Patents

Literature

84results about How to "Deep unity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

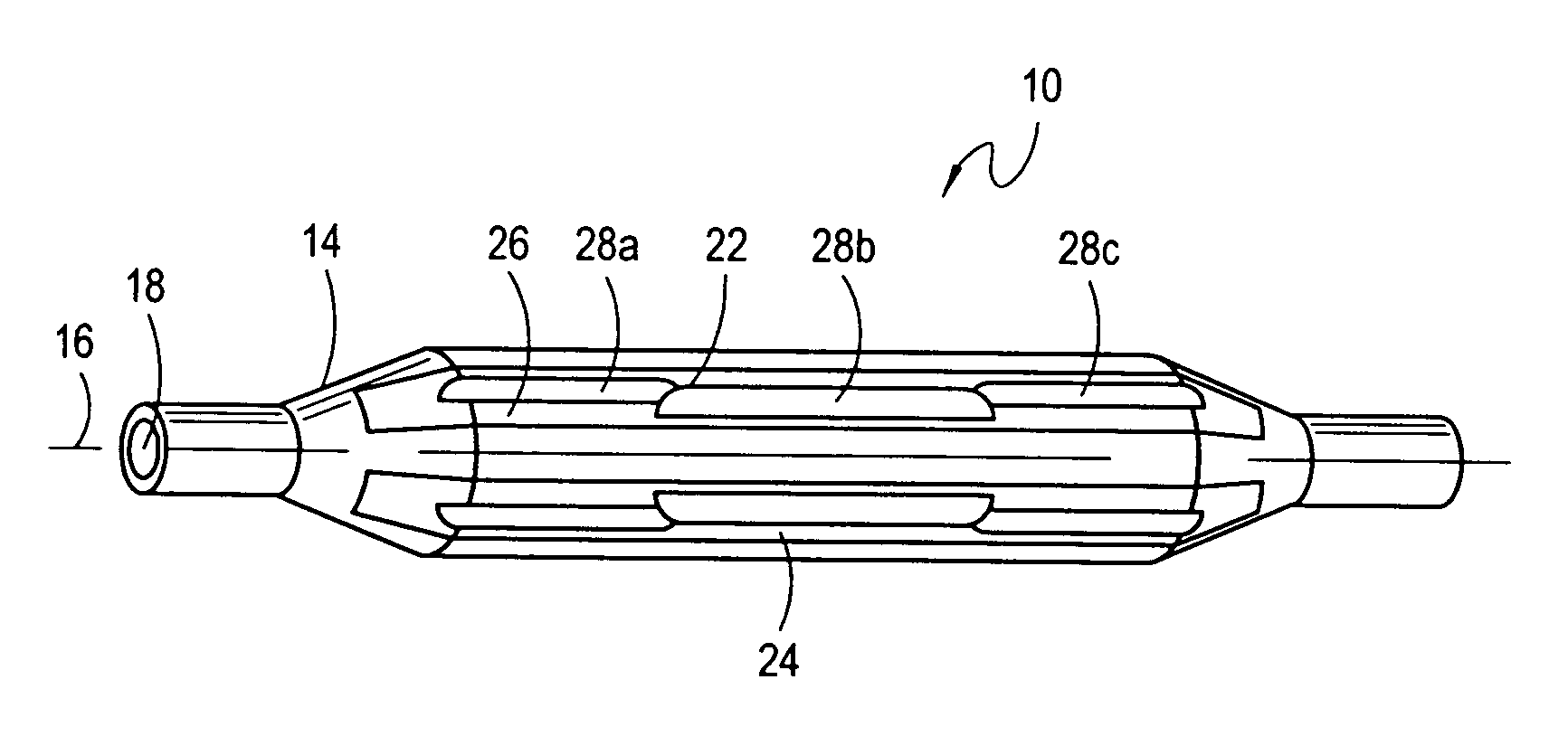

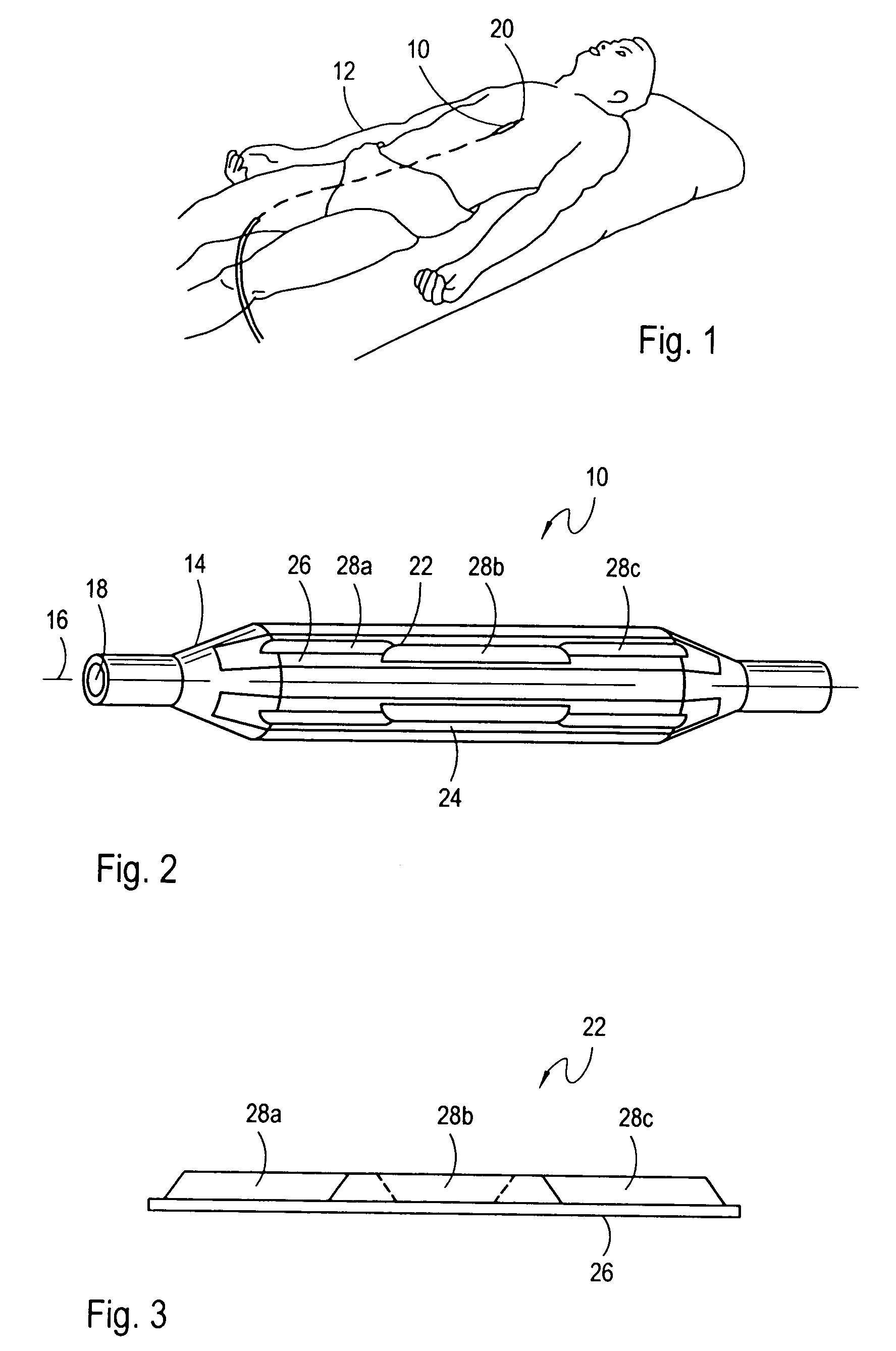

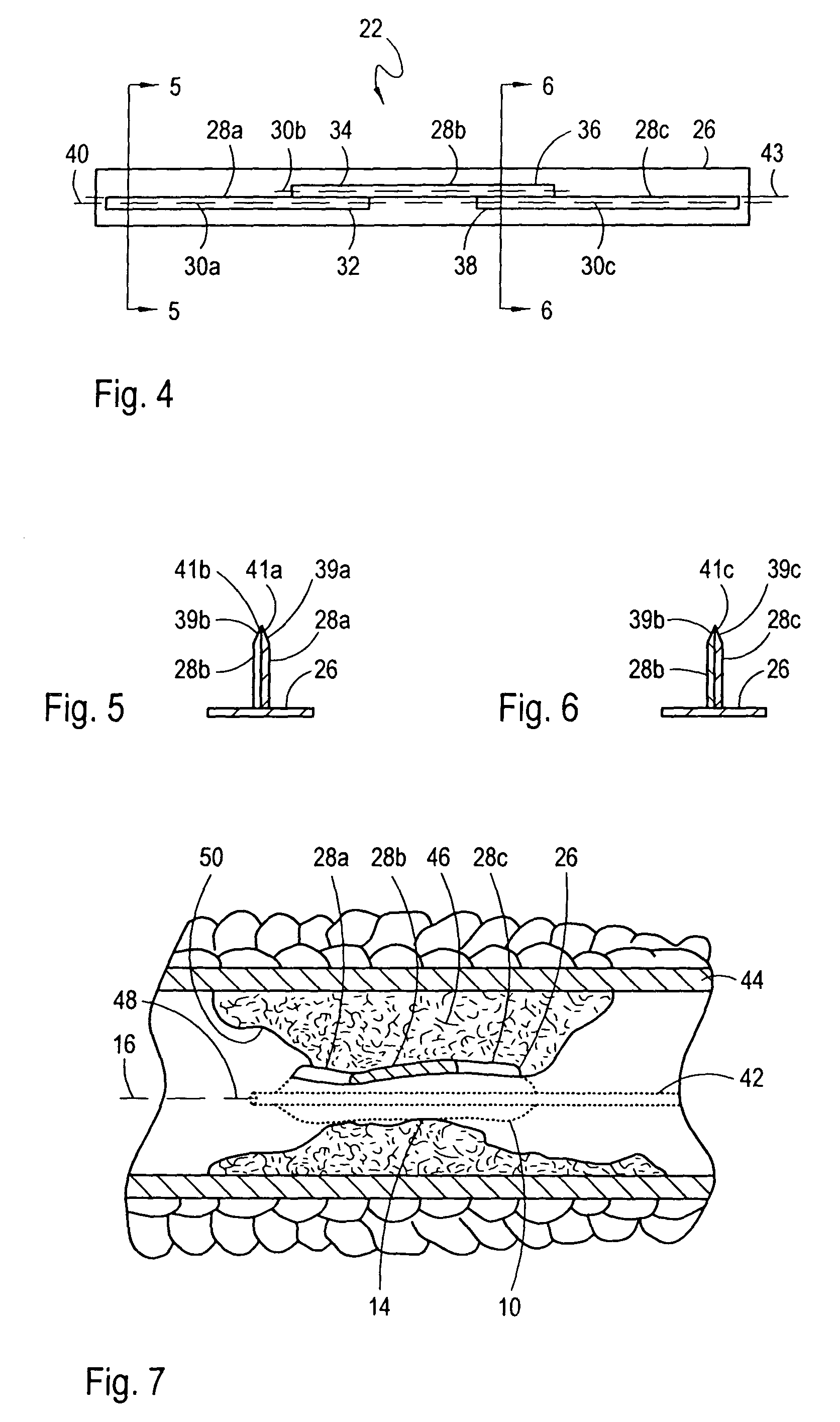

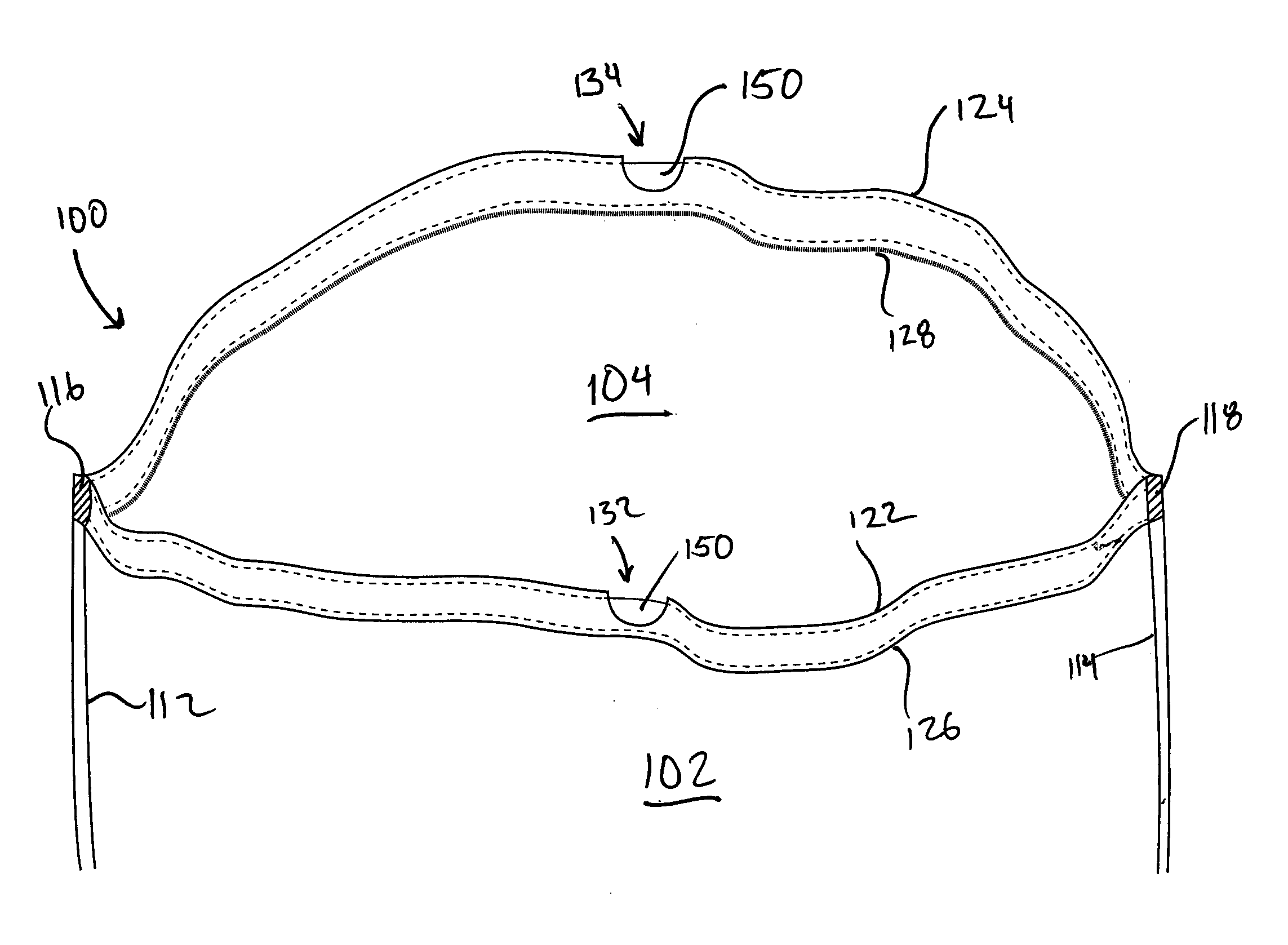

Segmented balloon catheter blade

A device for incising a stenosis in the vasculature of a patient includes a plurality of blades mounted on a resilient base member. The blades are arranged in a pattern to allow for relative movement between adjacent blades. Specifically, at least one end portion of each blade is juxtaposed with an end portion of the next closest blade. The base member, in turn, is mounted on the external surface of an inflatable angioplasty balloon. When the balloon is inserted into the vasculature of a patient, positioned across a stenosis and subsequently inflated, the individually moveable blades form an effective cutting edge that conforms to the surface of the stenosis to effectively allow the stenosis to be incised to a substantially uniform depth.

Owner:BOSTON SCI SCIMED INC

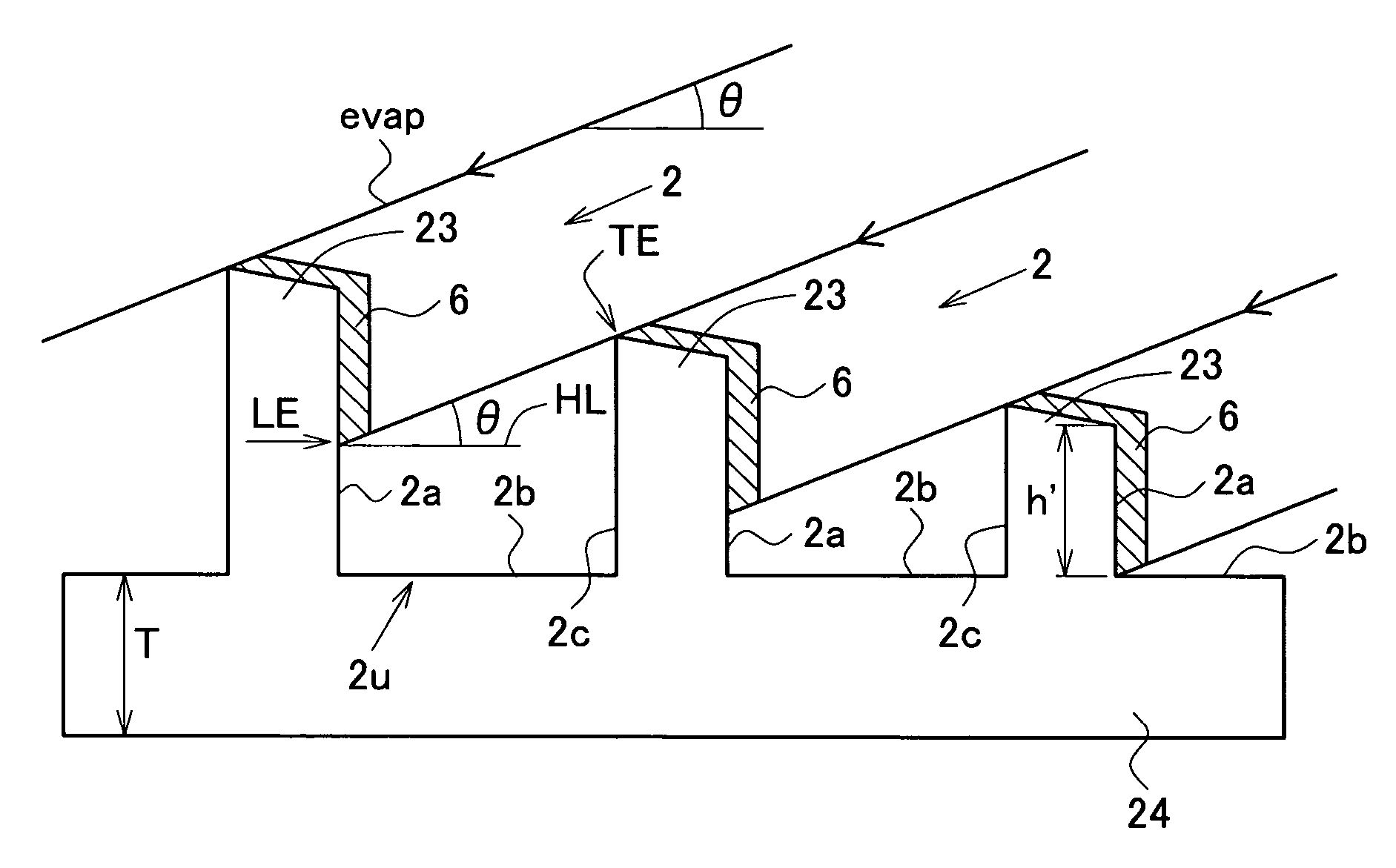

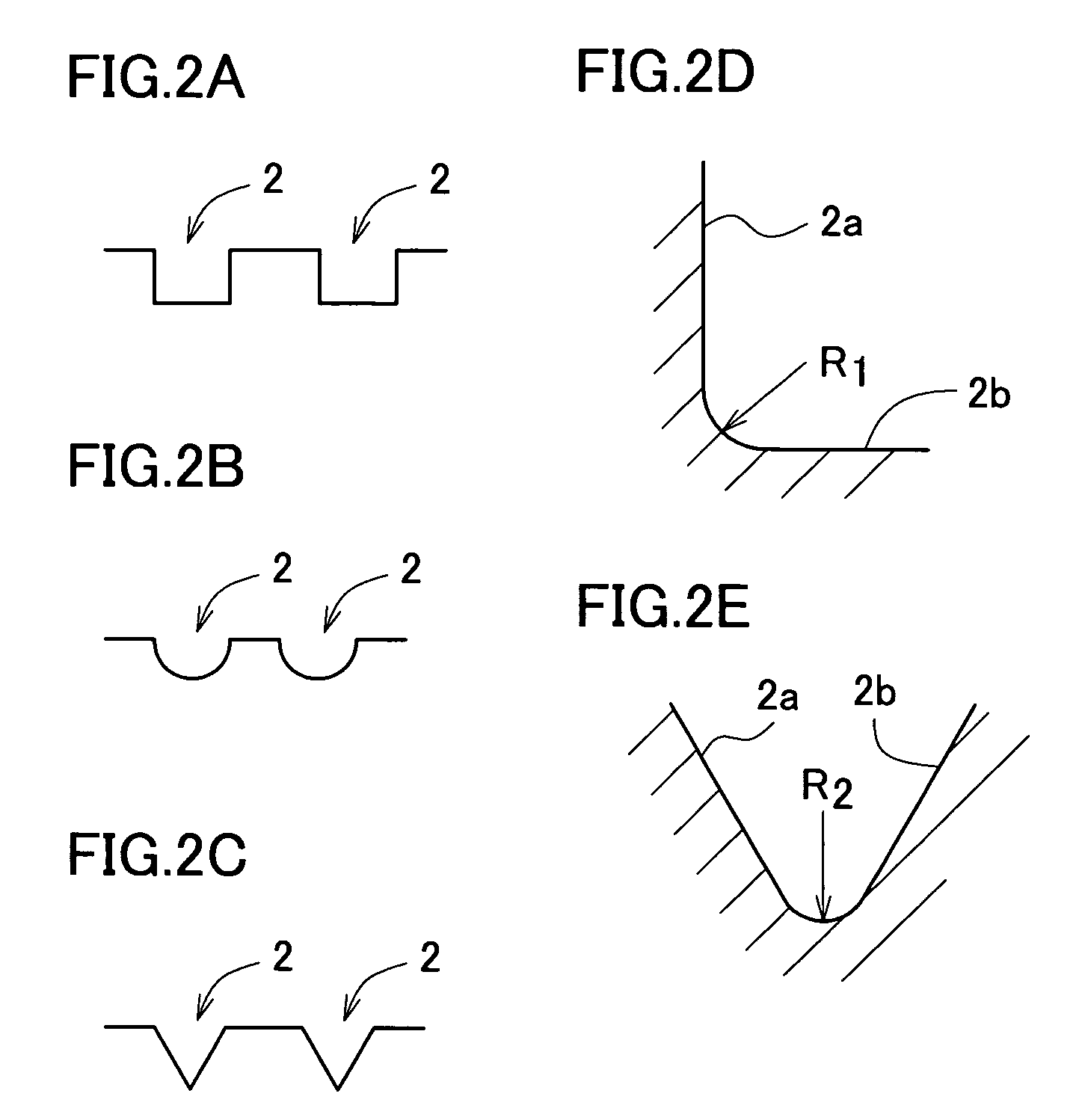

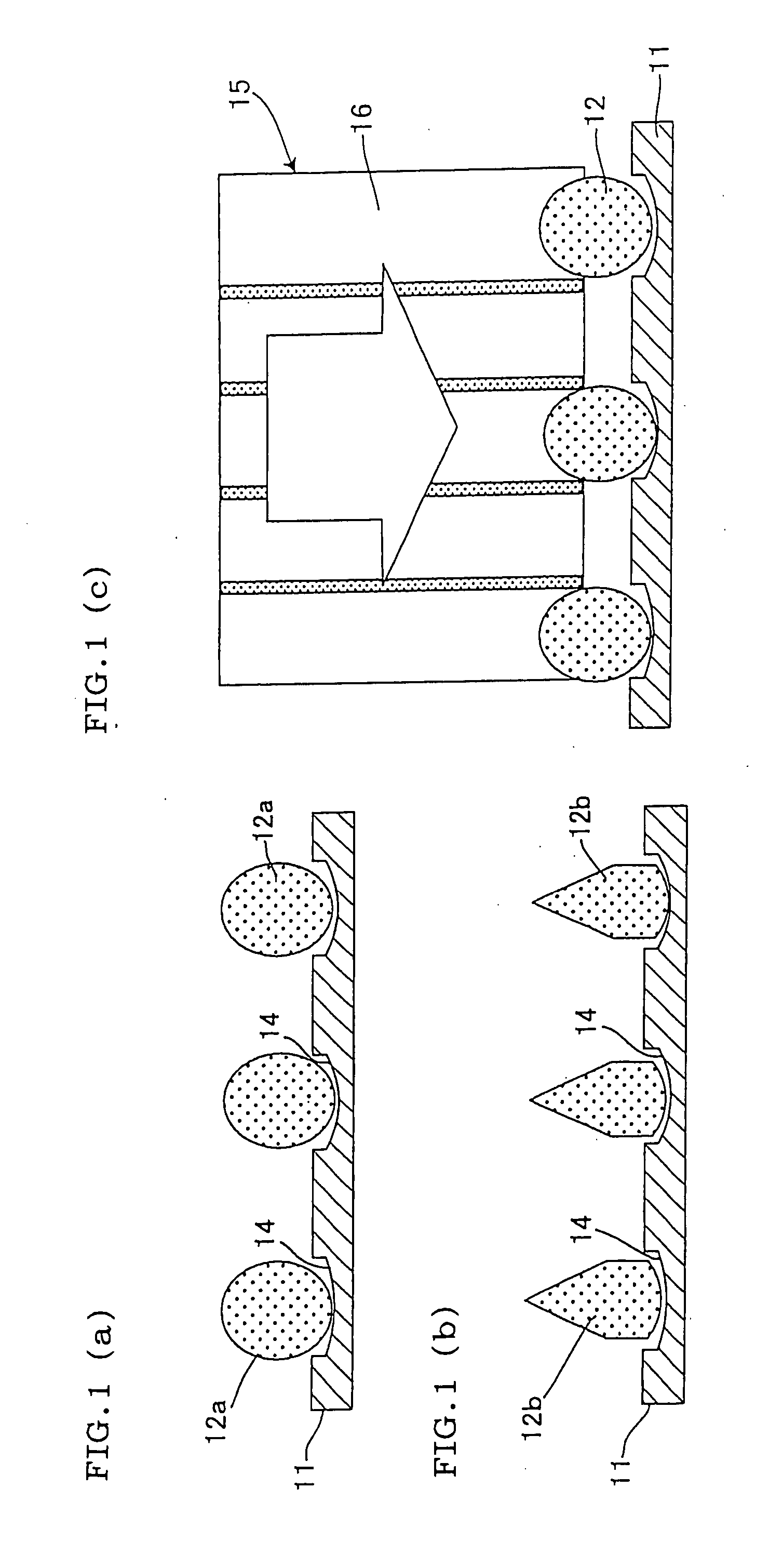

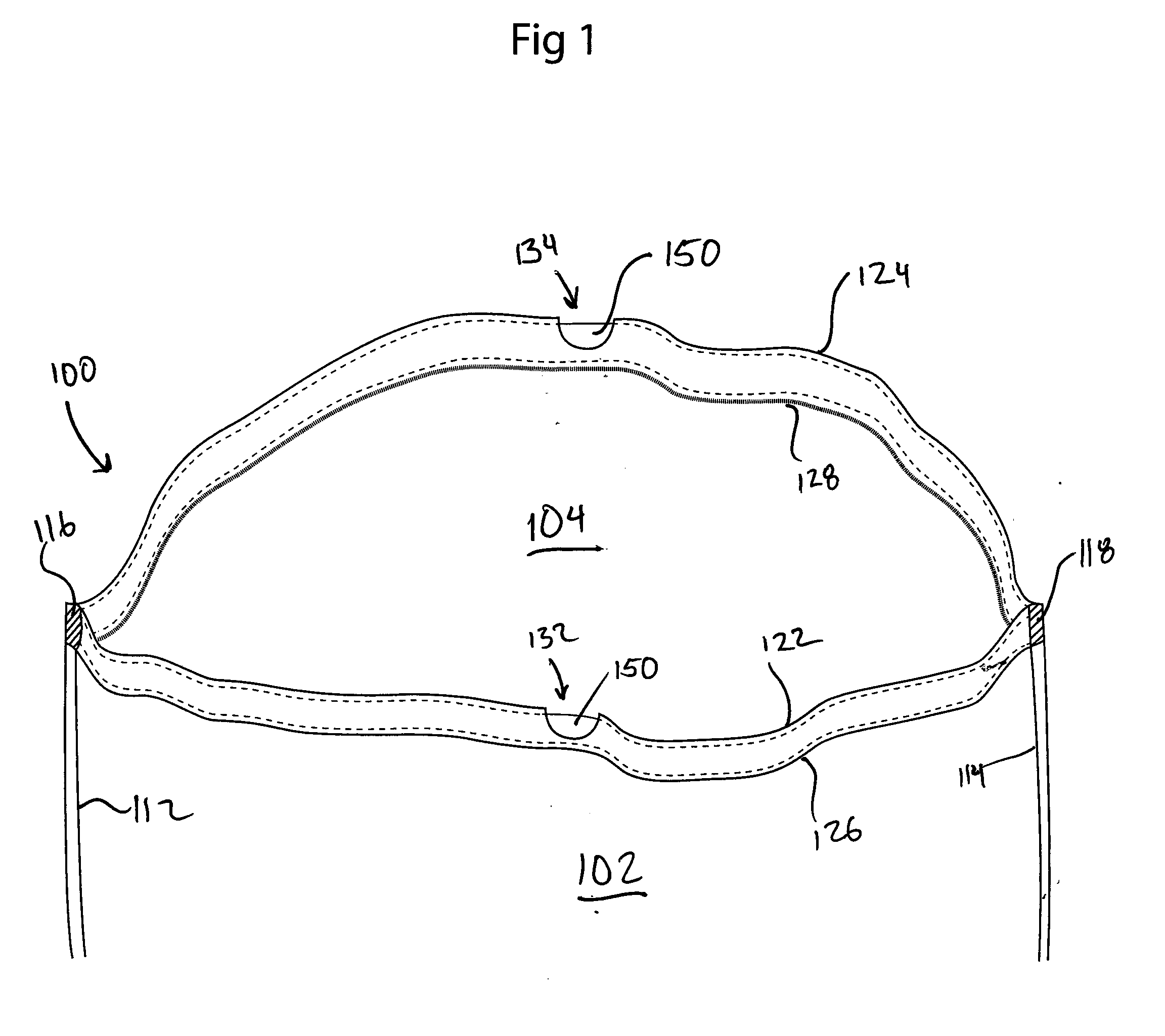

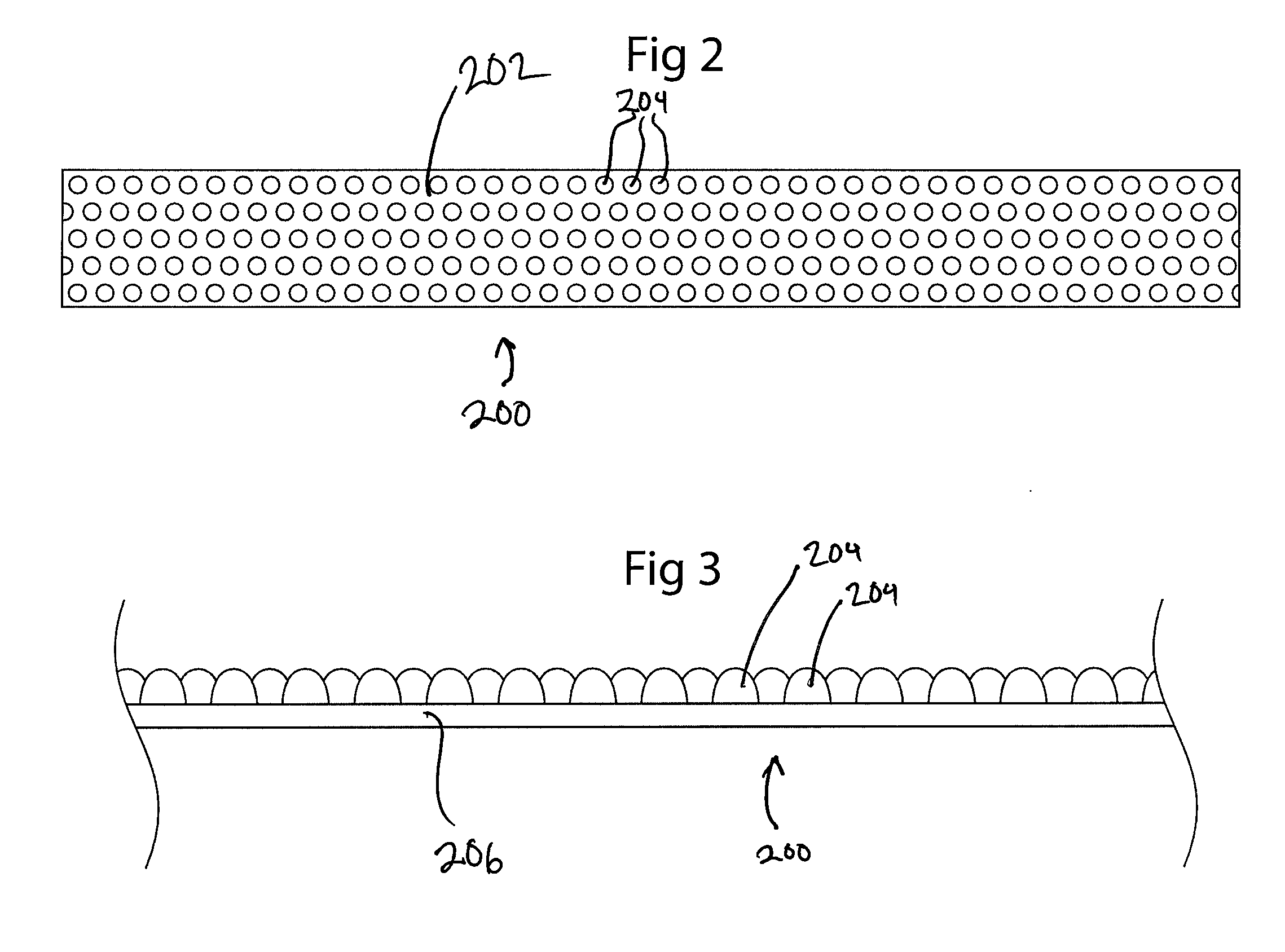

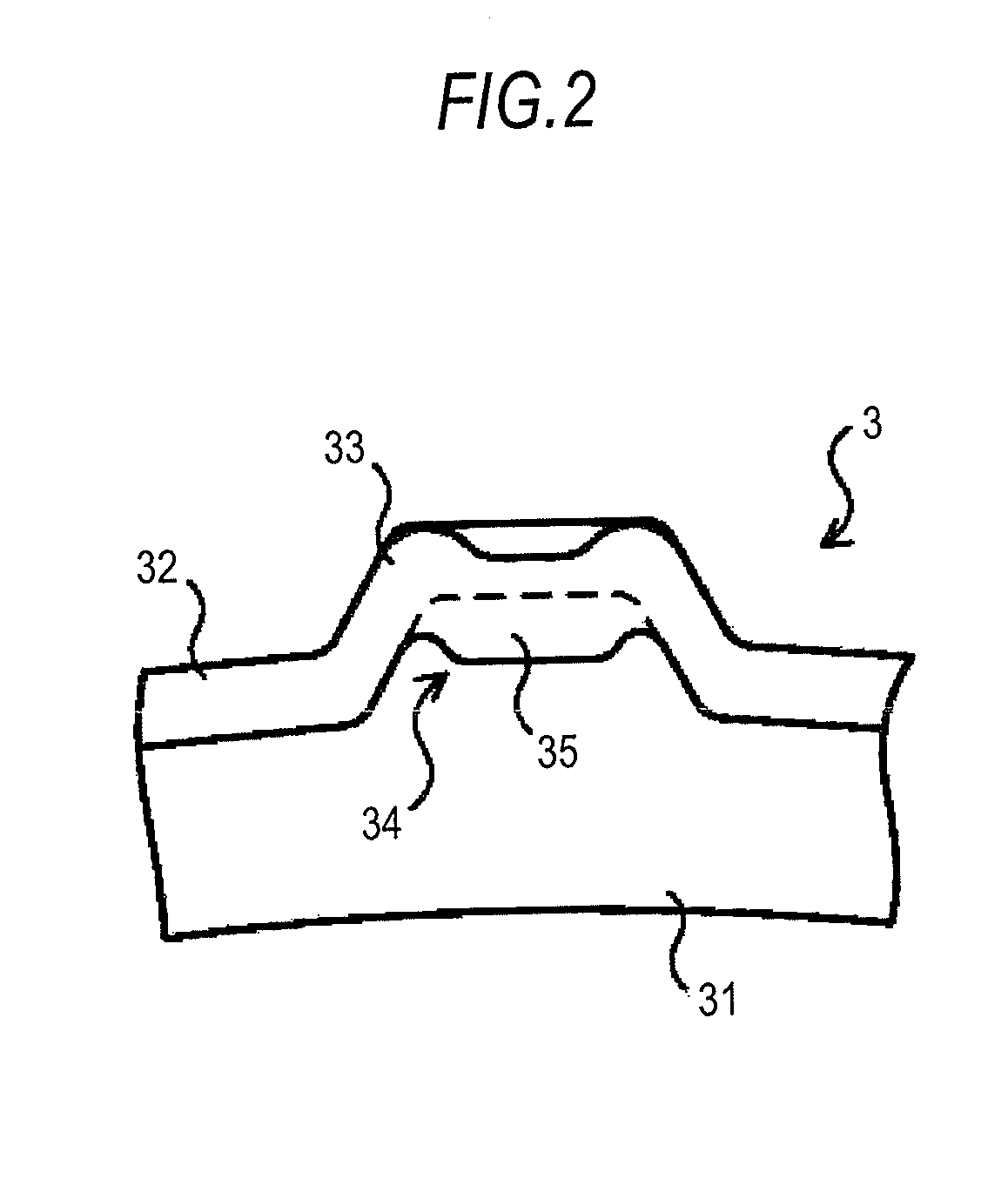

Solar cell and its manufacturing method

ActiveUS7355114B2Excellent in effect of reducing shadowing lossAvoid lack of depthPV power plantsFinal product manufactureSingle crystal substrateSingle crystal

An OECO solar cell using a semiconductor single crystal substrate having a plurality of grooves, wherein a minimum groove depth h of each groove always satisfies the relation of h≧W1tan θ where θ represents an angle between a line connecting the lower end, along the thickness-wise direction of the semiconductor single crystal substrate, of an electrode formed in the groove and the upper end of the inner side face of the same groove having no electrode formed thereon, and a reference line normal to the thickness-wise direction, and W1 represents a distance between both opening edges of the groove; wherein the semiconductor single crystal substrate has thickness decreasing from a first side of a first main surface to a second side opposed to the first side; and wherein the plurality of grooves have a depth distribution of being deepest at a thickest position of the substrate, and a gradually becoming shallower towards a thinnest position of the substrate.

