Reactive type flame-retardant vinyl ester resin having synergistic effect and preparation method thereof

A vinyl ester resin, reactive flame retardant technology, applied in the field of vinyl ester resin, can solve the problems of low flame retardant efficiency, unstable performance, poor operability, etc., achieve high flame retardant efficiency, ensure stability, and construction performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

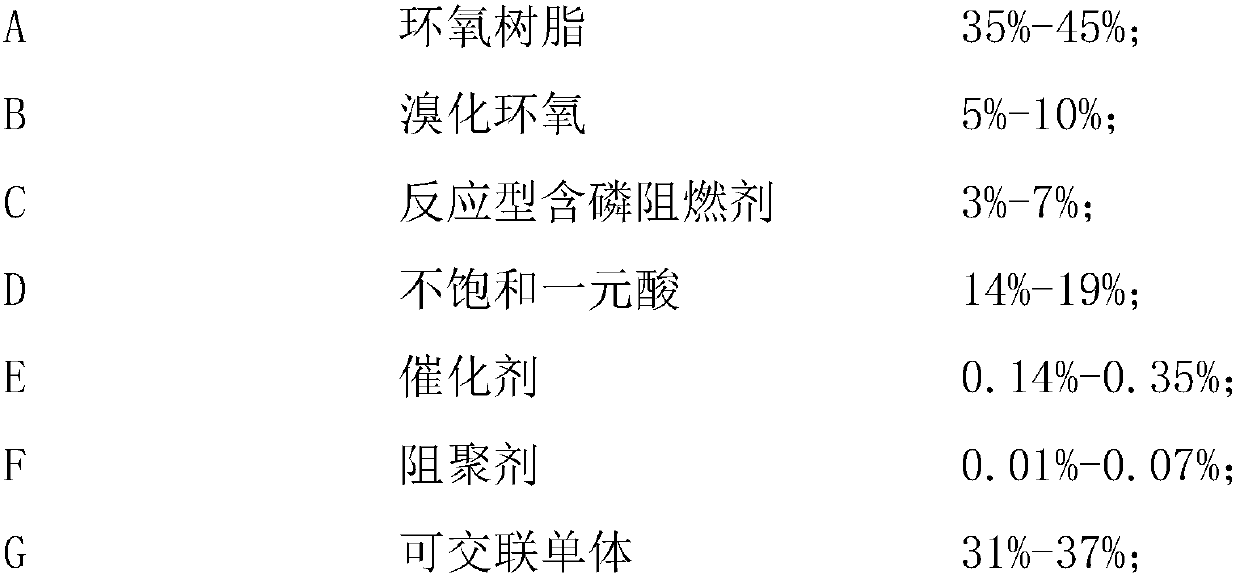

[0027] Weigh each component according to the following mass:

[0028]

[0029] Put raw materials A, B, and C into the reactor, react at 140°C for 2 hours, then add D, E, react at 120°C for 2 hours, add F, G after cooling down to room temperature, stir evenly at high speed, and seal save.

