Non-bright, anti-fingerprint and scraping-resistant single-side adhesive tape for conductive fabric and preparation method

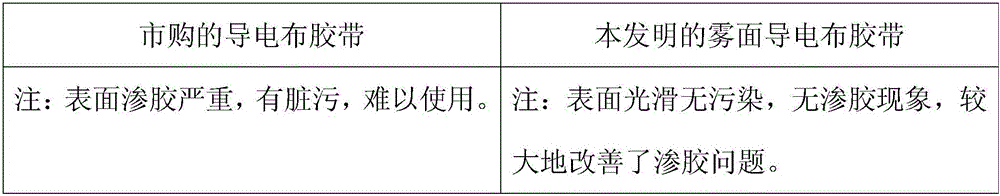

A conductive cloth, anti-fingerprint technology, applied in conductive adhesives, adhesives, adhesive types, etc., can solve the problems that restrict the large-scale application of conductive cloth materials, poor bending resistance and tensile strength, and shorten the use of electronic products. life and other issues, to achieve good market application prospects, good conformability and softness, and easy industrialization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

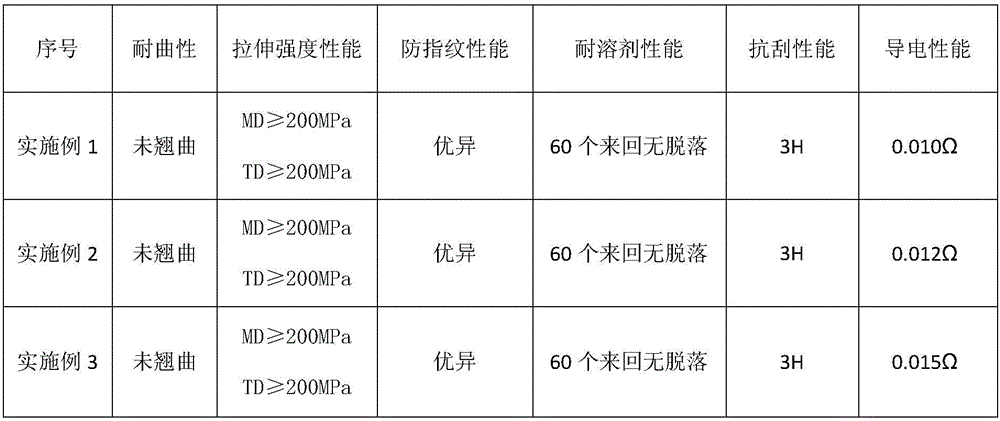

Embodiment 1

[0042] A1. Stir 100-150 parts of polyurethane resin, 20-30 parts of ethyl acetate, 6-9 parts of polyisocyanate curing agent, 3-5 parts of nano-calcium carbonate toughening agent, and 3-5 parts of cellulose acetate butyrate leveling agent Mix evenly to make a polyurethane coating and set aside;

[0043] A2, fully filter the polyurethane coating prepared in step A1 with a 400-mesh filter cloth, and seal it for use after filtering;

[0044] A3. Clean the conductive cloth material to remove oil and impurities on the surface;

[0045] A4. Polyurethane coating is applied on the surface of the conductive cloth by means of mesh coating;

[0046] A5. Put the conductive cloth coated with polyurethane coating into the oven to mature, so as to increase the curing speed and shorten the film forming time;

[0047] A6. Make an ink treatment layer with 100-150 parts of ink, 20-30 parts of ethyl acetate, 5-7 parts of epoxy resin curing agent, and 4-5 parts of acrylic leveling agent for use; ...

Embodiment 2

[0060] This embodiment is roughly the same as Example 1, and the difference is only that the raw material parts by weight of the polyurethane film coating, the ink treatment layer, the functional coating and the conductive adhesive layer are different, wherein the components of the polyurethane film coating It is: 100 parts of polyurethane resin, 20 parts of ethyl acetate, 6 parts of polyisocyanate curing agent, 3 parts of nano-calcium carbonate toughening agent, 3 parts of cellulose acetate butyrate leveling agent; the components of ink treatment layer are: ink 100 parts, 20 parts of ethyl acetate, 5 parts of epoxy resin curing agent and 4 parts of acrylic leveling agent; functional coating components are: 100 parts of anti-scratch and anti-fingerprint solution, 20 parts of ethyl acetate and 3 parts of silica matting agent ; The components of the conductive adhesive layer are: 100 parts of acrylic resin, 10 parts of epoxy group curing agent, 30 parts of toluene, 3 parts of con...

Embodiment 3

[0062] This embodiment is roughly the same as Example 1, and the difference is only that the raw material parts by weight of the polyurethane film coating, the ink treatment layer, the functional coating and the conductive adhesive layer are different, wherein the components of the polyurethane film coating It is: 150 parts of polyurethane resin, 30 parts of ethyl acetate, 9 parts of polyisocyanate curing agent, 5 parts of nano-calcium carbonate toughening agent, 5 parts of cellulose acetate butyrate leveling agent; the components of the ink treatment layer are: 150 parts of ink, 30 parts of ethyl acetate, 7 parts of epoxy resin curing agent and 5 parts of acrylic leveling agent; functional coating components are: 15 parts of anti-scratch and anti-fingerprint solution, 30 parts of ethyl acetate and 5 parts of silica matting agent ; The components of the conductive adhesive layer are: 150 parts of acrylic resin, 15 parts of epoxy group curing agent, 40 parts of toluene, 6 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com