Owner:SHIN ETSU CHEM CO LTD

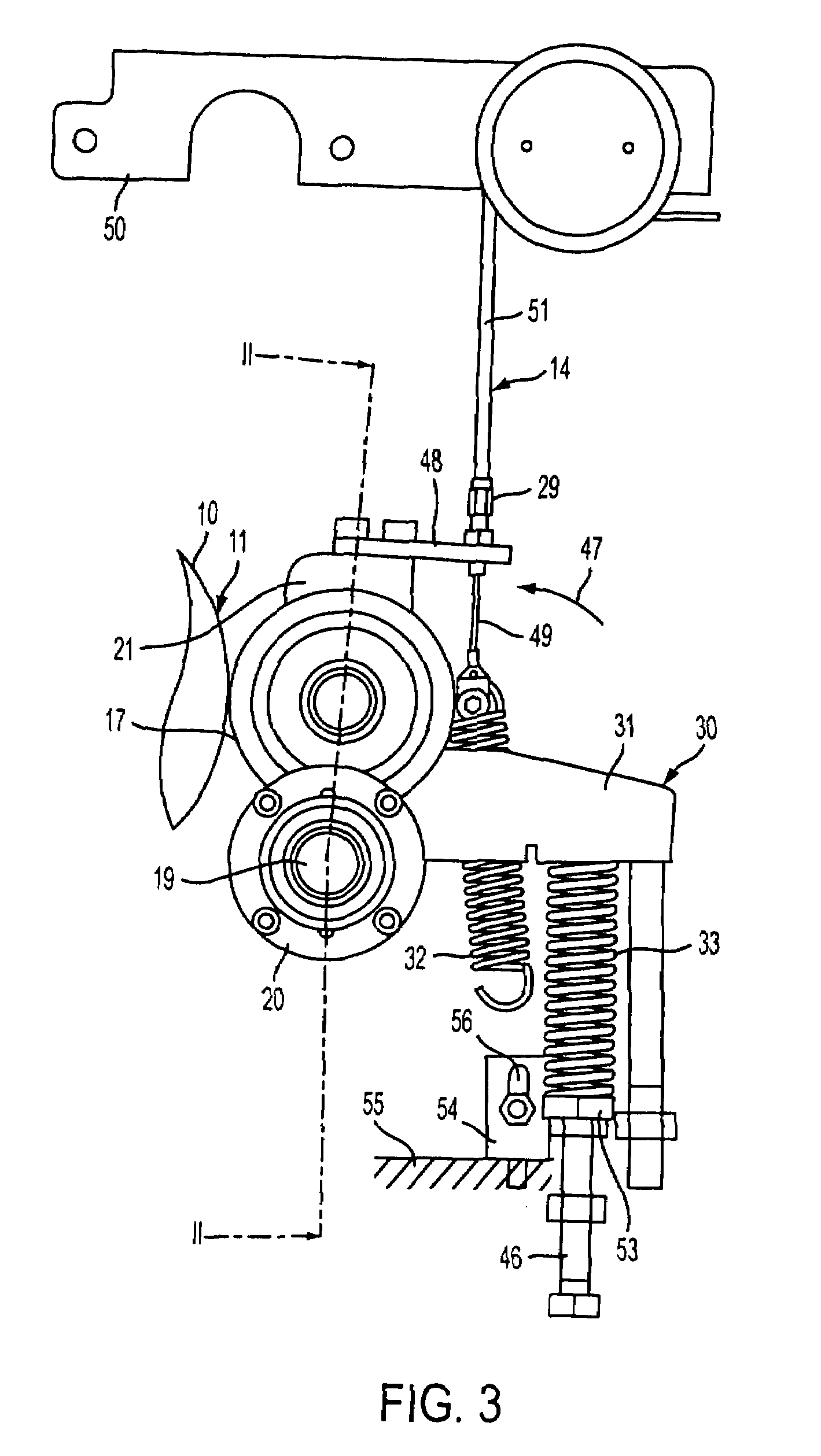

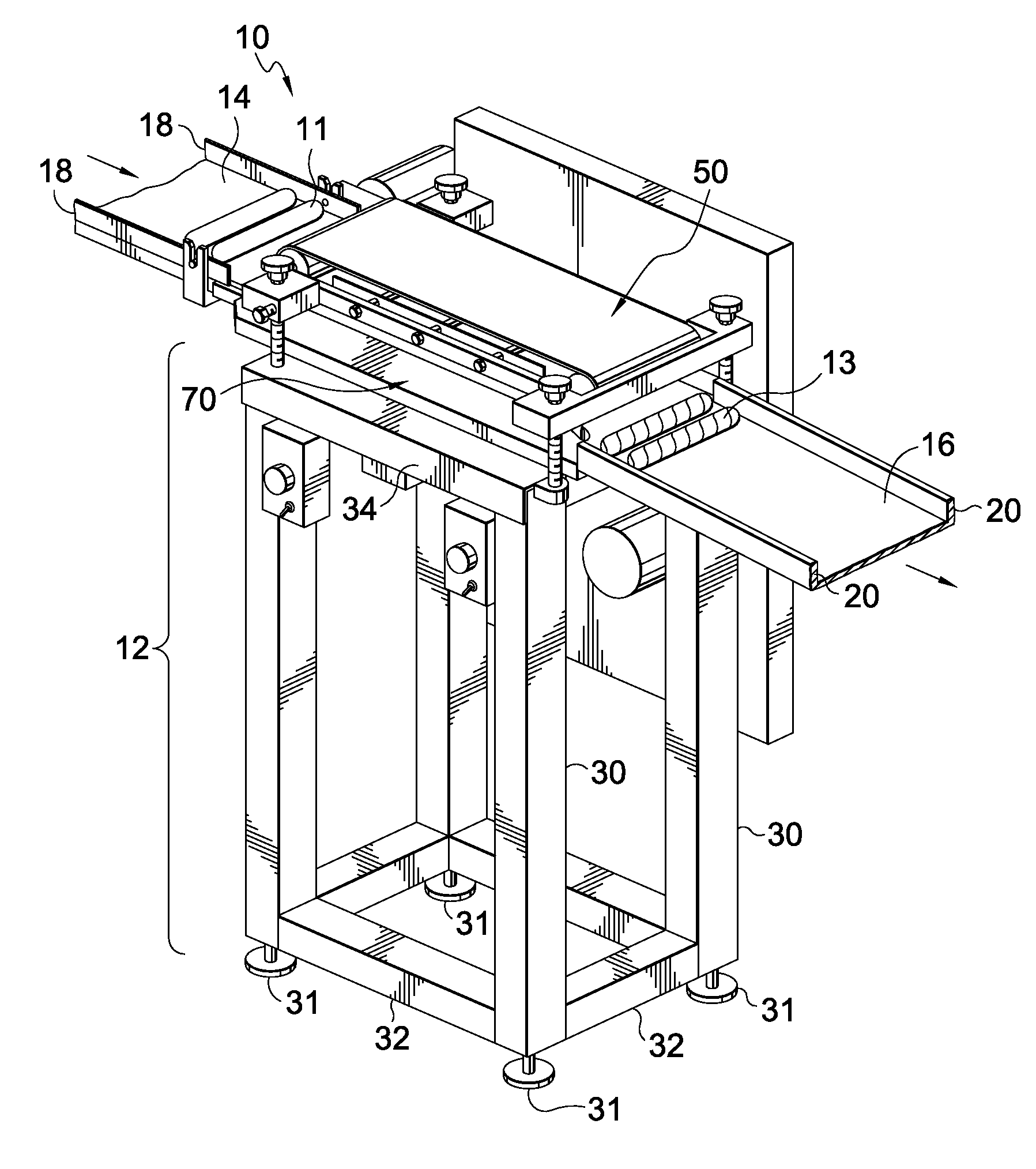

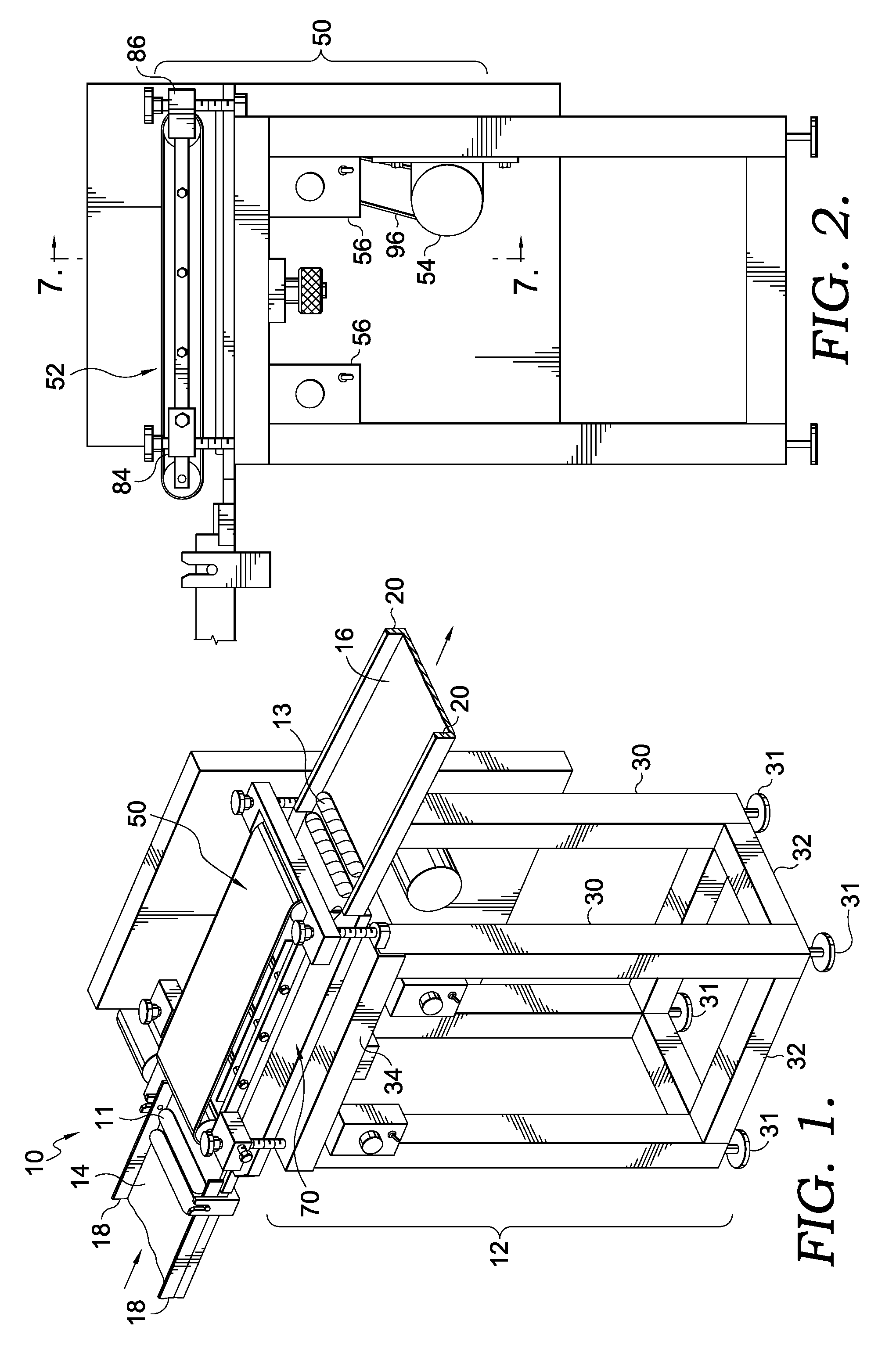

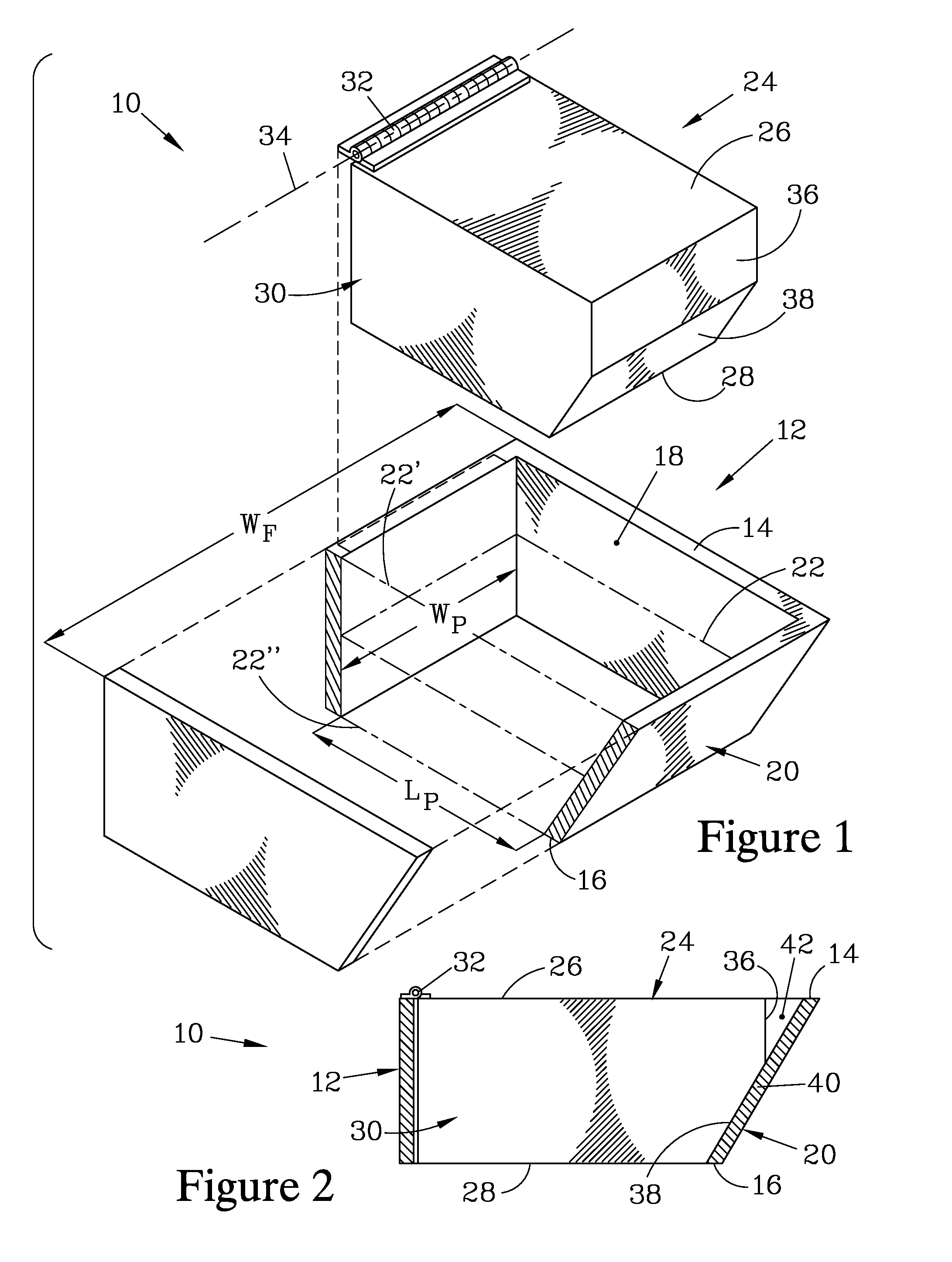

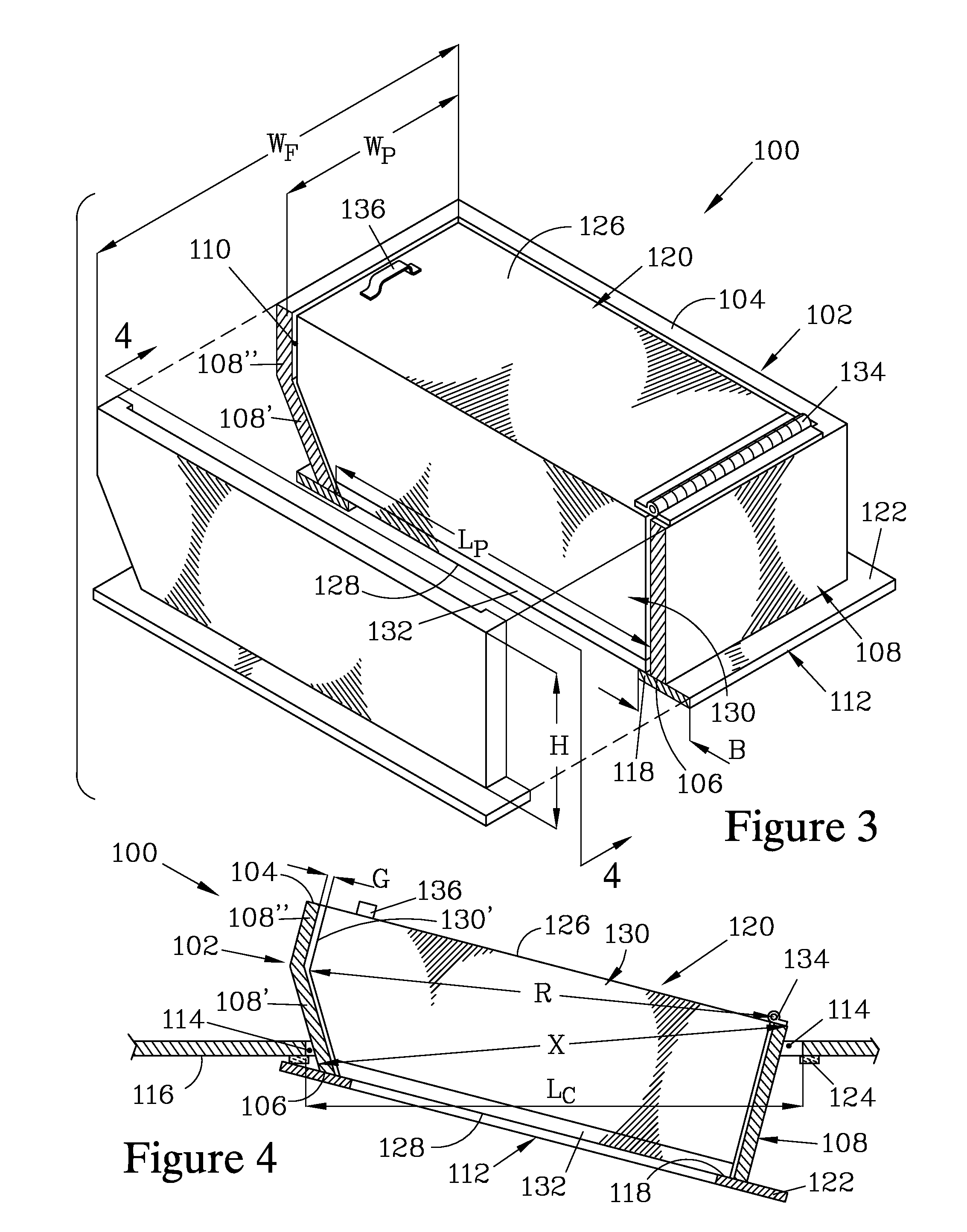

Folder feeder

ActiveUS7537557B2Higher-quality foldHigh outputEnvelopes/bags making machineryMechanical working/deformationEngineeringMechanical engineering

