Crash test table vehicle

A crash test and trolley technology, which is applied in the field of crash test trolleys and test trolleys, can solve the problems of high cost and achieve the effects of simple structure, cost reduction and investment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

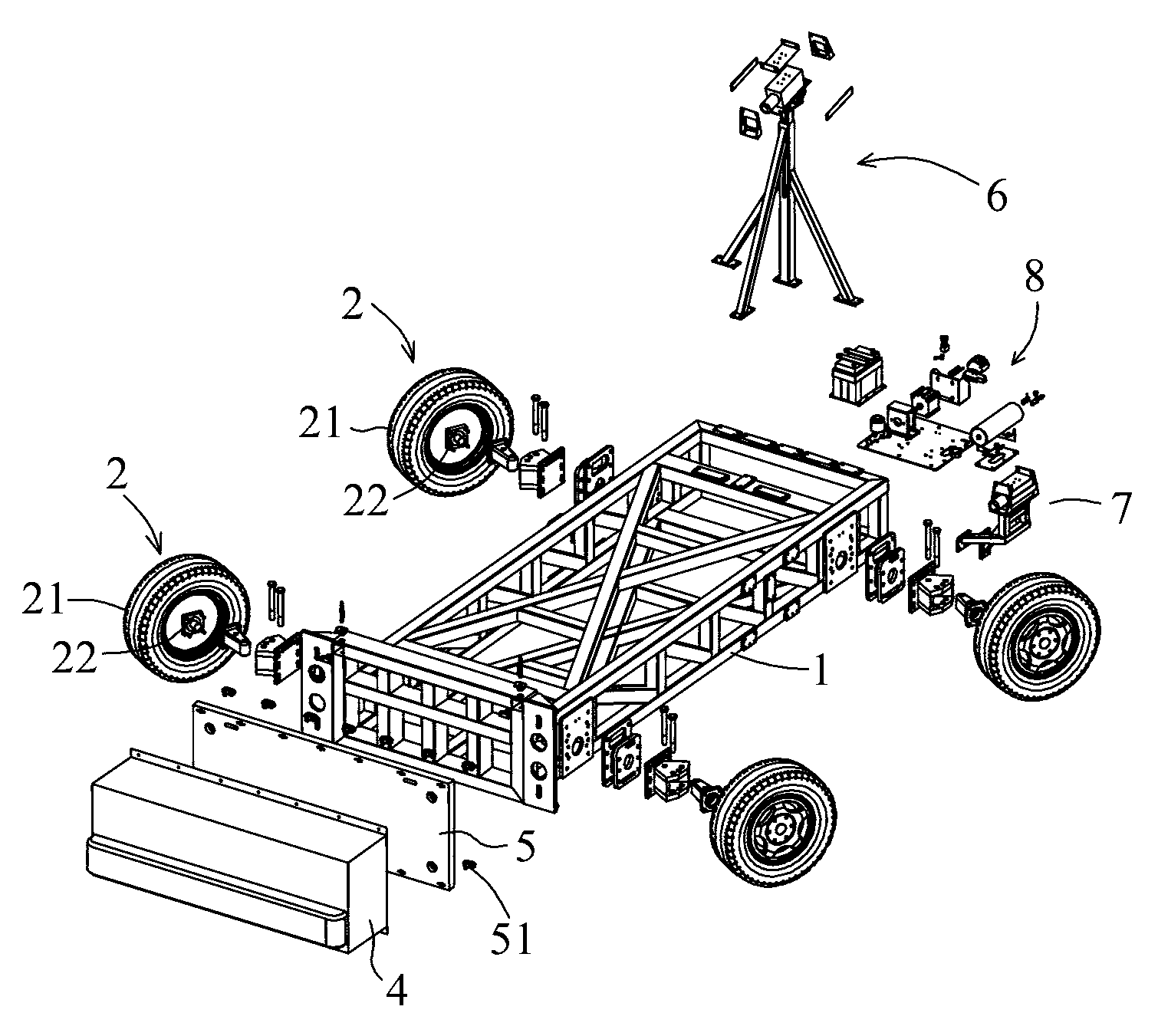

[0031] like figure 1 As shown, the invention discloses a crash test trolley. It includes a frame-type car body 1 welded by steel materials. A honeycomb aluminum mounting aluminum plate 5 is installed on the front end of the car body 1. A honeycomb aluminum crash block 4 for crash test is installed on the honeycomb aluminum mounting aluminum plate 5. The two sides of the body 1 are installed with the wheel assembly 2 supporting the car body 1, and the middle shot camera device 6 and the side shot camera device 7 for taking pictures are also arranged on the car body 1, as well as the time delay for braking and braking. Braking device 8.

