Down fabric and preparation method thereof

A technology of down fabrics and fabrics, applied in the field of textiles and garments, can solve the problems of non-environmental protection, cohesive force, complicated process, and easy leakage of down fabrics, etc., and achieve the effect of not being easy to tear, simple process, and good warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

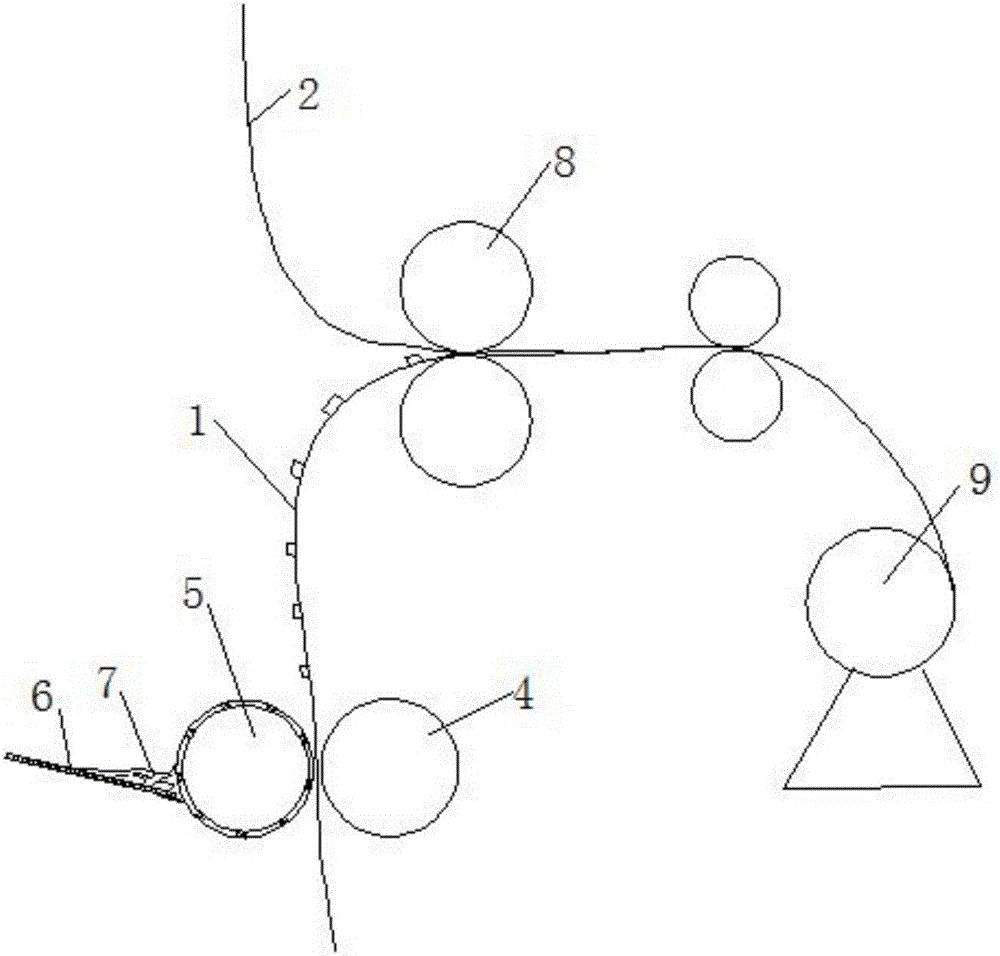

[0046] Such as figure 1 The production process diagram for the down fabric includes the following steps:

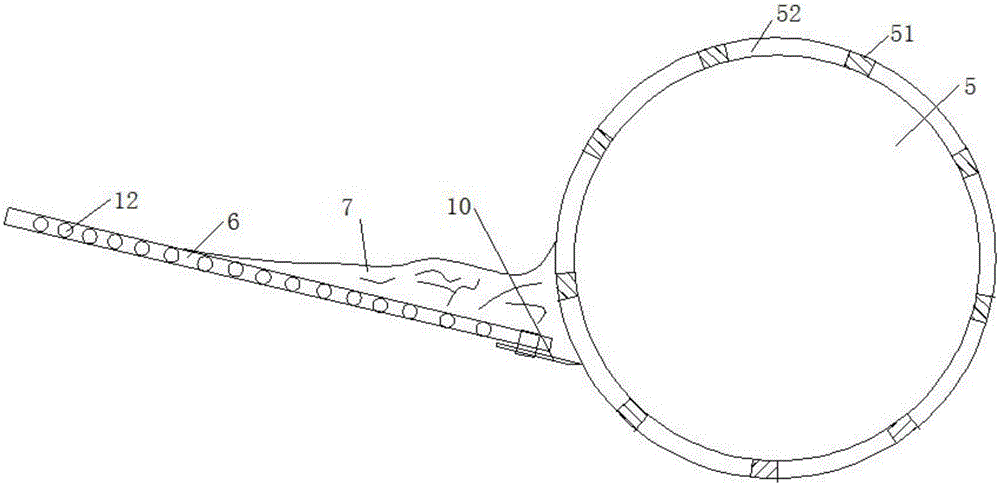

[0047] Step 1: The inner layer fabric 1 is subjected to a local gluing process, so that one side is distributed with a bonding layer 3 at a certain distance. The gluing process includes a pressure roller 4 and a rubber roller 5. The inner layer Fabric 1 passes between the two rollers, such as image 3 As shown, the upper rubber roller 5 has a plurality of strip grooves 51 uniformly distributed along the axial direction;

[0048] Step 2: Composite the side of the fabric obtained in step 1 with the adhesive layer 3 on it and the outer fabric 2;

[0049] Step 3: Wind the composited fabric in Step 2 and place it in a constant temperature and constant room environment to obtain the down fabric.