Owner:MULLER MARTINI HLDG

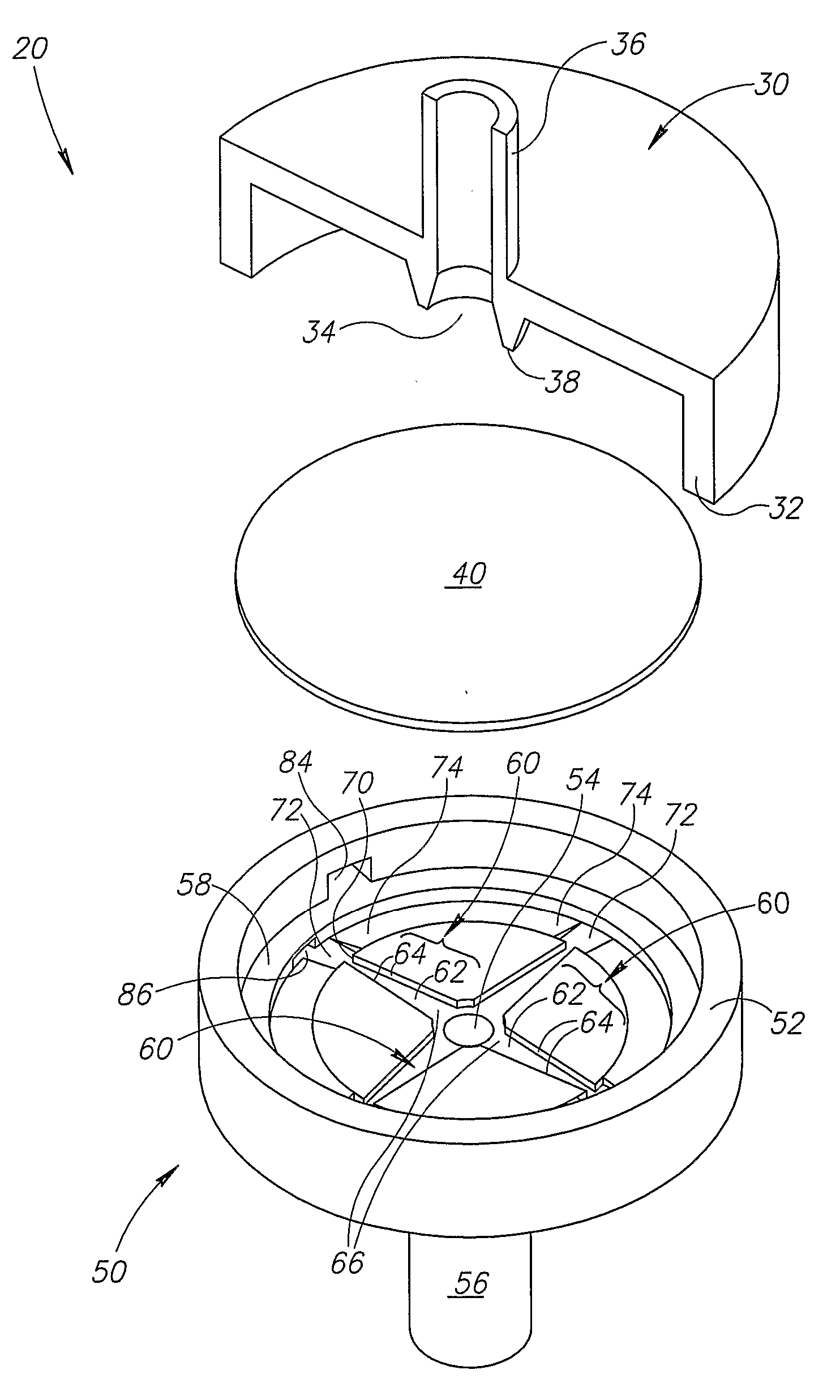

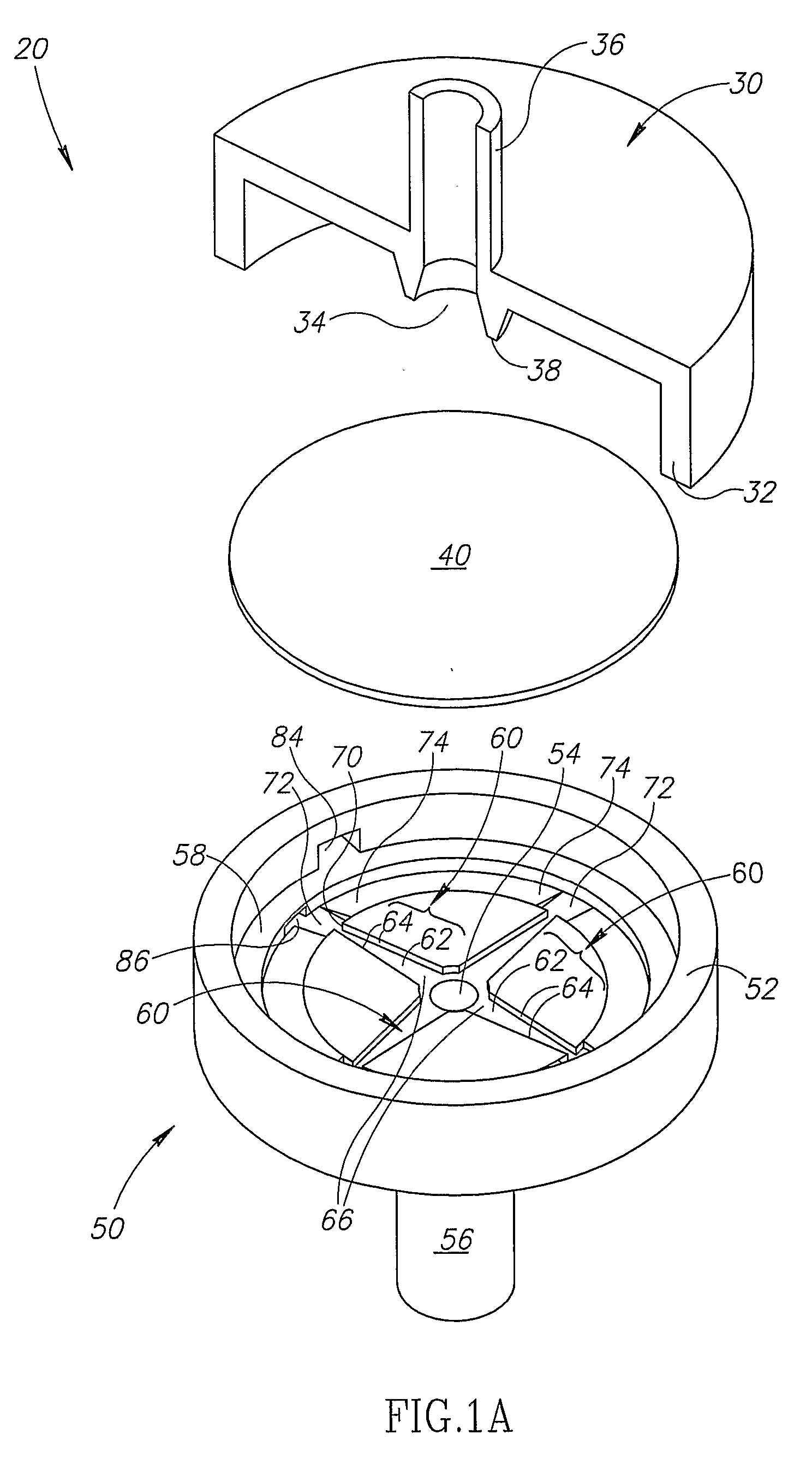

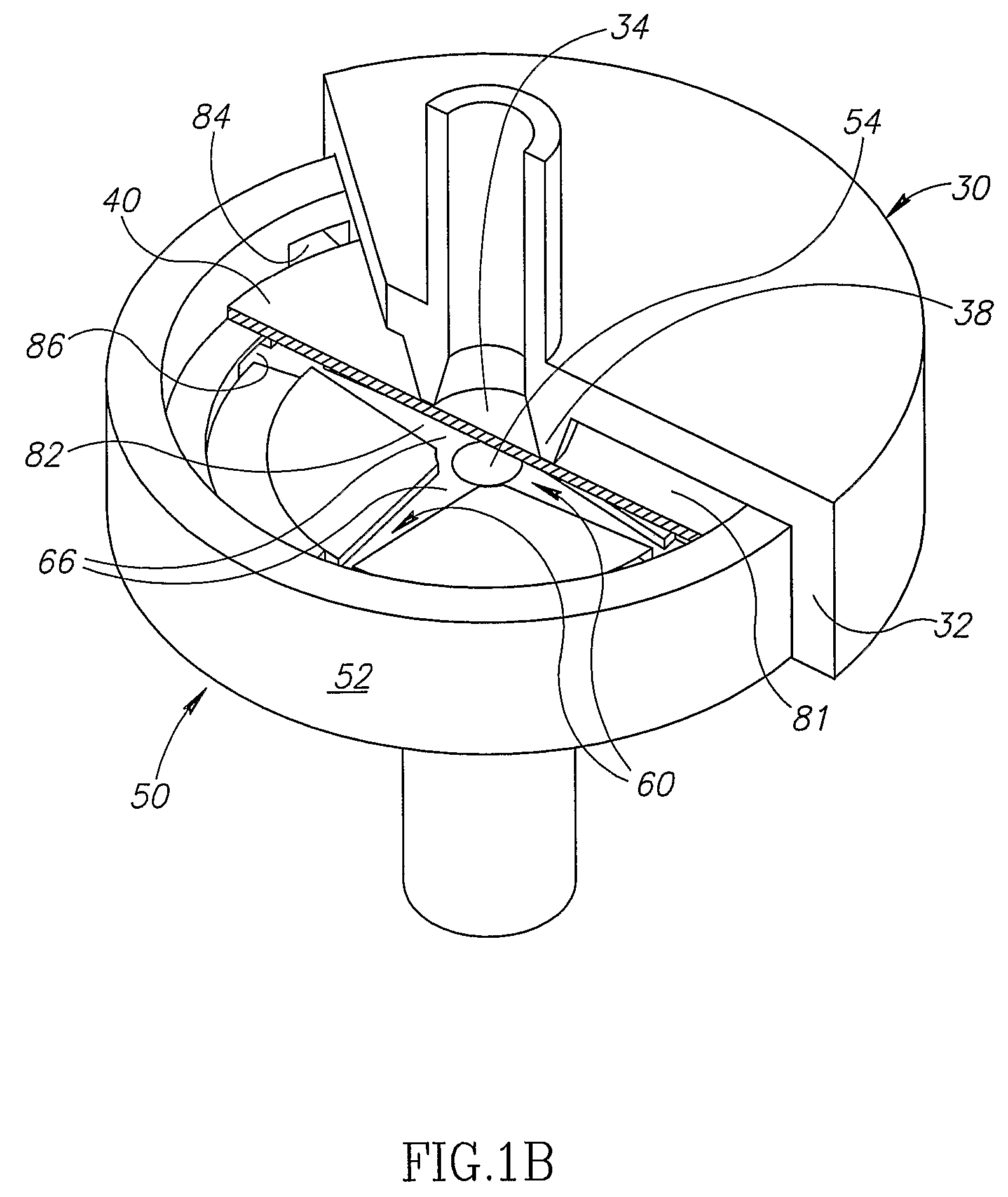

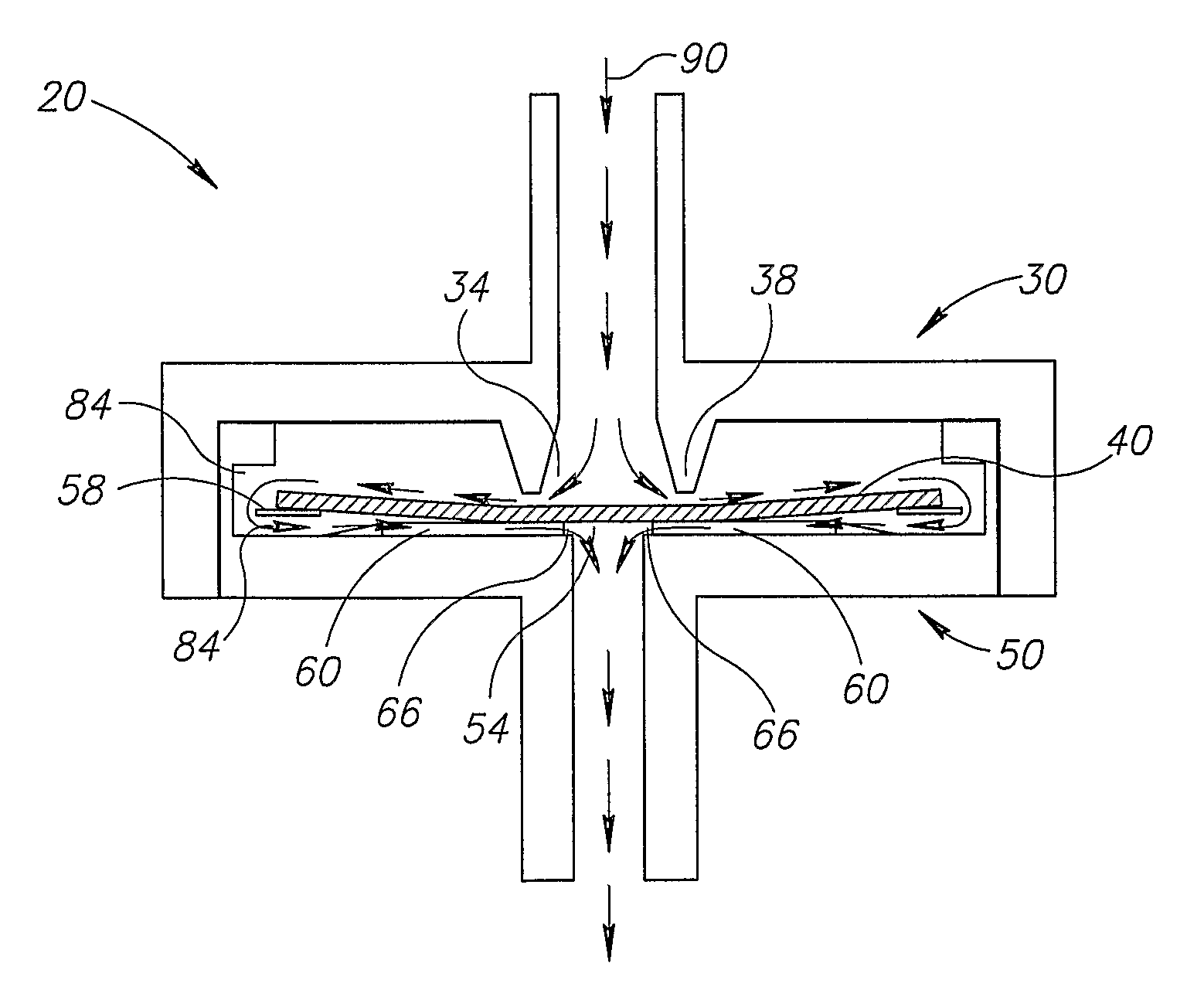

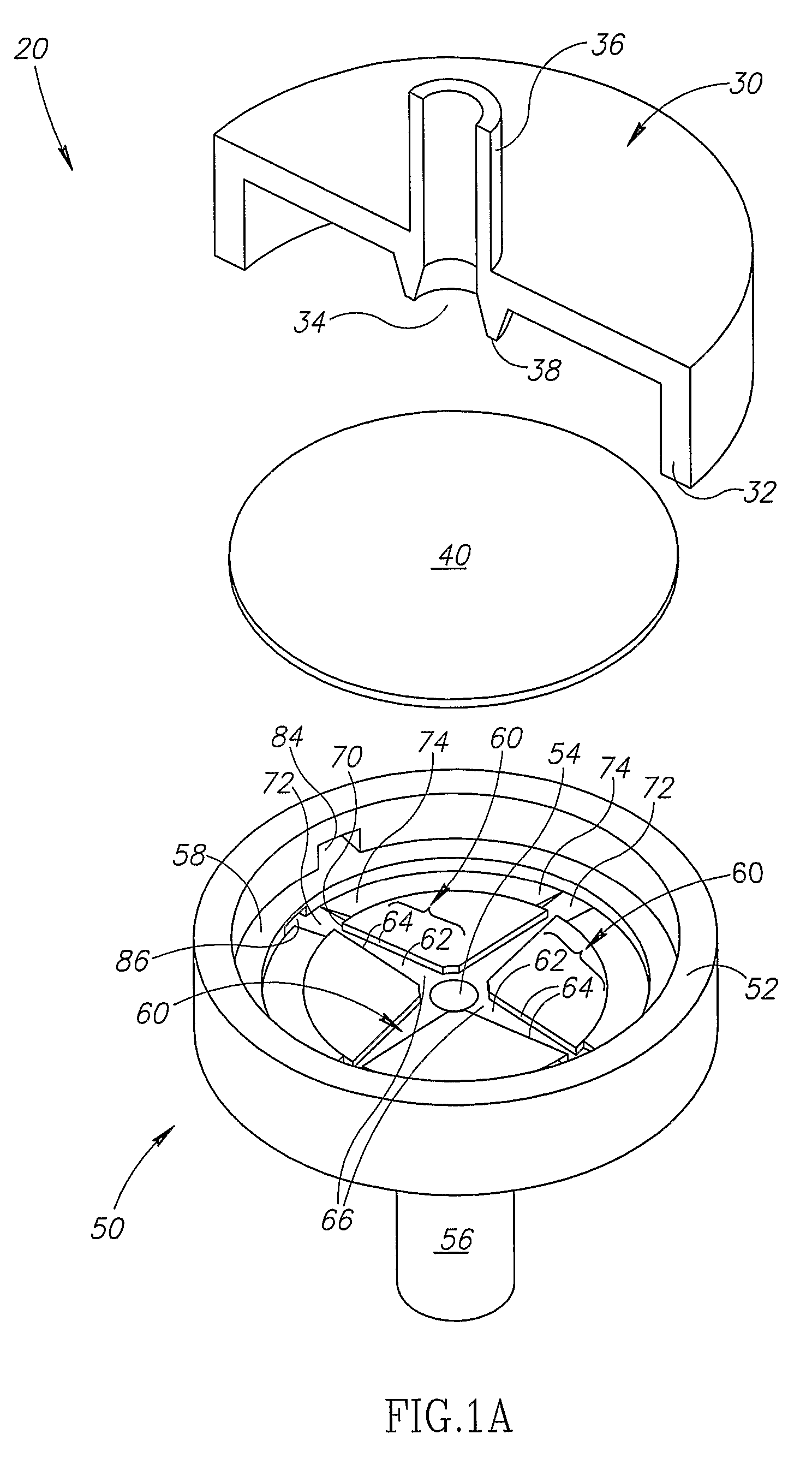

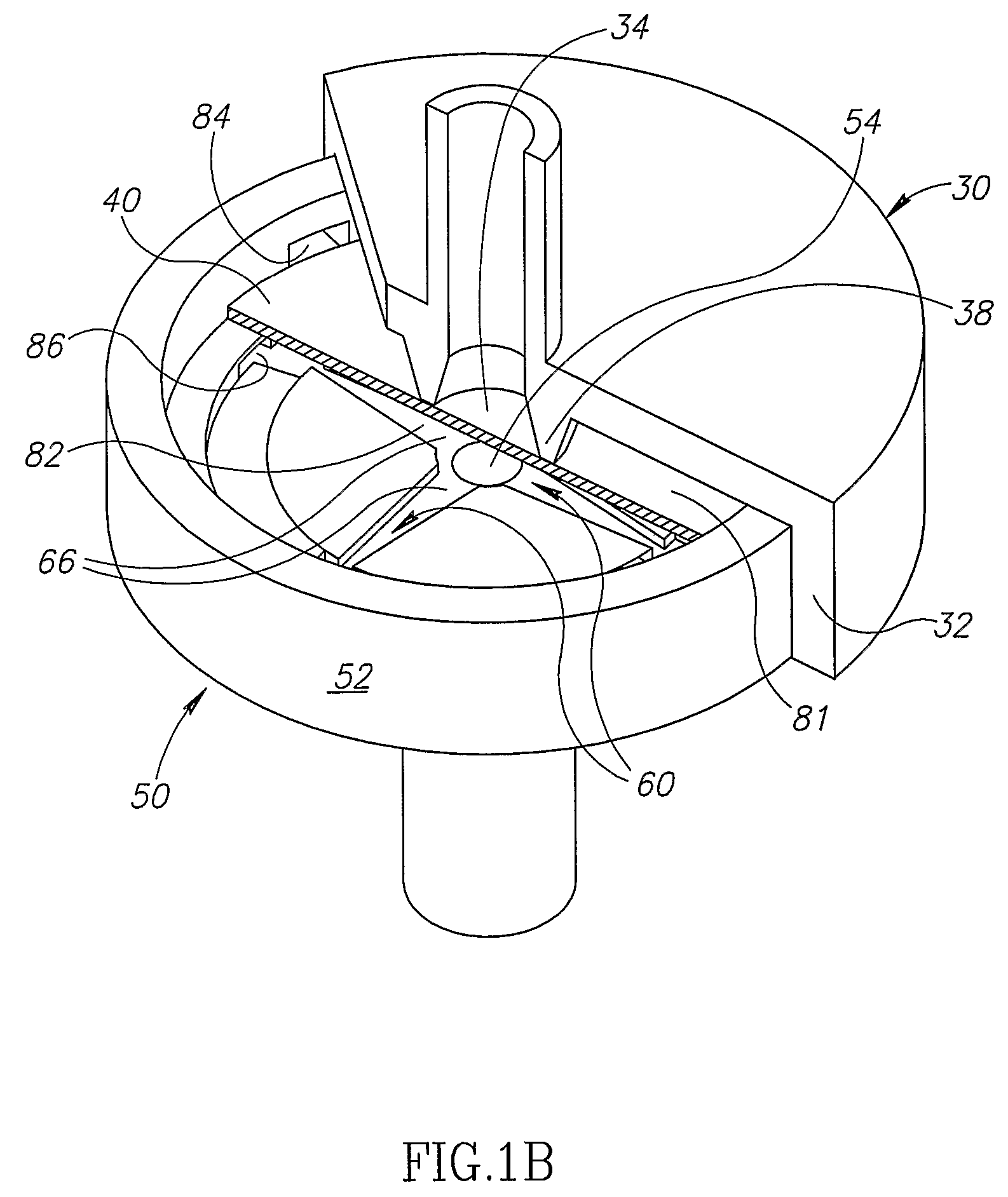

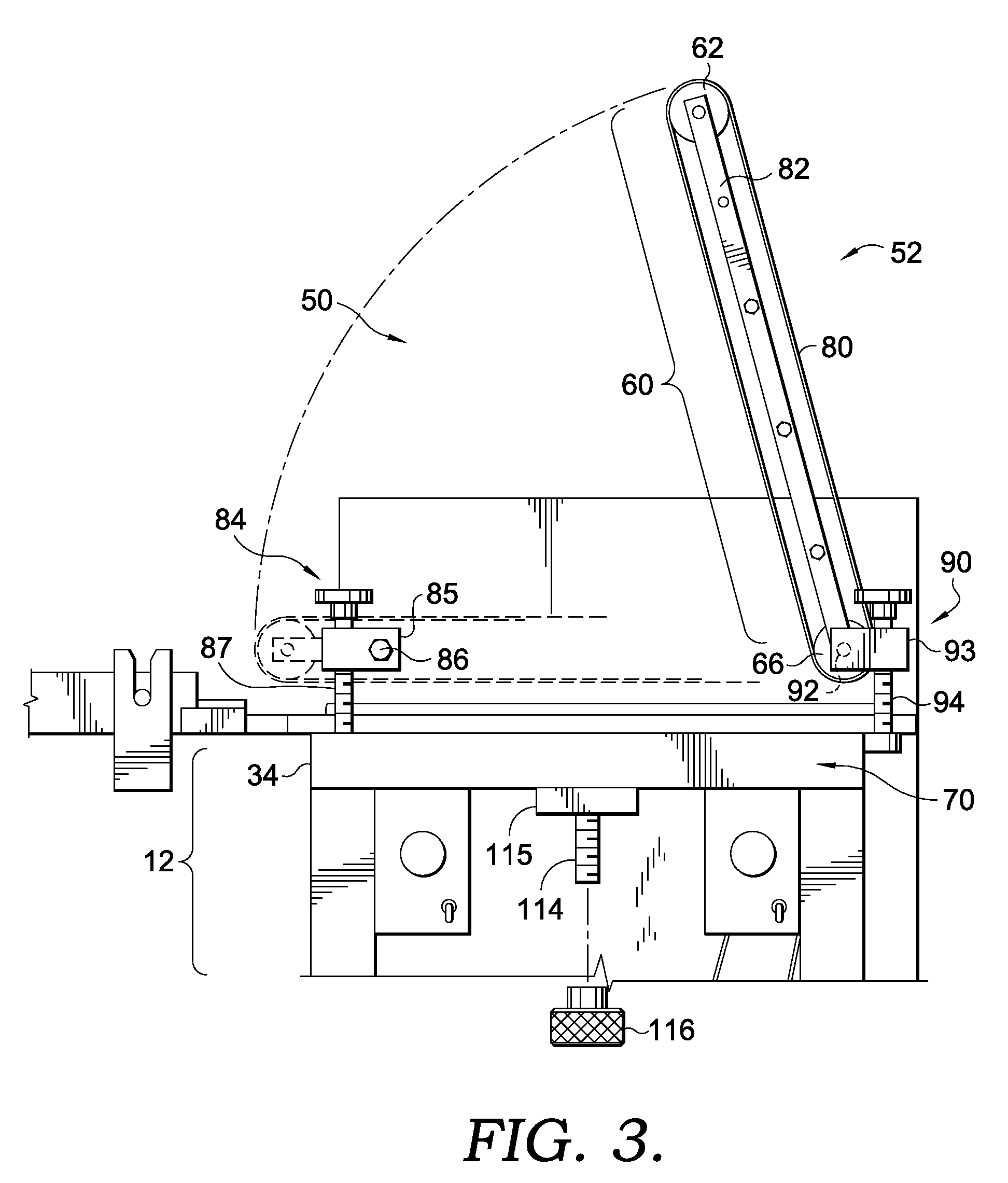

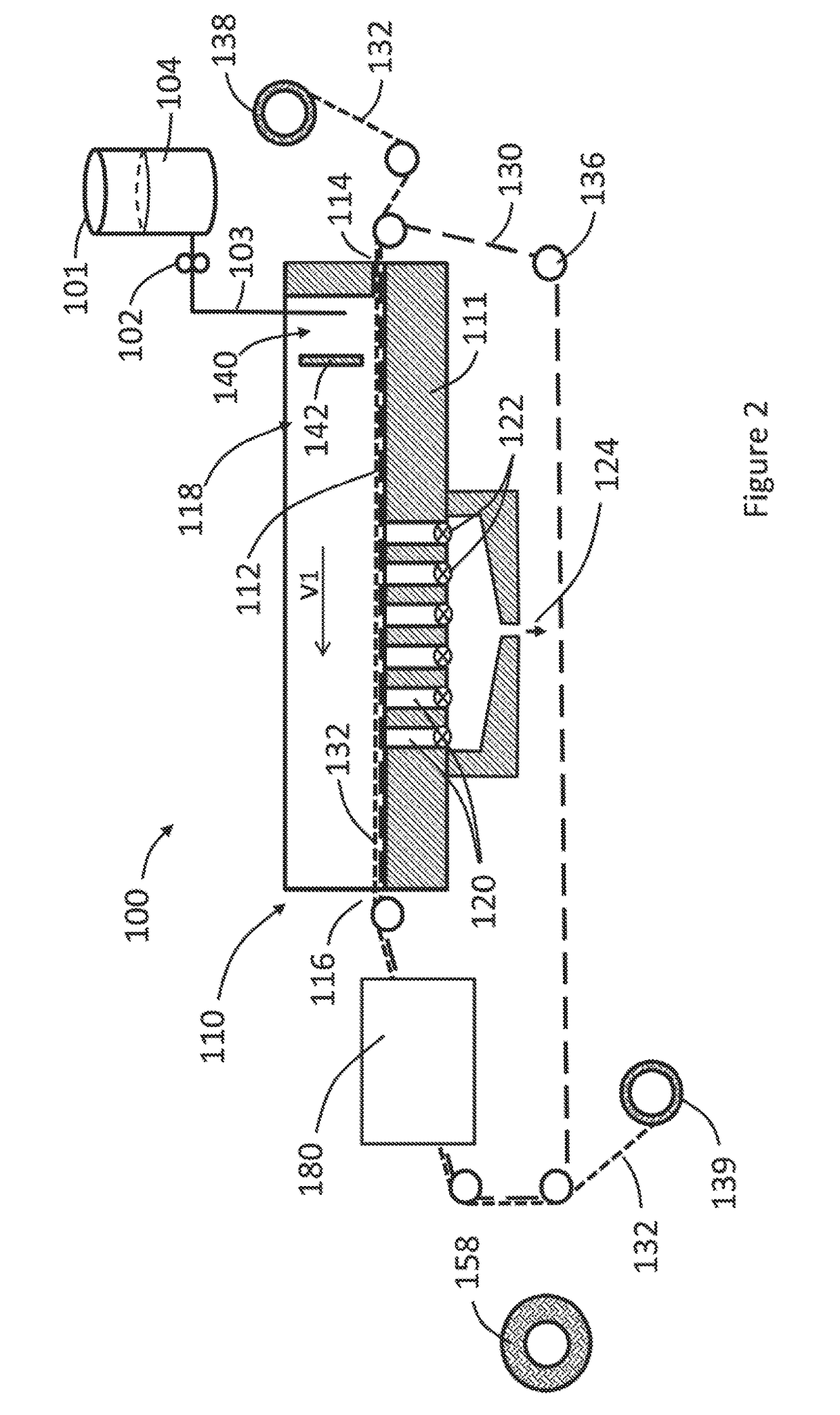

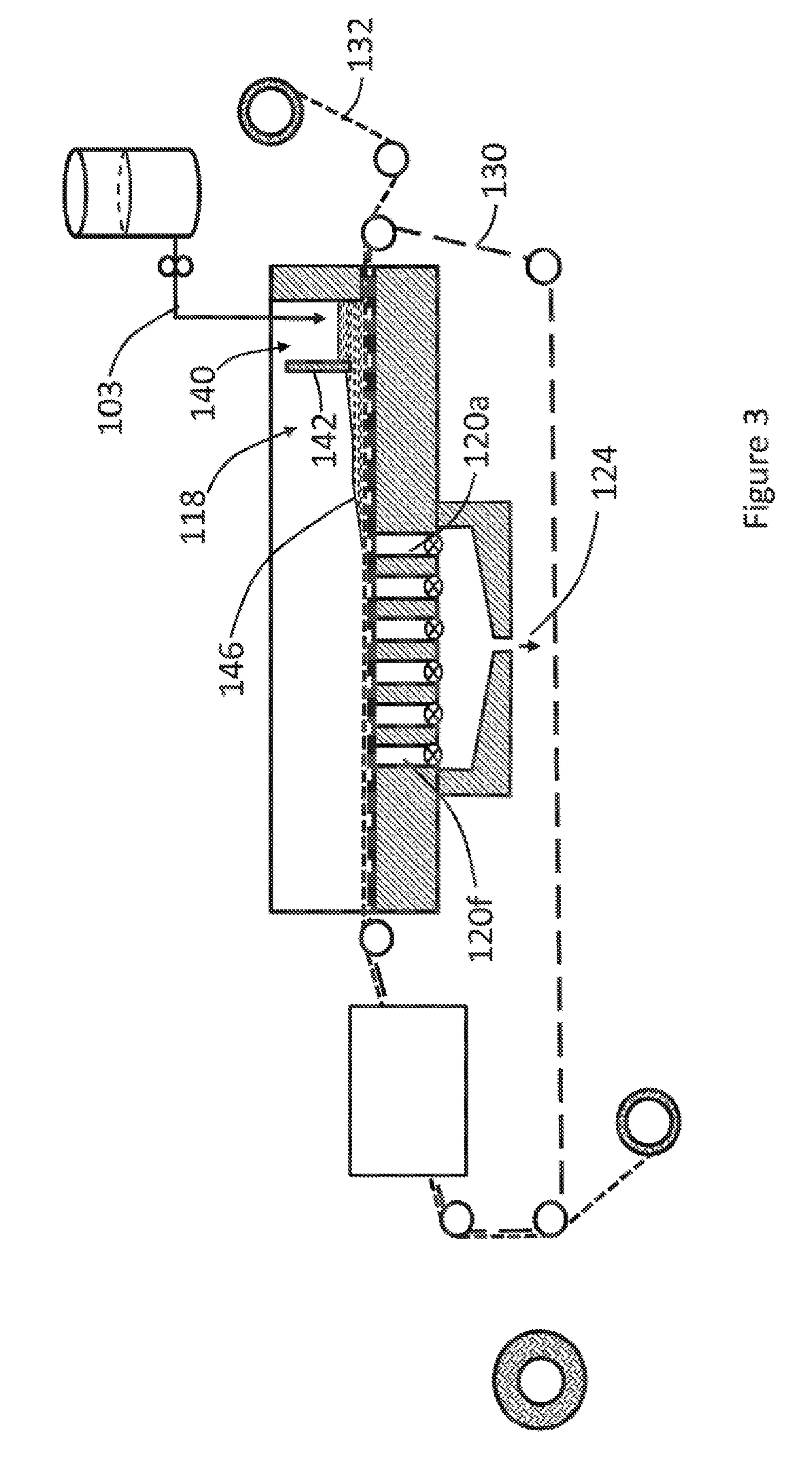

Fluid Flow Control Regulator

ActiveUS20080265064A1OptimizationEasy to modifyOperating means/releasing devices for valvesWatering devicesEngineeringFluid pressure

A fluid flow regulator (20) comprising: a fluid inlet port (34) and a fluid outlet port (54); at least one open-faced flow control channel (60) defined by a planar bottom (62) and two side-walls (64) that communicates with the outlet port (54) at a junction (66) and has a cross-section that decreases with distance from the junction; an elastic diaphragm (40); a support shelf (58) on which the diaphragm (40) seats and which supports the diaphragm (40) along a planar contour parallel to the bottom of each of the at least one channel (60); wherein to regulate fluid flow, with increasing inlet fluid pressure the diaphragm (40) covers portions of the open face that are farther from the junction (66) in a region where the cross-section decreases with distance from the junction (66).

Owner:NETAFIM LTD

Fluid flow control regulator

ActiveUS7775237B2OptimizationEasy to modifyOperating means/releasing devices for valvesWatering devicesEngineeringFluid pressure

A fluid flow regulator (20) comprising: a fluid inlet port (34) and a fluid outlet port (54); at least one open-faced flow control channel (60) defined by a planar bottom (62) and two sidewalls (64) that communicates with the outlet port (54) at a junction (66) and has a cross-section that decreases with distance from the junction; an elastic diaphragm (40); a support shelf (58) on which the diaphragm (40) seats and which supports the diaphragm (40) along a planar contour parallel to the bottom of each of the at least one channel (60); wherein to regulate fluid flow, with increasing inlet fluid pressure the diaphragm (40) covers portions of the open face that are farther from the junction (66) in a region where the cross-section decreases with distance from the junction (66).

Owner:NETAFIM LTD

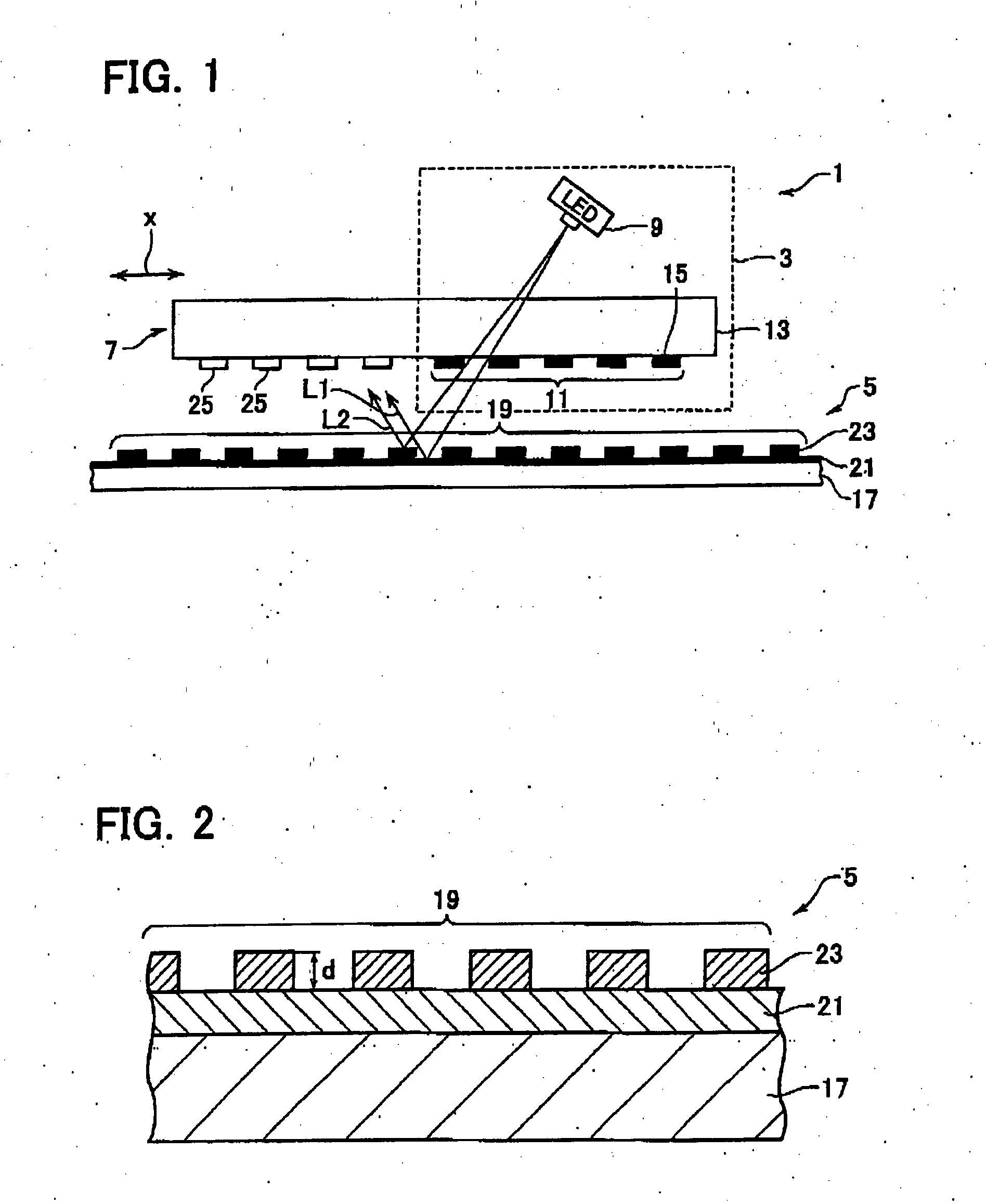

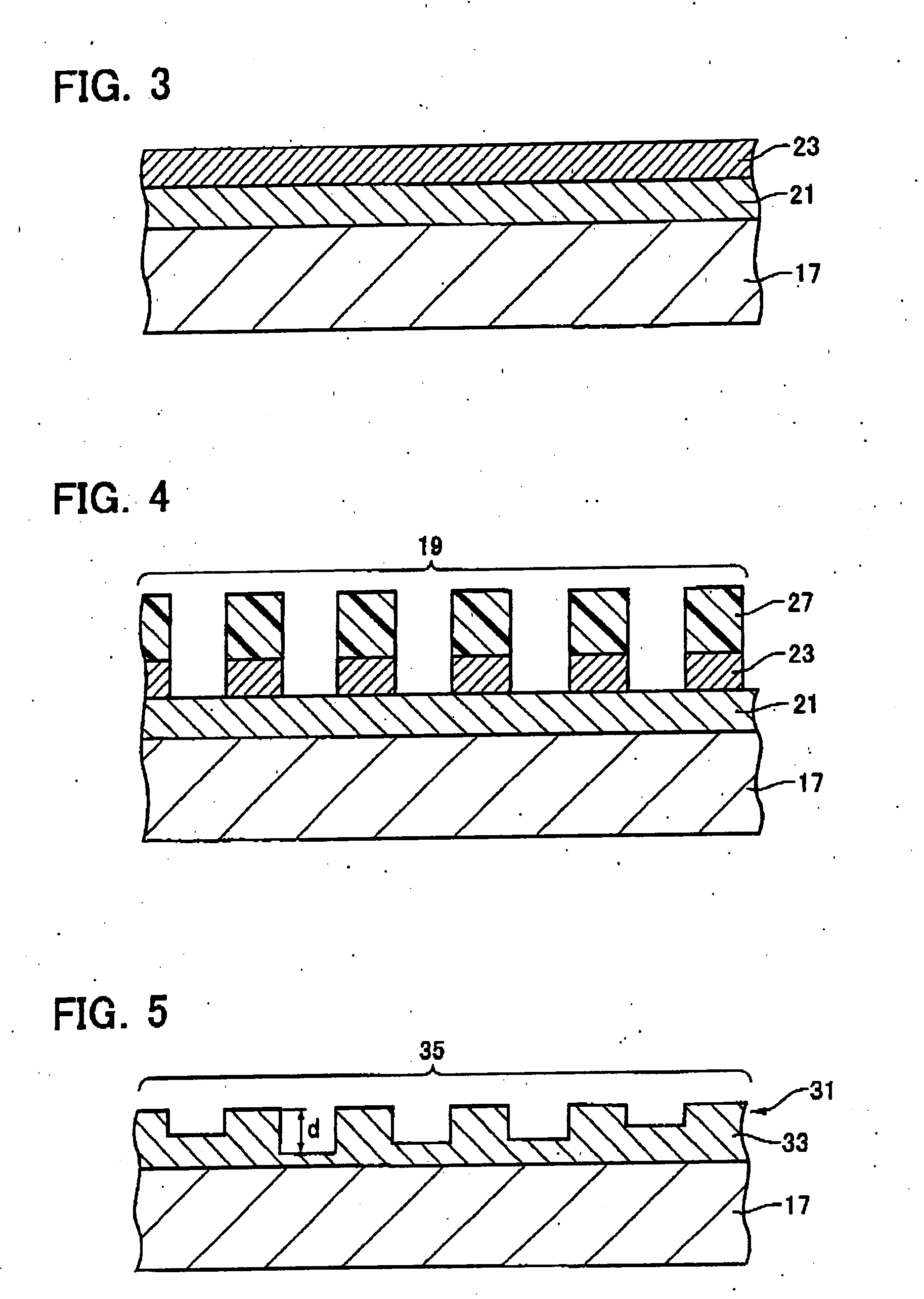

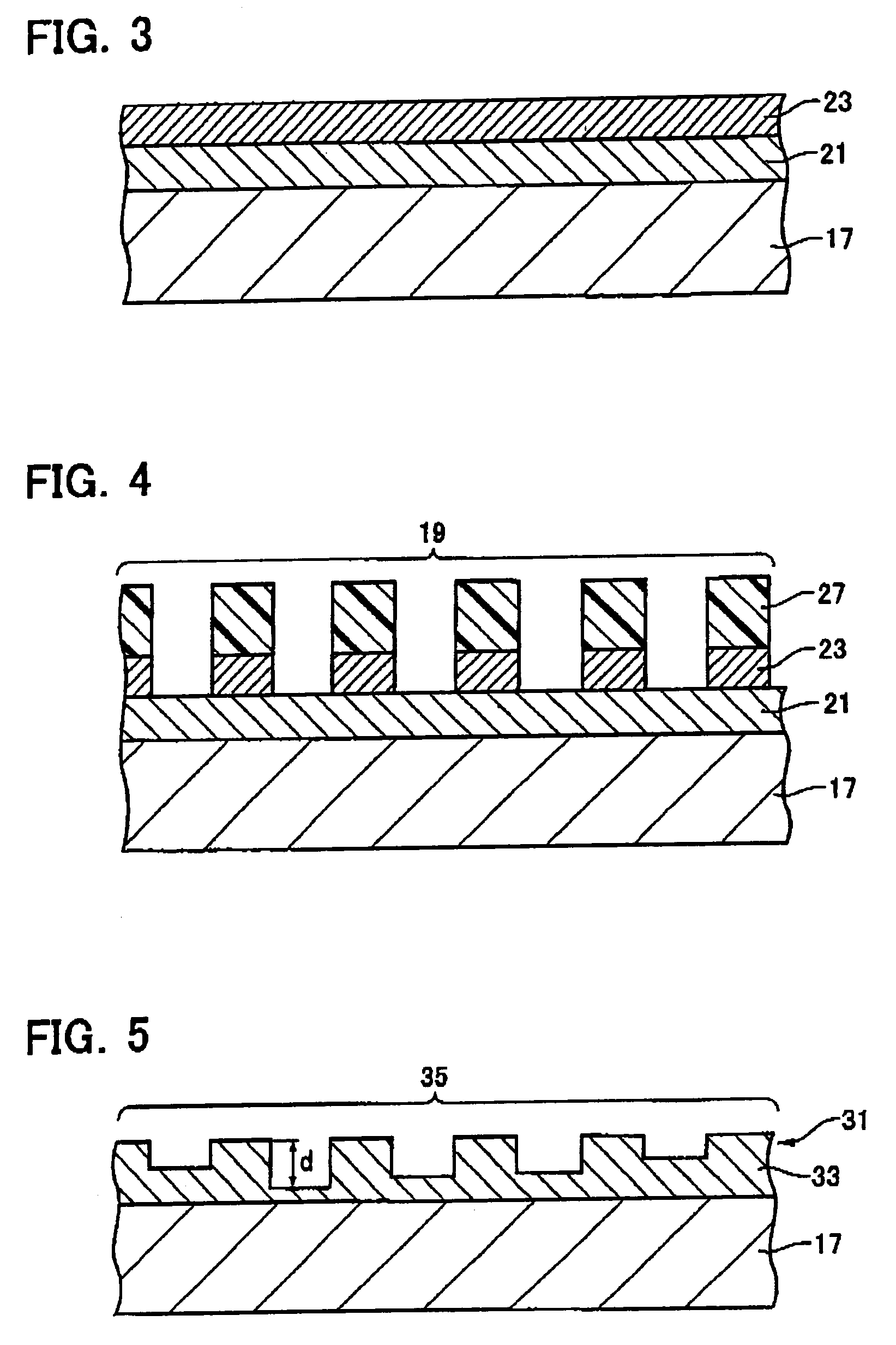

Photoelectric encoder and method of manufacturing scales

InactiveUS20050207013A1Improve controllabilityHigh mechanical strengthBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansResistGrating

Owner:MITUTOYO CORP

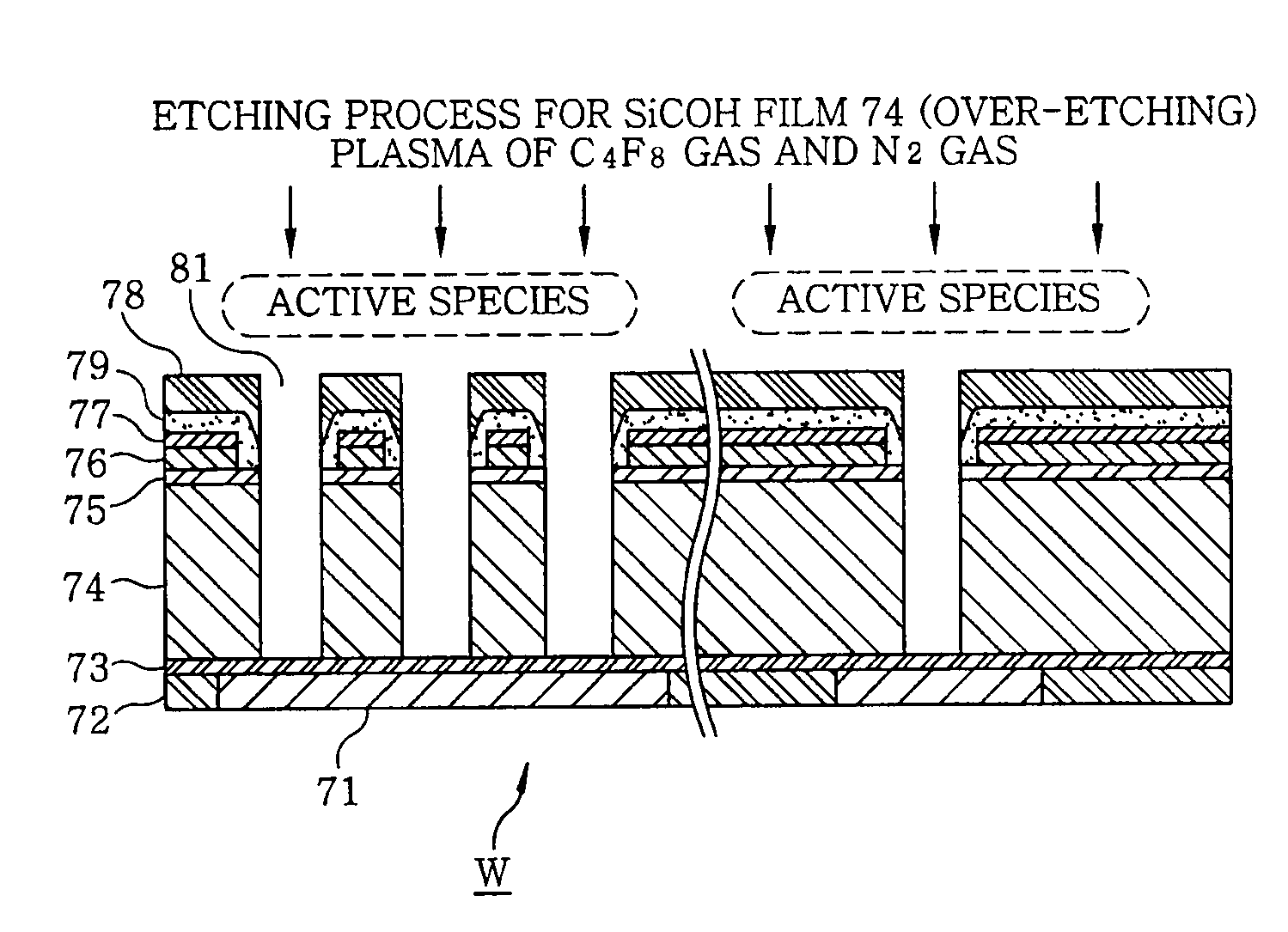

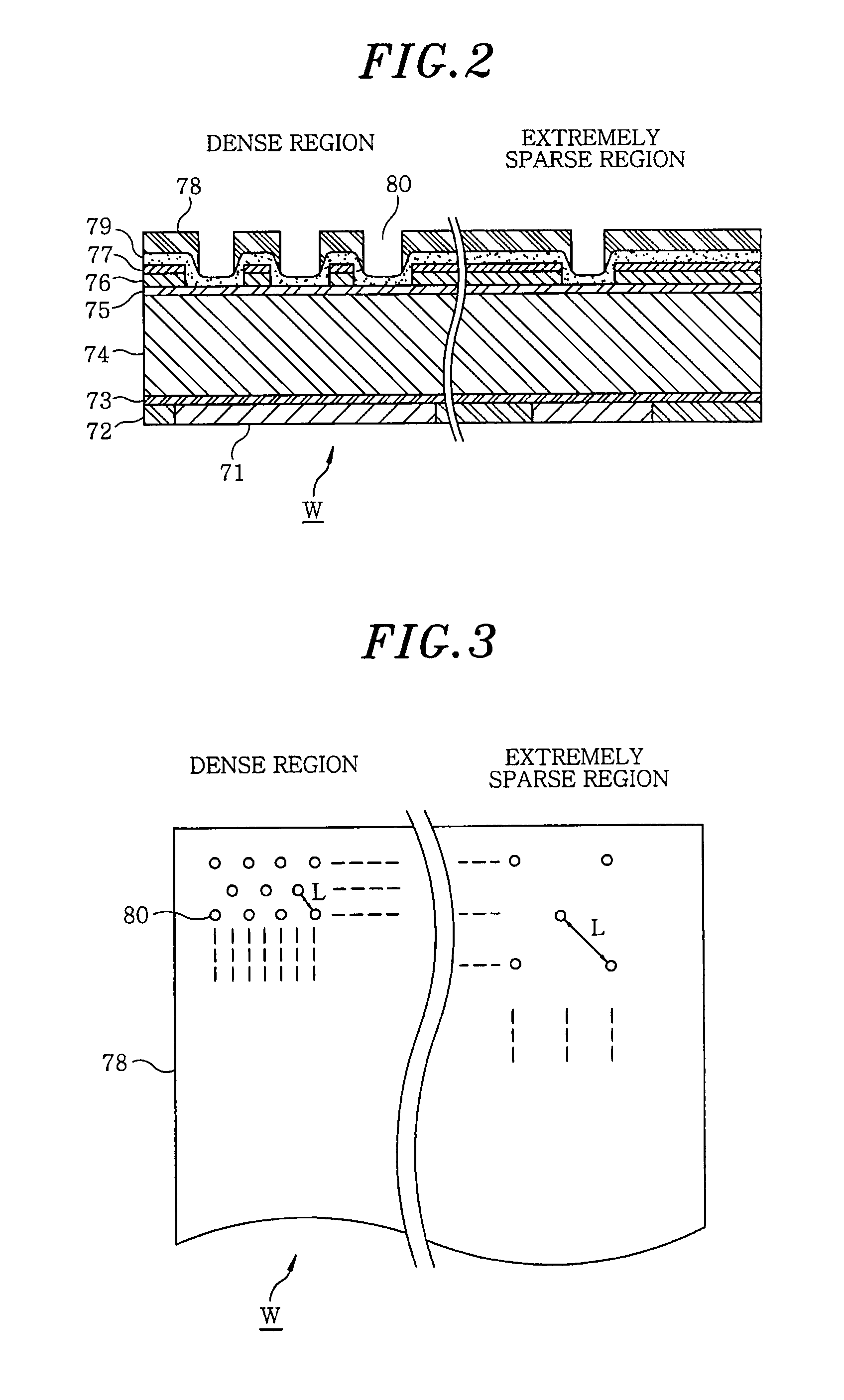

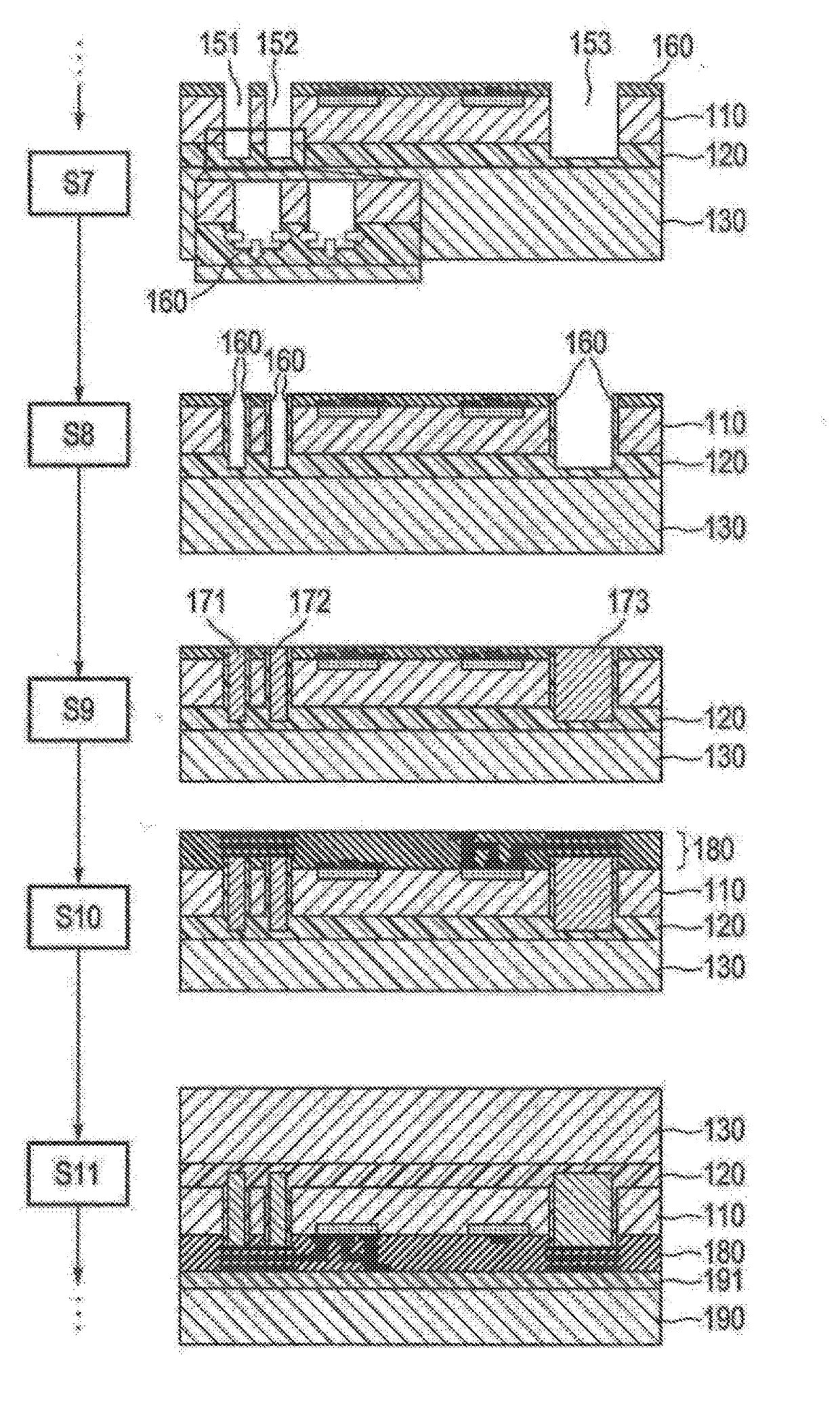

Plasma etching method

ActiveUS20080194114A1Deep unityReduce the ratioVacuum gauge using ionisation effectsDecorative surface effectsResistParallel plate

In a plasma etching method, a substrate including an underlying film, an insulating film and a resist mask is plasma etched to thereby form a number of holes in the insulating film including a dense region and a sparse region by using a parallel plate plasma etching apparatus for applying a plasma-generating high frequency electric power to a space between an upper and a lower electrode and a biasing high frequency electric power to the lower electrode. The plasma etching method includes mounting the substrate on a mounting table; supplying a first process gas containing carbon and fluorine to form the holes in the insulating film to a depth close to the underlying film; and supplying a second process gas including an inert gas and another gas contain carbon and fluorine to have the holes reach the underlying film while applying a negative DC voltage to the upper electrode.