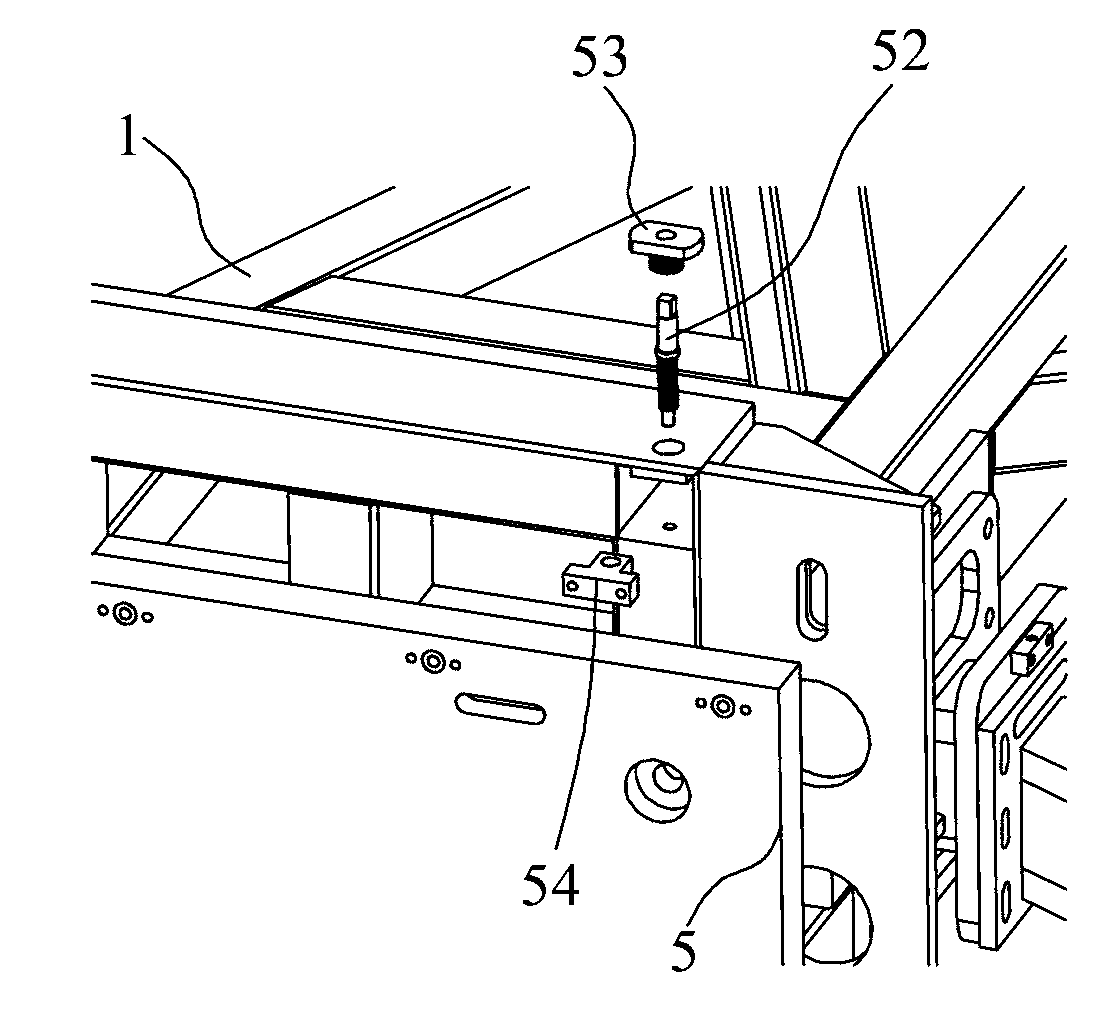

[0032] like figure 2 As shown, a height adjustment device for adjusting the installation height of the honeycomb aluminum mounting aluminum plate 5 relative to the vehicle body 1 is provided on the vehicle body 1. The height adjustment device includes a screw seat 53 fixedly arranged on the vehicle body 1 and a Install the connection block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com