Drilling equipment used before assembling of storage cabinet

A technology for drilling equipment and storage cabinets, which is used in fixed drilling machines, multi-purpose machinery, wood processing appliances, etc. Deeply unified, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

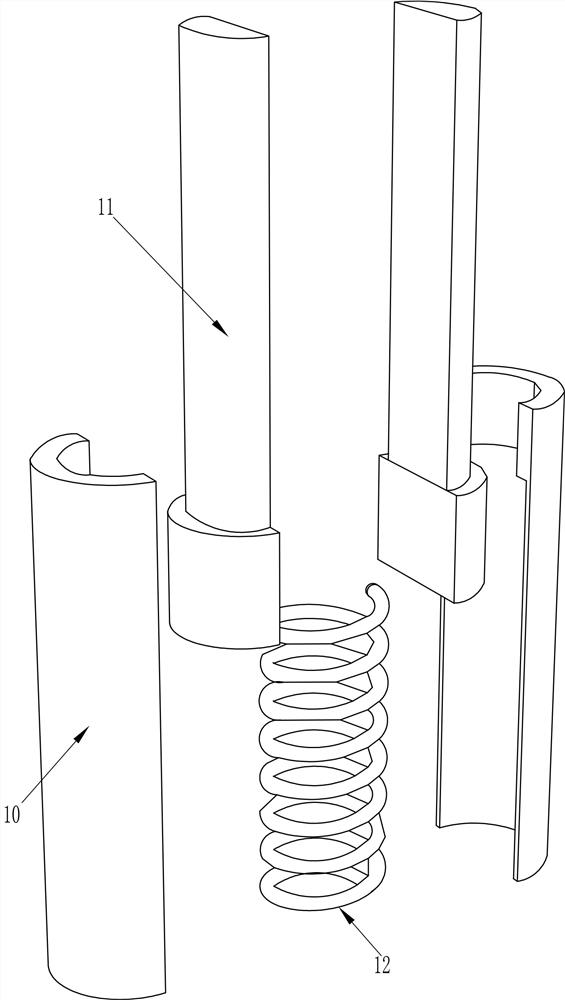

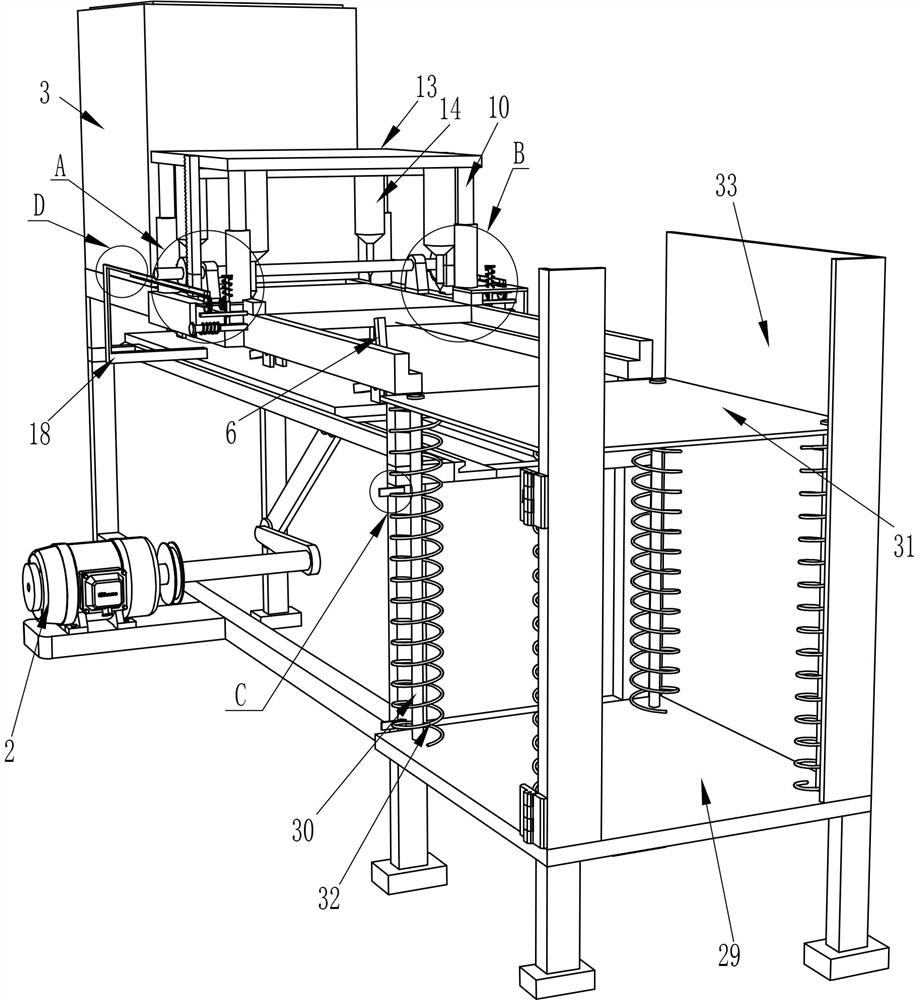

[0026] A device for drilling holes prior to assembly of lockers such as Figure 1-4 As shown, it includes a frame 1, a motor 2, a blanking box 3, a slide plate 5, an L-shaped push rod 6, a first connecting rod 7, a second connecting rod 8, a transmission mechanism 9, a sliding sleeve 10, a sliding rod 11, First spring 12, placement plate 13, electric drill 14, first rack 15, first rotating shaft 16 and sector gear 17, the front side lower part of frame 1 is fixed with motor 2 by bolt, the top left side of frame 1 A blanking box 3 is installed between them, and the upper part of the frame 1 is slidably connected to the slide plate 5, the slide plate 5 is located below the blanking box 3, and the top of the slide plate 5 is evenly spaced and rotated to be equipped with an L-shaped push rod 6, and an L-shaped push rod 6 The quantity is three, the gravity of the left part of the L-shaped push rod 6 is greater than the gravity of the right part, the output shaft of the motor 2 is f...