Owner:TOKYO ELECTRON LTD

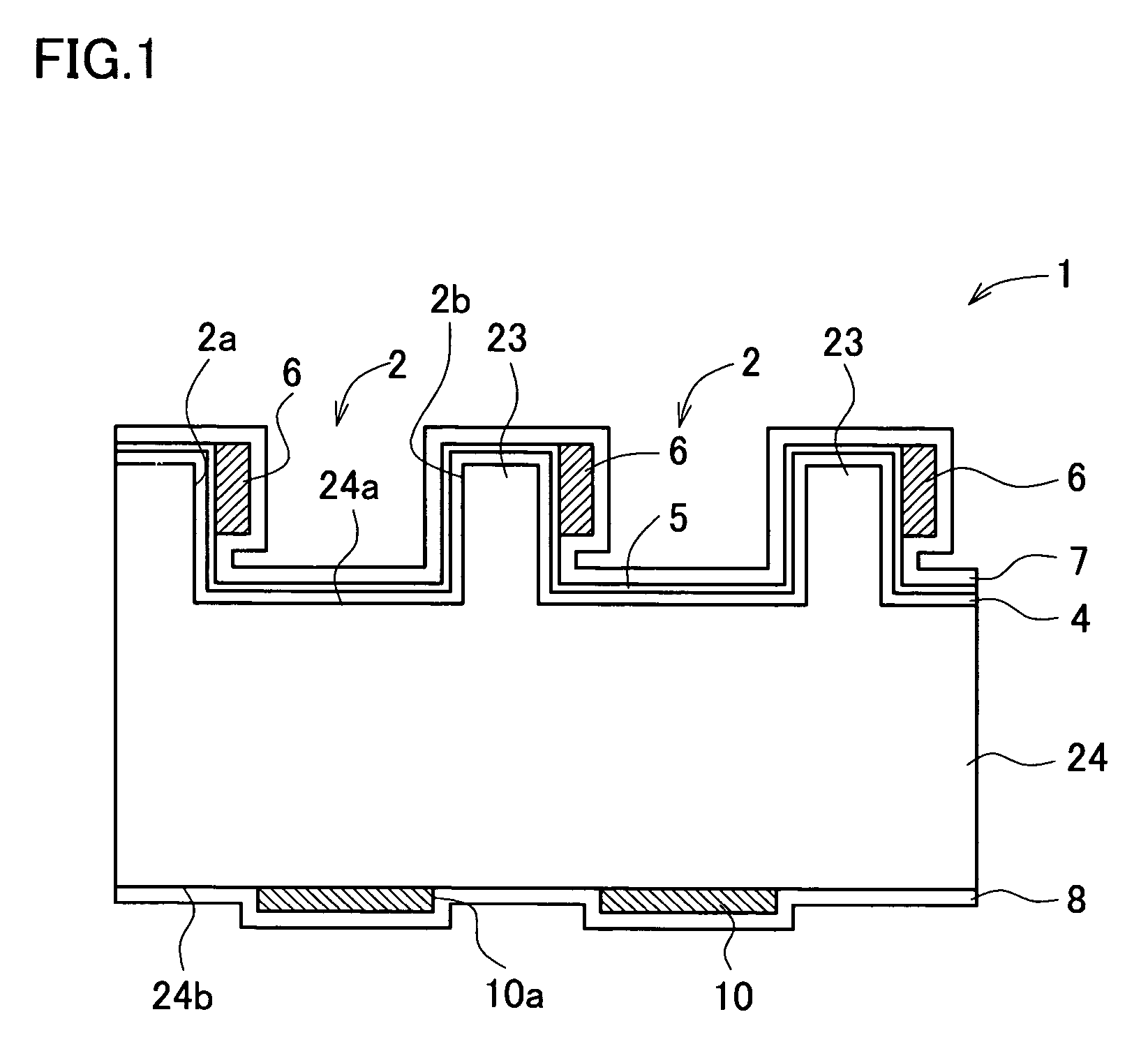

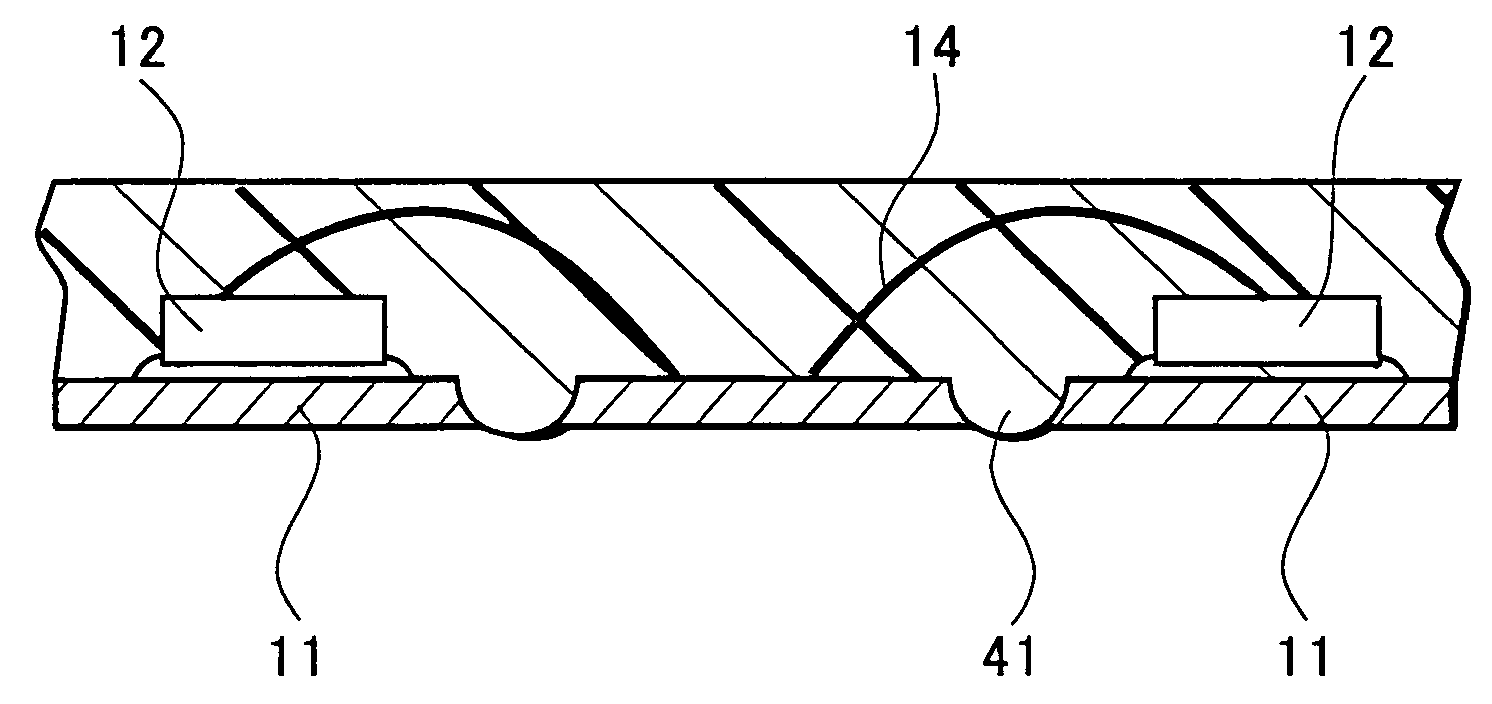

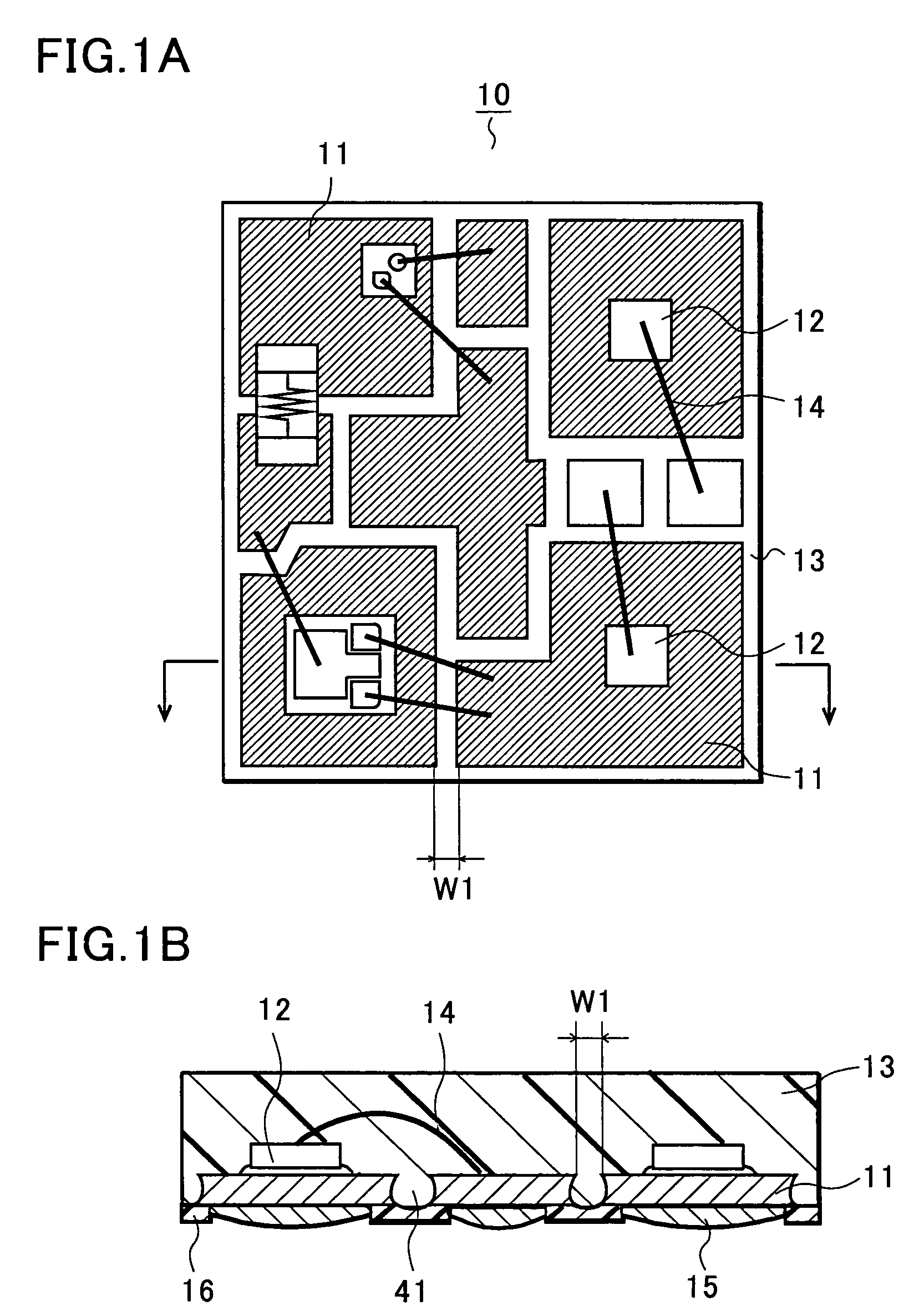

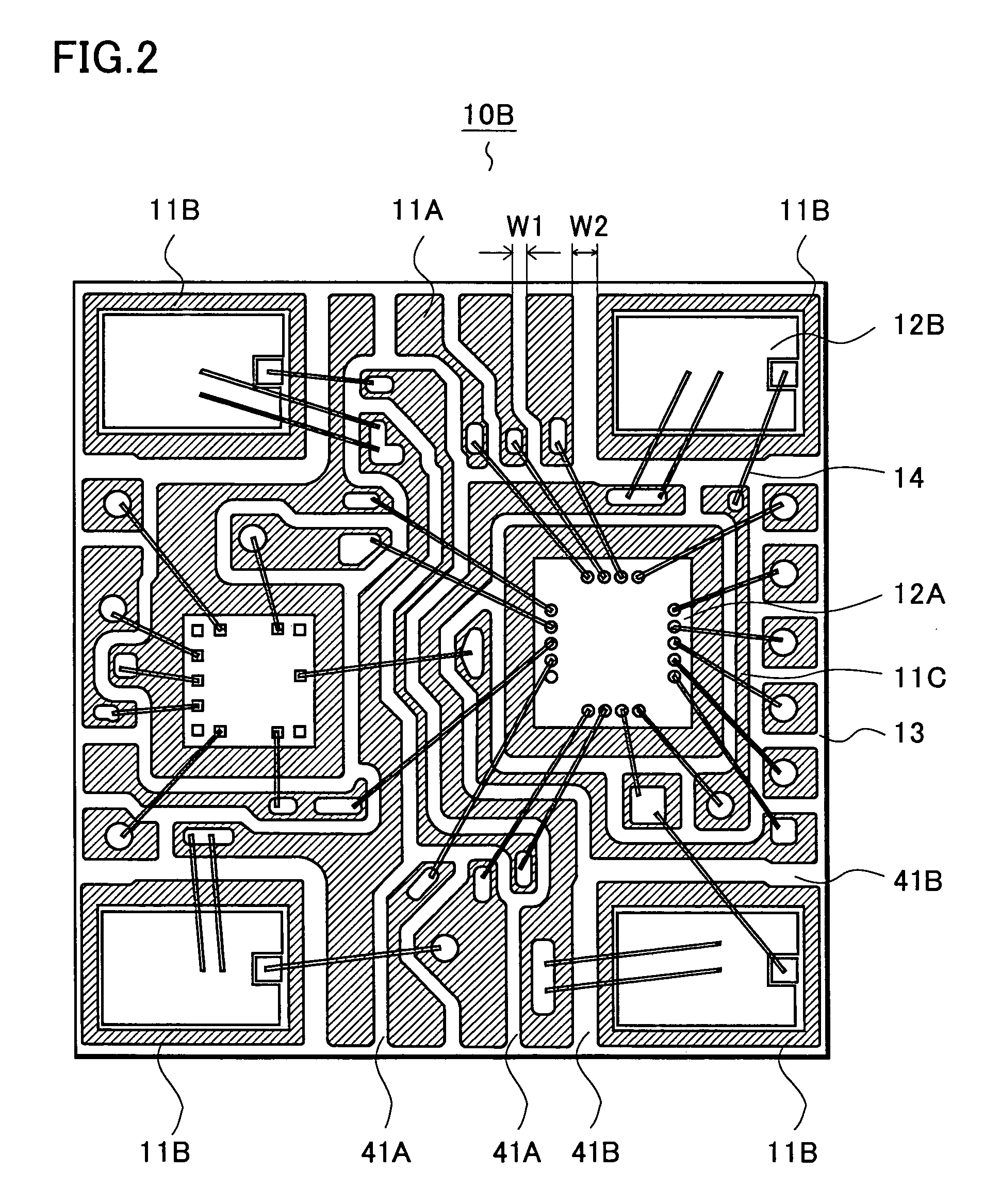

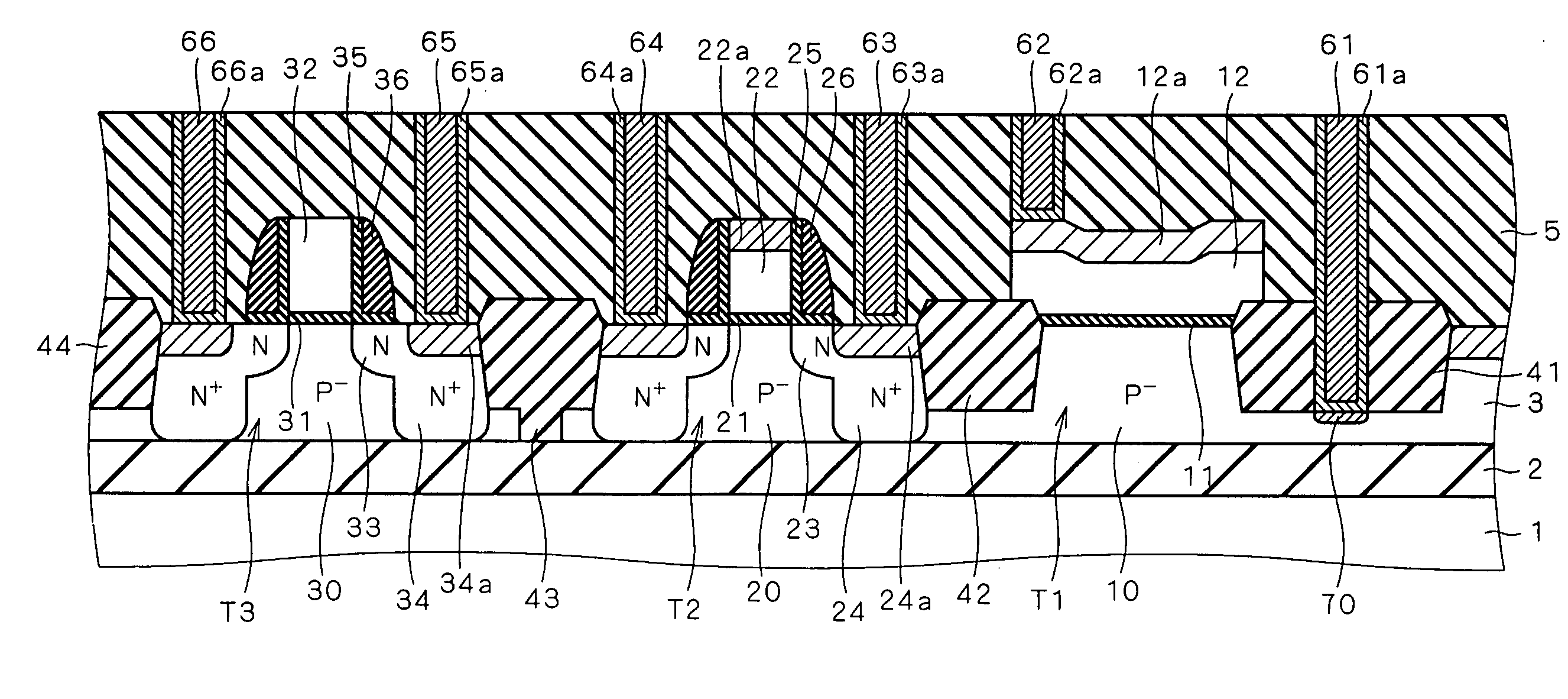

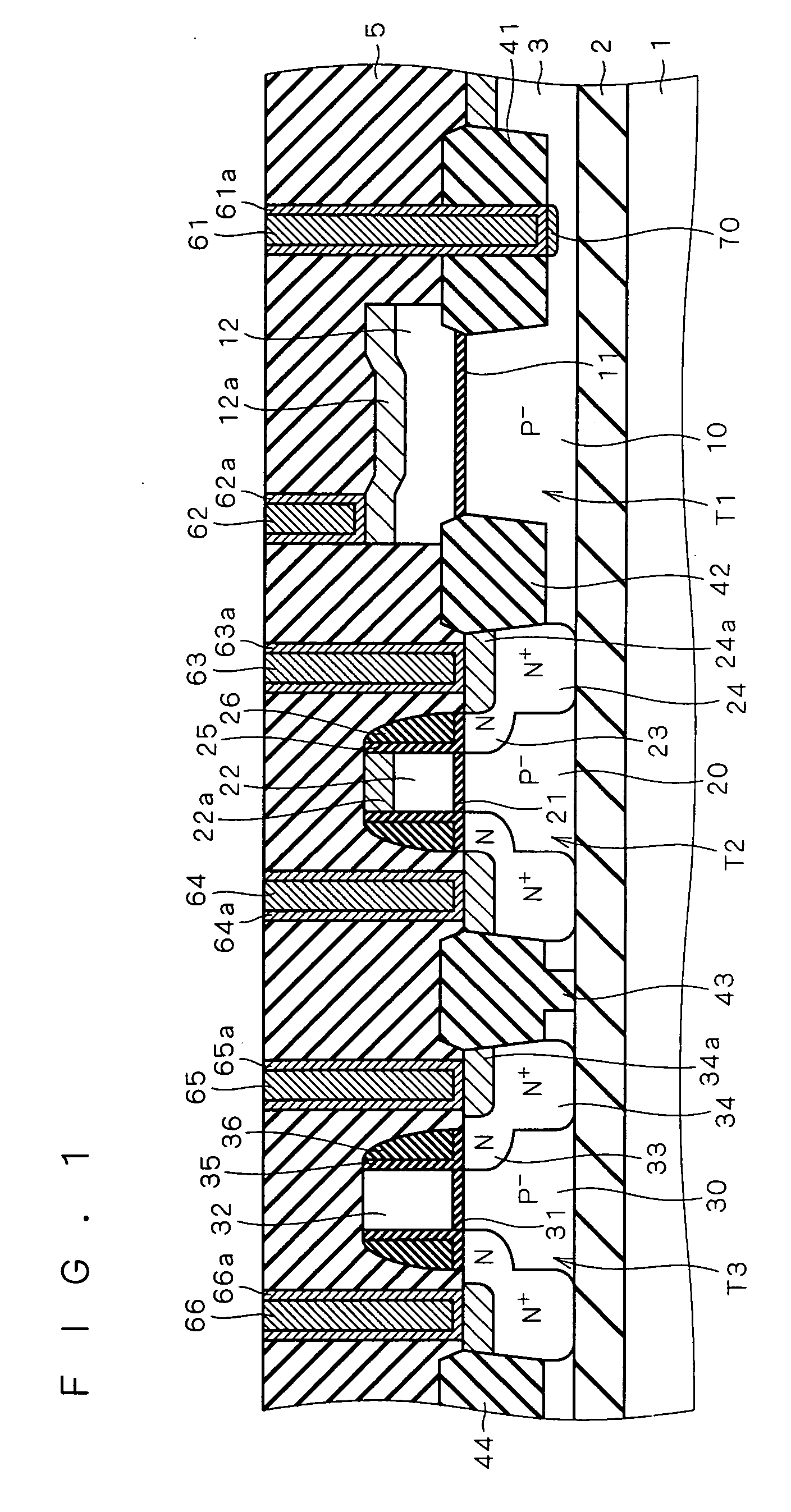

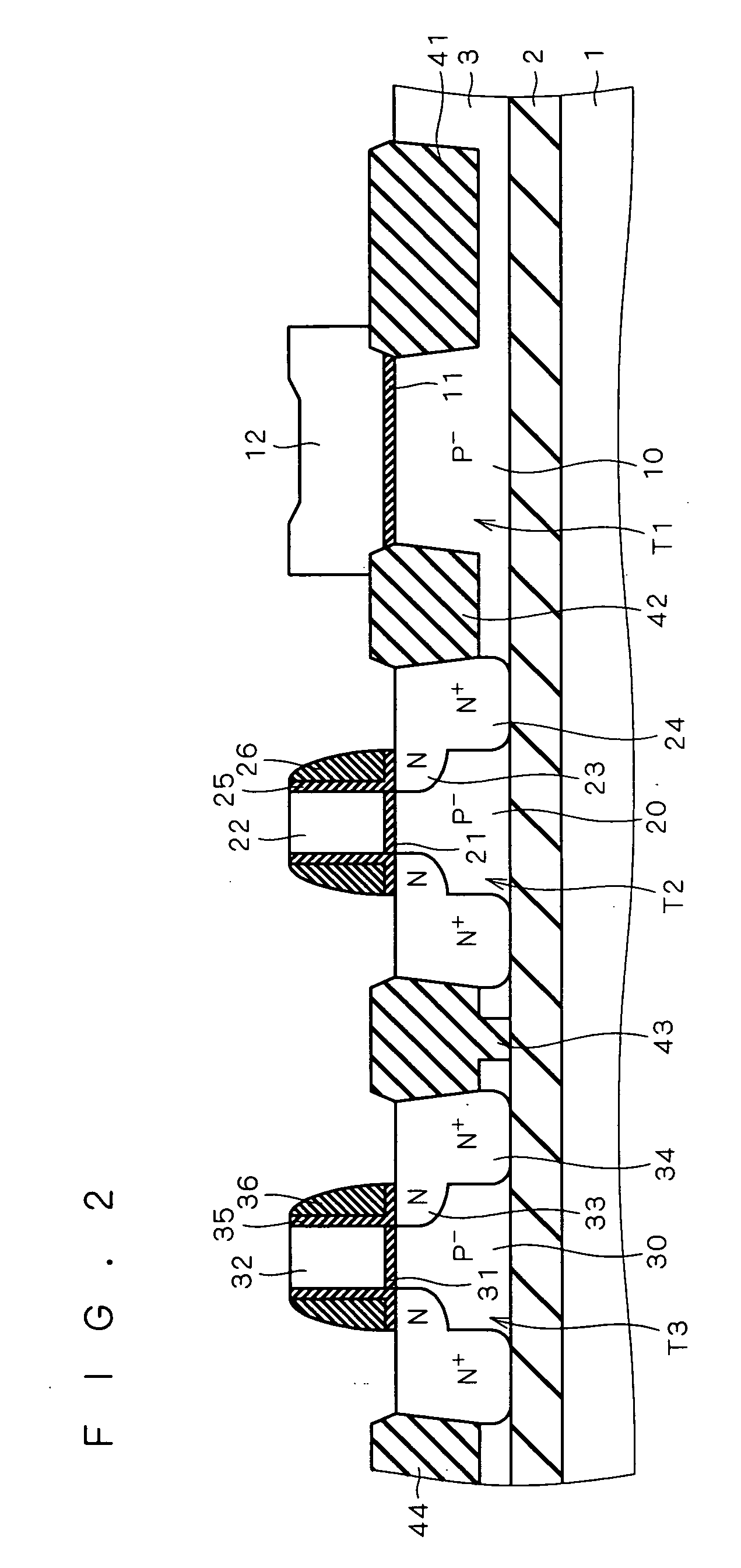

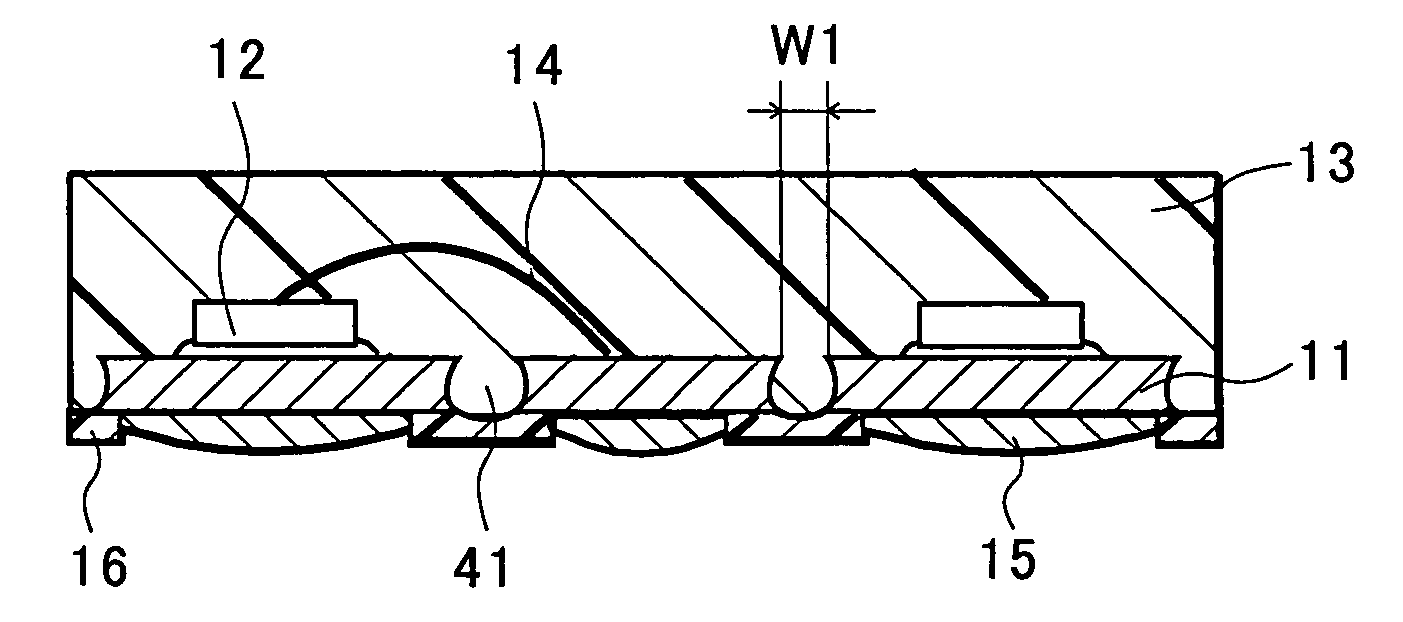

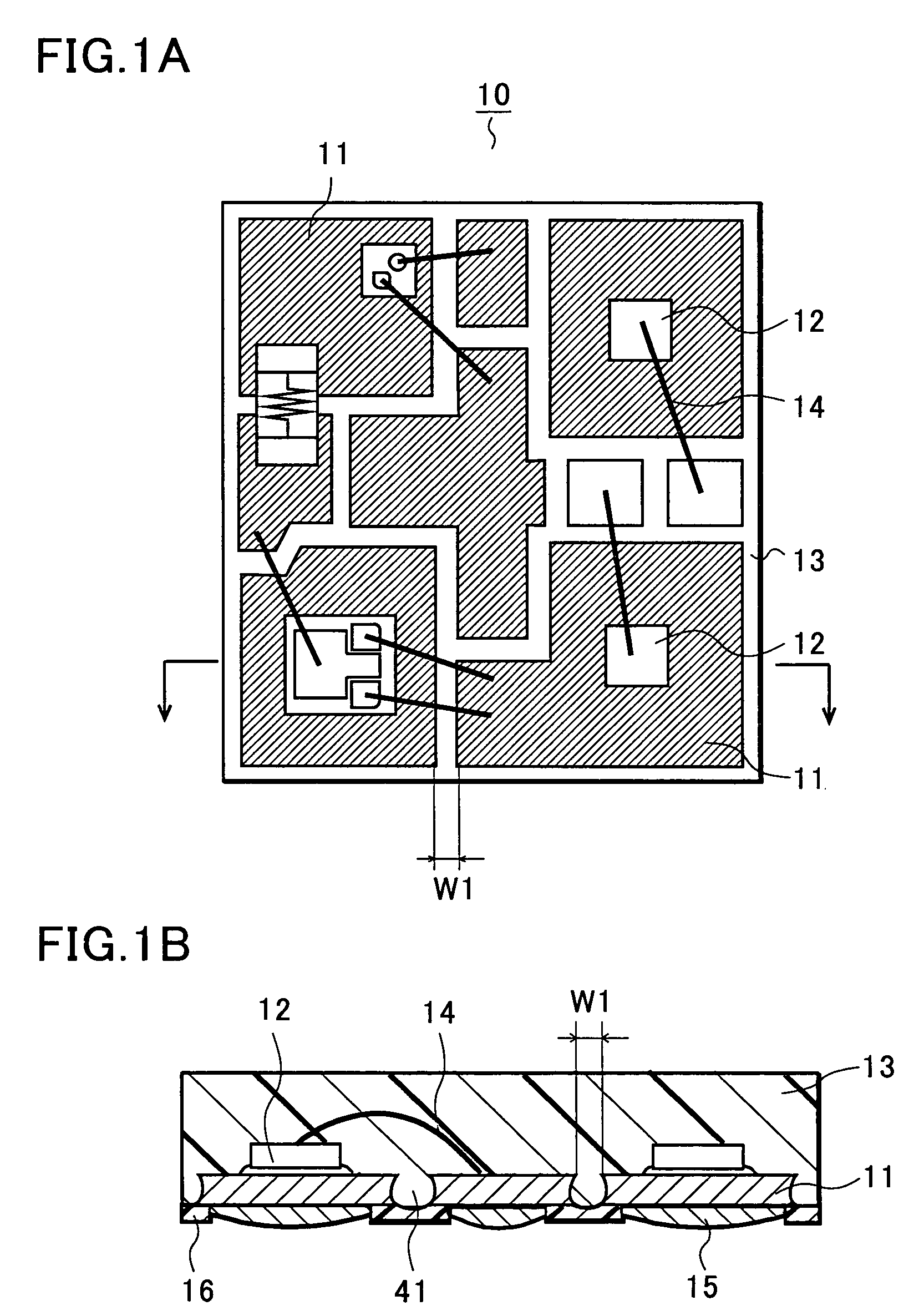

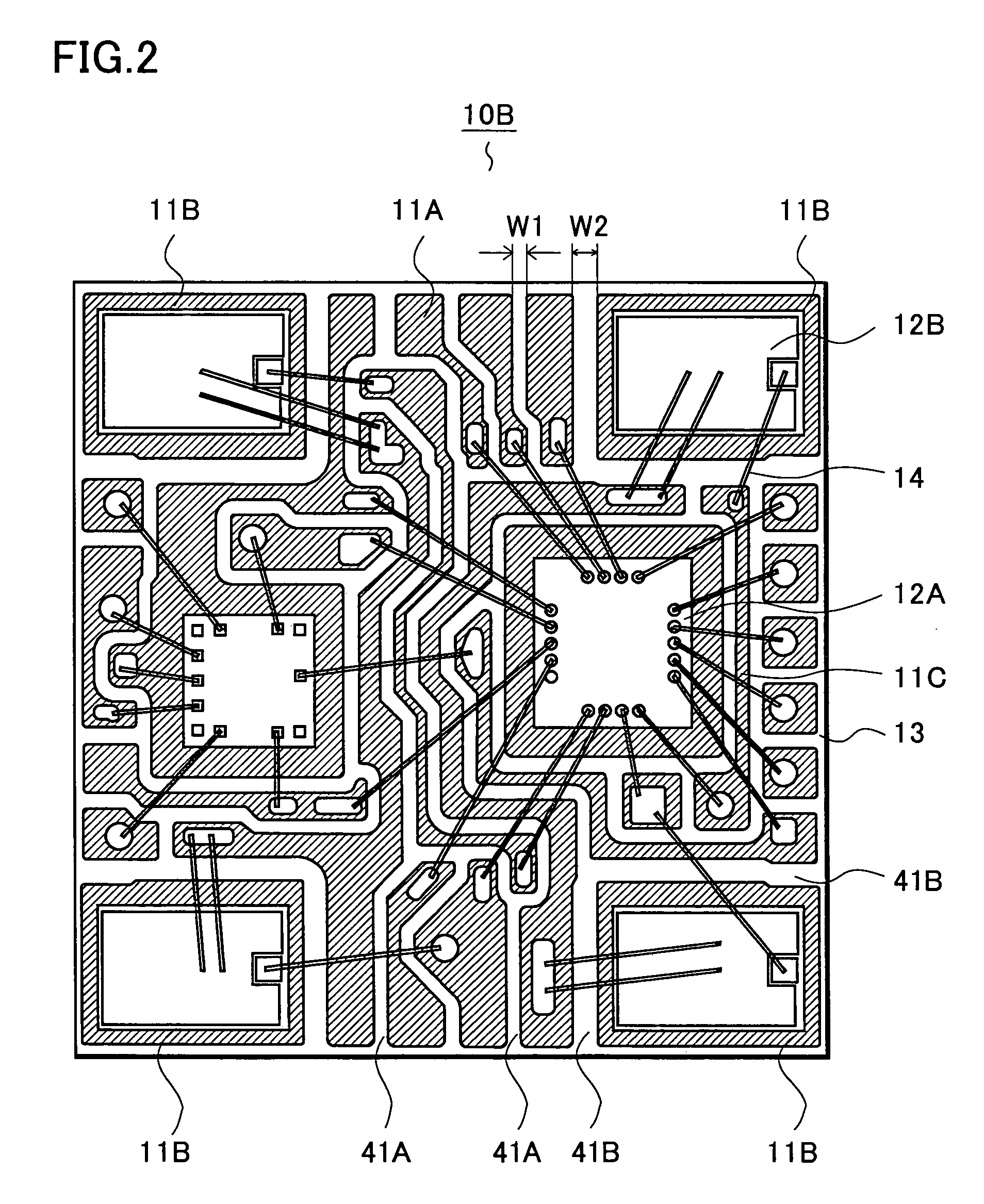

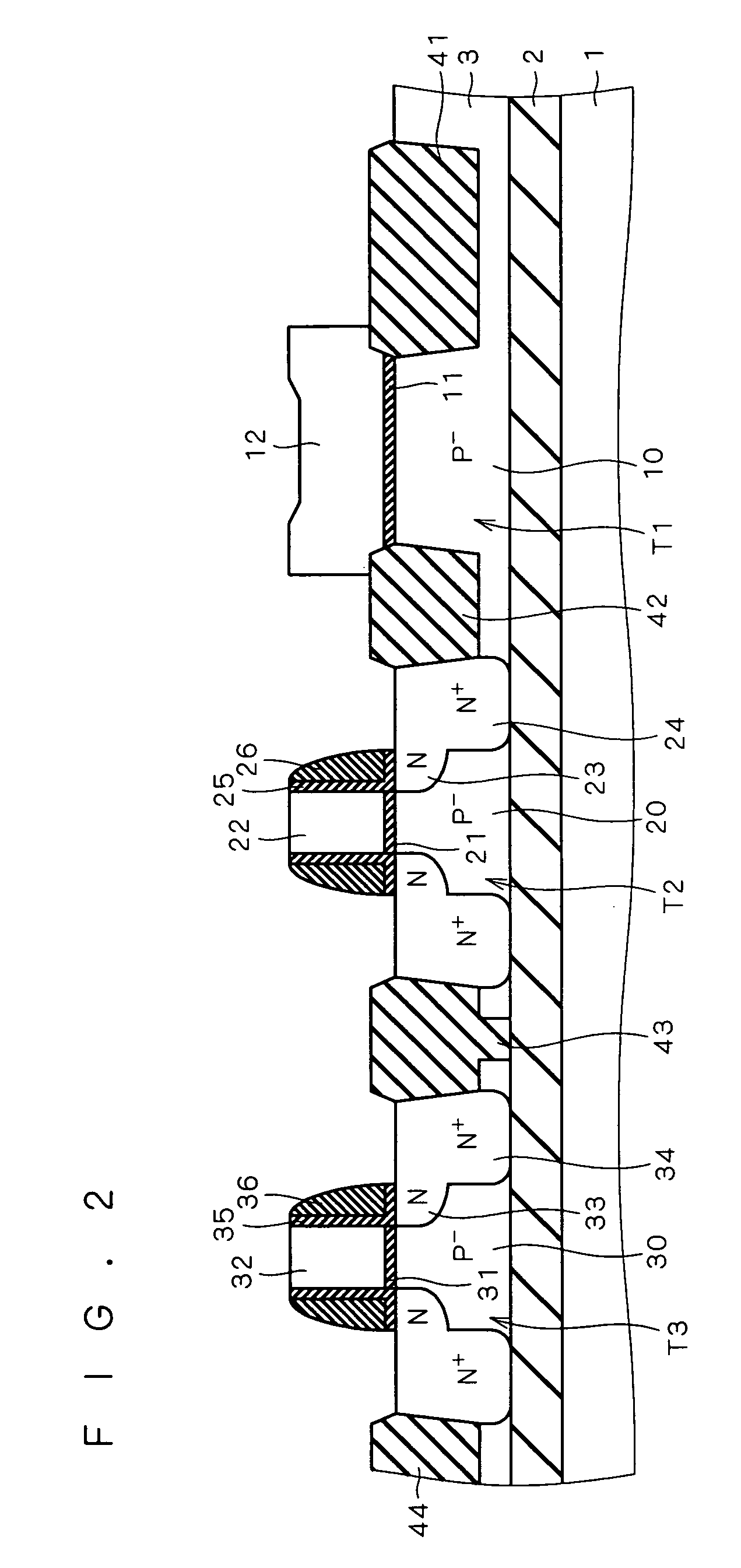

Circuit device and manufacturing method thereof

InactiveUS7420266B2Designing of a circuit pattern considering the parasitic capacitances is facilitatedDesigning can be facilitatedPrinted circuit detailsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

Owner:SANYO ELECTRIC CO LTD

Semiconductor device and method of manufacturing semiconductor device

InactiveUS20060043494A1Reduce resistance variationReduce variationSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialBody contact

A Schottky junction is formed at the connection between an SOI layer and a contact (namely, under an element isolation insulating film) without forming a P+ region with a high impurity concentration thereat. The surface of a body contact is provide with a barrier metal. A silicide is formed between the body contact and the SOI layer as a result of the reaction of the barrier metal and the SOI layer.

Owner:RENESAS ELECTRONICS CORP

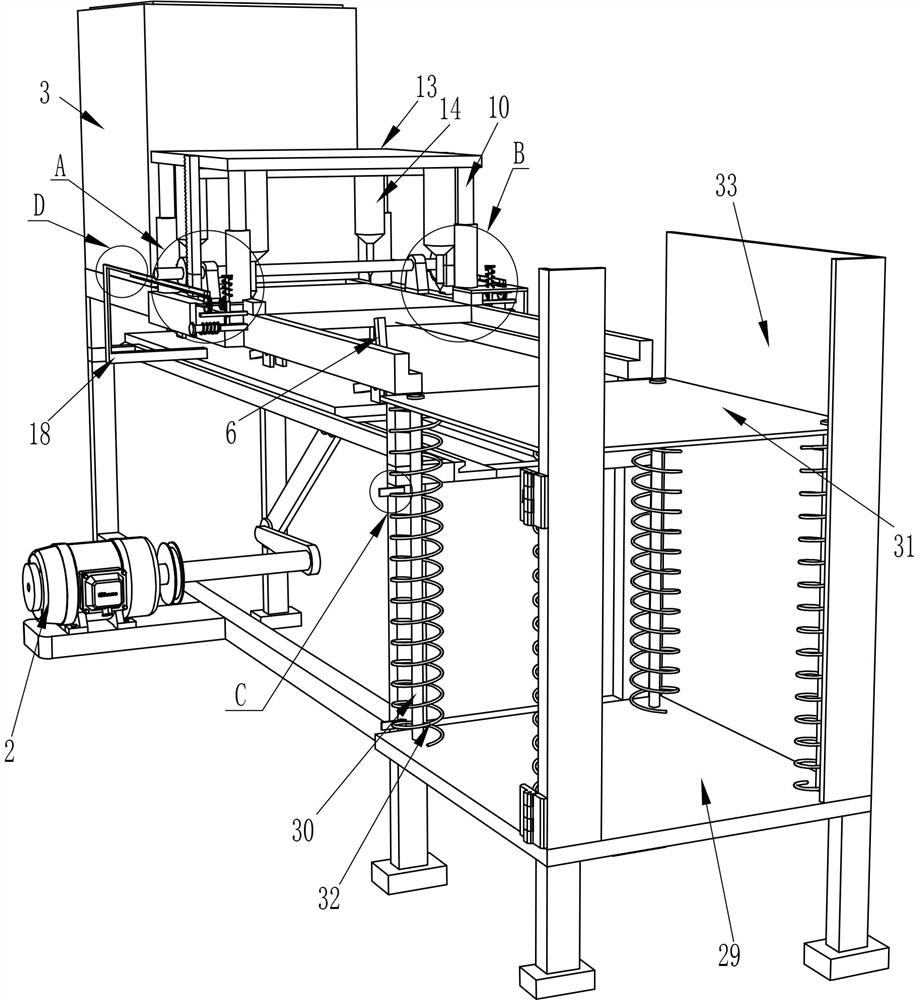

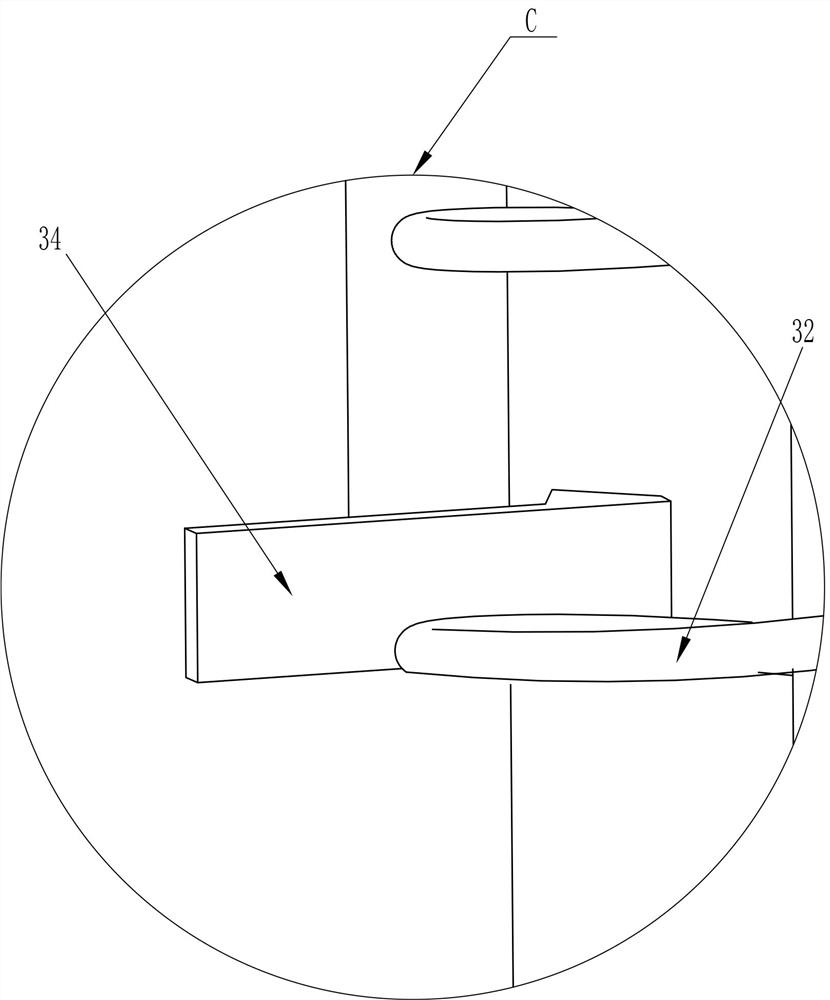

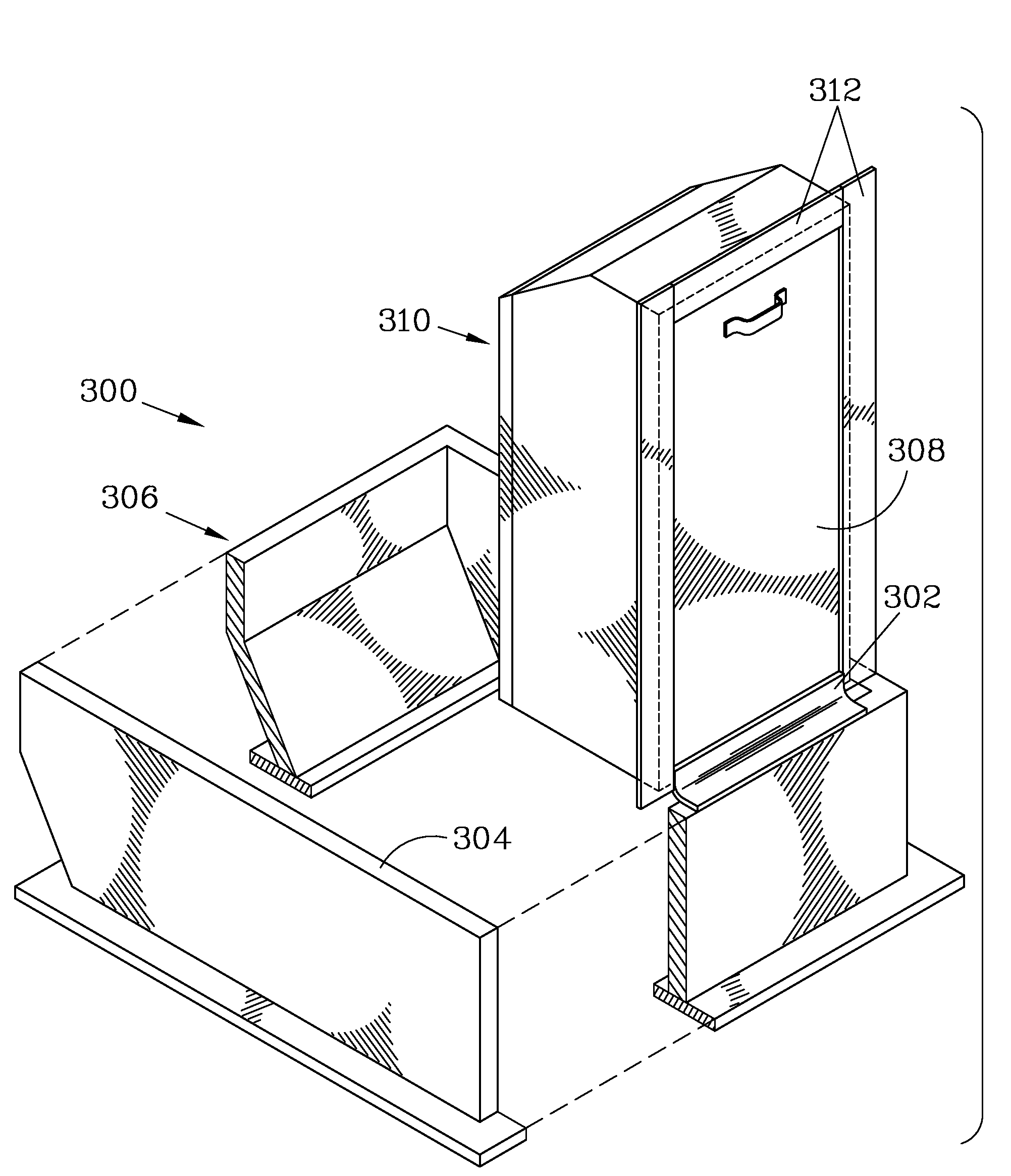

Drilling equipment used before assembling of storage cabinet

ActiveCN111673841AUniform sizeDeep unityStationary drilling machinesMulti-purpose machinesGear wheelElectric machinery

The invention relates to drilling equipment, in particular to drilling equipment used before assembling of a storage cabinet. The technical problem to be solved is to how to provide the drilling equipment used before assembling of the storage cabinet, in which a storage cabinet wood board needing to be drilled can be automatically and intermittently replaced, the storage cabinet wood board can beautomatically drilled, and the drilled wood board can be automatically stored. The drilling equipment used before assembling of the storage cabinet comprises a rack, a motor, a discharging box, a sliding plate and the like; and the motor is installed in the middle of the lower portion of the rack through bolts, the discharging box used for storing plates is installed between the tops of the rack,and the sliding plate is arranged on the upper portion of the rack in a sliding mode and located below the discharging box. Through the motor, the sliding plate, an L-shaped push rod, a first connecting rod and the like, a plate needing to be drilled can be automatically replaced, the plate can be transported, and the fixed position of the plate can be drilled through a transmission mechanism, a sector gear, a first rotating shaft, a placing plate, an electric drill and the like.

