Aluminum rod surface oxidation layer removing device

A surface oxidation, aluminum rod technology, applied in the direction of feeding devices, metal processing machinery parts, metal processing, etc., can solve the problem of removing the oxide layer of aluminum rods or aluminum tubes, affecting the conductivity of aluminum, affecting the bonding strength of aluminum and copper, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

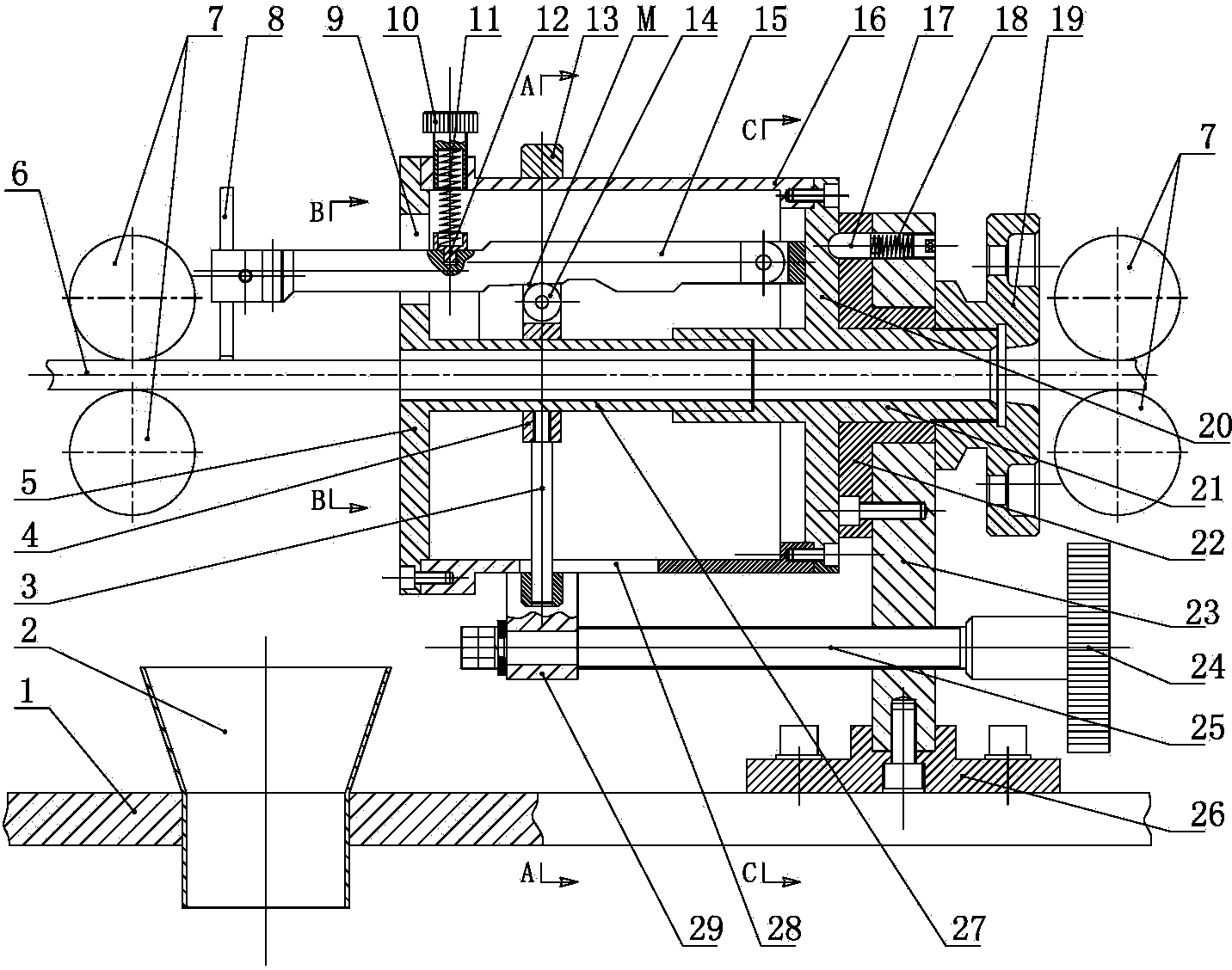

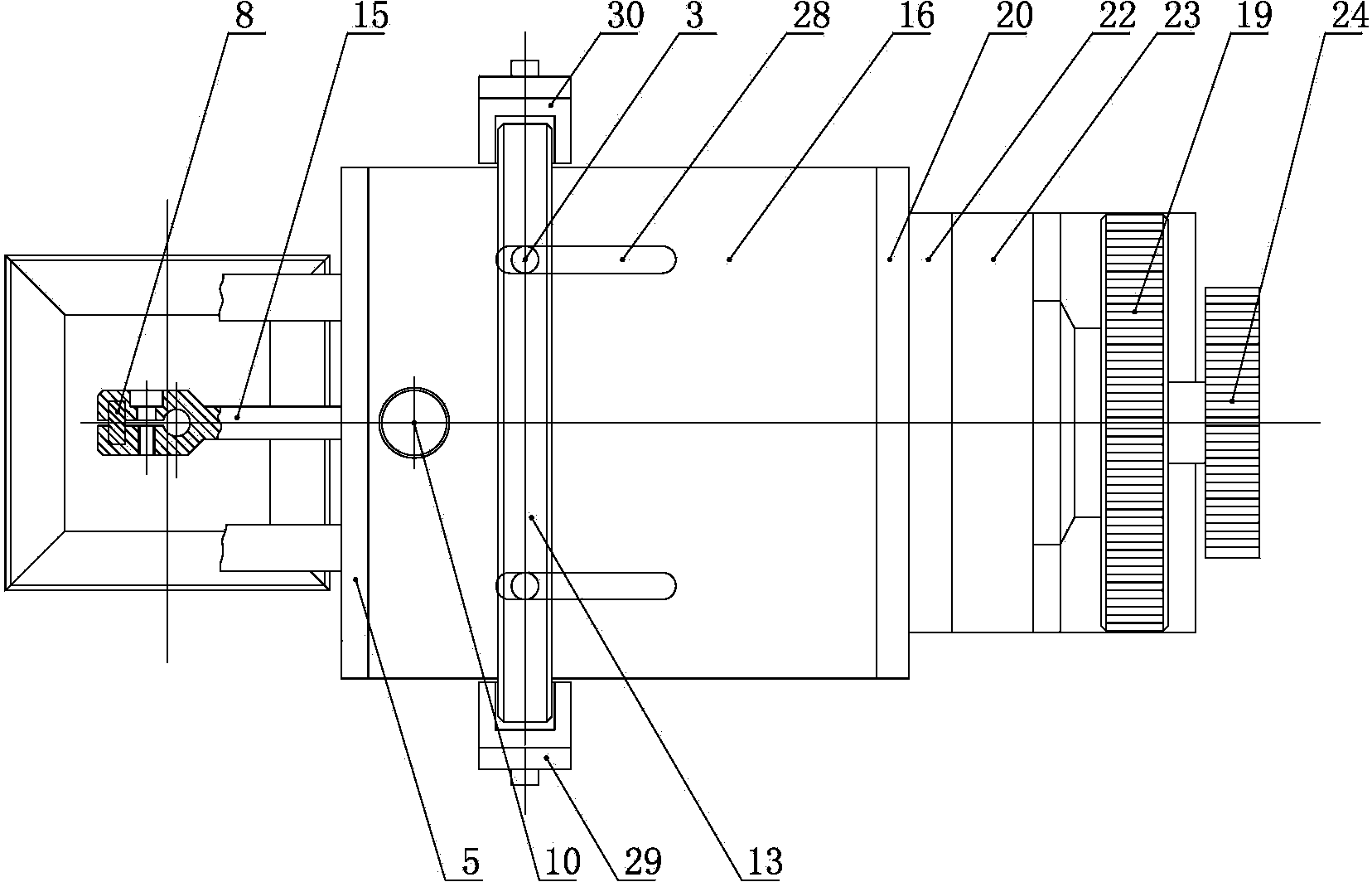

