Mortise-tenon type rubber farmland cofferdam plate

A mortise and tenon type and coaming technology, which is applied in agriculture, agricultural machinery, agricultural machinery and machine tools, etc., can solve the problems of long labor hours, waste, water leakage for seedling cultivation, etc., and achieve stable installation, convenient use, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

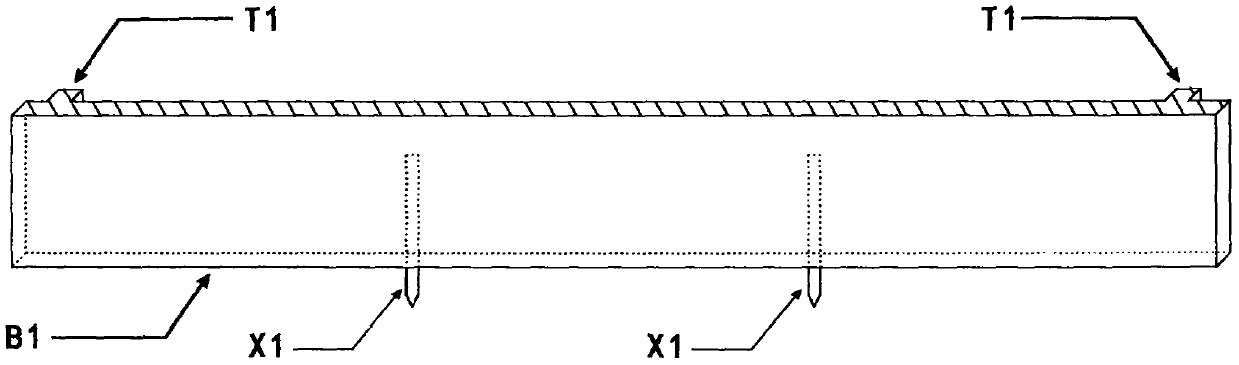

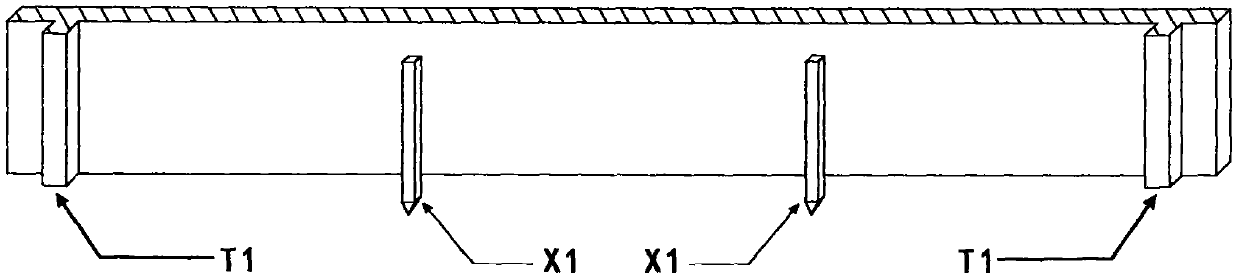

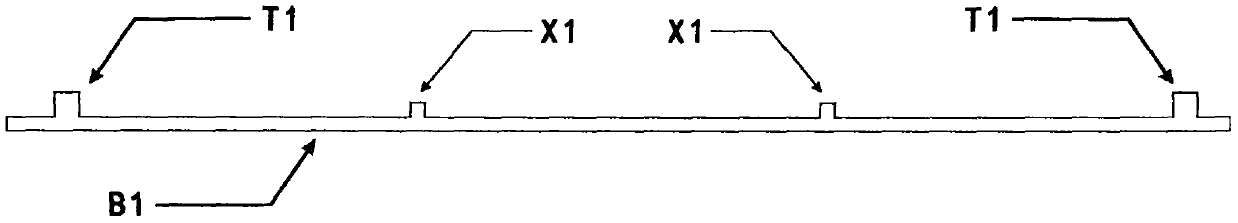

[0022] The board body of the mortise and tenon rubber farmland hoarding board is formed by one-time rectification, and the two ends of the board body are molded with convex protrusions (T1). Reinforcement support wedge strips (X1) are molded at three equal parts of the plate body. The card body of the double-concave rubber mortise and tenon card is formed by one-time pressing, and the middle part of the card body is molded with a double-concave groove (A1). When the coaming board is connected with the double concave rubber mortise and tenon card, the convex protrusion and the concave groove are integrated into one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com