Organic boron silicon adhesion promoter with high refractive index as well as preparation method and application of organic boron silicon adhesion promoter

An adhesion promoter and high refractive index technology, applied in the direction of polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problem of difficult control of reaction conditions, easy ring opening of epoxy groups, poor compatibility of silica gel, etc. Problems, to achieve the effect of cheap raw materials, good bonding performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 21.63g of diphenylsilanediol, 8.28g of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 8.13g of 3-methacryloxypropyltrimethoxysilane, 3.12g of boric acid trimethoxysilane Add methyl ester and 20g of toluene into a 250mL three-necked flask equipped with a thermometer, mechanical stirring, and a condensing reflux tube, stir well at room temperature, add 0.41g of tetraethyl titanate, control the reaction temperature at 30°C, react for 12h, and then control the vacuum The temperature is 0.06MPa, the temperature is 90°C, and the reaction is continued for 6h to obtain adhesion promoter 1 with a refractive index of 1.541.

[0024] 100 parts by mass of vinyl phenyl silicone resin with a vinyl content of 4 wt%, 15 parts by mass of vinyl phenyl silicone oil with a viscosity of 500mPa·s, 30 parts by mass of phenyl hydrogen-containing silicone oil with an active hydrogen content of 0.45 wt%, 3 parts by mass of adhesion promoter 1 and 0.02 parts by mass of 1-ethynyl-1-cyclohexanol were ...

Embodiment 2

[0026] 21.63g of diphenylsilanediol, 11.14g of 3-(2,3-epoxypropoxy)propyltriethoxysilane, 14.52g of 3-methacryloxypropyltriethoxysilane, 2.92g Add triethyl borate and 30g of xylene into a 250mL three-necked flask equipped with a thermometer, mechanical stirring and a condensing reflux tube, stir well at room temperature, add 0.25g of tetraisopropyl titanate, control the reaction temperature at 50°C, and react for 10h , and then control the vacuum degree to 0.08MPa, the temperature to 100°C, and continue the reaction for 4h to obtain adhesion promoter 2 with a refractive index of 1.537.

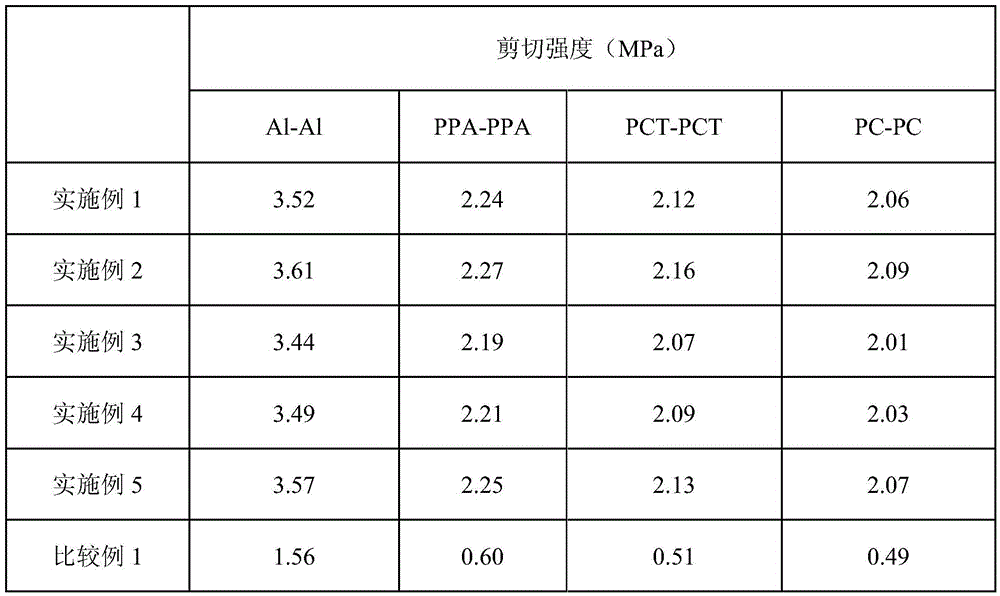

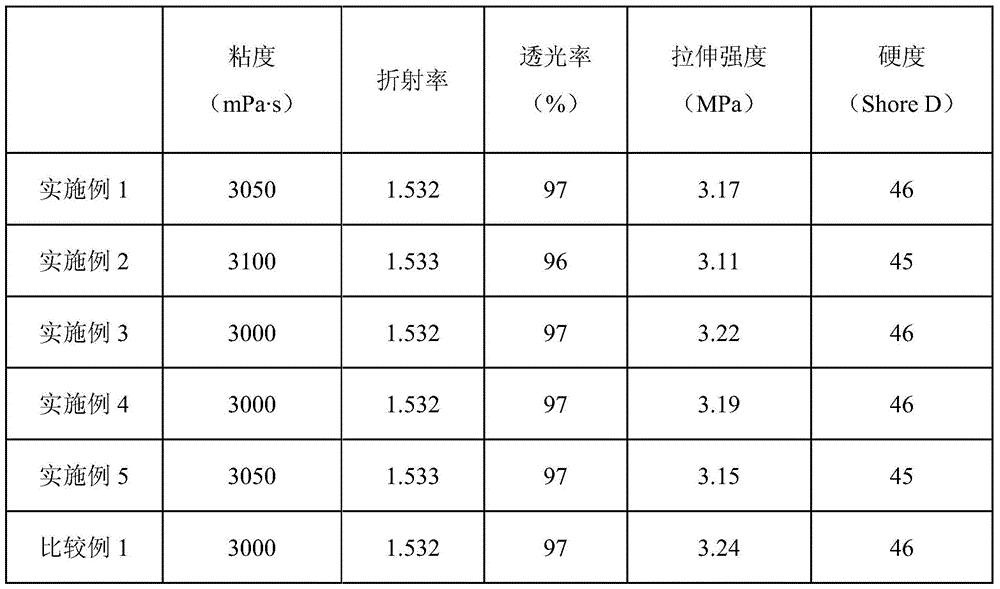

[0027] The adhesion promoter 1 in Example 1 was changed to the adhesion promoter 2, and the dosage was 4 parts by mass. The properties of the samples are shown in Table 1 and Table 2.

Embodiment 3

[0029] 21.63g of diphenylsilanediol, 4.93g of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 18.58g of 3-methacryloxypropyltrimethoxysilane, 1.88g Add tri-n-propyl borate and 40g of acetone into a 250mL three-neck flask equipped with a thermometer, mechanical stirring and a condensing reflux tube, stir well at room temperature, add 0.94g of tetra-n-butyl titanate, control the reaction temperature at 40°C, and react for 8h , and then control the vacuum degree to 0.06MPa, the temperature to 110°C, and continue the reaction for 3h to obtain adhesion promoter 3 with a refractive index of 1.539.

[0030] The adhesion promoter 1 in Example 1 was changed to the adhesion promoter 3, and the dosage was 2 parts by mass. The properties of the samples are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com