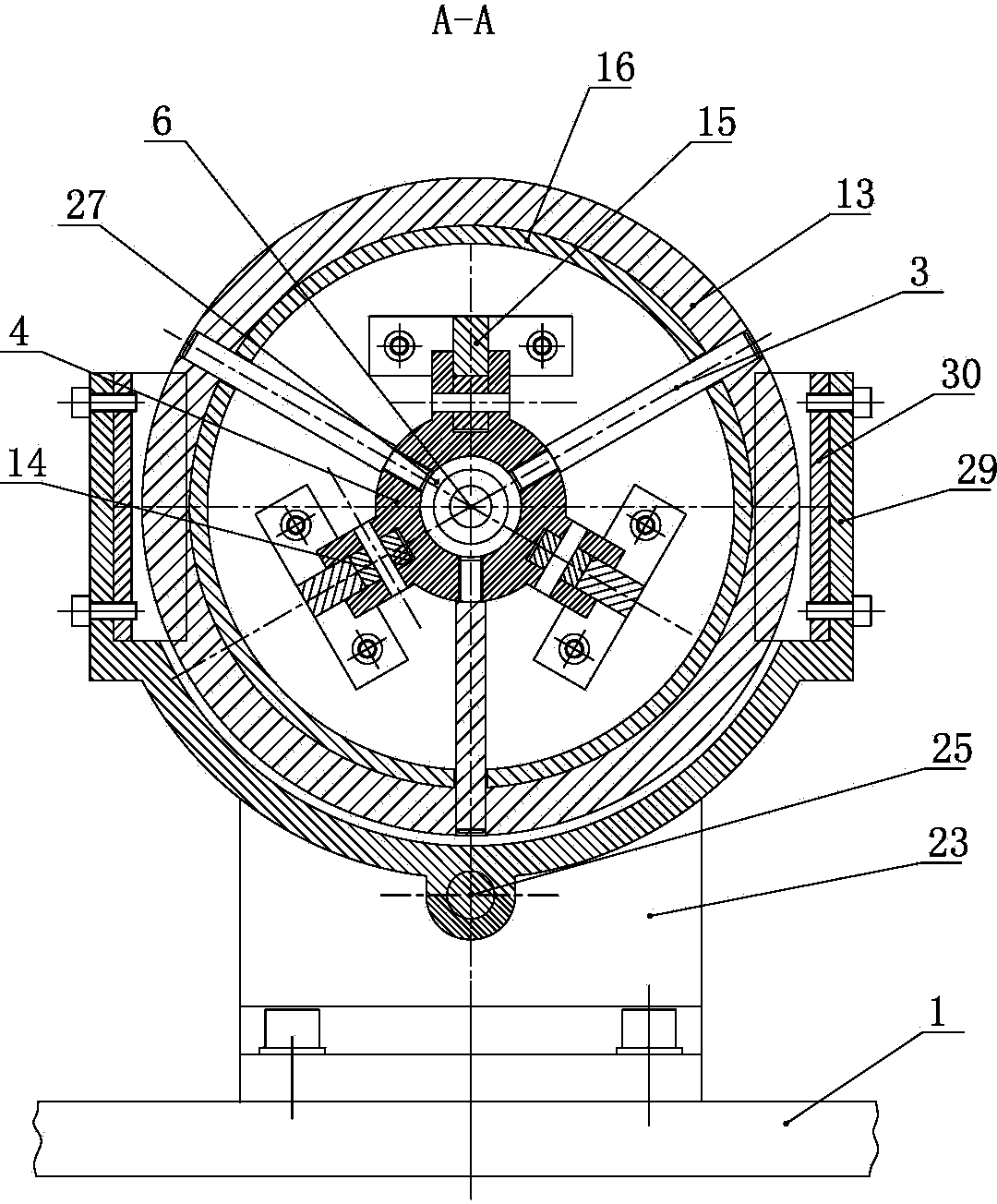

[0022] like Figure 1-6As shown, it is an oxide layer removal device on the surface of an aluminum rod, which includes two guide wheel sets 7, and a machine base 1 is arranged below the two guide wheel sets 7, and a fuselage is fixed on the machine base 1 via a seat plate 26 and a support plate 23. The seat plate 26 and the support plate 23 can be directly connected as one, and the body includes a housing 16, which is cylindrical or other shapes, and the two ends of the housing 16 are correspondingly provided with a left end plate 5 and a right end plate 20, The center of the housing 16 is provided with a hollow mandrel 27. The mandrel 27 is located on the same axis as the two guide wheel sets 7 and can accommodate the aluminum rod 6 to pass through. The sliding ring 4 is equipped with an outer sliding ring 13 that can slide axially along the outer surface of the housing 16 outside the housing 16. A chute 28 that runs through the inner and outer walls of the housing 16 is axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com