Device for making a spiral incision on a meat product

a technology for meat products and cutting tools, applied in the field of meat cutting tools, can solve the problems of inability to consistently achieve a precise superficial incision, inability to use manual cutting tools, and high labor intensity of these tools, and achieve the effect of preventing high volume production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention is directed to a device and a method for making a spiral incision on a meat product.

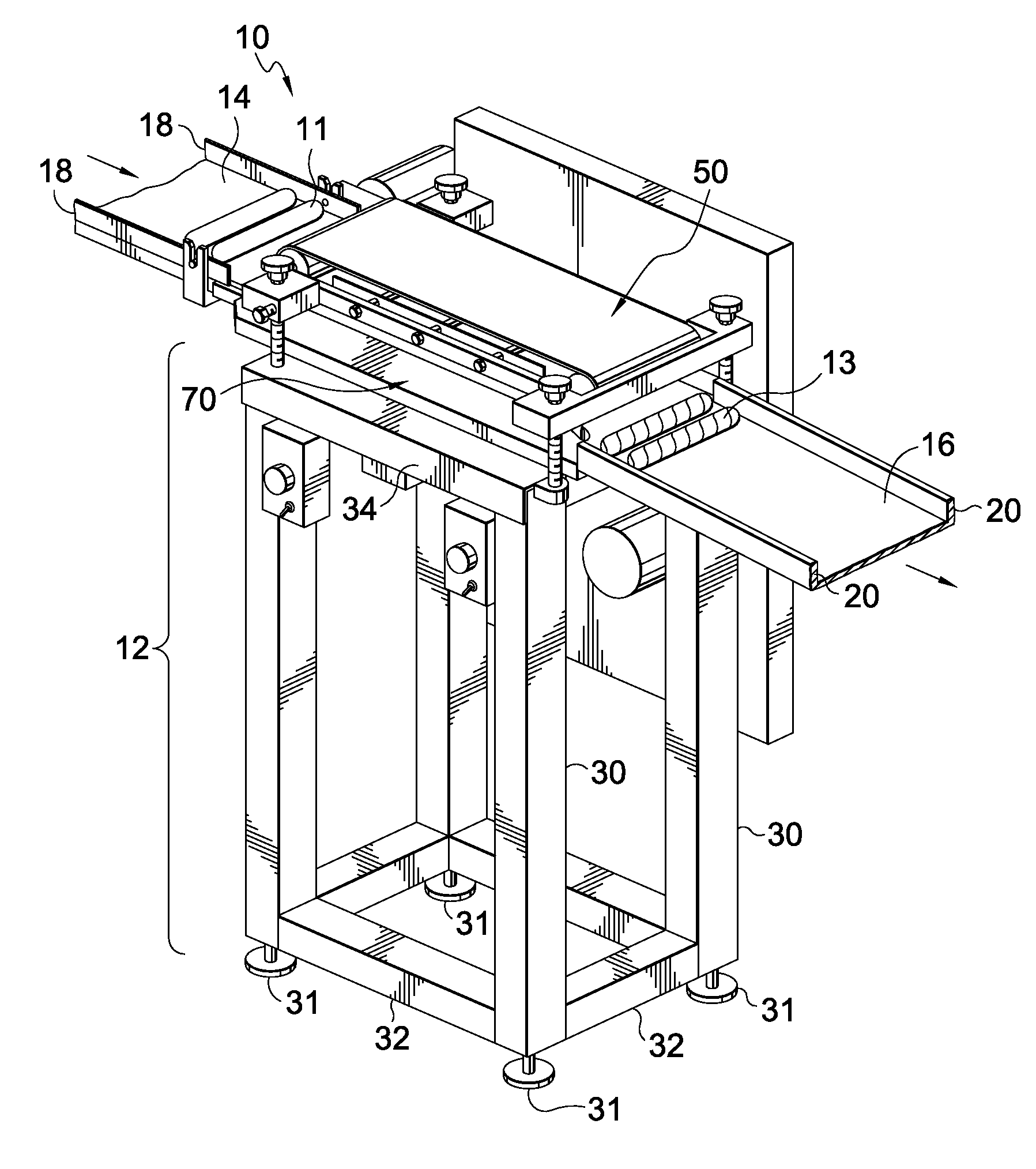

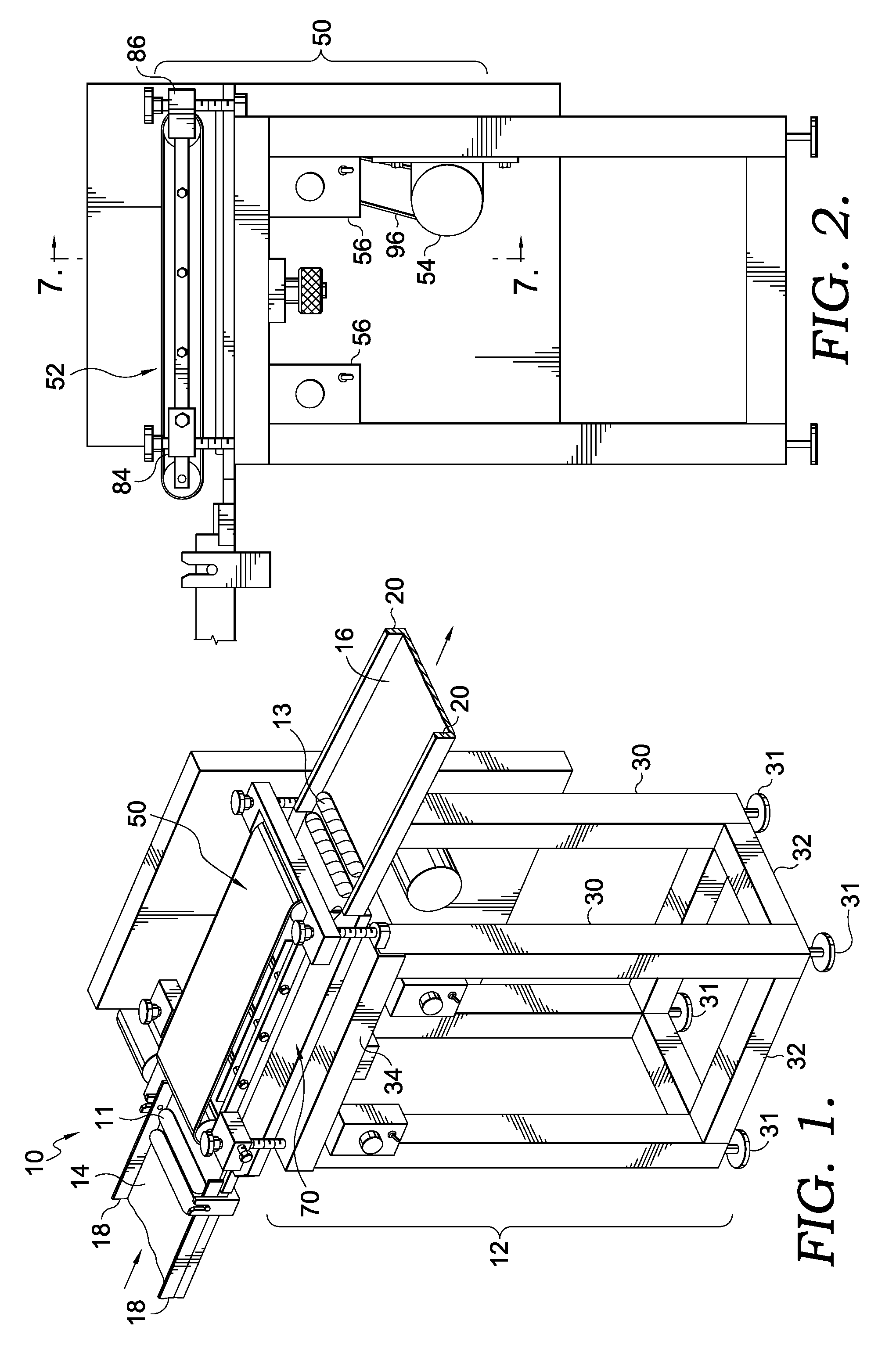

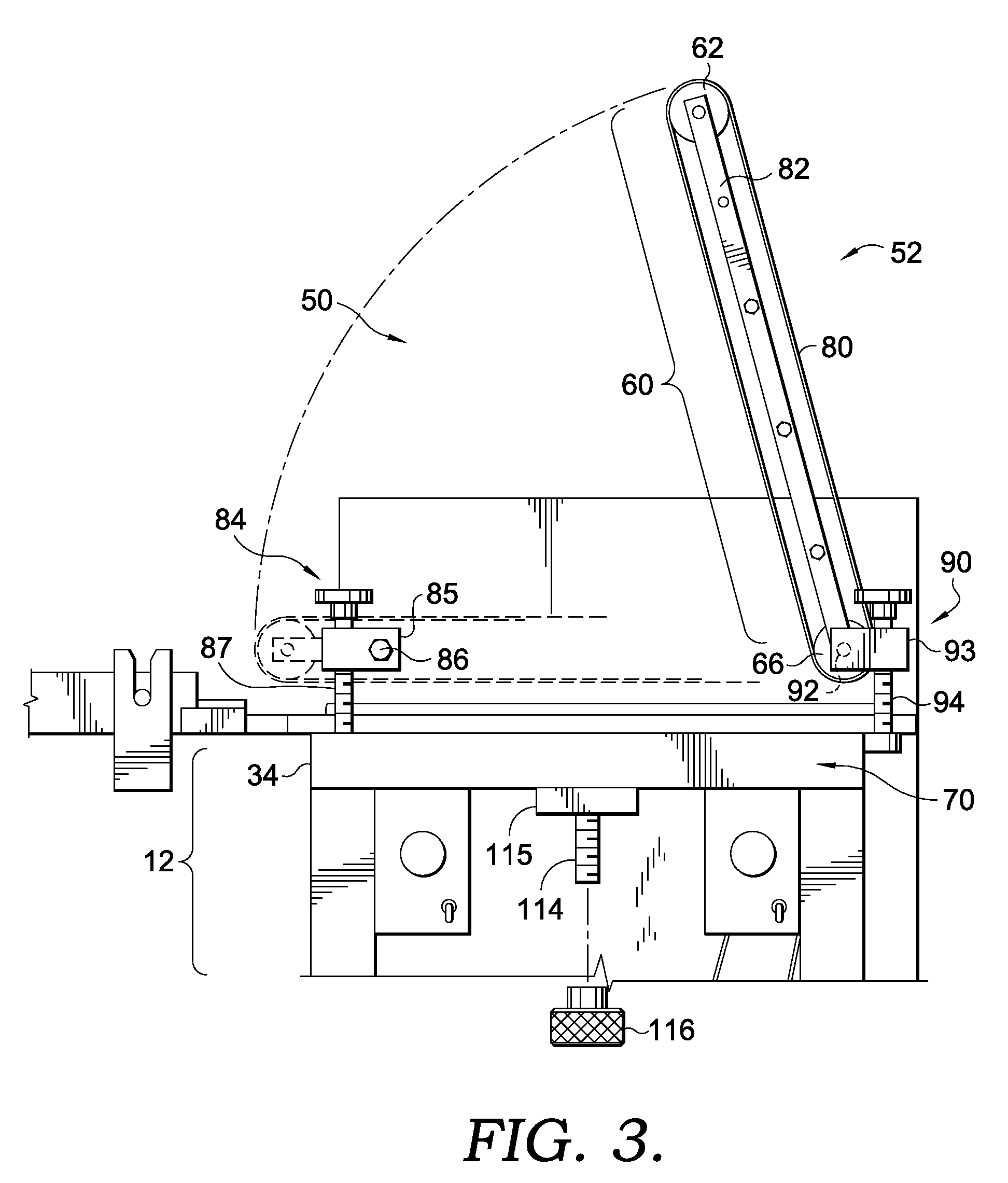

[0026]Referring to the drawings in greater detail, and initially to FIG. 1, a device for making a spiral incision on a meat product (hereinafter the “spiral incising device”) is shown and designated generally by the numeral 10. The spiral incising device 10 is used to form a spiral cut on a meat product. Specifically, the spiral incising device 10 provides a superficial spiral cut to a cylindrically-shaped meat product including, but not limited to, hotdogs, sausages, hot links, bratwurst, pepperoni, and the like. However, for the purposes of the discussion below the spiral slicer will be described as pertaining to processing one or more hotdog(s).

[0027]With further reference to FIG. 10, the spiral incising device 10 comprises a base 12, a drive mechanism 50, a cutting mechanism 70, a receiving channel 14, and an exit channel 16. The receiving channel 14 and exit channel 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com