Owner:TRANTEX PROD CO LTD

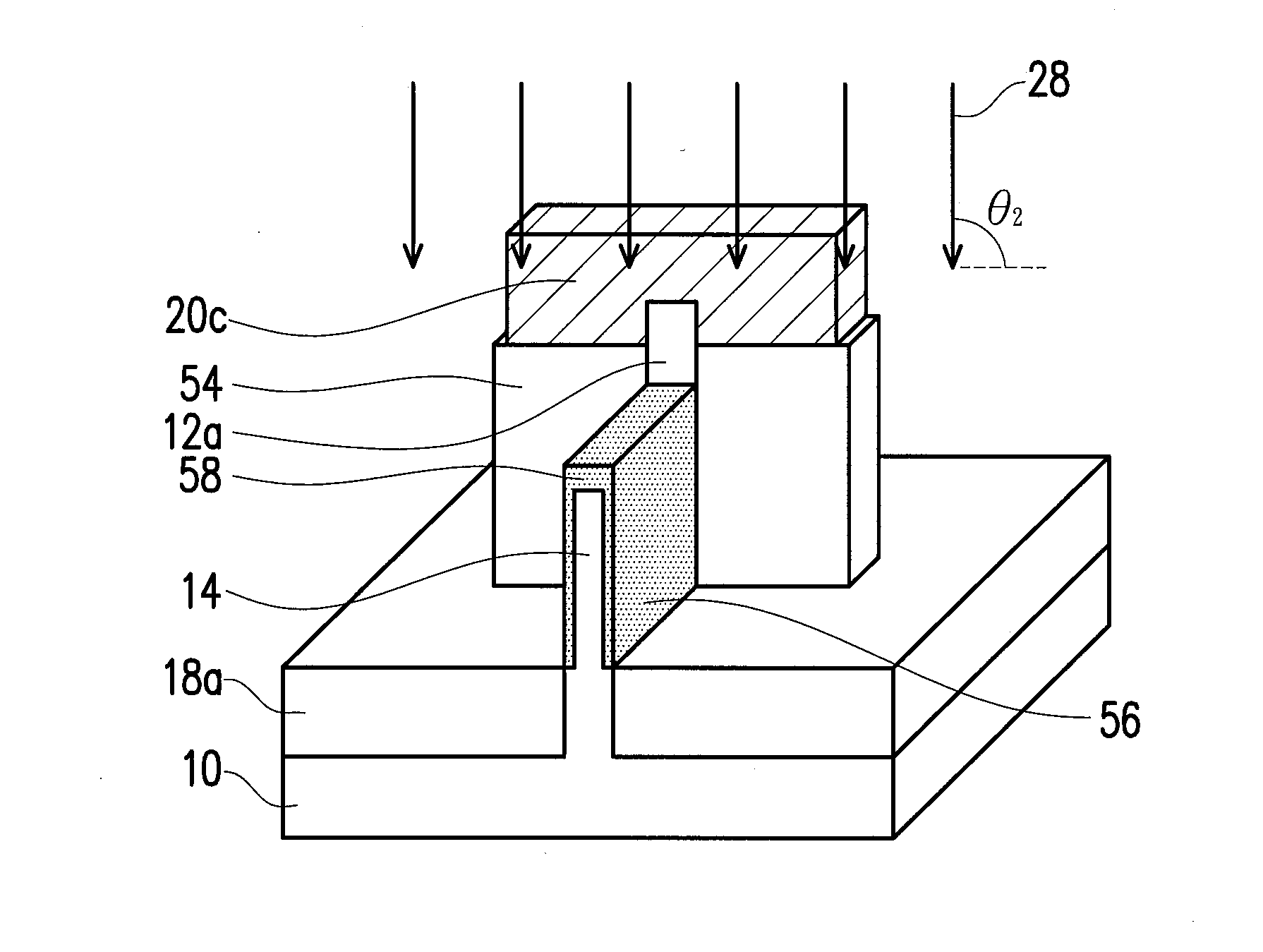

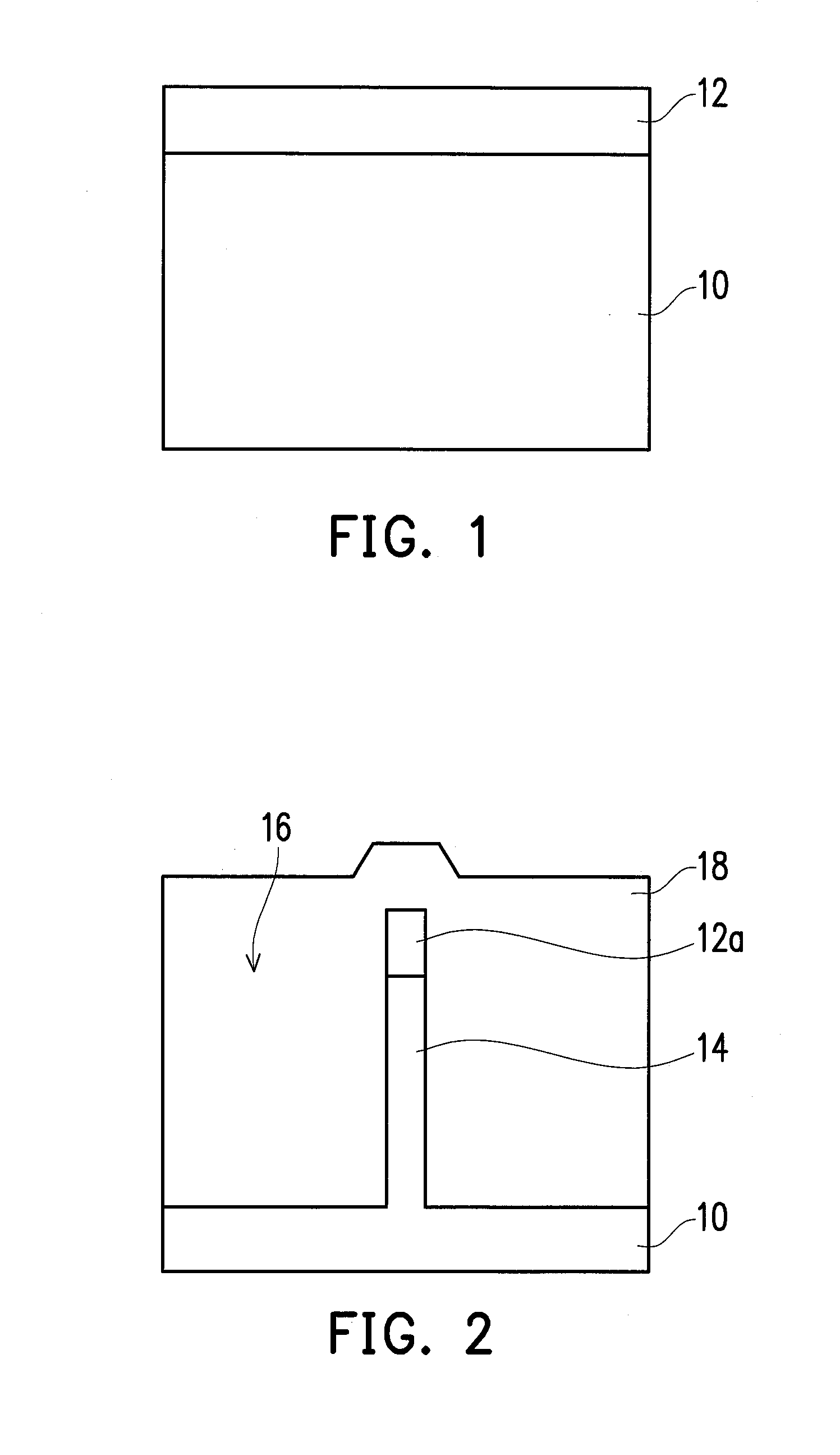

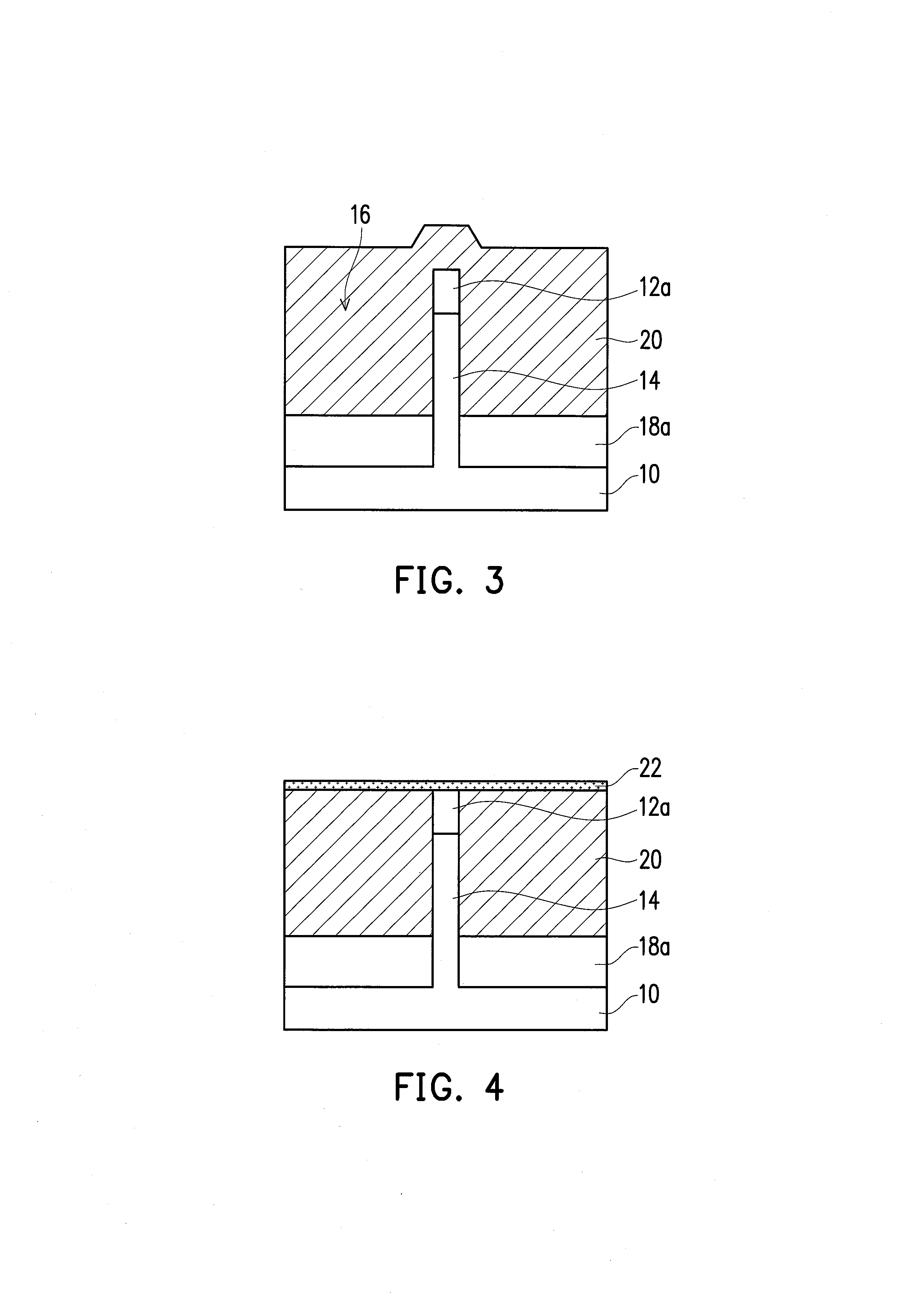

Method for fabricating mos device

ActiveUS20130183804A1Increase process marginDeep unitySemiconductor/solid-state device manufacturingSemiconductor devicesBiomedical engineeringHard mask

A method for fabricating a MOS device is described. A first hard mask layer is formed over a substrate. The first hard mask layer is patterned and a portion of the substrate removed to form a first patterned hard mask, and a fin structure surrounded by a trench and extending in a first direction. An insulating layer is formed at the trench bottom. A gate conductive layer is formed on the insulating layer, extending in a second direction. A first implant process is performed using the first patterned hard mask as a mask to form first S / D extension regions in the sidewalls of the fin structure. The first patterned hard mask is removed to expose the top of the fin structure, and then a second implant process is performed to form second S / D extension region therein.

Owner:UNITED MICROELECTRONICS CORP

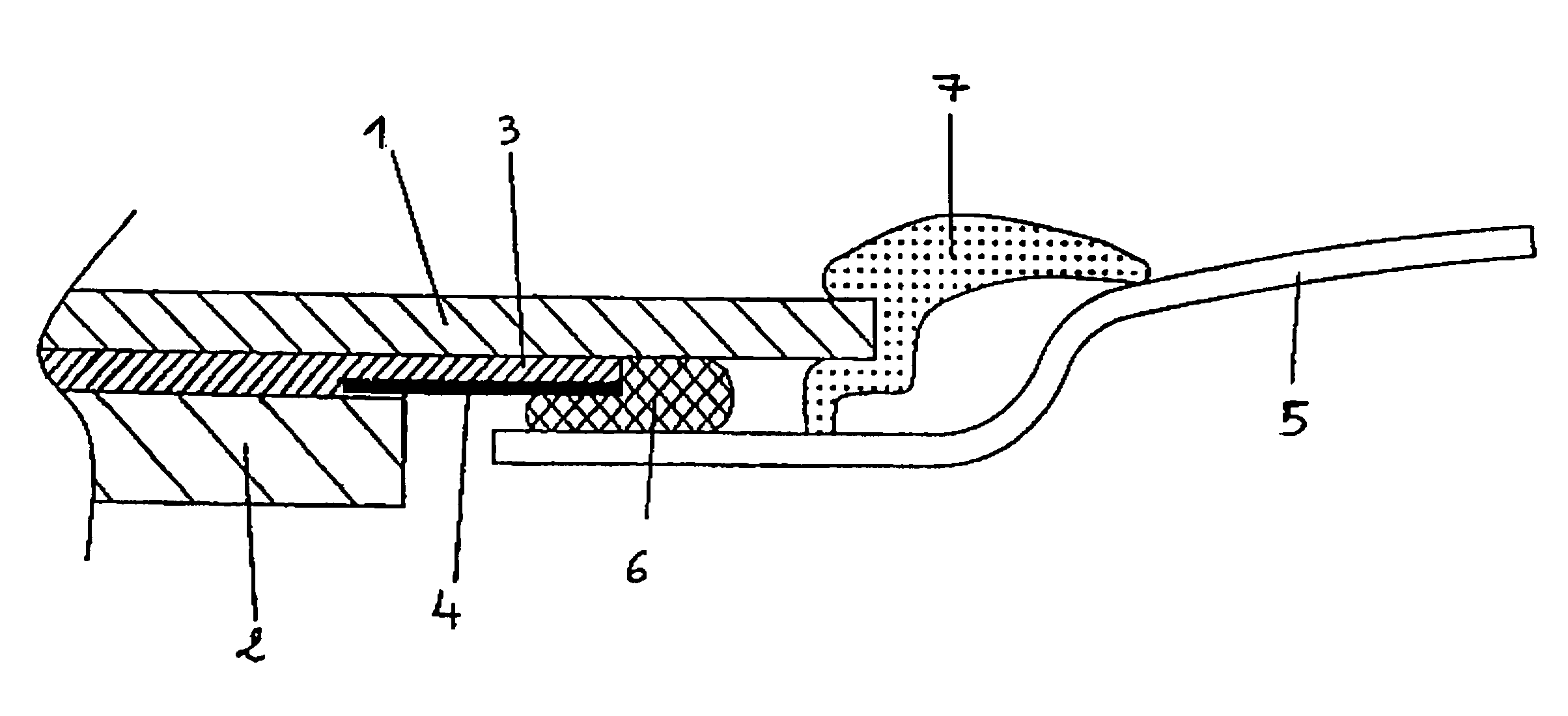

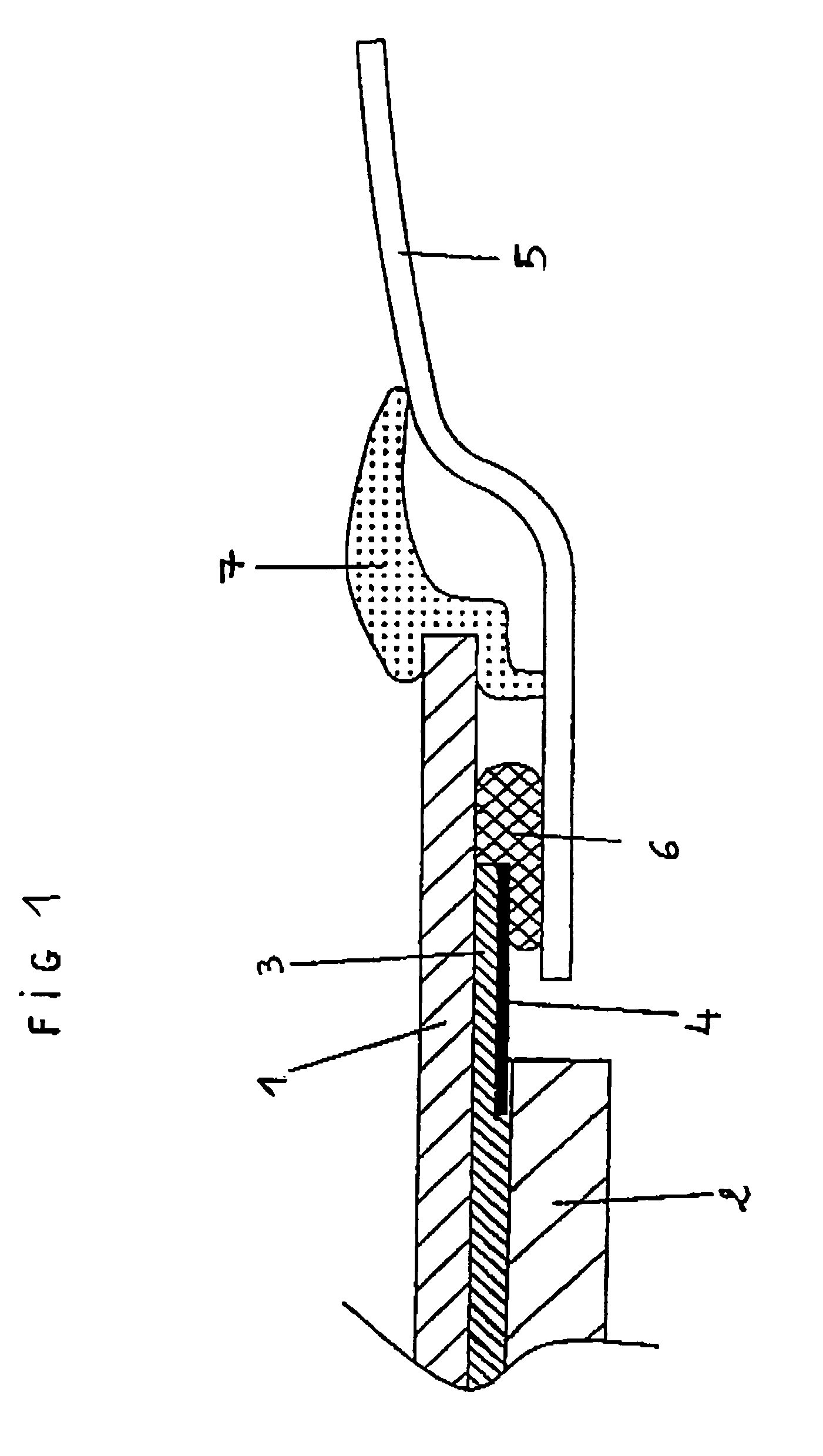

Laminated glazing with high crash test resistance

A laminated glazing includes at least one sheet (1) and a second sheet (2) bound to each other by an intercalated adhesive layer (3). The first sheet (1) projects beyond the second sheet (2) to form an exposed edge. The intercalated adhesive layer (3) extends over an exposed portion of the edge of the first sheet (1), and the edge of the intercalated adhesive layer (3) is at least in part covered by an intermediate element (4) suited to bond between the glazing or its constitutive elements (3) and on the body (5) through the intermediary of a cement element. This glazing has use as an automobile windshield with high crash test resistance.

Owner:SAINT-GOBAIN GLASS FRANCE

Circuit device and manufacturing method thereof

InactiveUS20050104198A1Designing of a circuit pattern considering the parasitic capacitances is facilitatedDesigning can be facilitatedPrinted circuit detailsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

Owner:SANYO ELECTRIC CO LTD

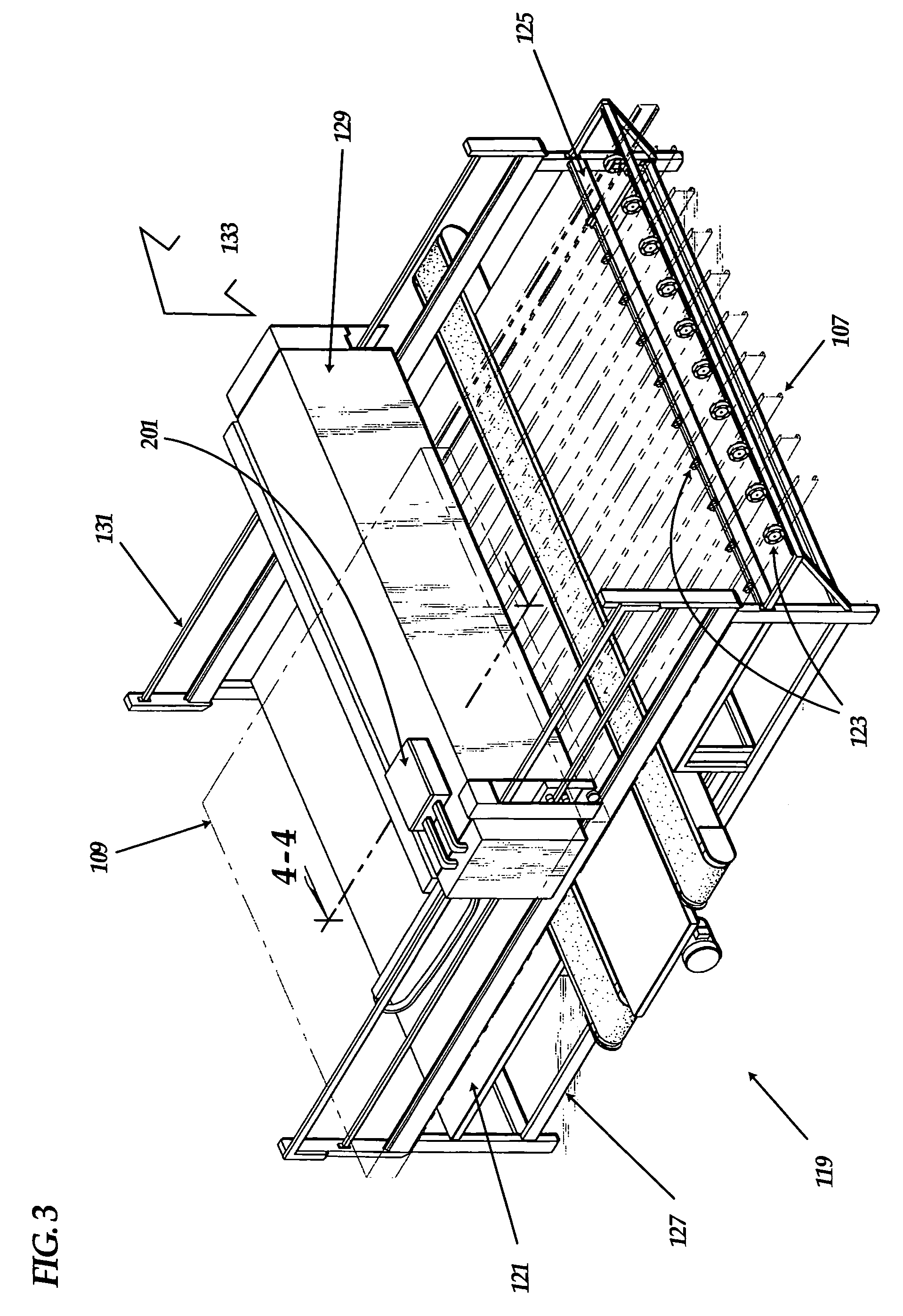

Automated foam panel apparatus, blade, and associated method

An apparatus and associated method for constructing prefabricated foam panels is provided. While making a longitudinal pass over a foam block, the apparatus flattens the foam block, cuts longitudinal kerfs in the foam block, and draws metal studs into the kerfs. The apparatus comprises a unique, heated blade having a shape similar to the cross section of a metal stud. The blade kerfs foam blocks, including blocks made of recycled or low-grade foam. The associated method includes kerfing the foam blocks by passing the blade through the foam blocks and drawing metal studs into the kerfs.

Owner:SYSTECO CAYMAN LTD SECZ

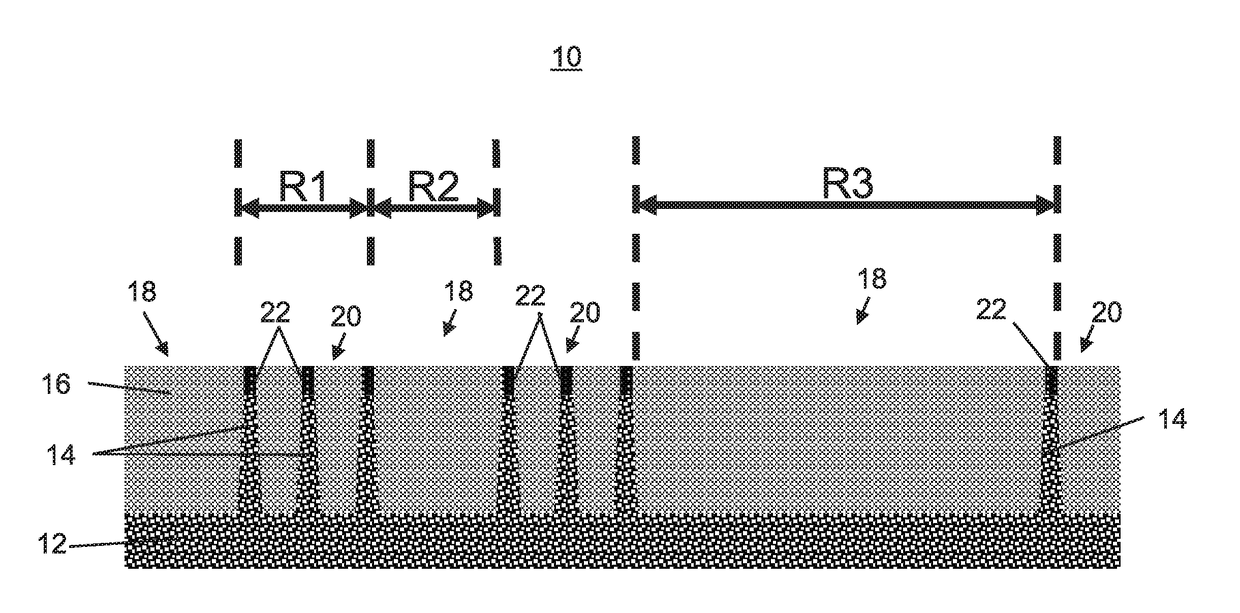

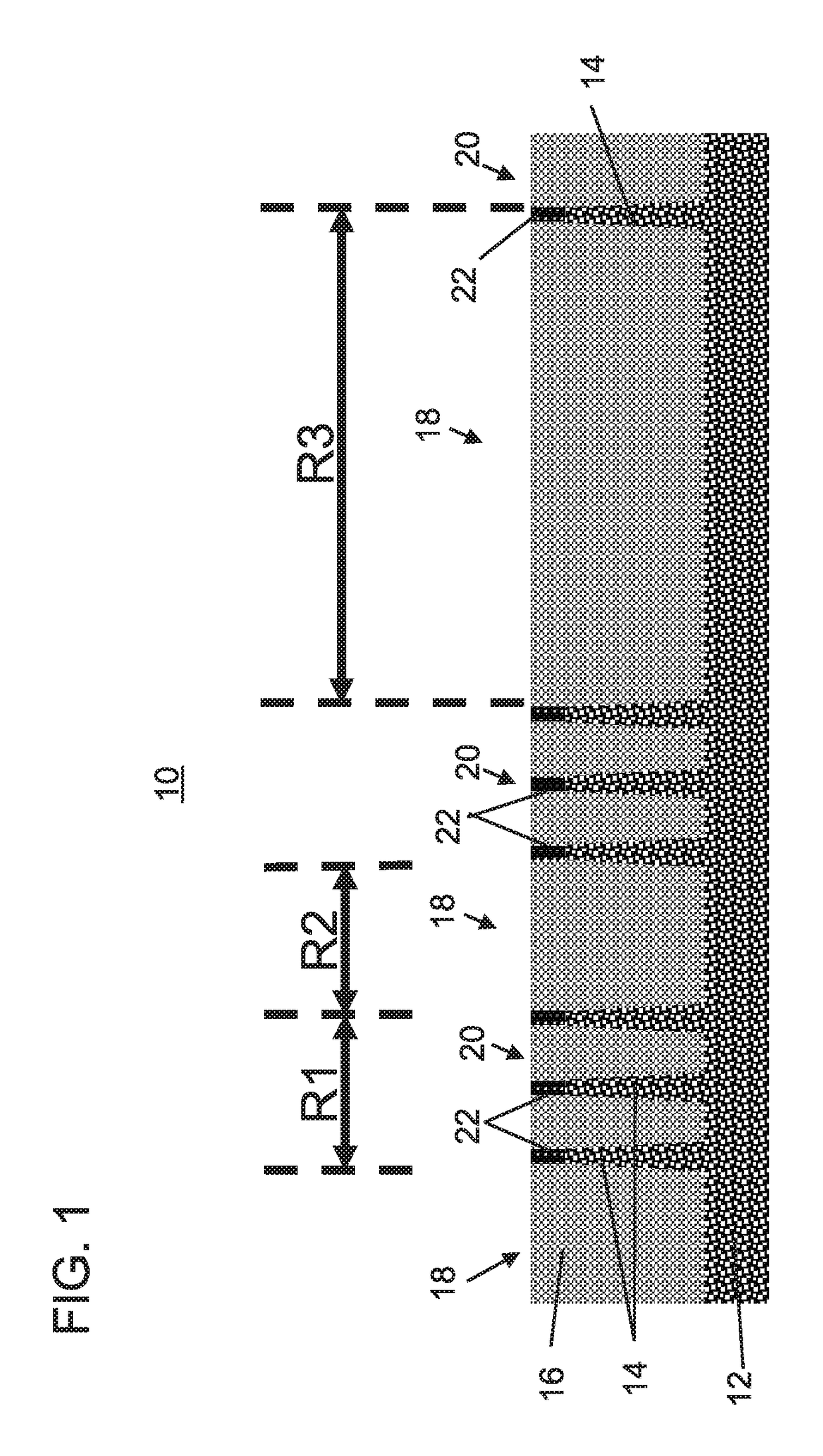

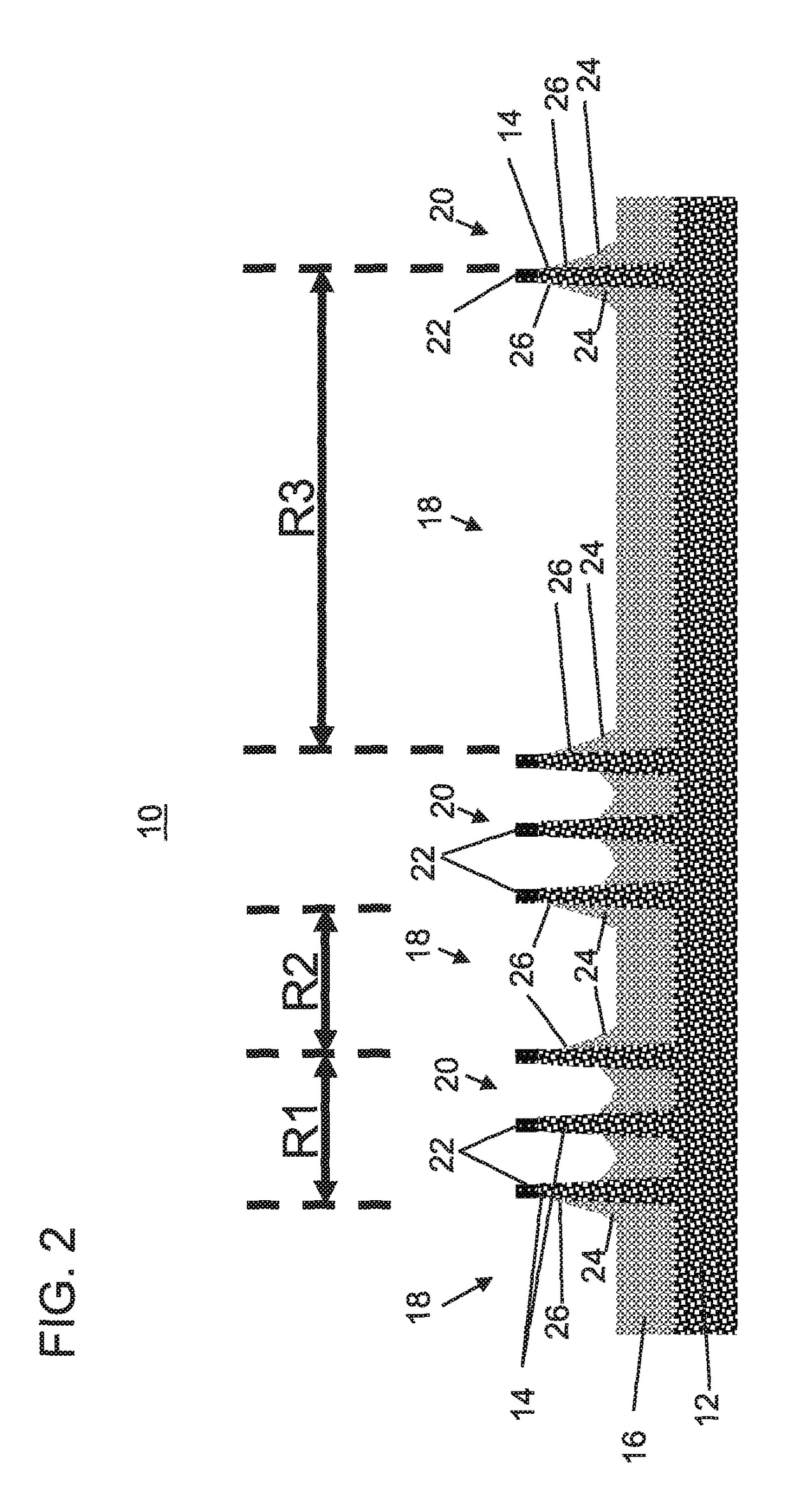

Hybridization fin reveal for uniform fin reveal depth across different fin pitches

InactiveUS9754798B1Deep unityUniform heightSemiconductor/solid-state device manufacturingSemiconductor devicesDry etchingSemiconductor

A method for uniform fin reveal depth for semiconductor devices includes dry etching a dielectric material to reveal semiconductor fins by a quasi-atomic layer etching (quasi-ALE) process to achieve depth uniformity across different fin pitches. A lateral bias induced by the quasi-ALE process is compensated for by isotropically etching the dielectric material.