Embodiment 2

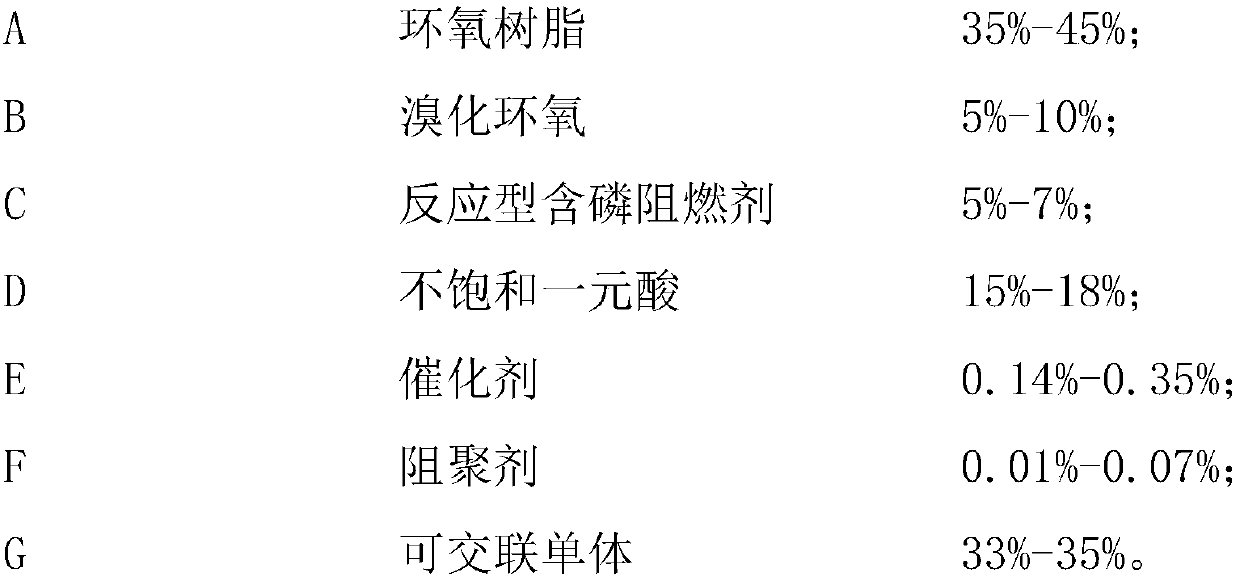

[0031] Weigh each component according to the following mass:

[0032]

[0033] Put raw materials A, B, and C into the reactor, react at 120°C for 2.5 hours, then add D, E, react at 125°C for 2 hours, add F, G after cooling down to room temperature, stir evenly at high speed, and seal save.

Embodiment 3

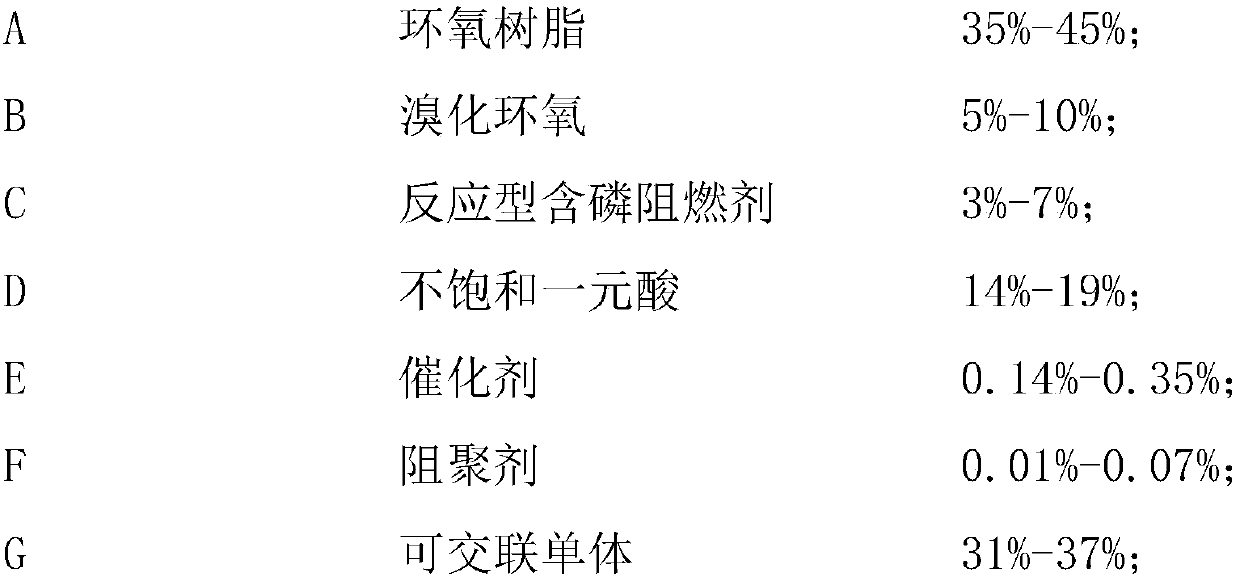

[0035] Weigh each component according to the following mass:

[0036]

[0037] Put raw materials A, B, and C into the reactor, react at 110°C for 3 hours, then add D, E, react at 105°C for 4 hours, add F, G after cooling down to room temperature, stir evenly at high speed, and seal save.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com