Defect detection device for OLED

A defect detection and detection device technology, applied in the direction of single semiconductor device testing, etc., can solve problems such as mass production, and achieve the effects of ensuring the quality of inspection, reducing fatigue, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

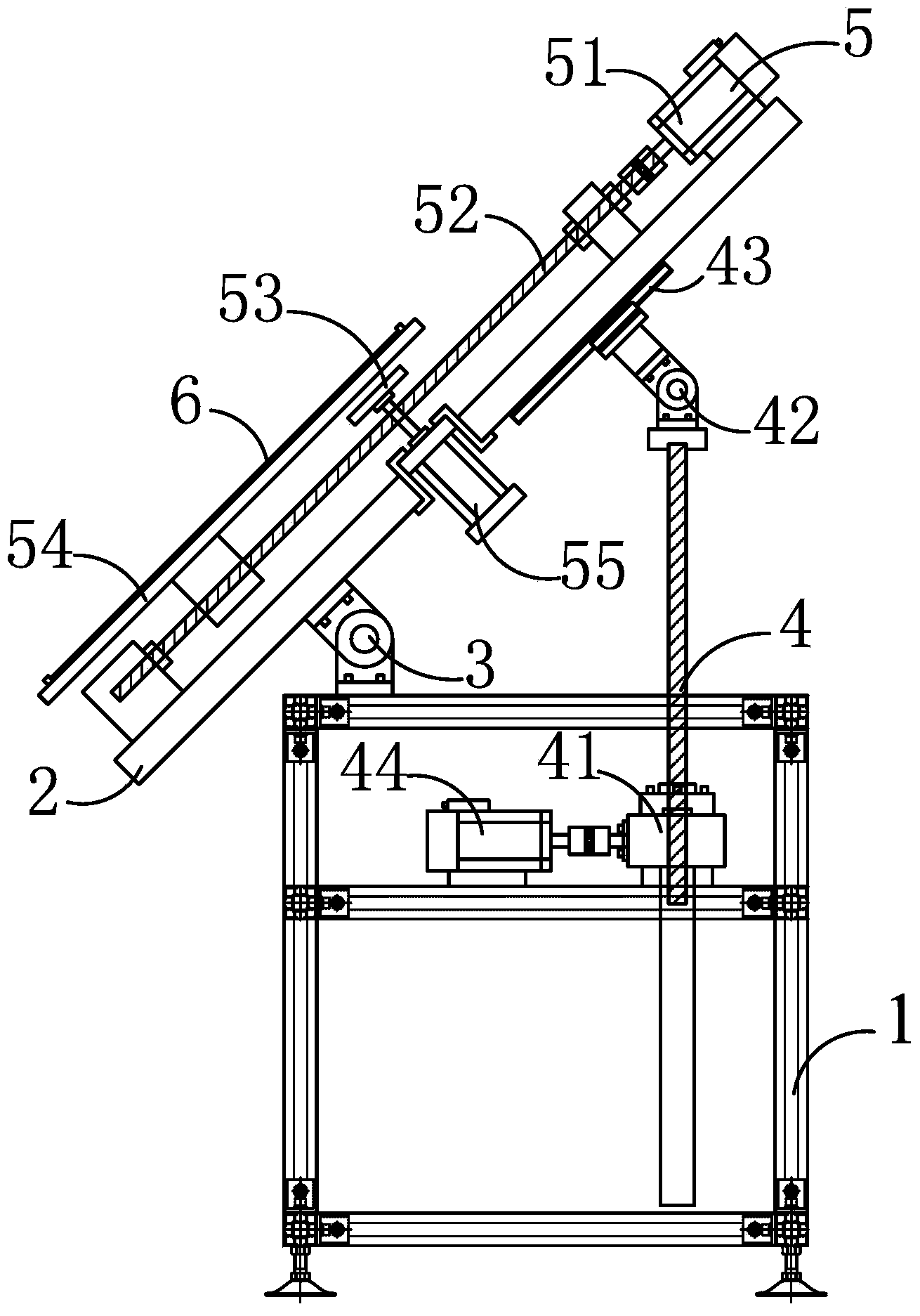

[0016] Such as figure 1 As shown, the OLED defect detection device of this embodiment includes a frame 1 , a mounting plate 2 , a posture adjustment assembly 4 , a detection adjustment assembly 5 , a clamping back plate 54 and a probe assembly 55 . The mounting bracket 2 is movably connected with the frame 1 through the fixed joint 3 , so that the mounting bracket 2 has a degree of freedom of rotation in a vertical plane relative to the frame 1 . The posture adjustment assembly 4 is connected between the frame 1 and the mounting pallet 2, and adjusts the inclination of the mounting pallet 2 by adjusting the rotation angle of the mounting pallet 2 in the vertical plane. The clamping backplane 54 is used to fix the OLED display screen, the clamping backplane 54 is connected with the detection and adjustment assembly 5, the detection and adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com