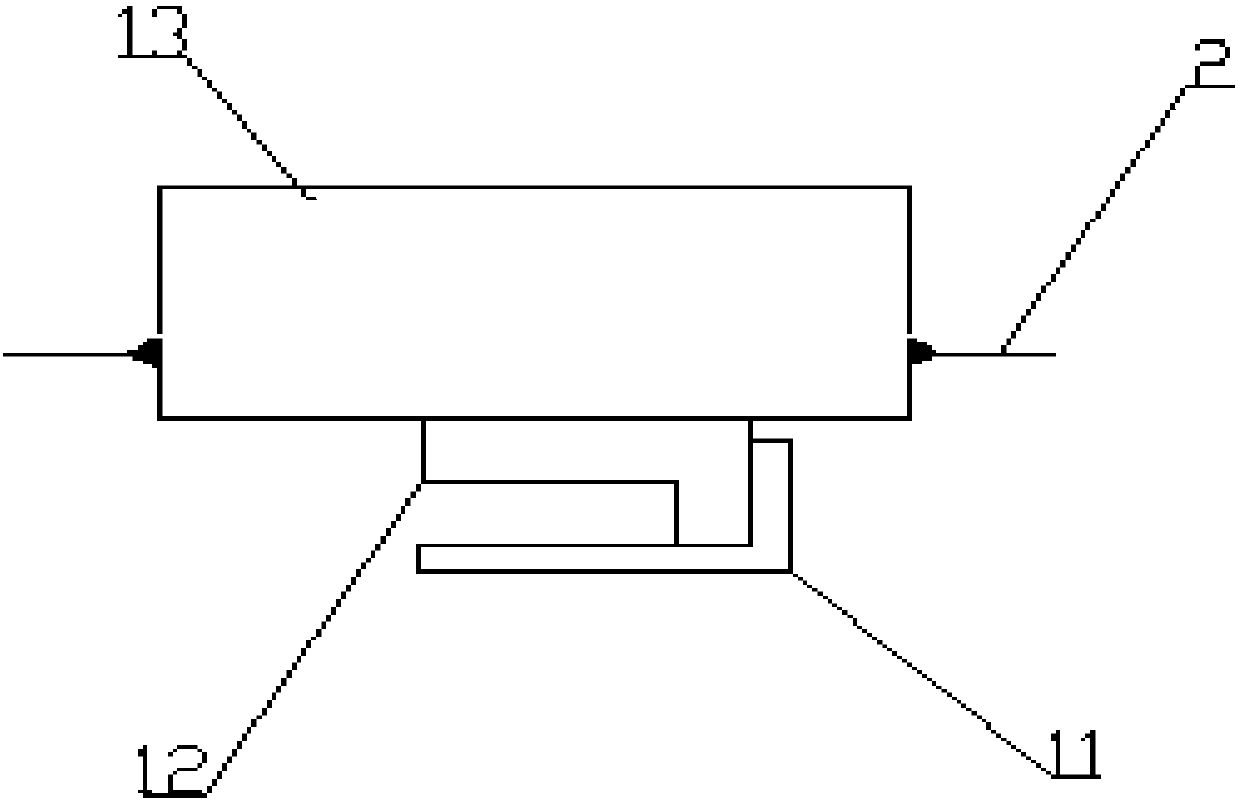

[0016] A traction-type high-speed train crash test bench includes a rigid wall 6 and a crash car body 10 arranged at the front end of a track 7 . The front and rear of both sides of the track 7 are respectively provided with four uprights 9, and the tops of the uprights 9 on both sides are provided with a front crossbeam 21 and a rear crossbeam 20, and the middle part of the front and rear crossbeams is erected with an I-shaped steel guide rail 16, and the two ends of the guide rail 16 are respectively Front stopper 4 and rear stopper 15 are provided, tension pulley 3 is provided above the middle part of guide rail 16, driven wheel 5 is provided on fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com