Frame type high efficiency impeller of impeller aerator

An aerator, frame type technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of poor comprehensive benefits, easy damage to the blade, service life, high cost, improve the oxygen melting capacity, simple and convenient use , The effect is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

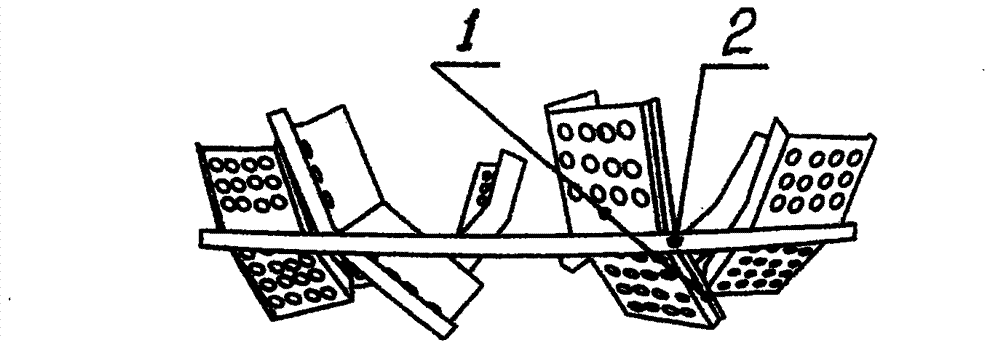

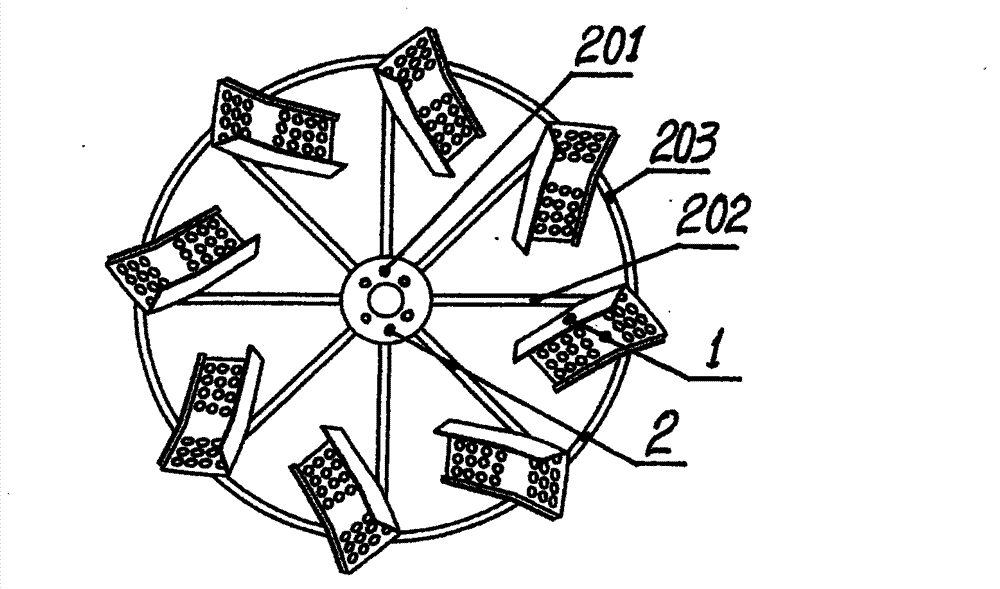

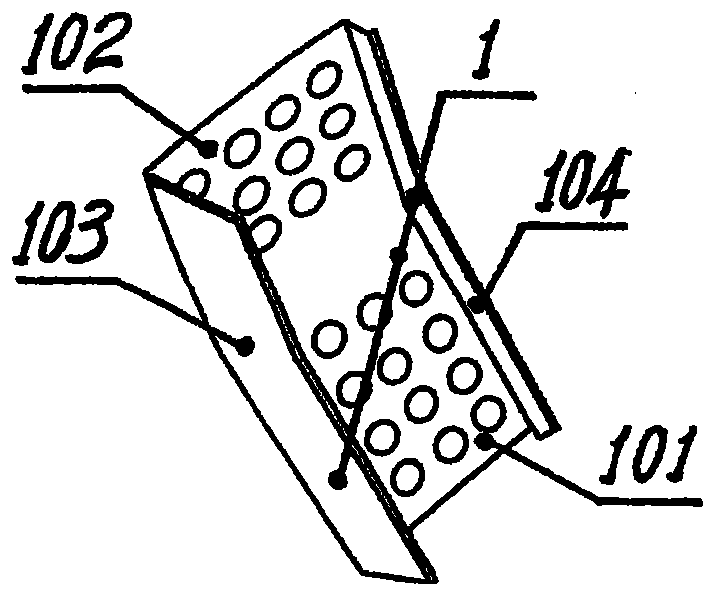

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , as shown in 3:

[0024] A frame-type high-efficiency impeller of an impeller-type aerator, which is composed of a lower water-repelling plate 101, an upper water-guiding plate 102, an inner water-guiding plate 103, and an outer water-guiding plate 104. Radial support 202, the transmission connection plate 2 formed by the ring 203 is jointly formed;

[0025] The frame-type high-efficiency impeller of the impeller-type aerator, the angle formed by the lower water-repelling plate 101 and the upper water-guiding plate 102 is 90-160 degrees, and the lower water-repelling plate 101 and the upper water-guiding plate are vertically connected to each other. The inner side of the plate 102 is provided with an inner water guide plate 103 and the outer side is provided with an outer water guide plate 104 to form the blade 1, and the inne...

specific Embodiment approach 2

[0031] Carry out according to specific embodiment one, just as specification attached figure 1 , 2 , 3, only: each part of the present invention is made of plastics as a raw material, and is made by injection molding, and then connected as a whole and implemented; the same good effect is obtained.

specific Embodiment approach 3

[0032] Carry out implementation on the basis of the implementation of specific implementation mode 1 and 2, just as the description attached figure 1 , 2 , 3, only: the lower water-repelling plate 101, the upper water-guiding plate 102, the inner water-guiding plate 103, and the outer water-guiding plate 104 are all made of plastic, and are all made by injection molding and set as Integral, thereby constituting the blade 1 is implemented; the shaft disc 201, the radial support 202, and the ring 203 are all made of plastics, and are all made by injection molding to form an integral body, thereby constituting the transmission connection plate 2. Implemented; then the blade 1 is fixedly connected to the transmission connection plate 2 for implementation; the expected good effect is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com