Owner:ELPIS TECH INC

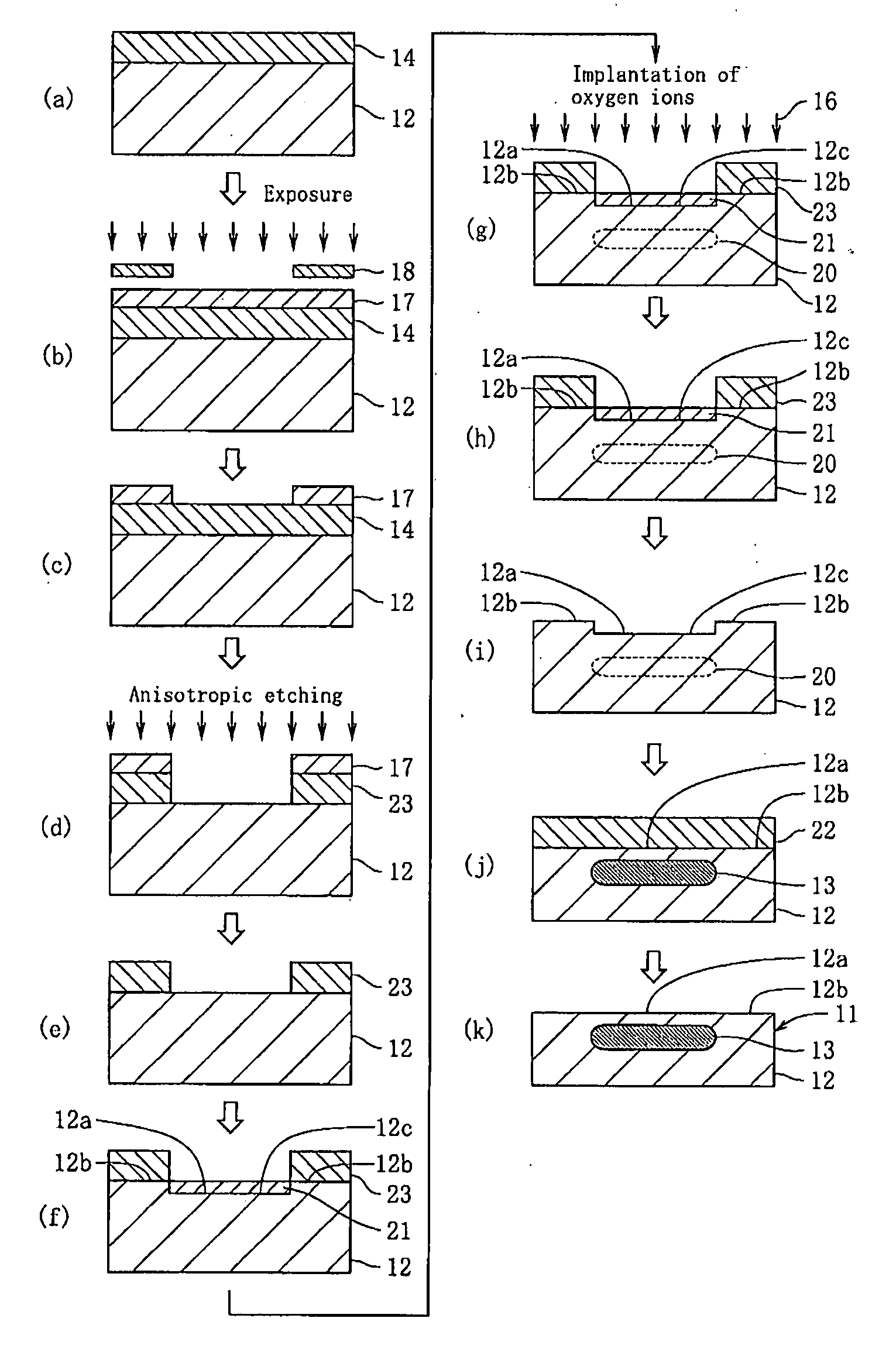

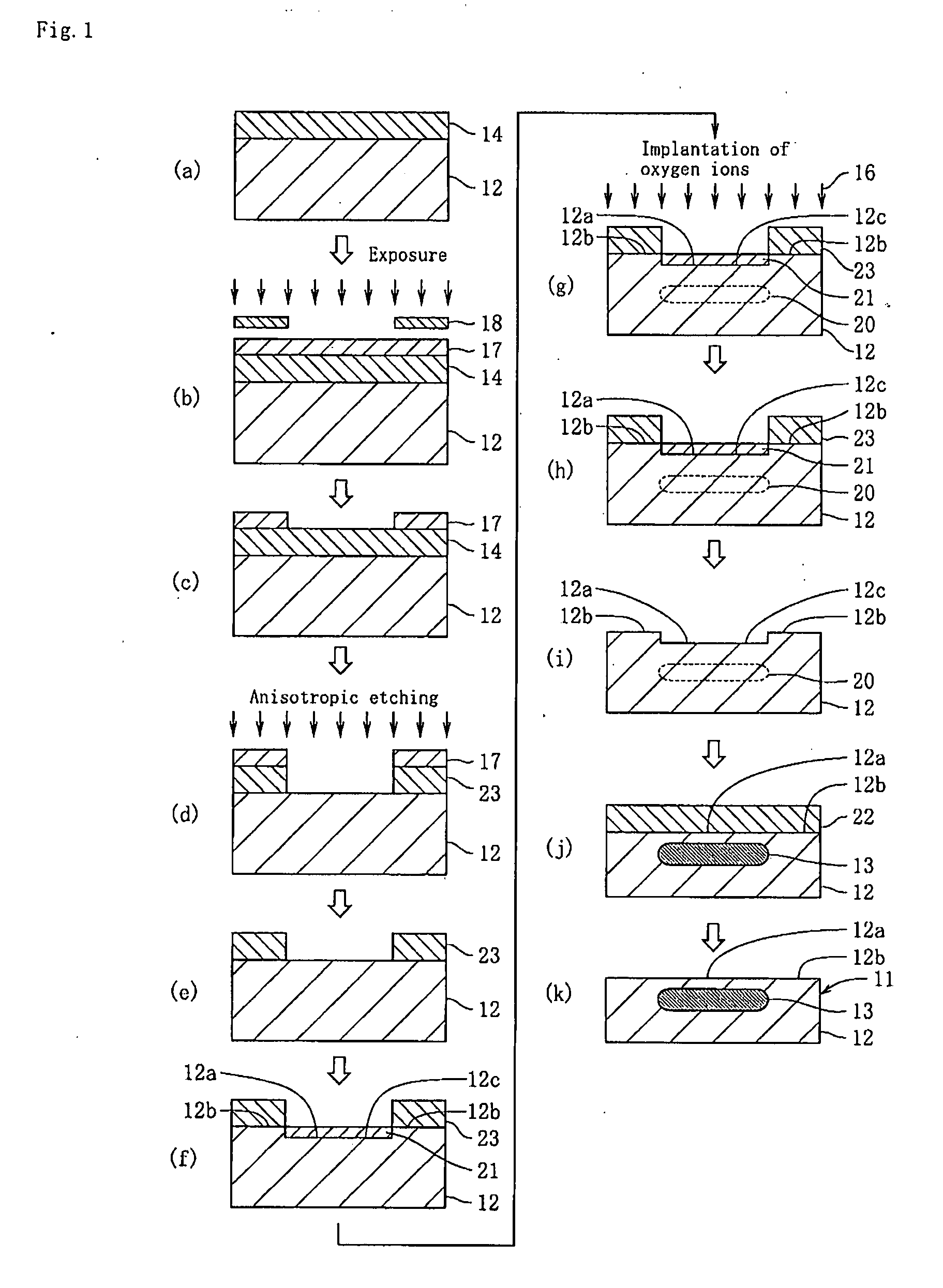

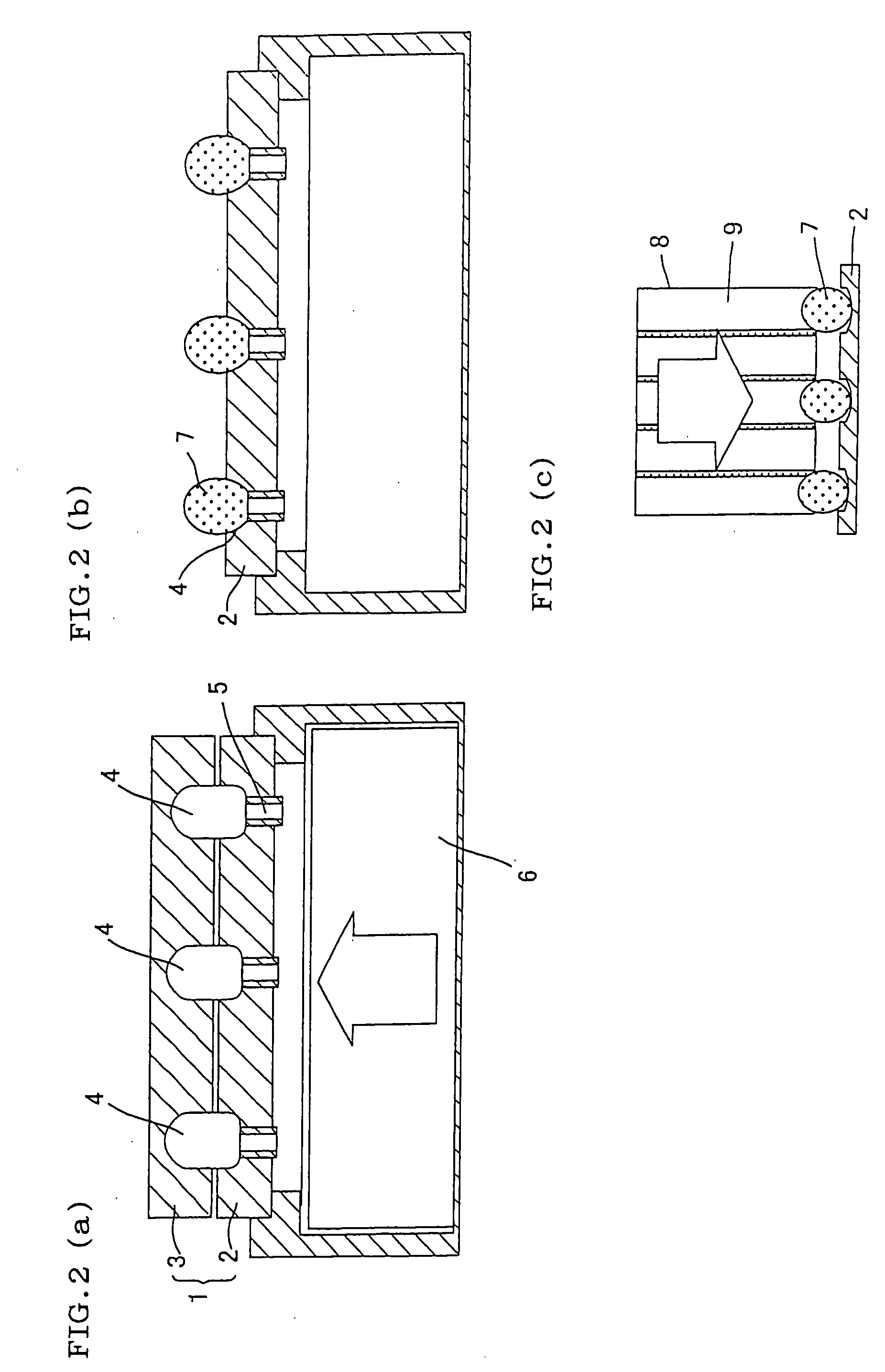

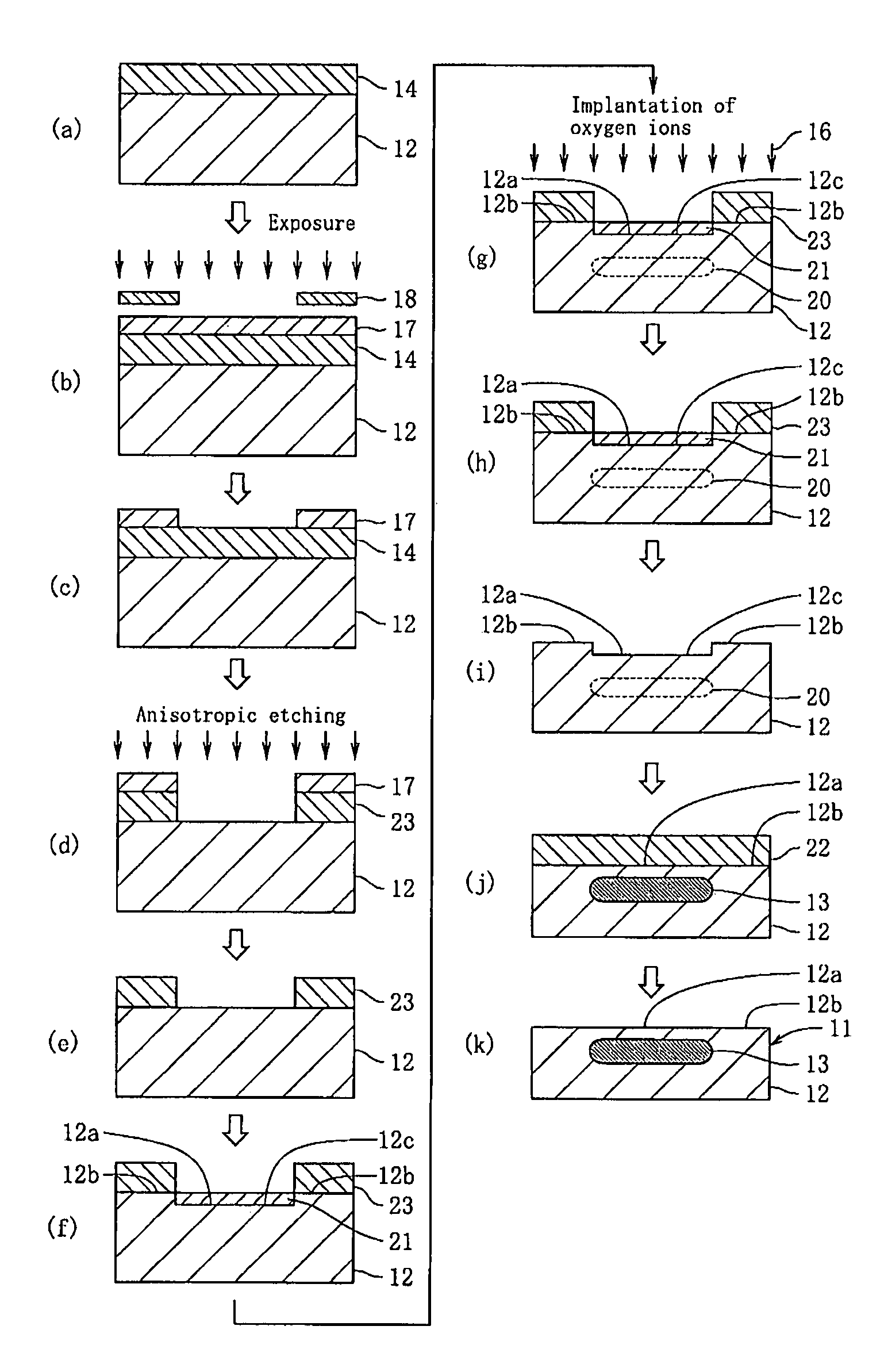

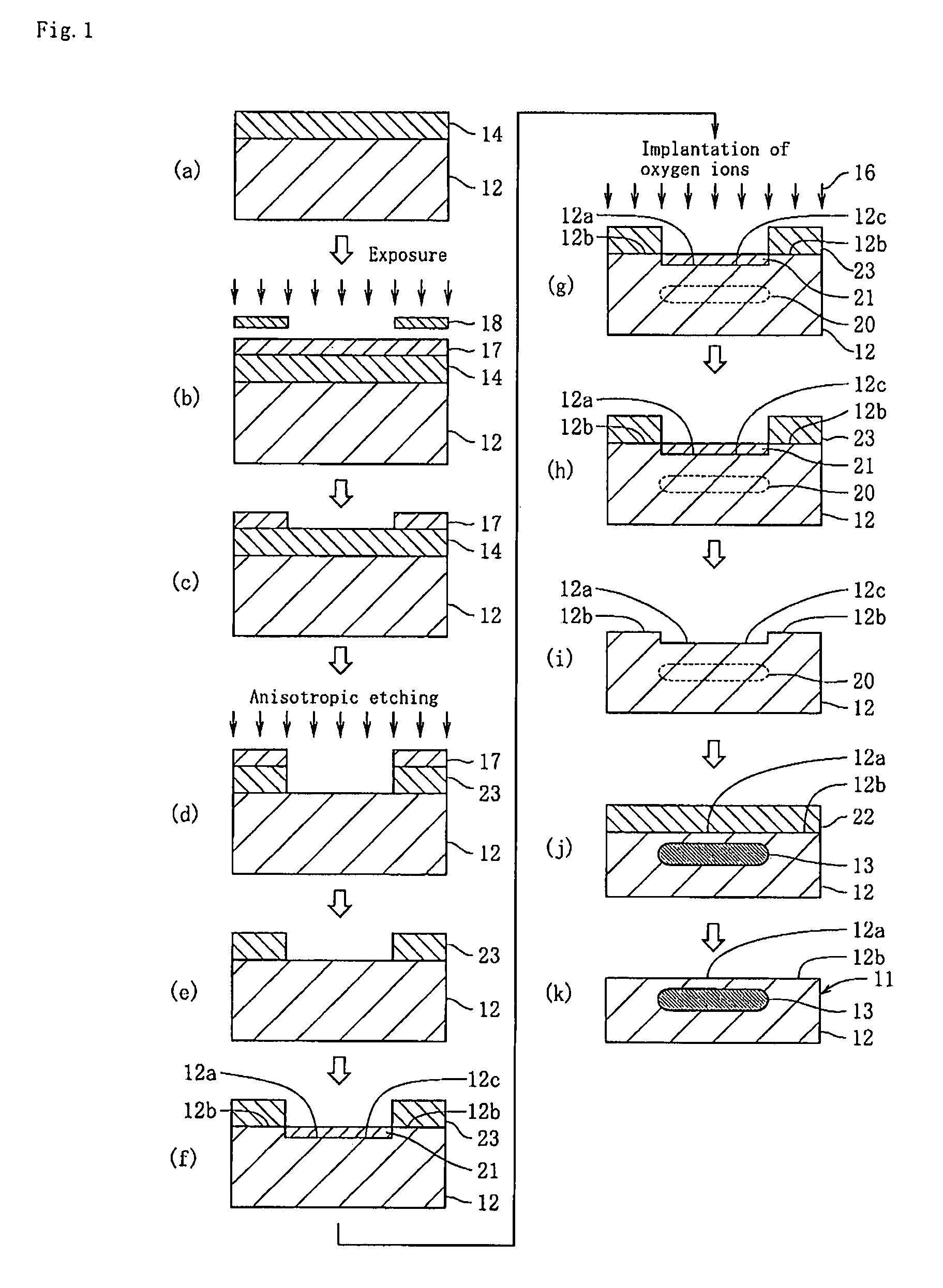

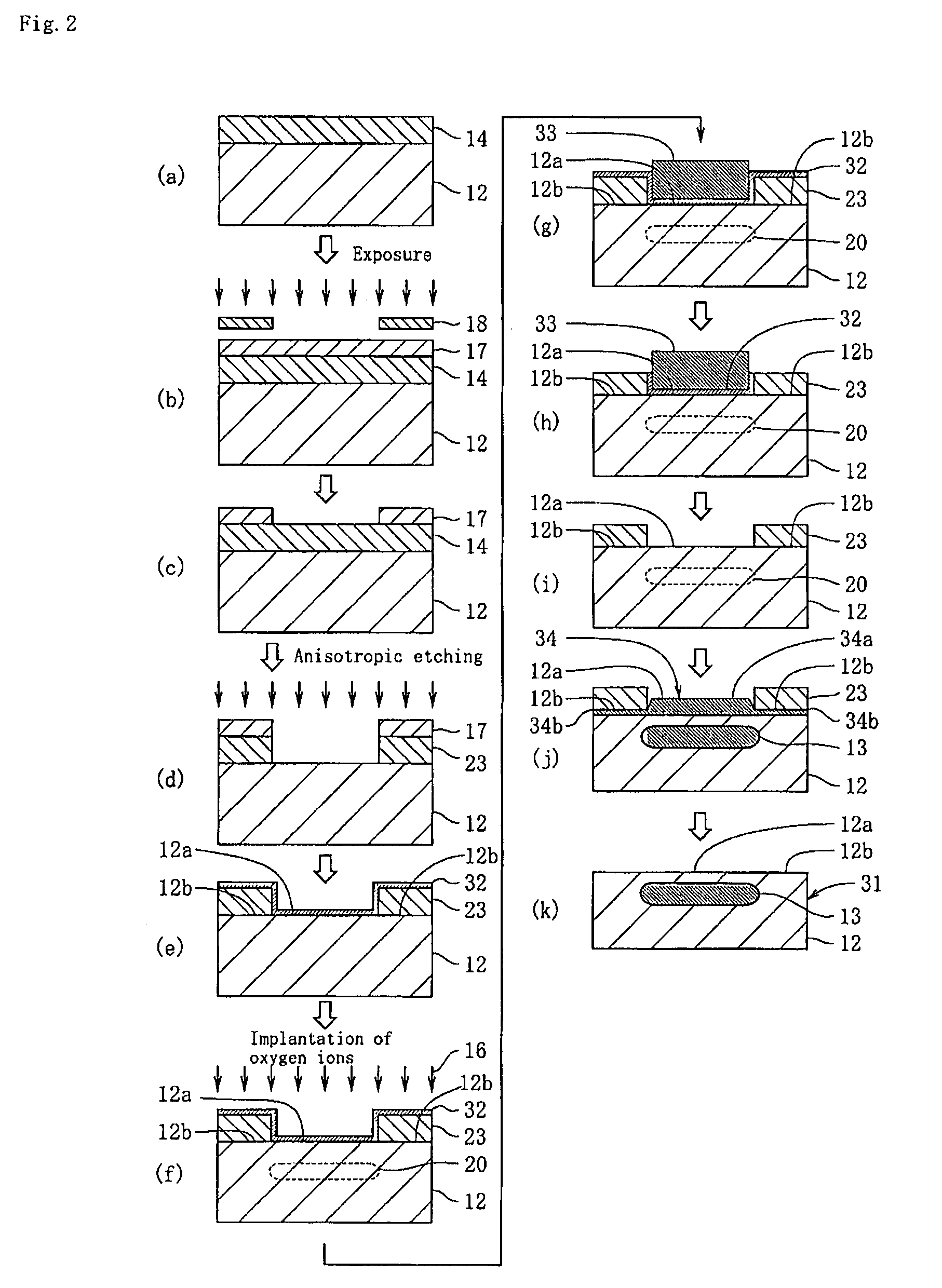

Method for manufacturing soi substrate

ActiveUS20080242048A1Uniformity of implantation depthAvoid enteringSemiconductor/solid-state device manufacturingBuried oxideMonocrystalline silicon

To easily and accurately flush a substrate surface serving an SOI area with a substrate surface serving as a bulk area, make a buried oxide film, and prevent an oxide film from being exposed on substrate surface.After partially forming a mask oxide film 23 on the surface of a substrate 12 constituted of single crystal silicon, oxygen ions 16 are implanted into the surface of the substrate through the mask oxide film, and the substrate is annealed to form an buried oxide film 13 inside the substrate. Further included is a step of forming a predetermined-depth concave portion 12c deeper than substrate surface 12b serving as a bulk area on which the mask oxide film is formed on the substrate surface 12a serving as an SOI area by forming a thermally grown oxide film 21 on the substrate surface 12a serving as an SOI area on which the mask oxide film is not formed between the step of forming the mask oxide film and the step of implanting oxygen ions.

Owner:KIOXIA CORP +1

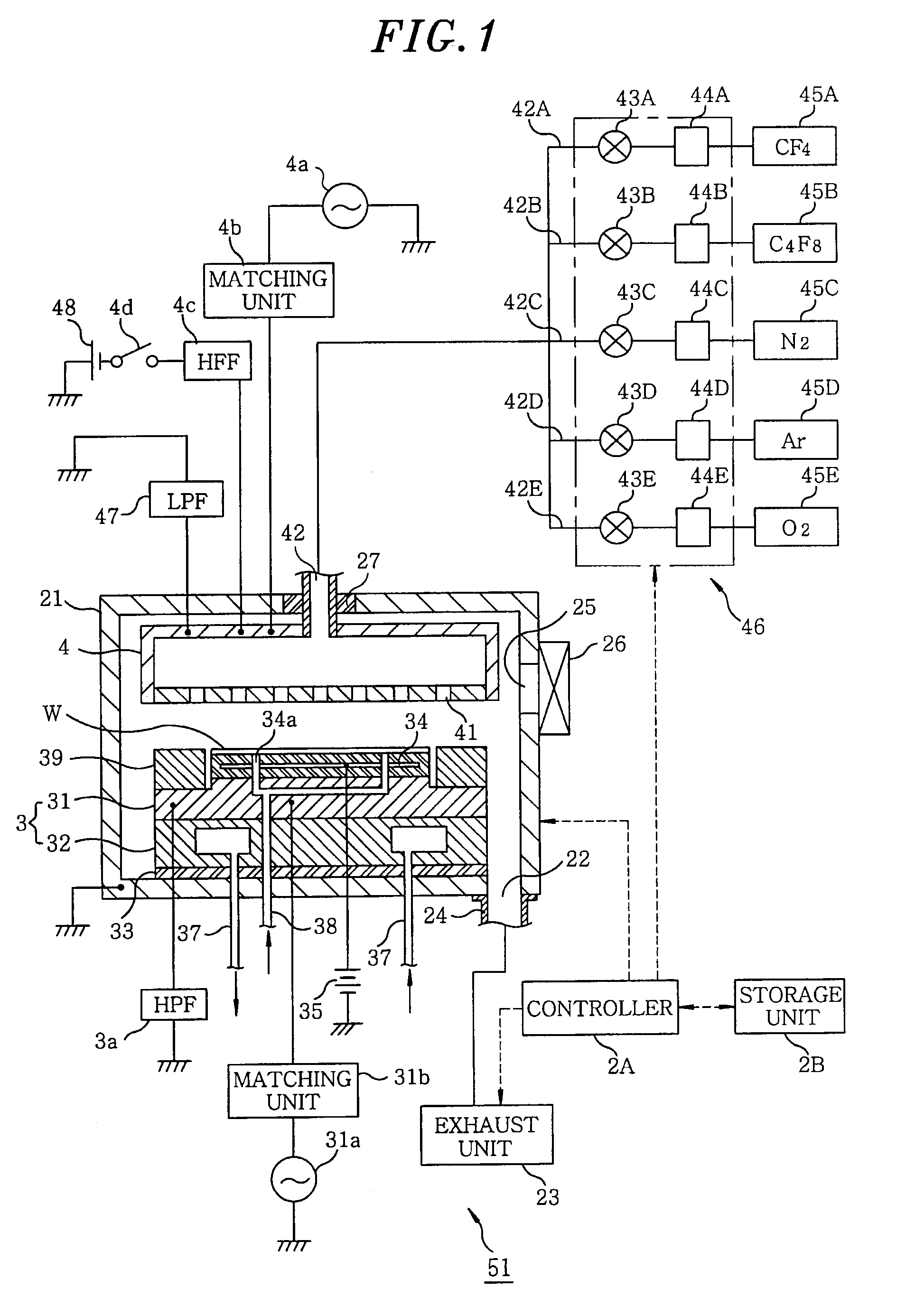

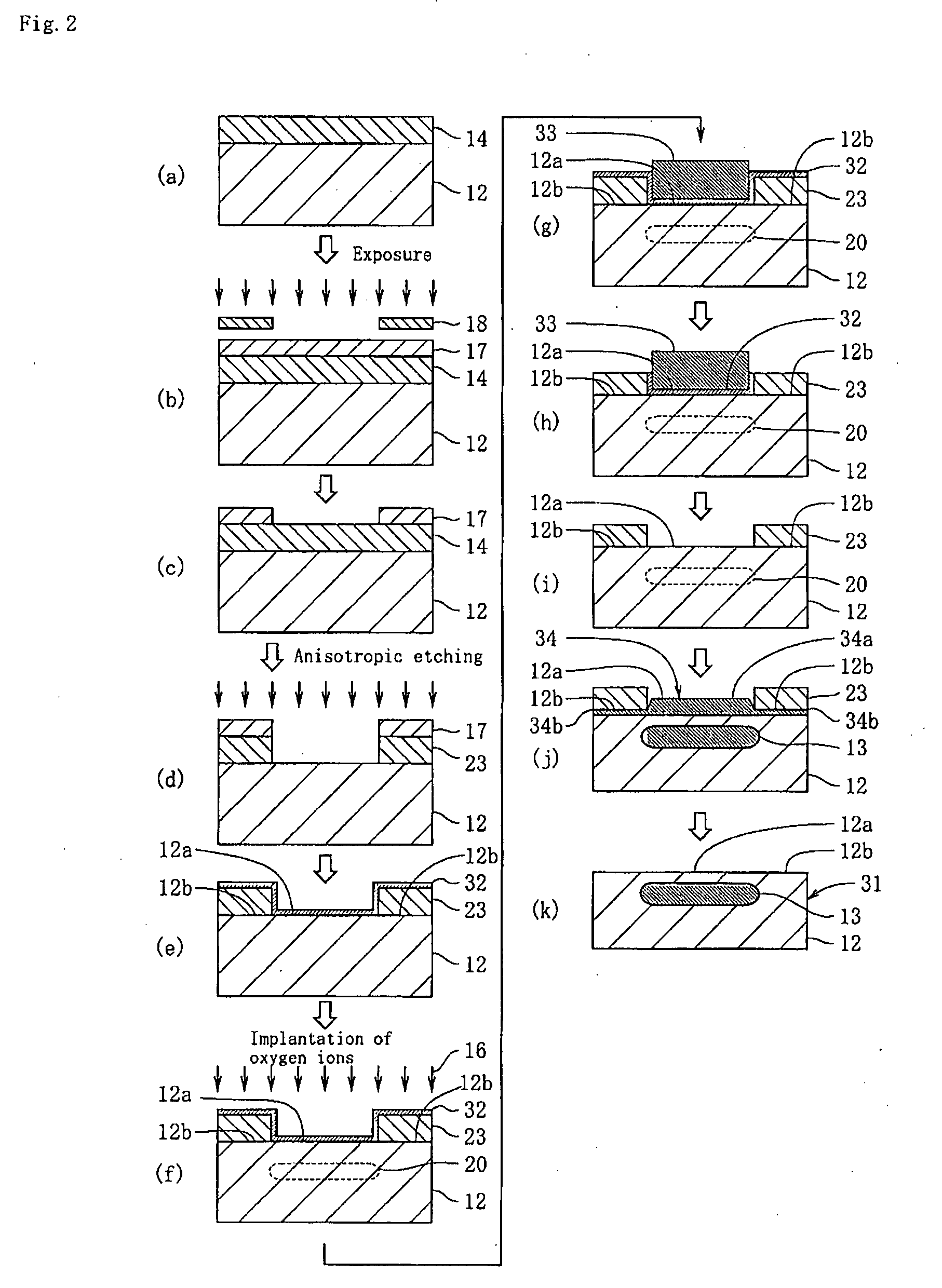

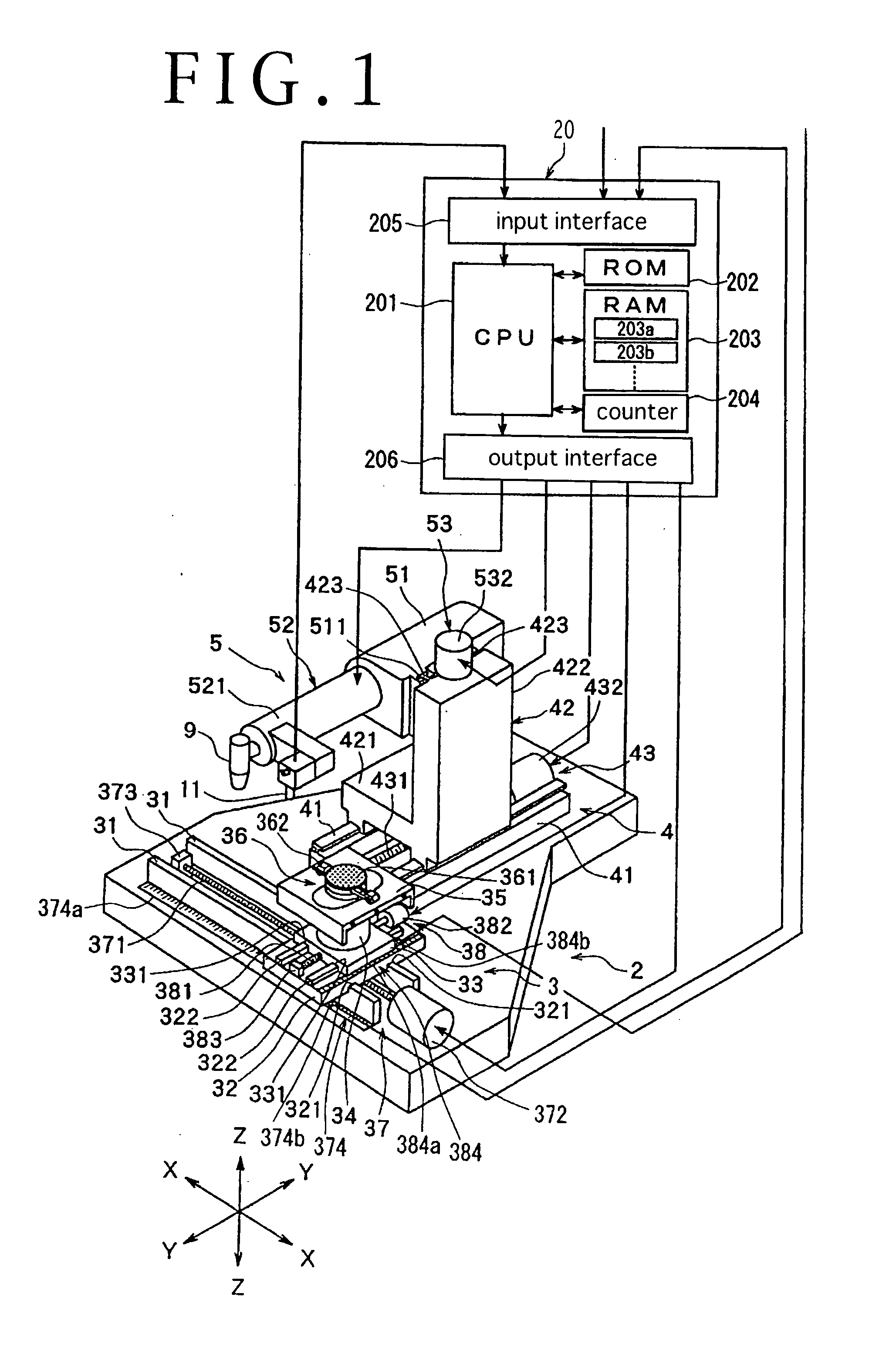

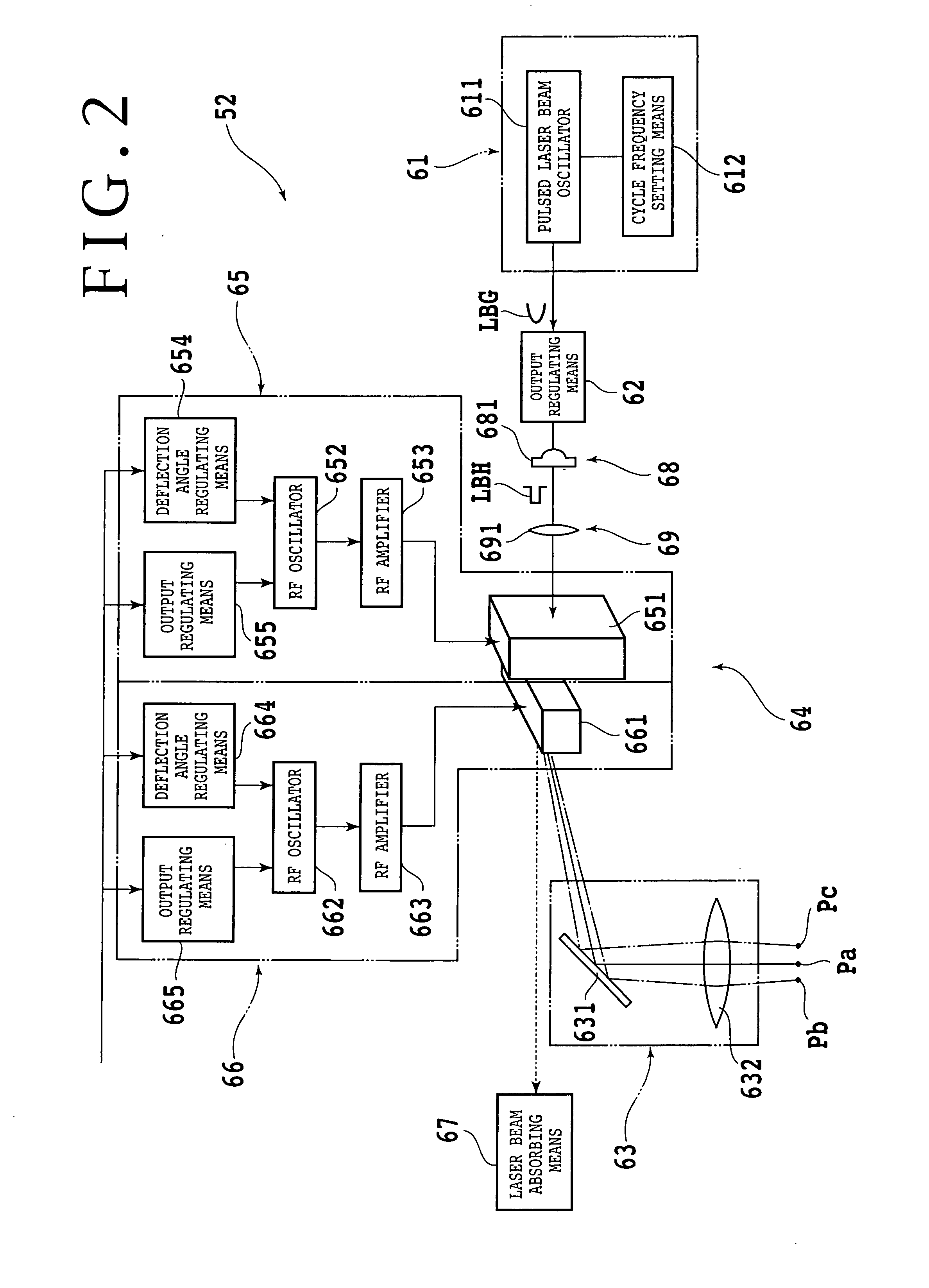

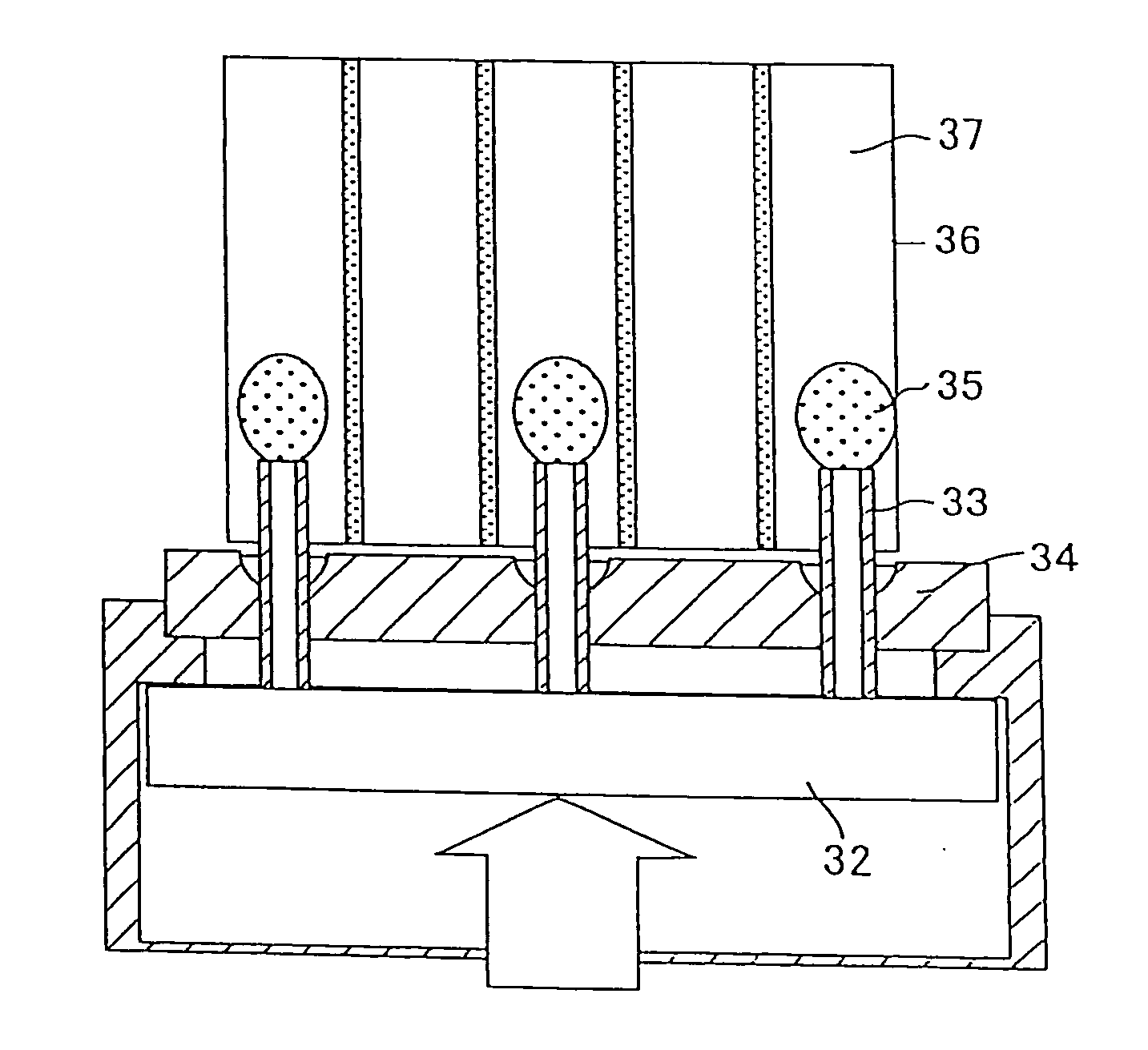

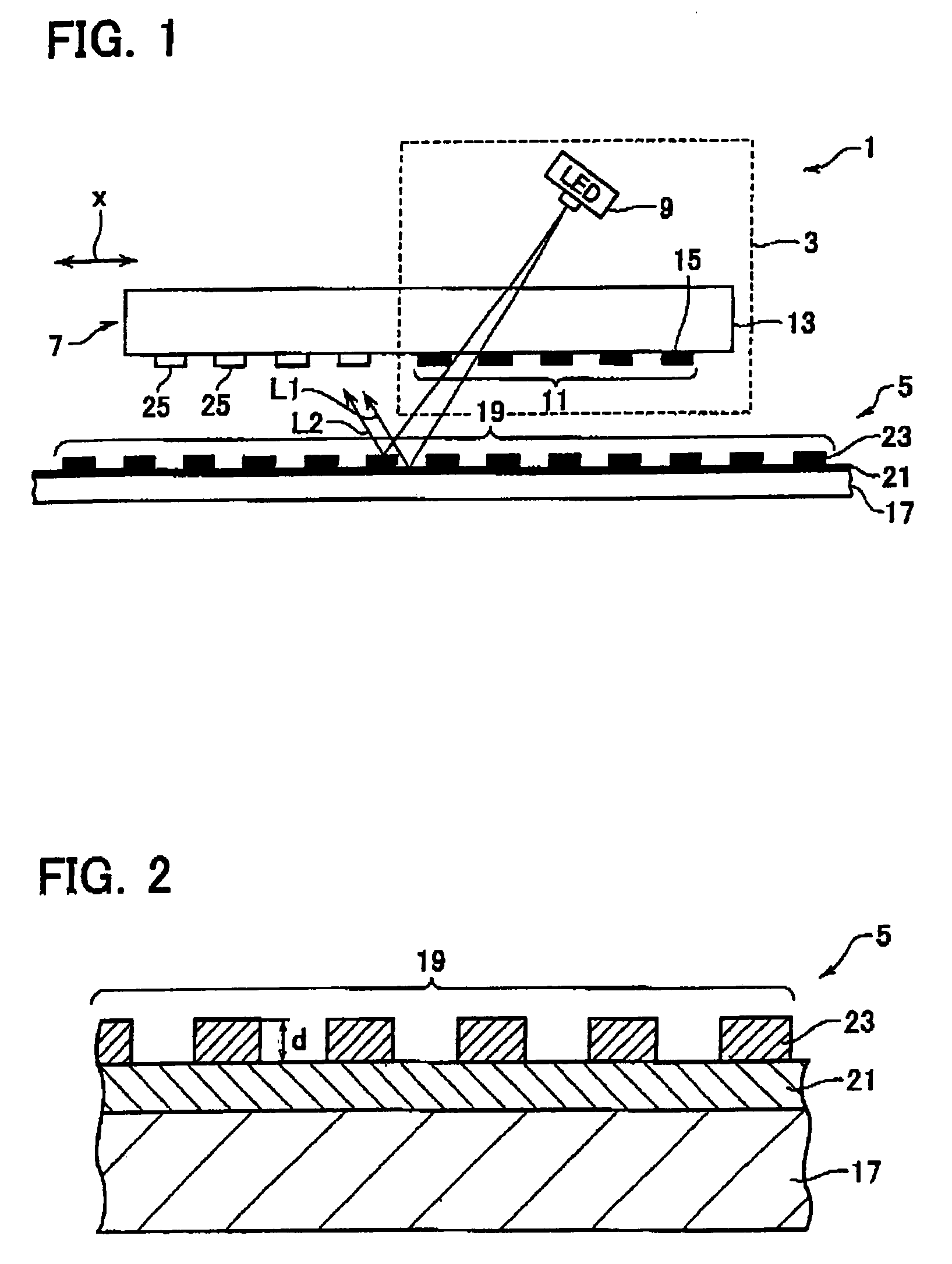

Laser beam machining system

ActiveUS20080061042A1Efficiently provideDeep unityLaser beam welding apparatusLight beamLaser beam machining

A laser beam machining system including a chuck table for holding a work, and a laser beam irradiation unit for irradiating the work held on the chuck table with a laser beam, wherein the laser beam irradiation unit includes: a pulsed laser beam oscillator for oscillating a pulsed laser beam; a condenser for condensing the pulsed laser beam oscillated from the pulsed laser beam oscillator; a laser beam scanning unit disposed between the pulsed laser beam oscillator and the condenser and operative to deflect the pulsed laser beam to be inputted to the condenser; and a laser beam reshaping unit which ids disposed between the pulsed laser beam oscillator and the laser beam scanning unit and by which the energy distribution of the pulsed laser beam oscillated from the pulsed laser beam oscillator is reshaped into a top hat shape.