Embodiment 2

[0029] On the basis of Example 1, such as figure 2 , Figure 4 , Figure 5 and Figure 7 Shown, also comprise L-shaped rack 18, support frame 19, second rotating shaft 20, first gear 21, second gear 22, second rack 23, telescoping link 24, second spring 25, stop bar 26 and The third spring 28, the top front and rear sides of the slide plate 5 are all connected with L-shaped racks 18, the front and rear sides of the top of the frame 1 are symmetrically equipped with a support frame 19, the support frame 19 is located on the right side of the placement plate 13, and the support frame 19 top Opening is arranged, and the second rotating shaft 20 is equipped with the second rotating shaft 20 in the supporting frame 19 of front and rear sides, and the outside of the second rotating shaft 20 is equipped with a first gear 21, and the top of the first gear 21 passes through the opening that supporting frame 19 offers, L The gear rack 18 meshes with the first gear 21, the second gea...

Embodiment 3

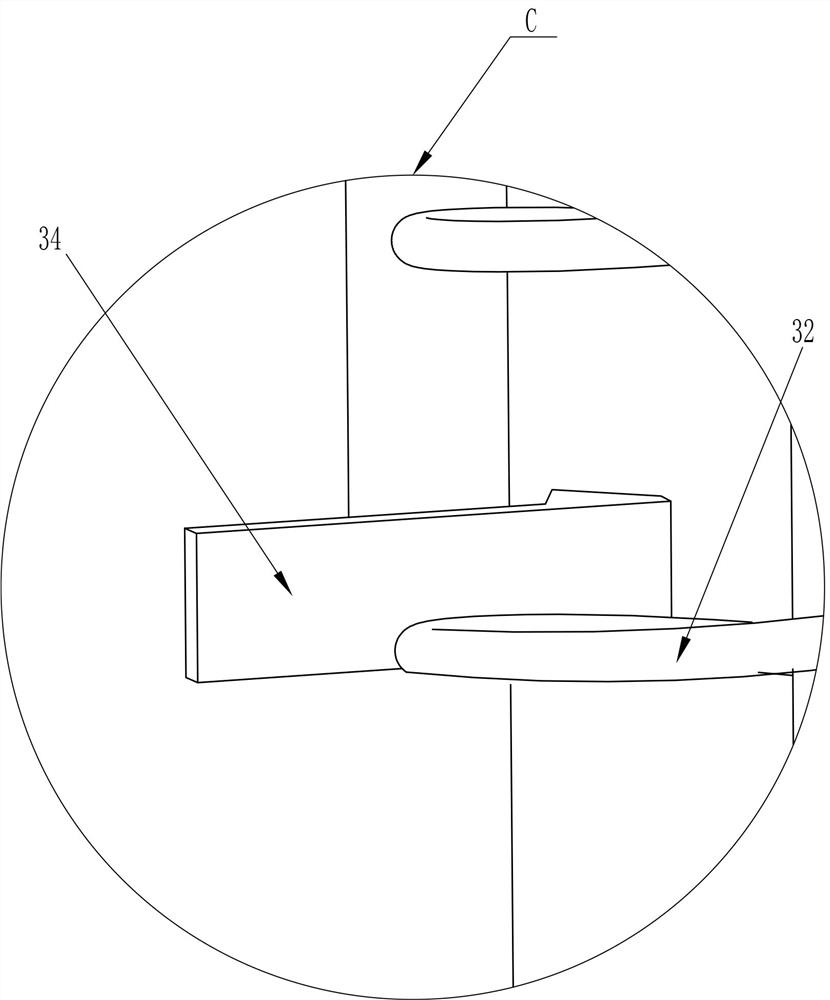

[0032] On the basis of Example 2, such as figure 1 , figure 2 and Figure 6 As shown, it also includes a first support plate 29, a support rod 30, a second support plate 31, a fourth spring 32, a baffle plate 33 and an L-shaped rubber clamp 34, and the right side of the frame 1 is equipped with a first support plate 29. The top, front, rear, left, and right sides of the top of the first support plate 29 are connected with support rods 30, and the support rod 30 is slidably connected with a second support plate 31, and a fourth support plate 31 is connected between the first support plate 29 and the second support plate 31. The spring 32 and the fourth spring 32 are all wound on the support rod 30, the front and rear sides of the first support plate 29 top are connected with baffle plates 33, the front baffle plate 33 is a reverse setting, and the front side baffle plate 33 left An L-shaped rubber clamp 34 is installed on the rear side of the part, and the L-shaped rubber cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com