[0050] Such as image 3 and Figure 4 As shown, the area other than the strip groove 51 on the upper rubber roller 51 is a smooth surface 52, and a plurality of grooves 53 are ev...

Embodiment 2

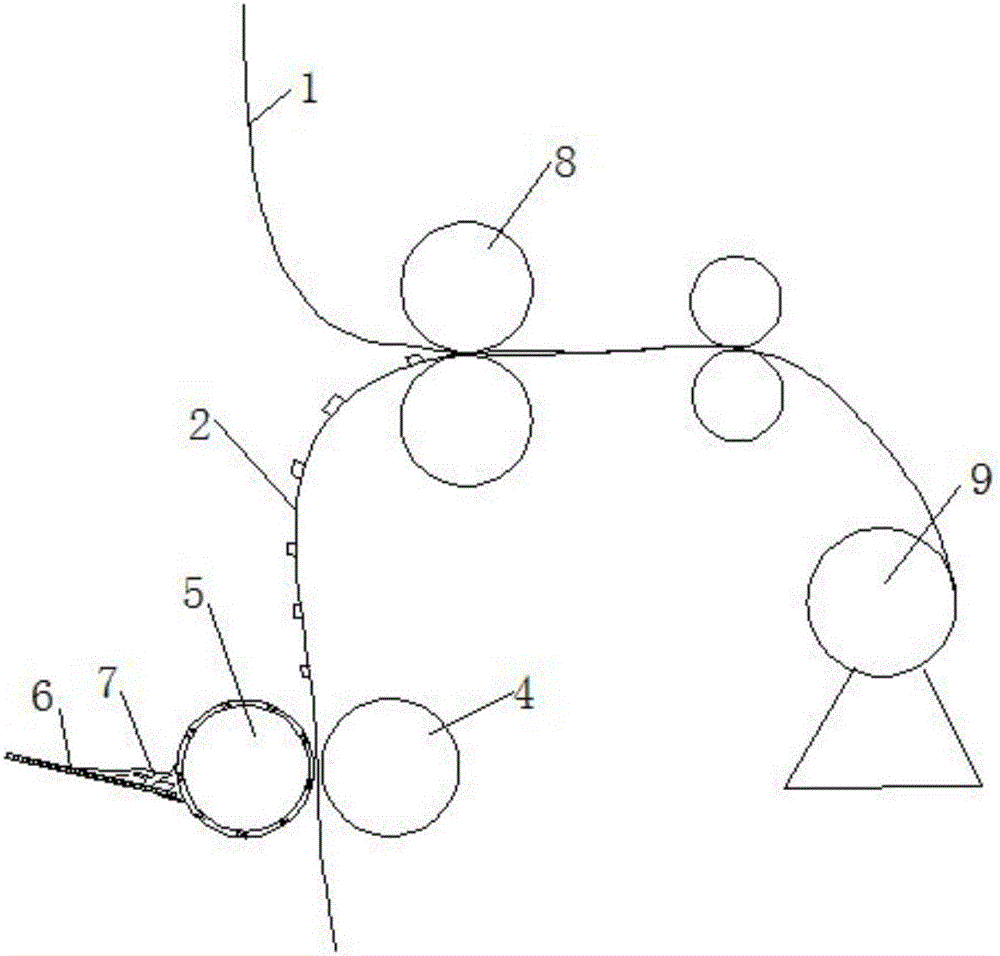

[0063] Such as figure 2 The production process diagram for the down fabric includes the following steps:

[0064] Step 1: The outer layer fabric 2 is subjected to a local gluing process, so that one side is distributed with a bonding layer 3 at a certain distance. The gluing process includes a pressure roller 4 and a rubber roller 5. The outer layer Fabric 2 passes between the two rollers, such as image 3 As shown, the upper rubber roller 5 has a plurality of strip grooves 51 uniformly distributed along the axial direction;

[0065] Step 2: Compositing the side of the fabric obtained in step 1 with the adhesive layer 3 on it and the inner fabric 1;

[0066] Step 3: Wind the composited fabric in Step 2 and place it in a constant temperature and constant room environment to obtain the down fabric.

[0067] Such as image 3 and Figure 4 As shown, the area other than the strip groove 51 on the upper rubber roller 51 is a smooth surface 52, and a plurality of grooves 53 are...

Embodiment 3

[0080] Such as figure 1 The production process diagram for the down fabric includes the following steps:

[0081] Step 1: The inner layer fabric 1 is subjected to a partial gluing process, so that one side is distributed with a bonding layer 3 at a certain distance. The gluing process includes a pressure roller 4 and a rubber roller 5. The inner layer Fabric 1 passes between the two rollers, such as image 3 As shown, the upper rubber roller 5 has a plurality of strip grooves 51 uniformly distributed along the axial direction;

[0082] Step 2: Composite the side of the fabric obtained in step 1 with the adhesive layer 3 on it and the outer fabric 2;

[0083] Step 3: Wind the composited fabric in Step 2 and place it in a constant temperature and constant room environment to obtain the down fabric.

[0084] Such as image 3 and Figure 4 As shown, the area other than the strip groove 51 on the upper rubber roller 51 is a smooth surface 52, and a plurality of grooves 53 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com