Owner:FUJITSU LTD +1

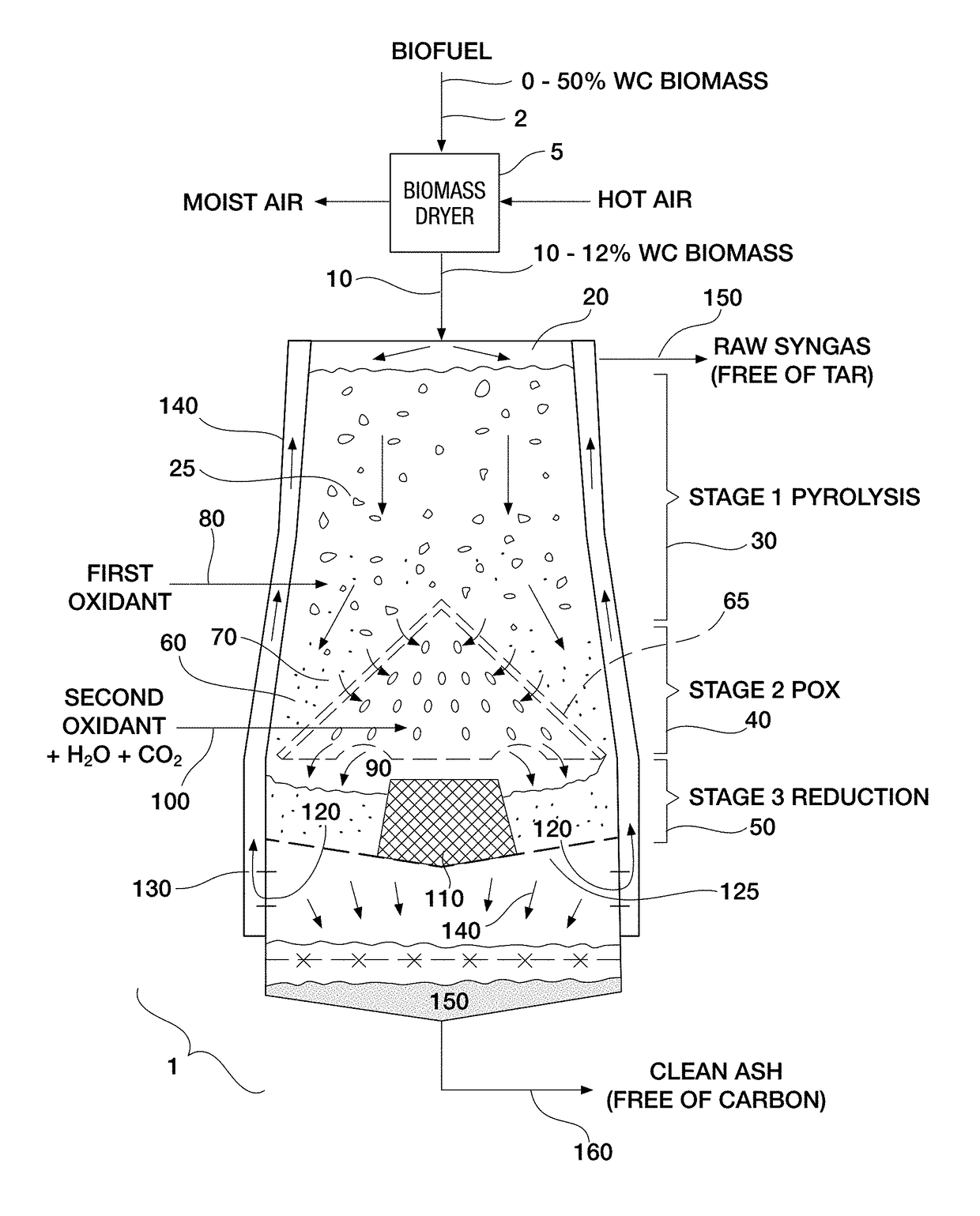

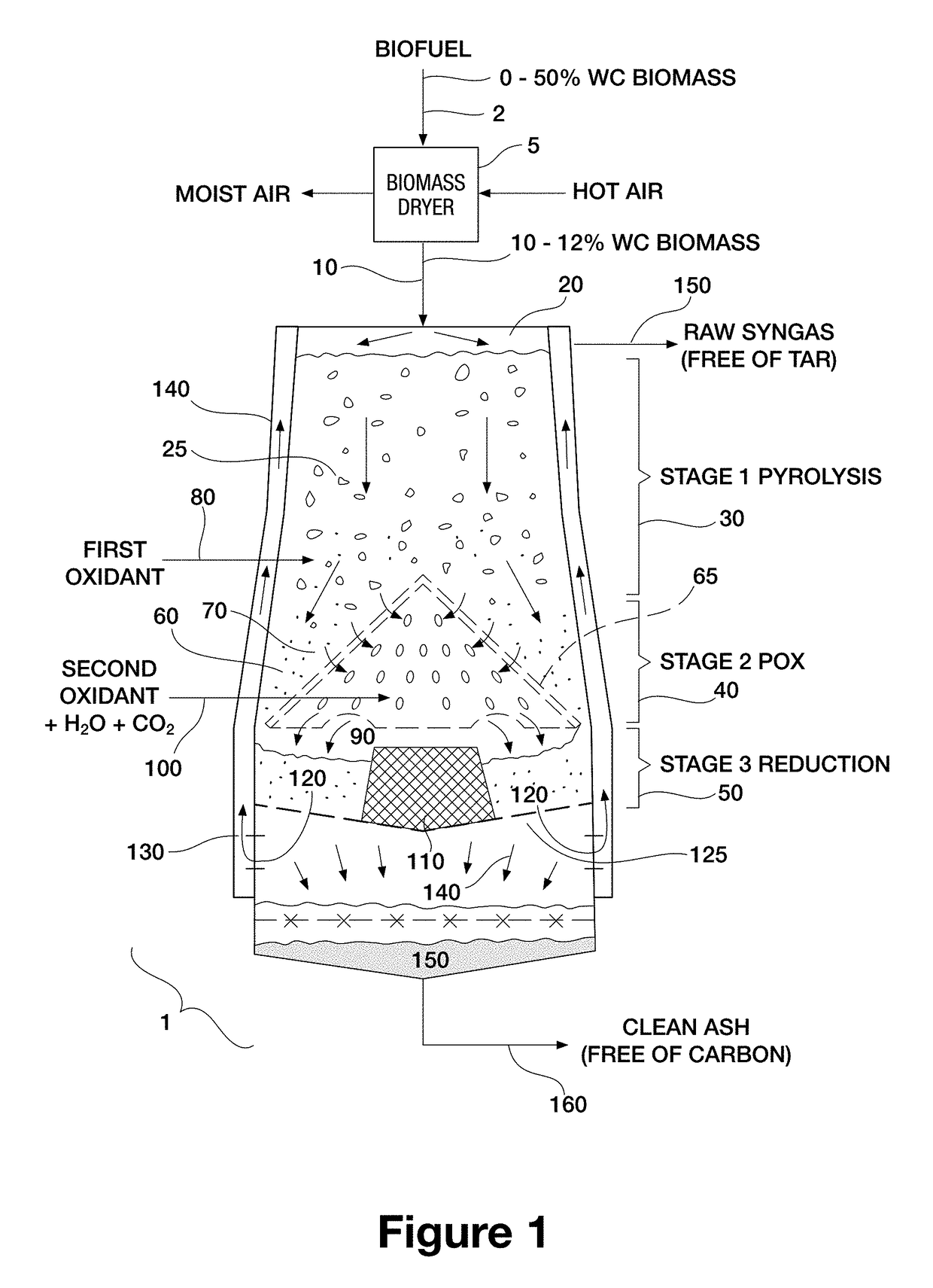

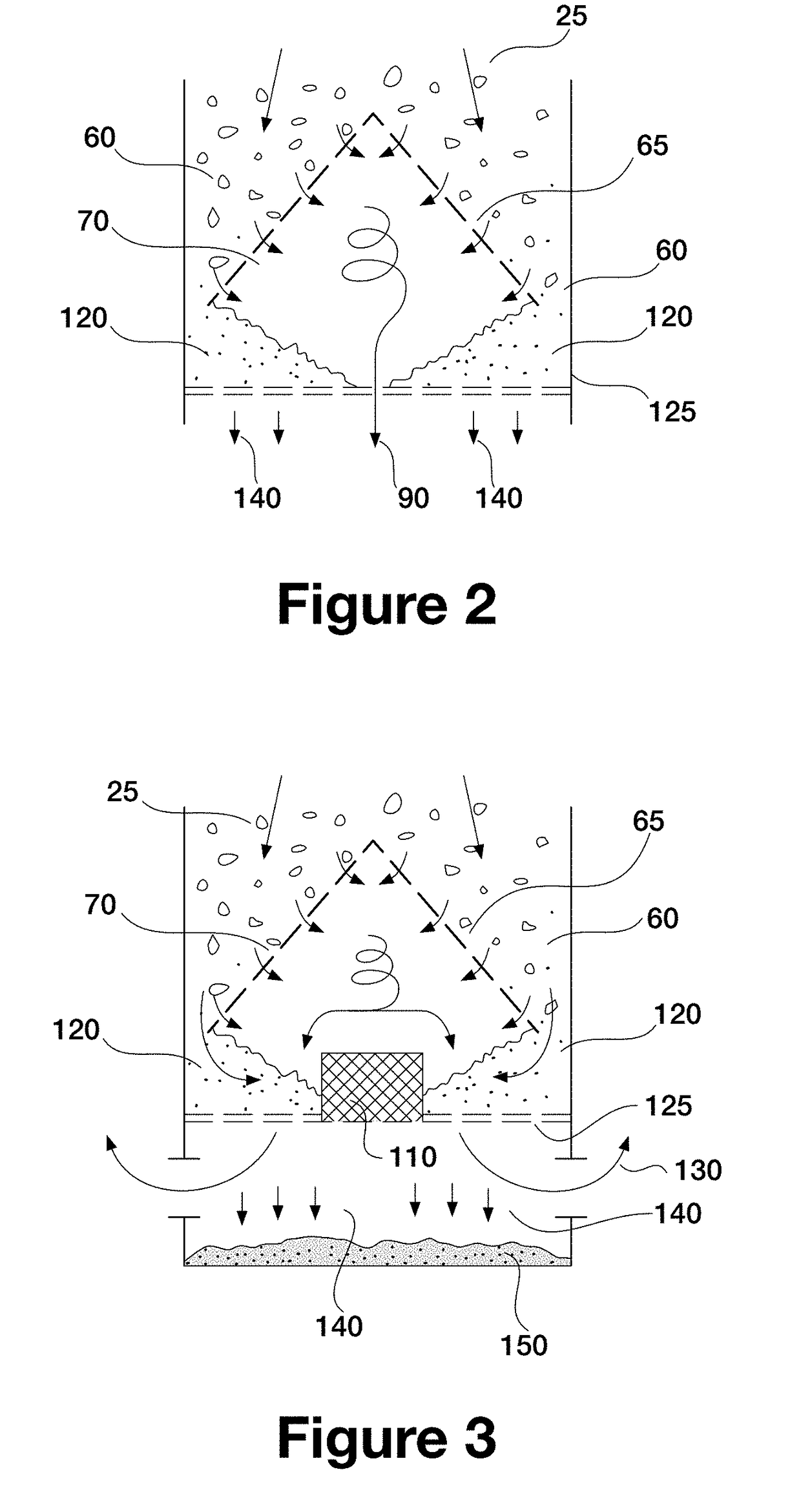

Process For Converting Carbonaceous Material Into Low Tar Synthetic Gas

InactiveUS20180086994A1Deep unityReduce the temperatureVertical chamber coke ovensDirect heating destructive distillationSyngasPartial oxidation

A continuous multi-stage vertically sequenced gasification process for conversion of solid carbonaceous fuel material into clean (low tar) syngas. The process involves forming a pyrolysis residue bed having a uniform depth and width to pass raw syngas there through for an endothermic reaction, while controlling the reduction zone pressure drop, resident time and syngas flow space velocity during the endothermic reaction to form substantially tar free syngas, to reduce carbon content in the pyrolysis residue, and to reduce the temperature of raw syngas as compared to the temperature of the partial oxidation zone.

Owner:EXPANDER ENERGY

Manufacturing method of plugged honeycomb structure

ActiveUS20080006972A1Easily be inserted into cell passageWell formedGas treatmentInternal combustion piston enginesPlastic materialsEngineering

There is disclosed a manufacturing method of a plugged honeycomb structure so that the plugged honeycomb structure for use in a filter or the like having reduced deposits deposited on an end surface of the structure can easily be manufactured with low cost and so that a plugging depth of a slurry-like plugging member at an outer peripheral portion of the honeycomb structure can easily be set to be uniform. In the manufacturing method of the plugged honeycomb structure in which plugging portions are formed at opening end portions of predetermined cells on one side of a cylindrical honeycomb structure including a plurality of cells separated from one another by porous partition walls, constituting channels of a fluid and formed in a honeycomb-like shape, plugging members which are formed into a predetermined shape and which are to be inserted into cell passages to be plugged include a plastic material having viscosity and fluidity.

Owner:NGK INSULATORS LTD

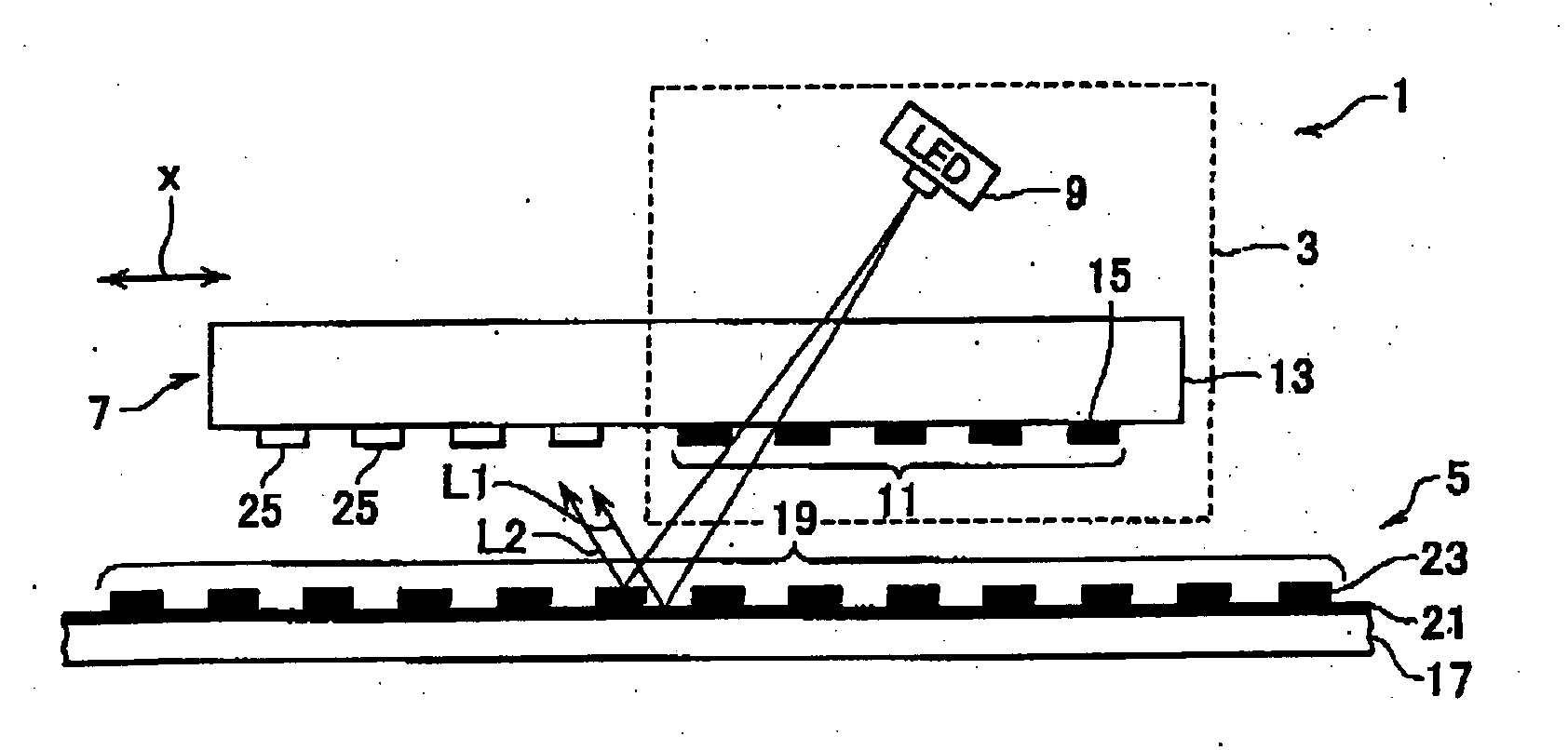

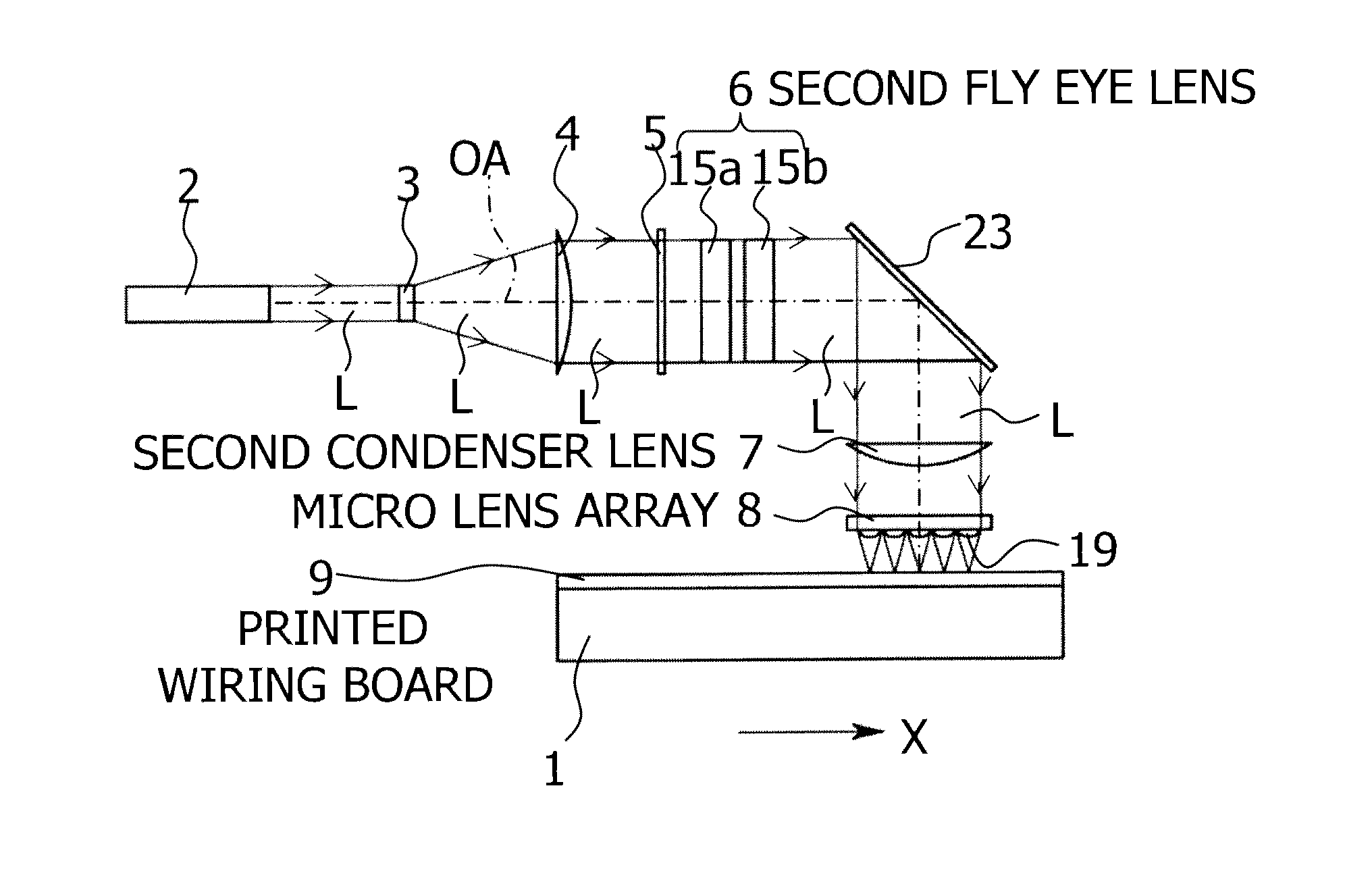

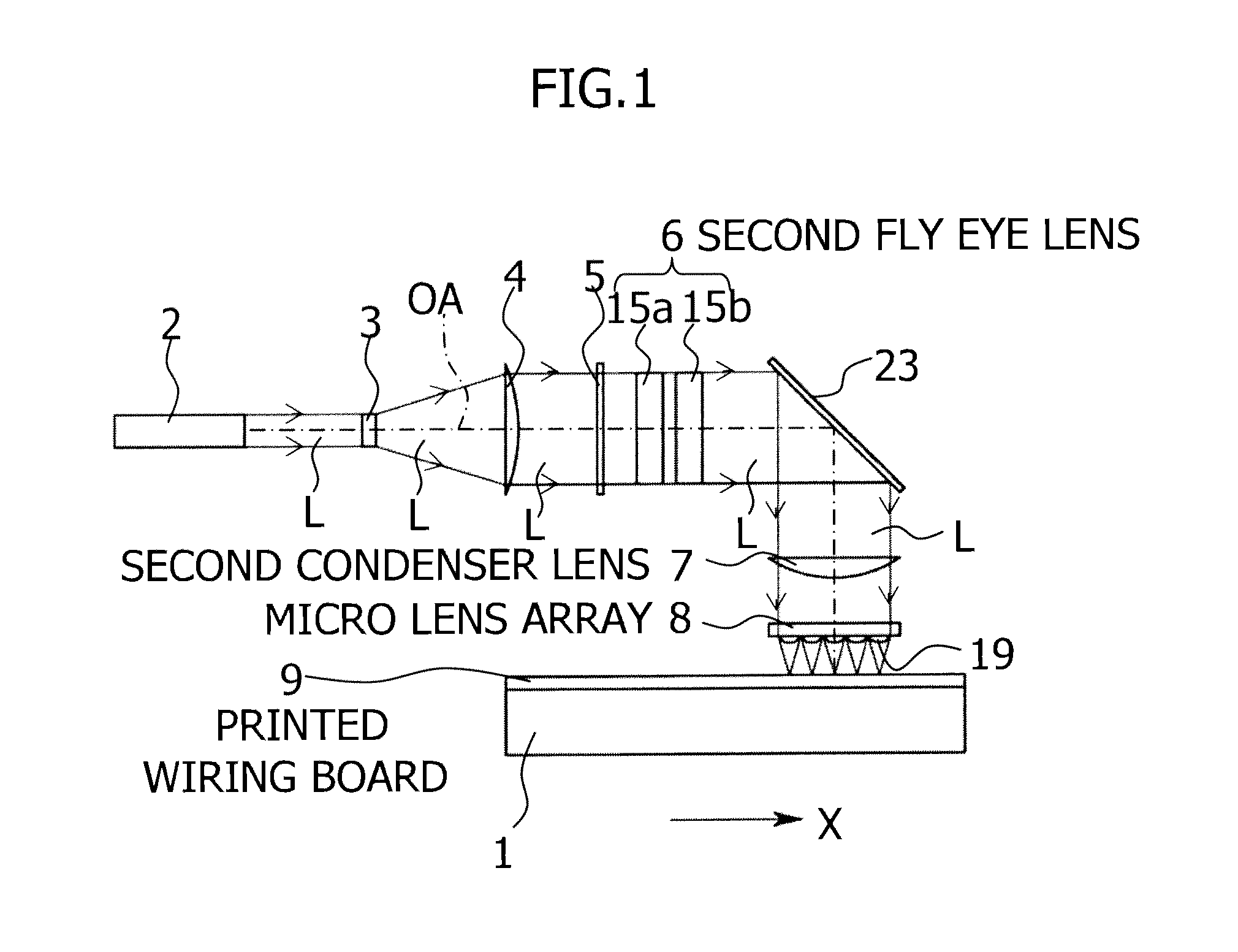

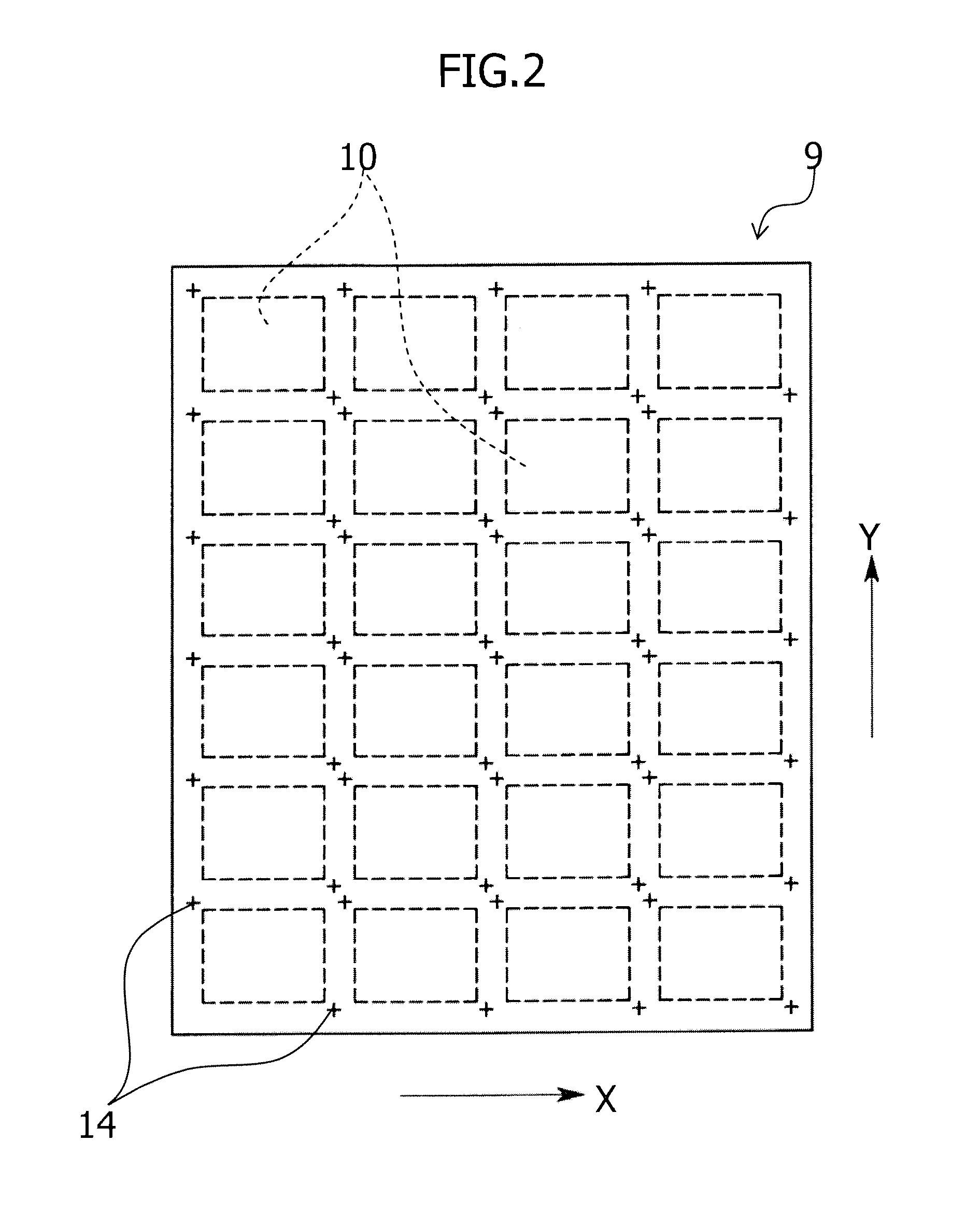

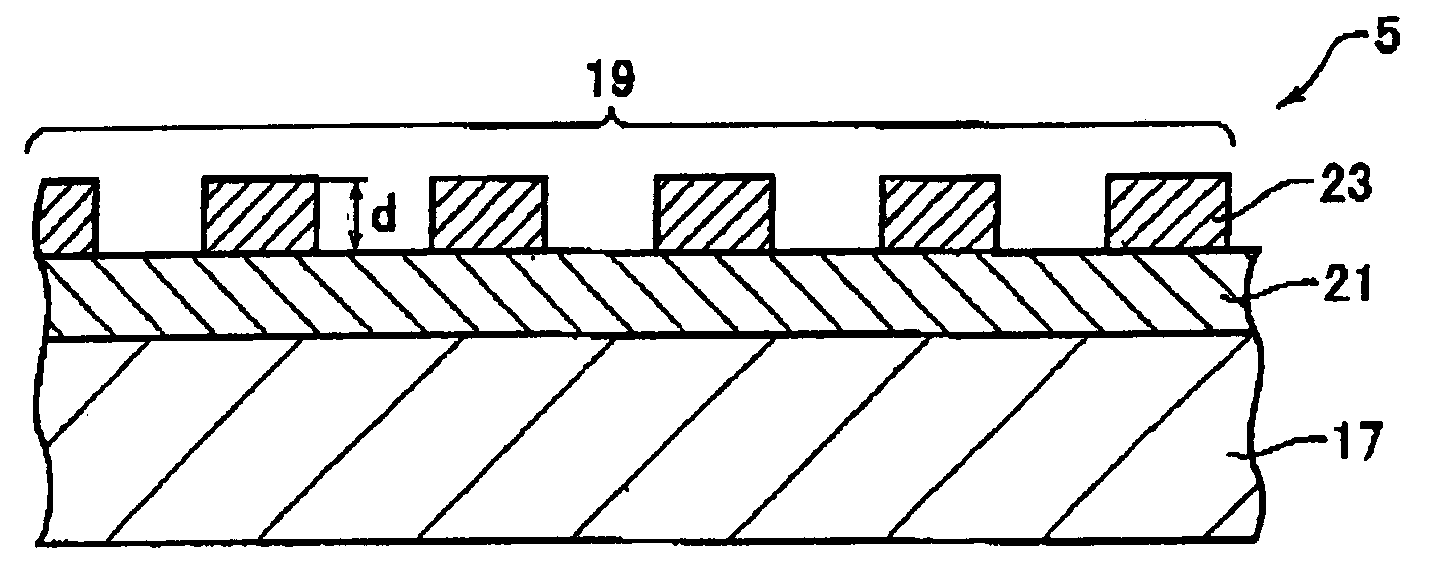

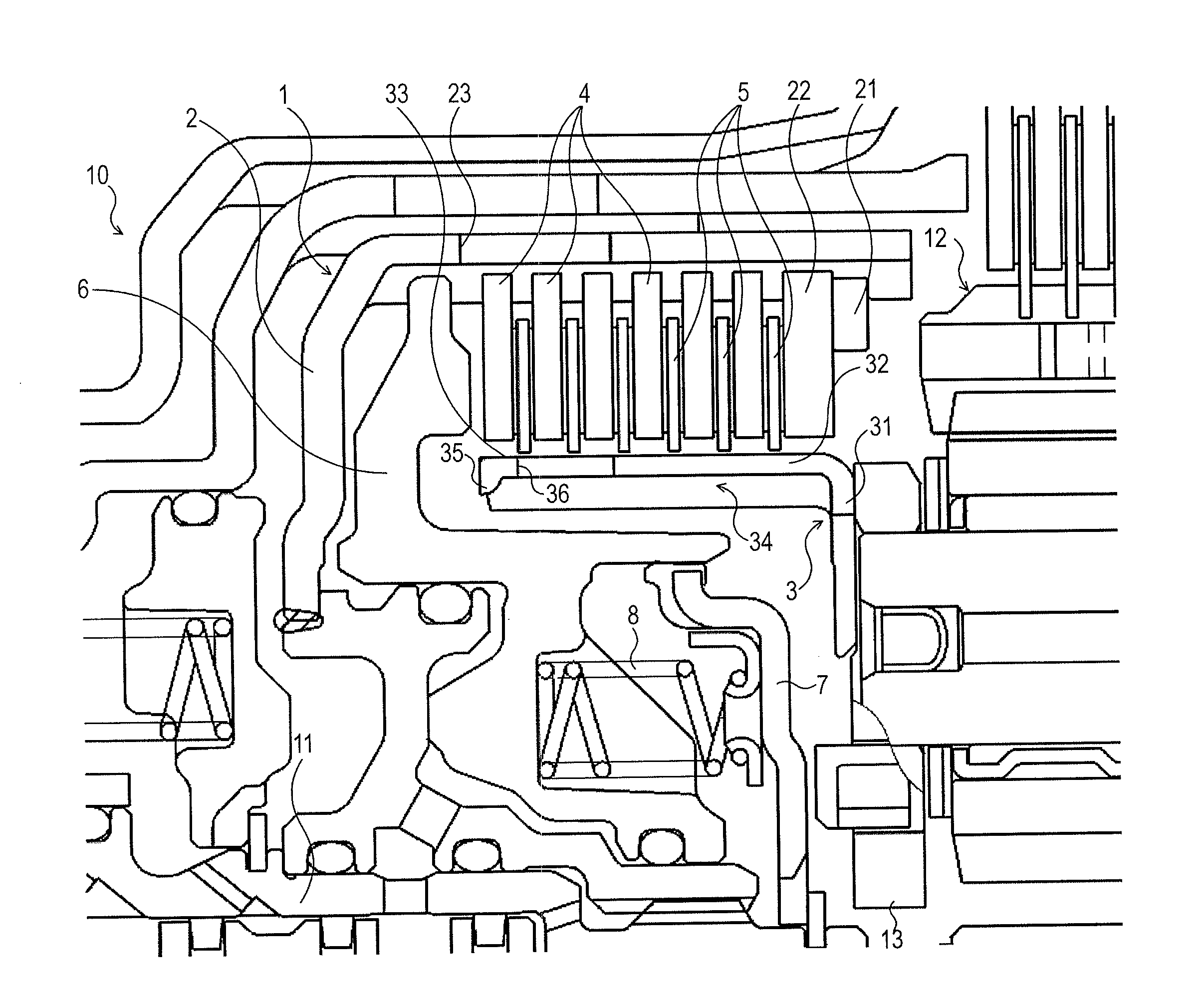

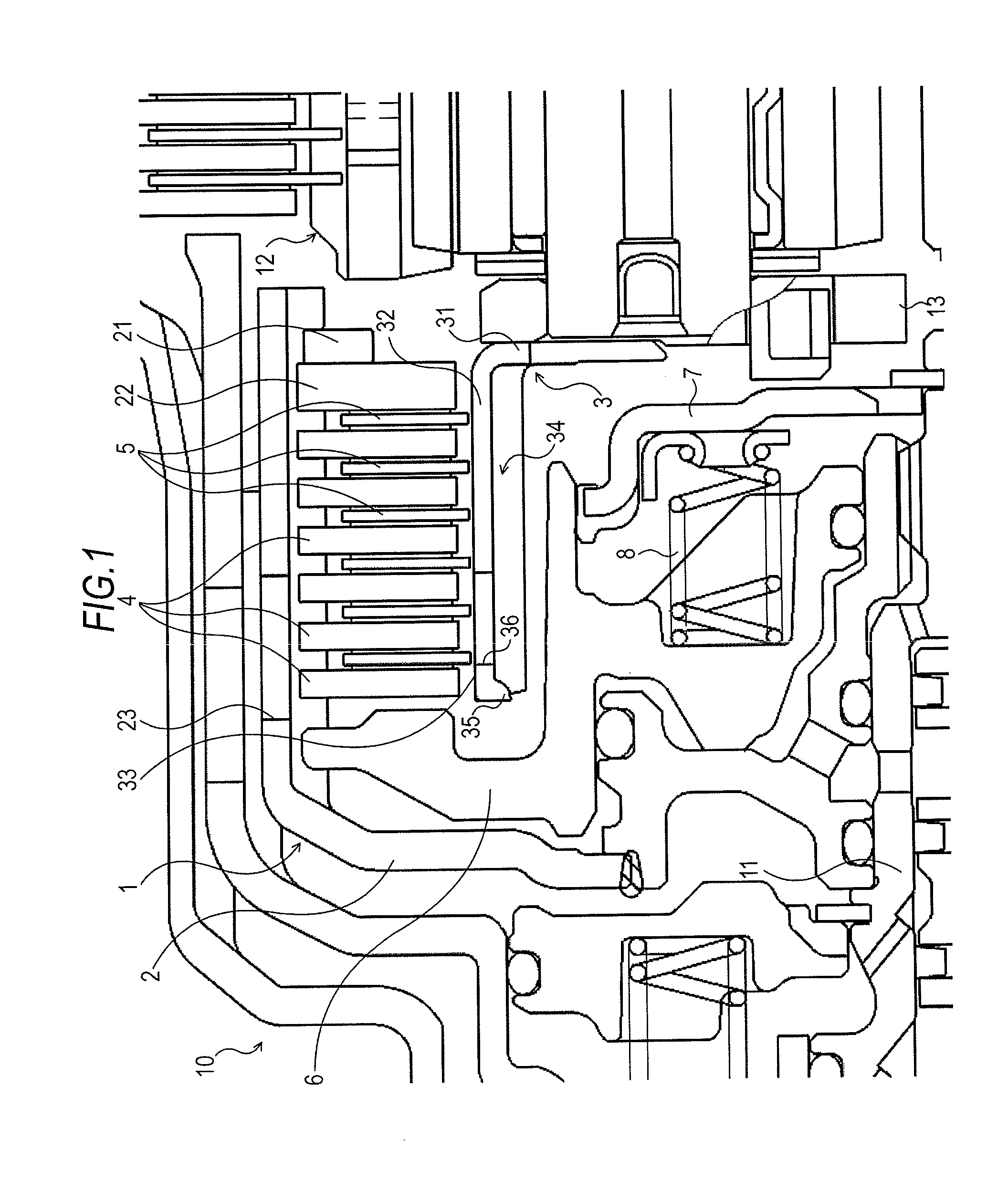

Laser processing apparatus

ActiveUS20130284708A1High positioning accuracyShorten cycle timePrinted circuit manufactureWelding/soldering/cutting articlesLaser processingEye lens

The present invention relates to a laser processing apparatus for irradiating a printed wiring board 9 with a laser beam L so as to form holes 22 at a plurality of predetermined positions on the printed wiring board 9. The device includes, from upstream on an optical path of the laser beam: a second fly eye lens 6 that achieves the uniform intensity distribution of the laser beam L; a second condenser lens 7 that collimates the laser beam L emitted from the second fly eye lens 6; and a micro lens array 8 positioned in a manner facing the printed wiring board 9 and having a plurality of micro lenses 19 formed in a manner corresponding to the plurality of positions on the printed wiring board 9.

Owner:V TECH CO LTD

Photoelectric encoder and method of manufacturing scales

InactiveUS7129475B2High mechanical strengthDifference in etching rateBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansResistGrating

Owner:MITUTOYO CORP

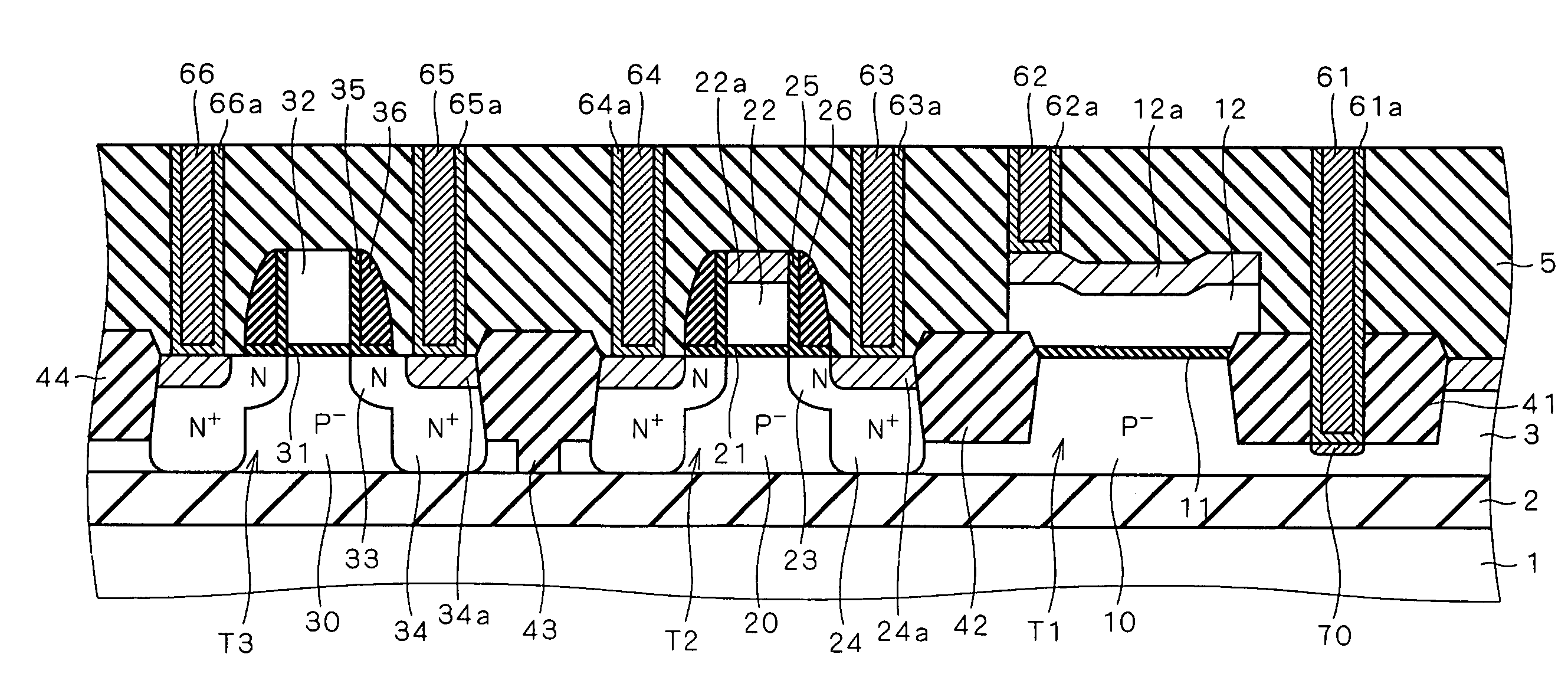

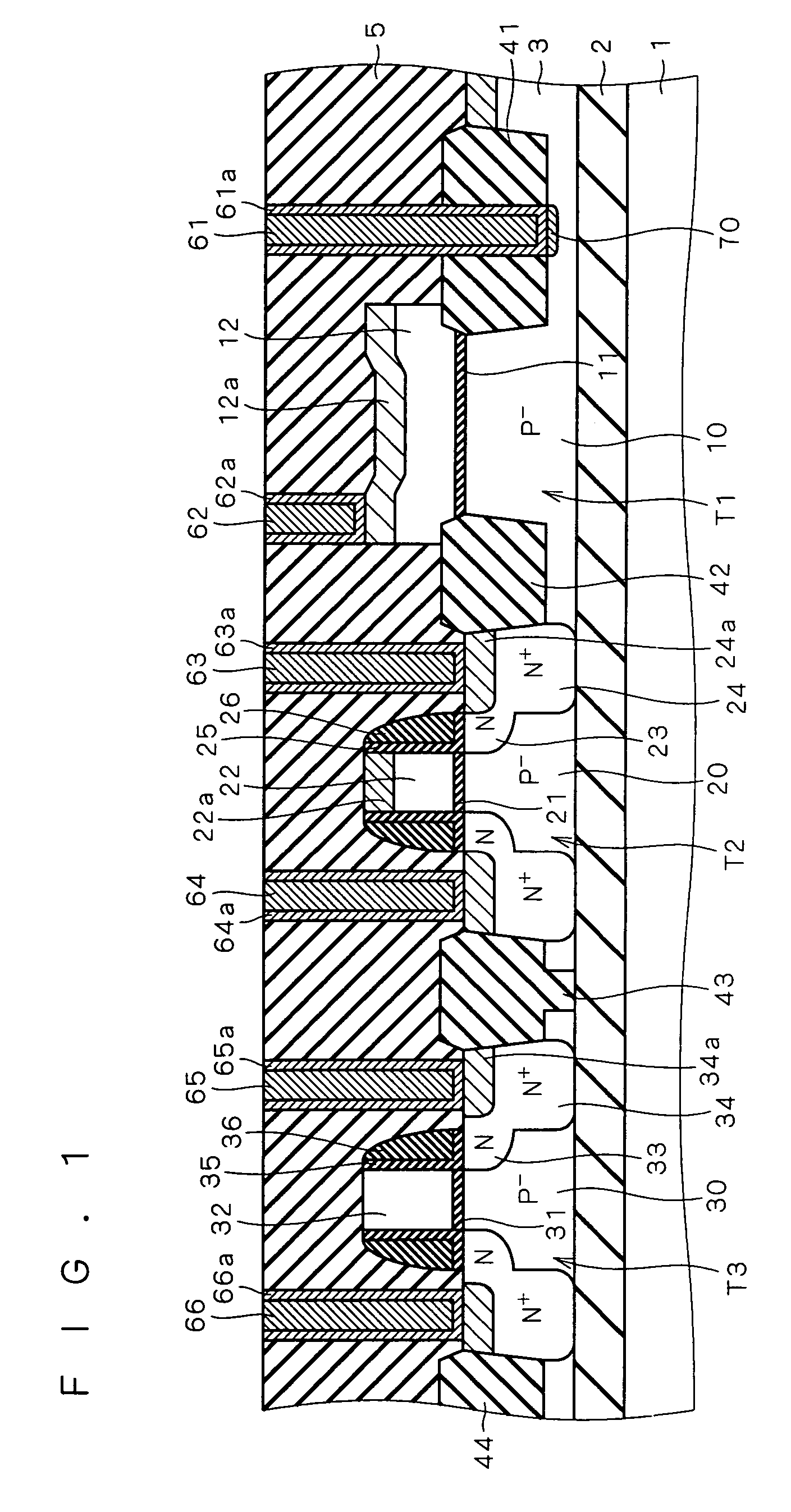

Semiconductor device including a contact connected to the body and method of manufacturing the same

InactiveUS7402865B2Reduce variationFirmly connectedSolid-state devicesSemiconductor/solid-state device manufacturingBody contactSemiconductor

A Schottky junction is formed at the connection between an SOI layer and a contact (namely, under an element isolation insulating film) without forming a P+ region with a high impurity concentration thereat. The surface of a body contact is provide with a barrier metal. A silicide is formed between the body contact and the SOI layer as a result of the reaction of the barrier metal and the SOI layer.

Owner:RENESAS ELECTRONICS CORP

Method for manufacturing SOI substrate

ActiveUS7537989B2Avoid exposureDeep unitySemiconductor/solid-state device manufacturingOptoelectronicsSoi substrate

To easily and accurately flush a substrate surface serving an SOI area with a substrate surface serving as a bulk area, make a buried oxide film, and prevent an oxide film from being exposed on substrate surface. After partially forming a mask oxide film 23 on the surface of a substrate 12 constituted of single crystal silicon, oxygen ions 16 are implanted into the surface of the substrate through the mask oxide film, and the substrate is annealed to form a buried oxide film 13 inside the substrate. Further included is a step of forming a predetermined-depth concave portion 12c deeper than substrate surface 12b serving as a bulk area on which the mask oxide film is formed on the substrate surface 12a serving as an SOI area by forming a thermally grown oxide film 21 on the substrate surface 12a serving as an SOI area on which the mask oxide film is not formed between the step of forming the mask oxide film and the step of implanting oxygen ions.

