Large-inclination wavy-retaining-edge conveying belt and processing method thereof

A processing method and a technology with a large inclination angle, applied in the directions of conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems of base belt edge wear, poor strength and rigidity, unsafe, etc., to prevent blistering, delamination, increase Strength, good tear-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

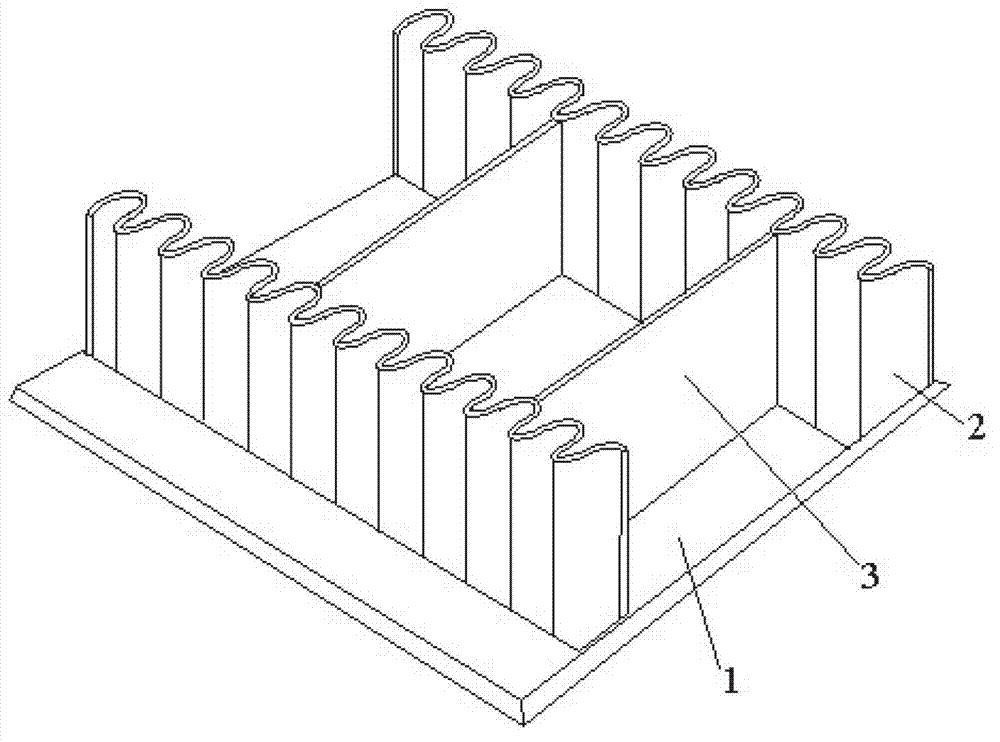

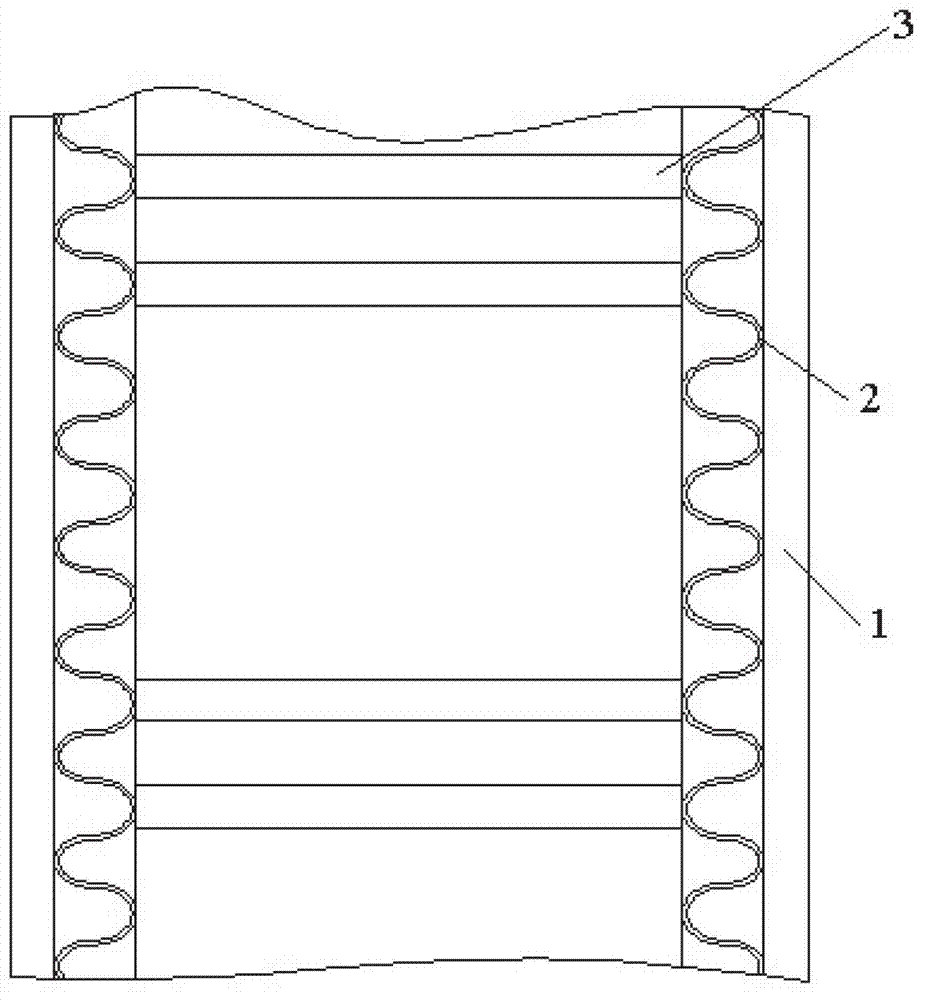

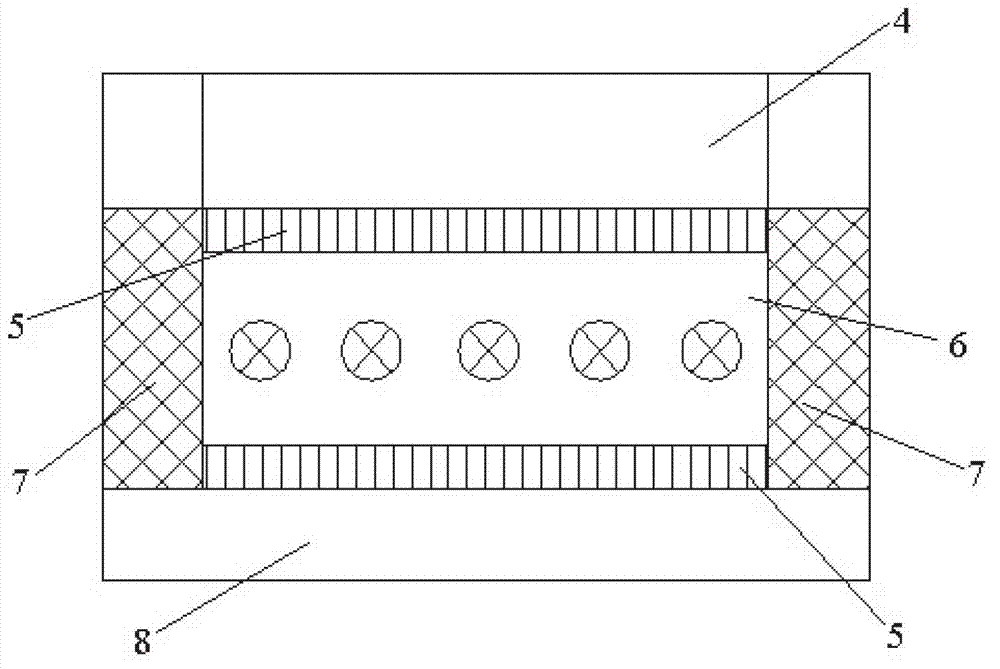

[0050] like Figure 1~3Shown, a large inclination angle corrugated sidewall conveyor belt, including a base belt 1, a sidewall 2 and a transverse partition 3, the base belt 1 is composed of an upper cover rubber layer 4, a latitudinal steel cord anti-corrosion layer arranged sequentially from top to bottom The tear layer 5, the steel cord skeleton layer 6, the edge rubber layer 7 and the lower covering rubber layer 8 are bonded and molded at one time and then vulcanized to form a composite rubber layer; the steel cord skeleton layer 6 is embedded with multiple horizontally uniform The steel wires are arranged, and the steel wires are embedded in the middle of the steel cord skeleton layer 6 and located in the same plane; the edge rubber layer 7 is arranged on the side of the steel cord skeleton layer 6 .

[0051] Both sides of the base belt 1 are symmetrically provided with corrugated sidewalls 2 fixed by secondary vulcanization bonding; the transverse partitions 3 are multipl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com