Owner:KIOXIA CORP +1

Embossed Drawtape for Polymeric Bags

Owner:POLY AMERICA

Device for making a spiral incision on a meat product

A method and device for forming a spiral incision on a meat product that includes a compression plate, a cutting element, a plurality of rollers, and a spacing device. The compression plate is supported by legs and includes an elongated slot therein. The cutting element is positioned in a vertical orientation and has a cutting portion that projects upwardly through the elongated slot. The plurality of rollers are pivotably coupled to guide brackets and are frictionally engaged by a one or more flexible belts such that one roller is rotated concomitantly with another roller. The spacing device adjustably couples the guide brackets and compression plate such that the flexible belts and compression plate are arranged in substantially parallel-spaced relation. In operation, the flexible belts rotatably engage the meat product and draw the it over the cutting element forming a superficial spiral incision of generally uniform depth.

Owner:FARMLAND FOODS

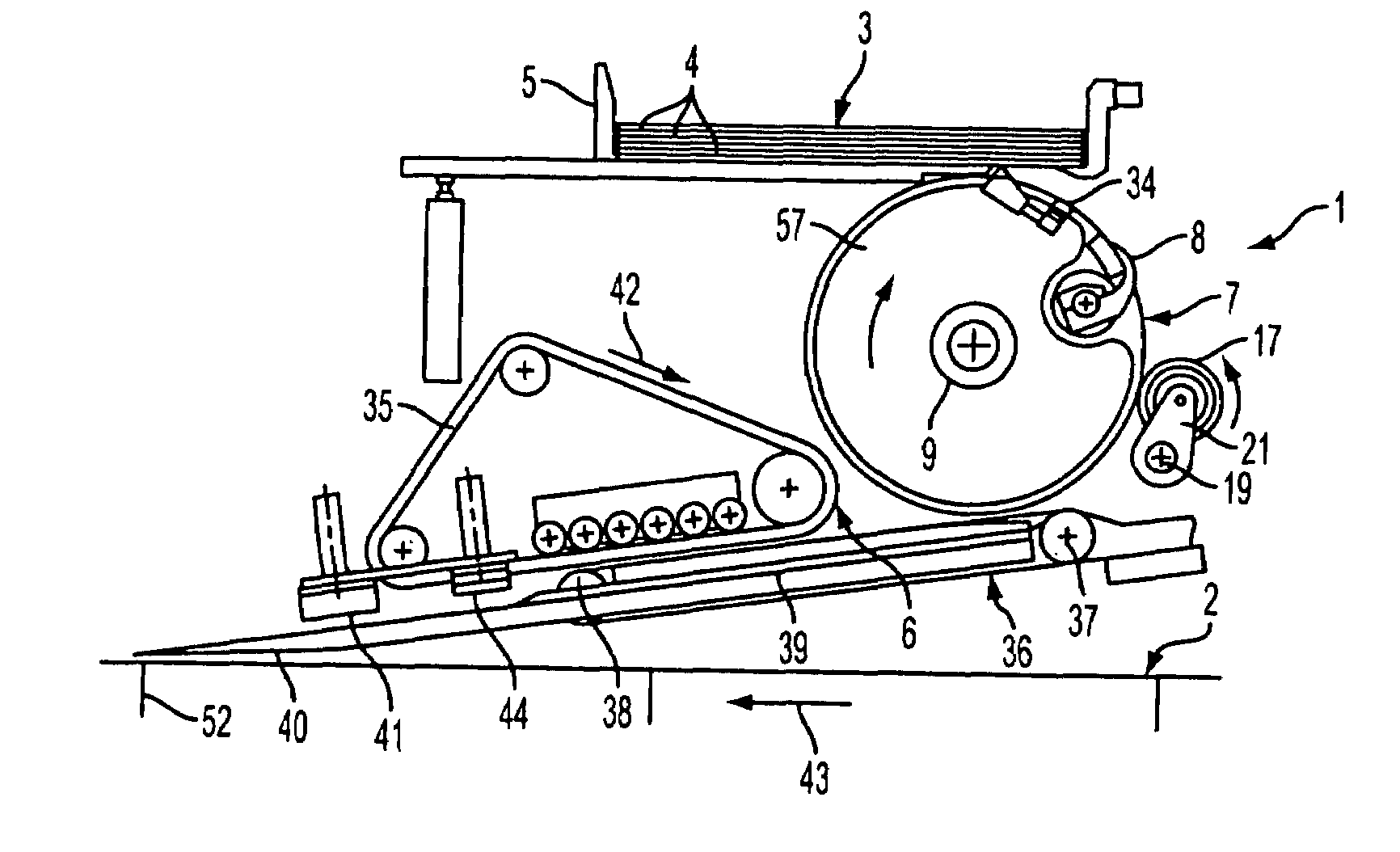

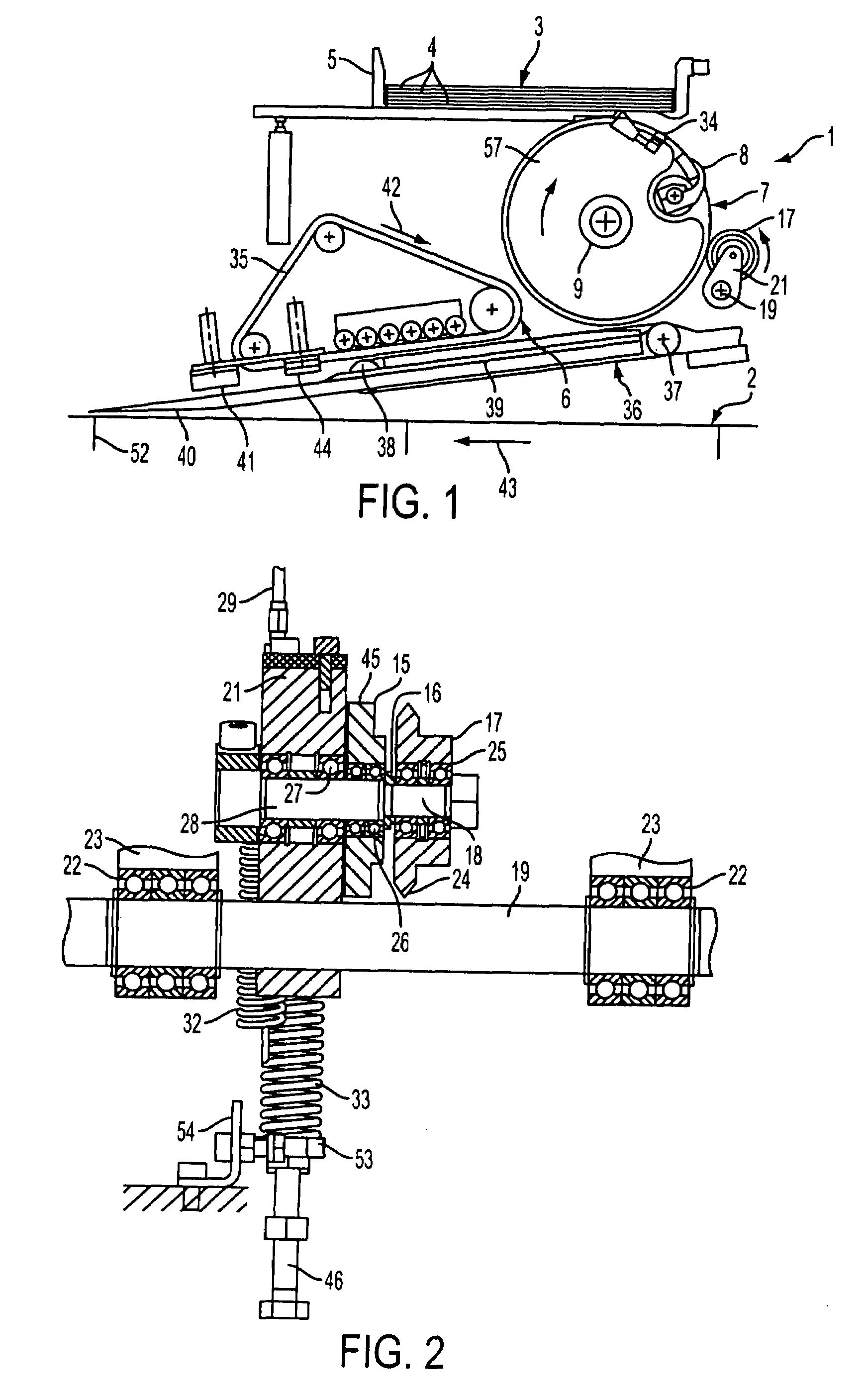

Multi-plate clutch and manufacturing method of clutch hub

ActiveUS20120080284A1Well formedEffectively lubricate and coolMetal-working apparatusFriction clutchesEngineeringClutch

A multi-plate clutch including a clutch hub having a cylindrical portion; a plurality of clutch plates splined to the outer periphery of the cylindrical portion of the clutch hub, and a plurality of spline teeth being formed on the outer periphery of the cylindrical portion of the clutch hub. A recessed portion is formed on the inner side of each spline tooth, and a weir portion is formed at one end of each recessed portion by depressing one portion of the spline tooth to the inner side on one end side of the cylindrical portion. Thus forming a depressed portion, and removing, with one portion of the depressed portion left behind, a portion of the cylindrical portion on the one end side of the one portion of the depressed portion.

Owner:AISIN AW CO LTD

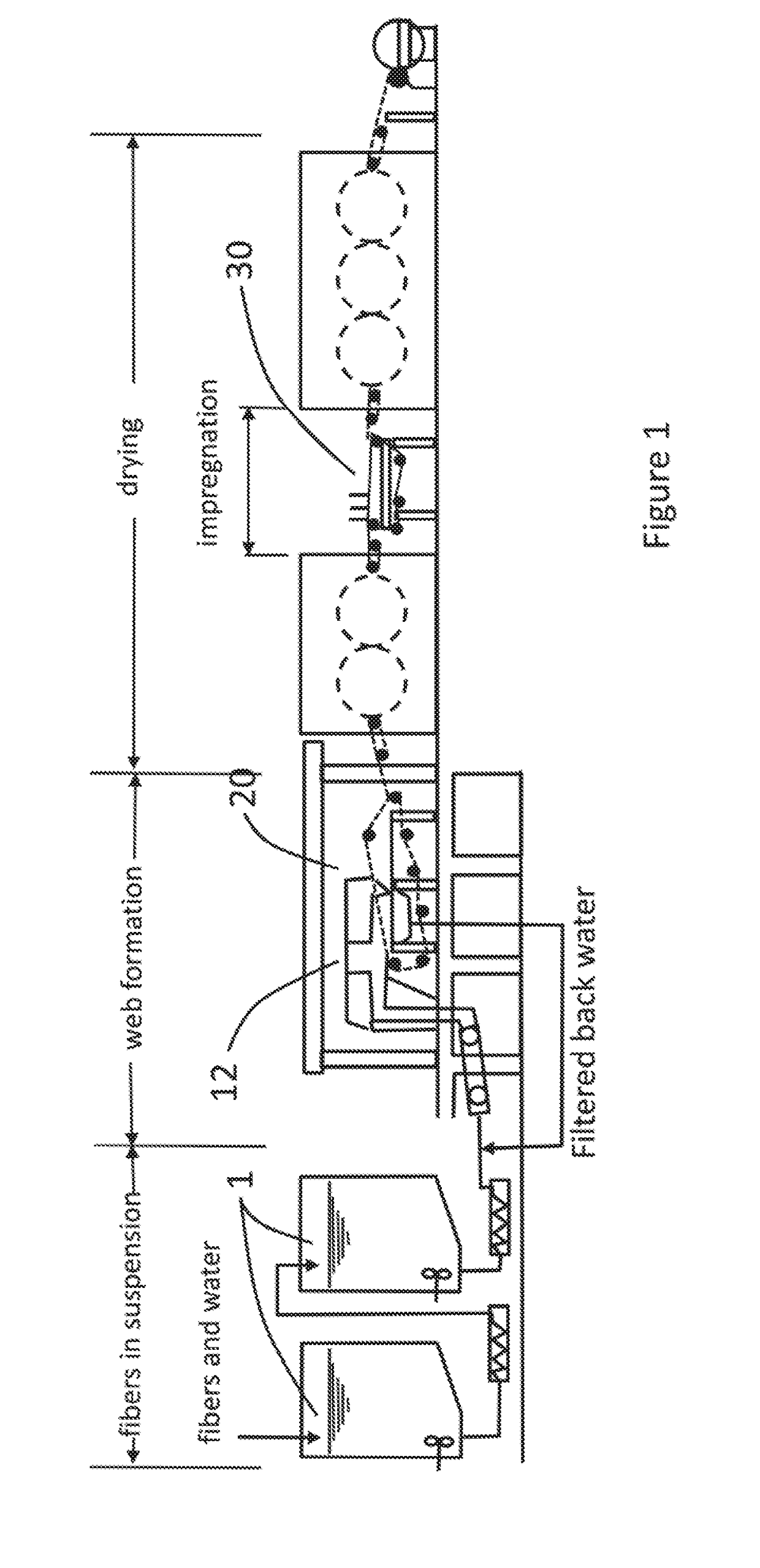

Carbon nanotube sheet structure and method for its making

ActiveUS20190047864A1Improve functional propertiesGood physical propertiesMaterial nanotechnologyNon-fibrous pulp additionLightning strikeCarbon nanotube

A carbon nanotube (CNT) sheet containing CNTs, arranged is a randomly oriented, uniformly distributed pattern, and having a basis weight of at least 1 gsm and a relative density of less than 1.5. The CNT sheet is manufactured by applying a CNT suspension in a continuous pool over a filter material to a depth sufficient to prevent puddling of the CNT suspension upon the surface of the filter material, and drawing the dispersing liquid through the filter material to provide a uniform CNT dispersion and form the CNT sheet. The CNT sheet is useful in making CNT composite laminates and structures having utility for electro-thermal heating, electromagnetic wave absorption, lightning strike dissipation, EMI shielding, thermal interface pads, energy storage, and heat dissipation.

Owner:GENERAL NANO LLC

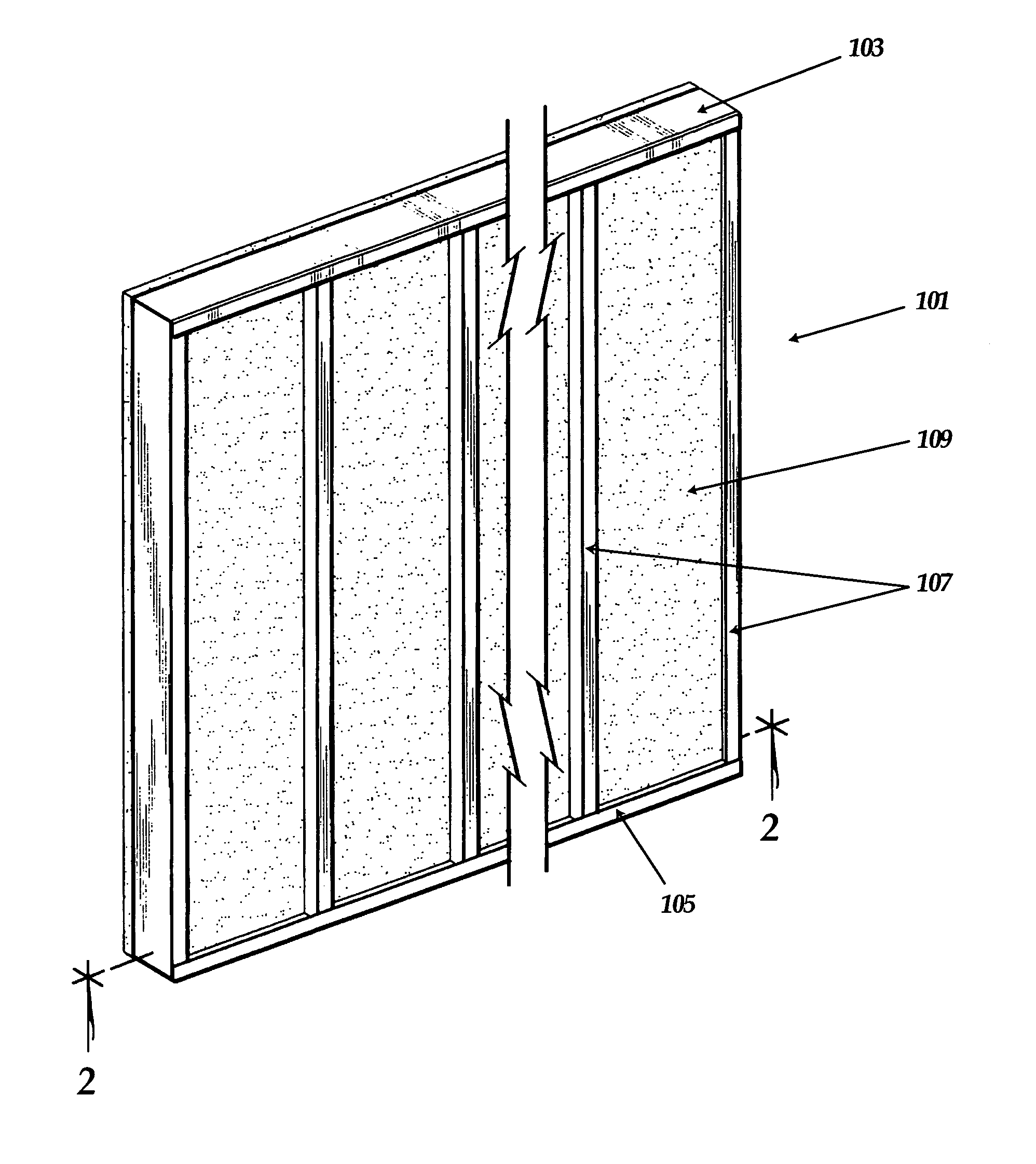

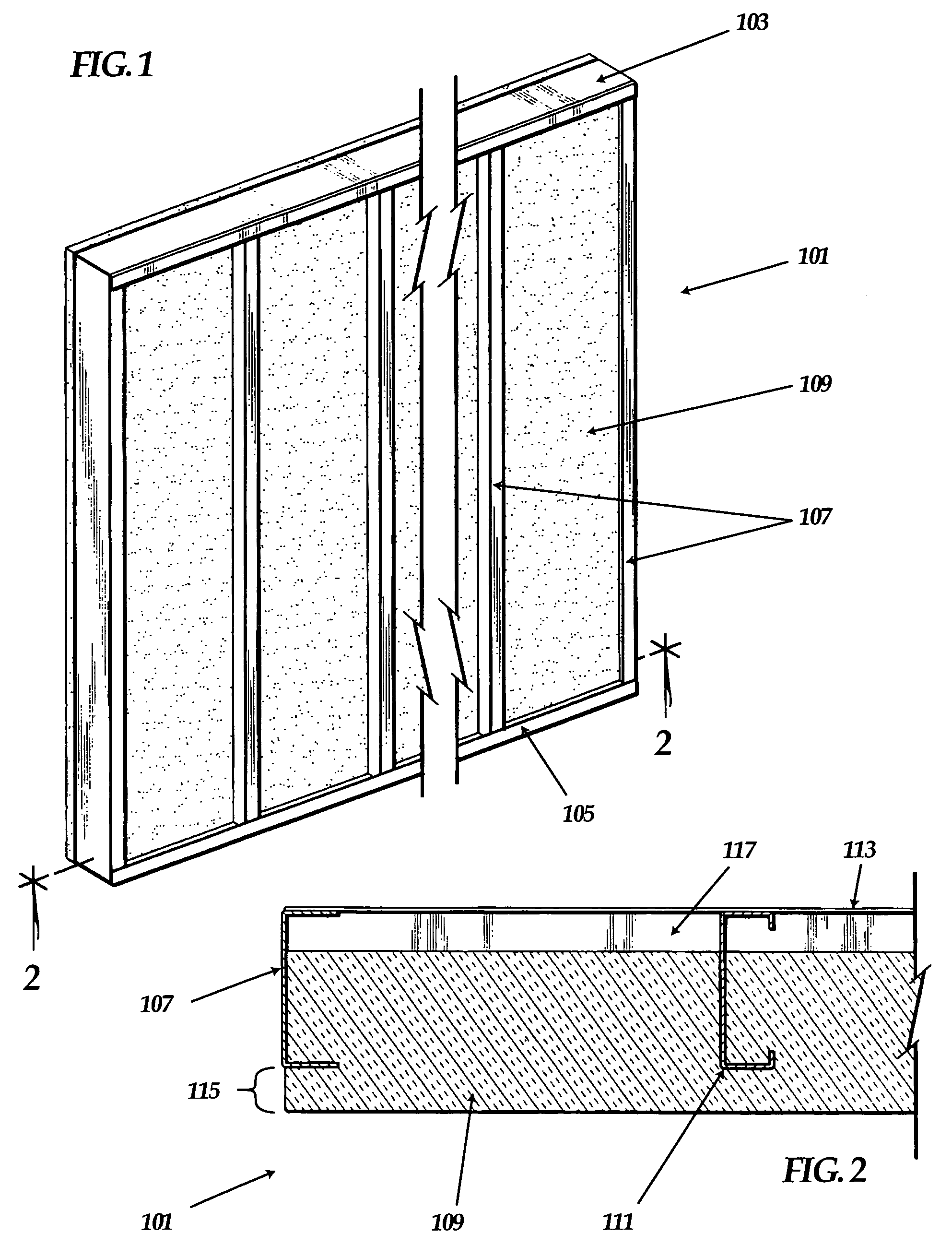

Insulated ceiling hatch

InactiveUS7337584B2Easy to closeReduce air leakageBuilding roofsArtificial islandsEngineeringElectrical and Electronics engineering

Owner:C & E ENTERPRISES INC

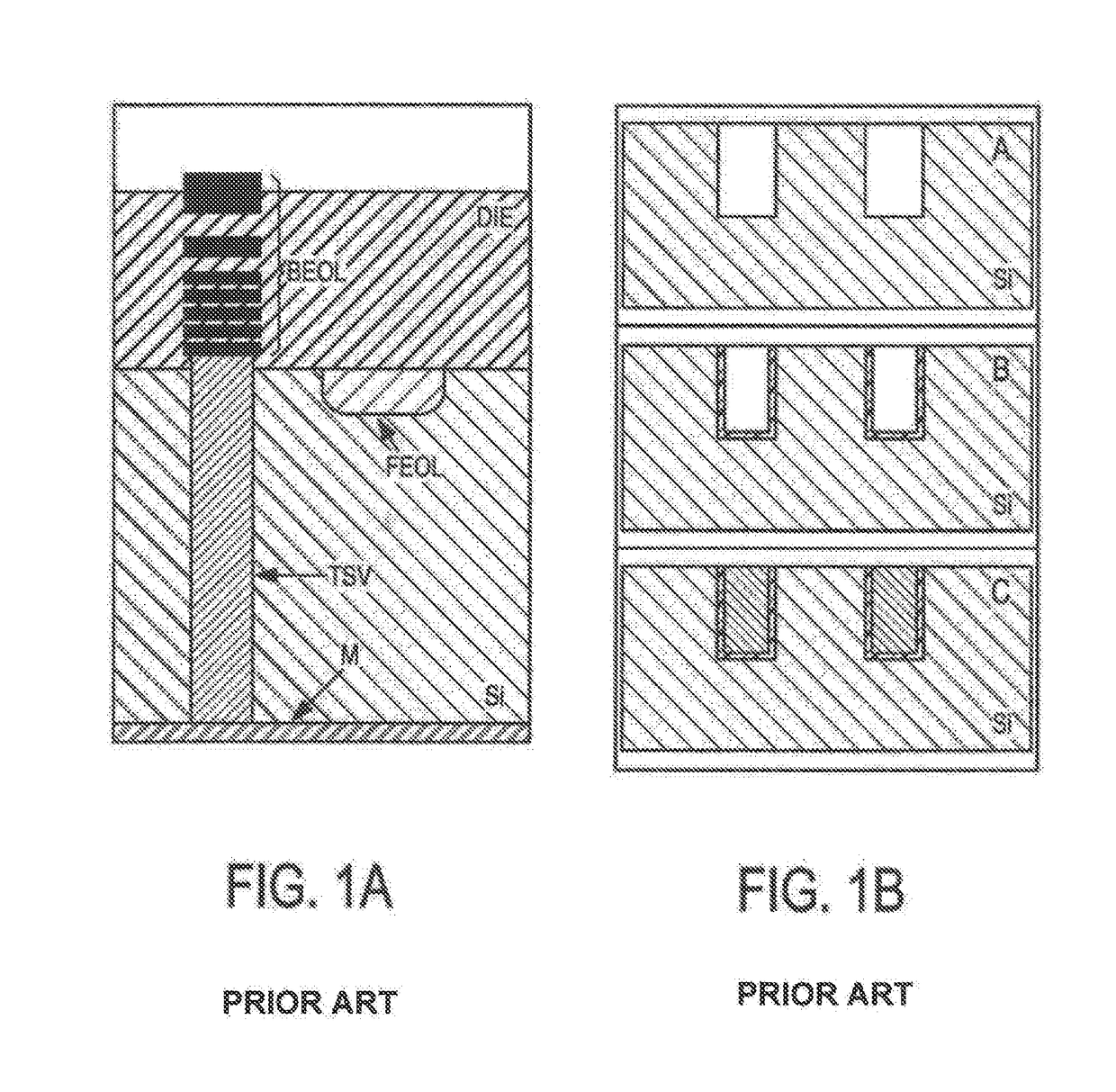

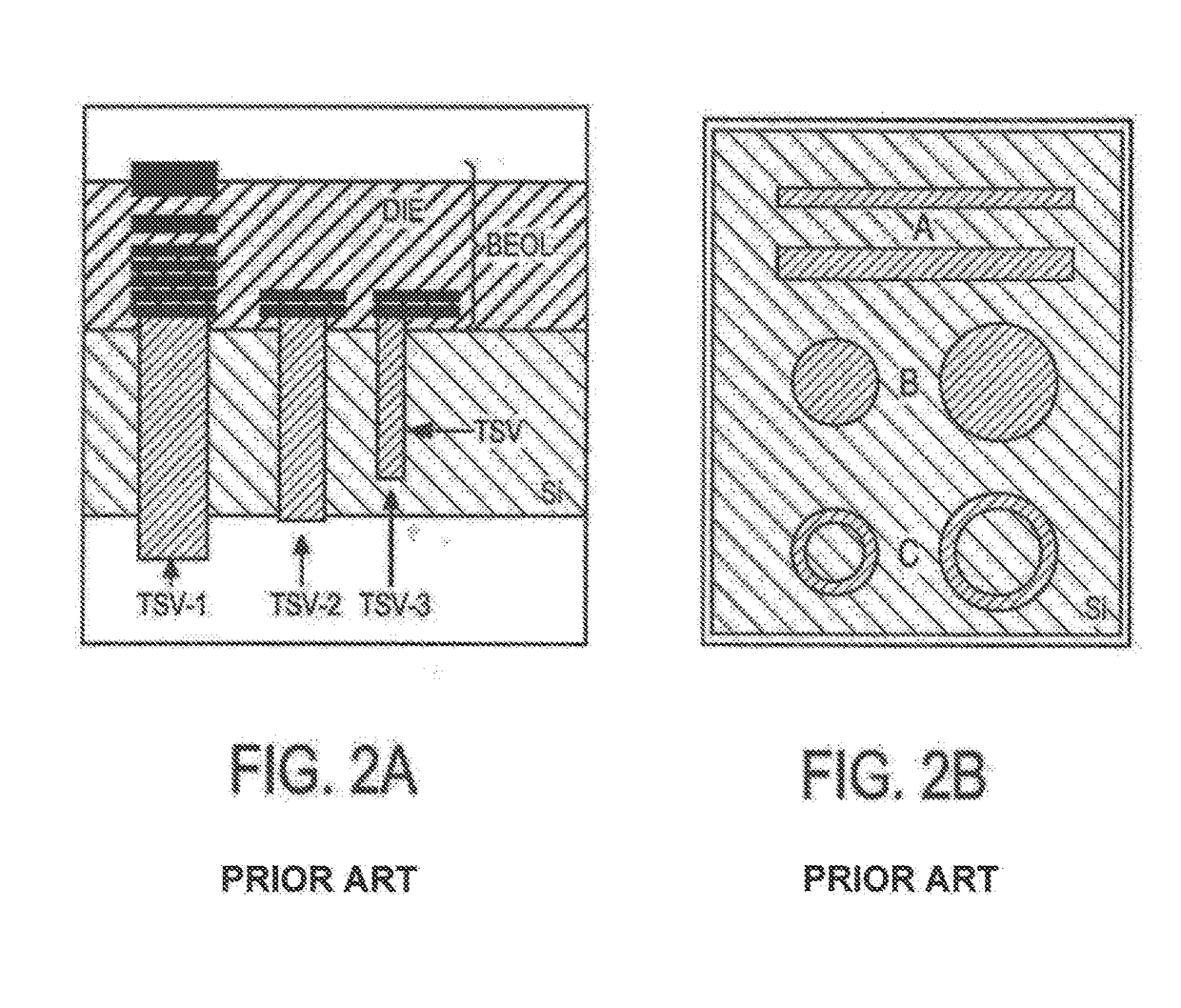

Technological method for preventing, by means of buried etch stop layers, the creation of vertical/lateral inhomogeneities when etching through-silicon vias

ActiveUS20180286751A1Easy to operateUniform lengthSemiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical conductor

Method for producing a semiconductor device by providing a silicon wafer having a plurality of equal height raised portions on a first surface thereof; depositing an etch stop layer on the first surface; planarizing a surface of the etch stop layer; permanently bonding a first carrier wafer on the etch stop layer surface; producing components on or in a second wafer surface in a FEOL process; etching a plurality of trenches into the wafer, each trench formed at the respective location of one of the raised portions; depositing side wall insulation layers on side walls of the trenches; forming through-silicon vias by filling the trenches with electrically conductive material; producing a conductor path stack in a BEOL process for contacting the active components on the second surface; temporarily bonding a second carrier wafer onto a surface of the conductor path stack; removing the first carrier wafer and exposing the vias.

Owner:IHP GMBH INNOVATIONS FOR HIGH PERFORMANCE MICROELECTRONICS LEIBNIZ INST FUR INNOVATIVE

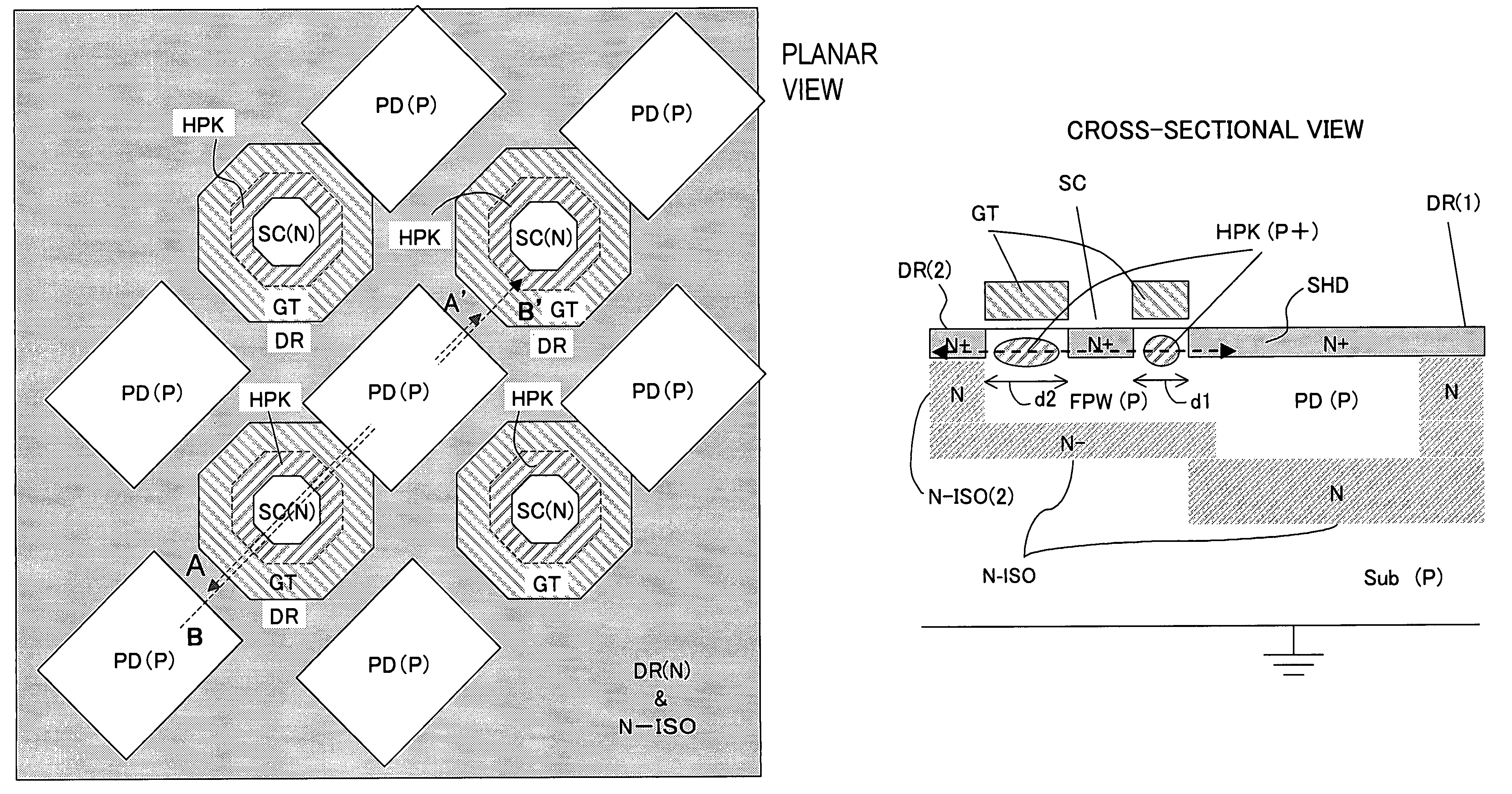

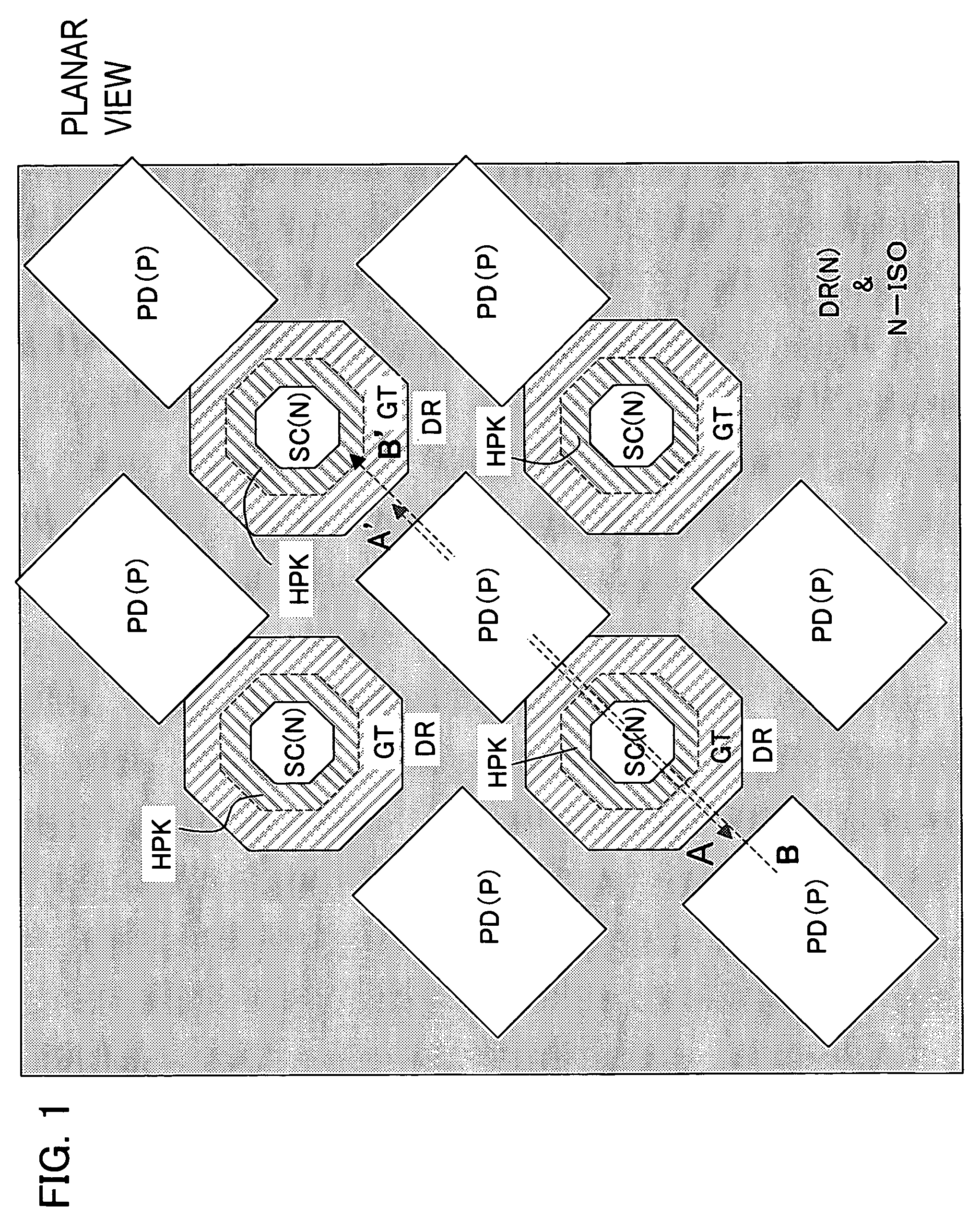

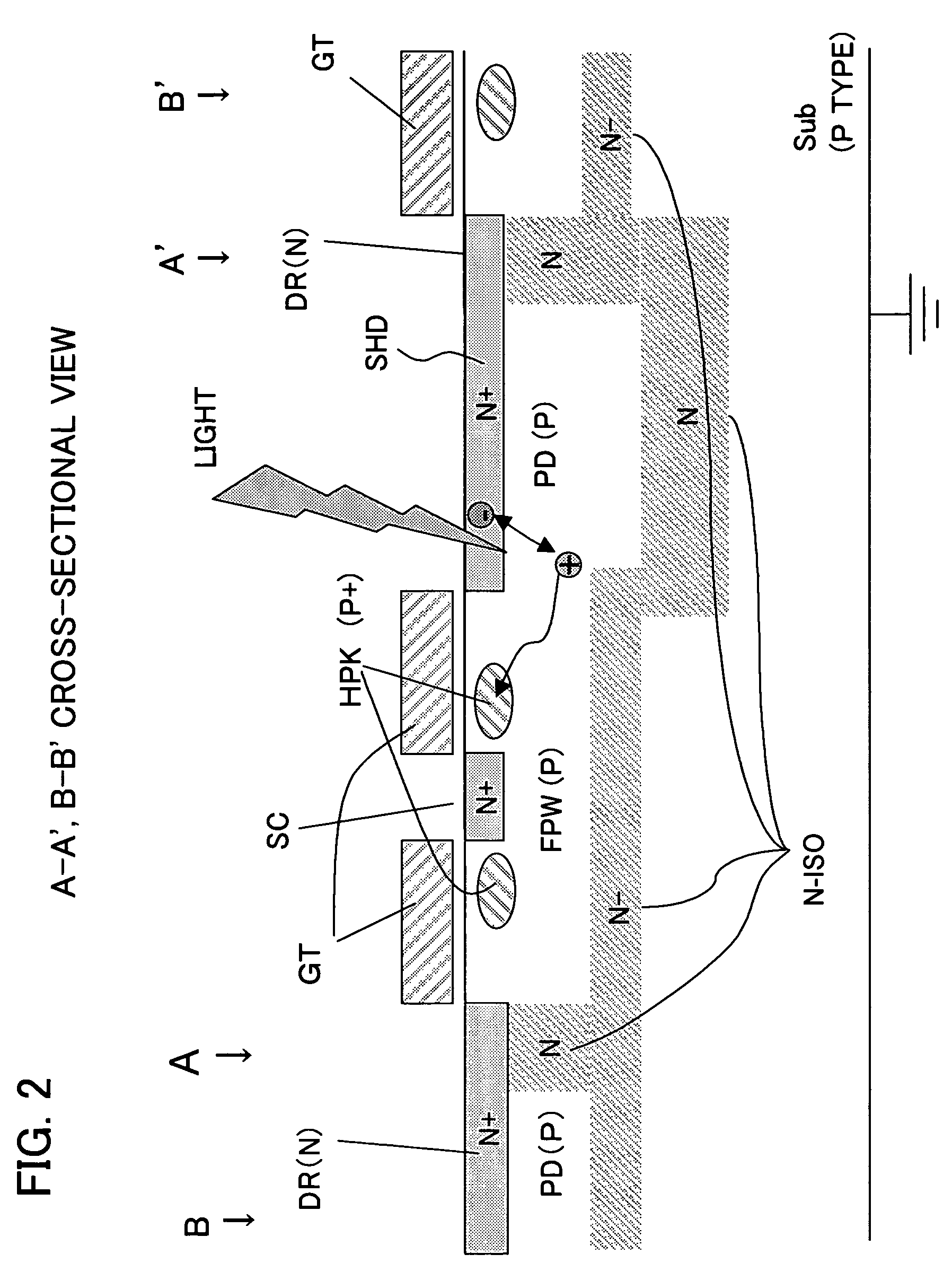

Threshold voltage modulation image sensor

InactiveUS7683452B2High sensitivityReduced areaTelevision system detailsSolid-state devicesPhotoelectric conversionThreshold voltage

An image sensor has a plurality of pixels each with a photoelectric conversion element and a detection transistor the threshold voltage of which fluctuates in accordance with electrical charge generated in the photoelectric conversion element. The image sensor includes a second conductivity type shield region and a first conductivity type photoelectric conversion region; a first conductivity type well region linked to the photoelectric conversion region; a ring-like gate electrode; a second conductivity type source region at the inside of the ring-like gate electrode; a second conductivity type drain region. The image sensor further includes a potential pocket region that is formed in the well region below the ring-like gate electrode and accumulates the electrical charge, wherein the width of the gate electrode is formed narrower in the part adjacent to the photoelectric conversion region than in other parts.

Owner:FUJITSU SEMICON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com