Organosilicon bonding promoter for LED packaging high-refractive-index addition-type silica gel and preparation method and application of organosilicon bonding promoter

An adhesion promoter, LED packaging technology, applied in the direction of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problem of easy damage to the curing performance of silica gel, light transmittance and mechanical properties, high refractive index addition type packaging Solve the problems of poor compatibility of silica gel and large amount of addition, so as to achieve the effect of easy control of the reaction process, easy control, low mechanical properties and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

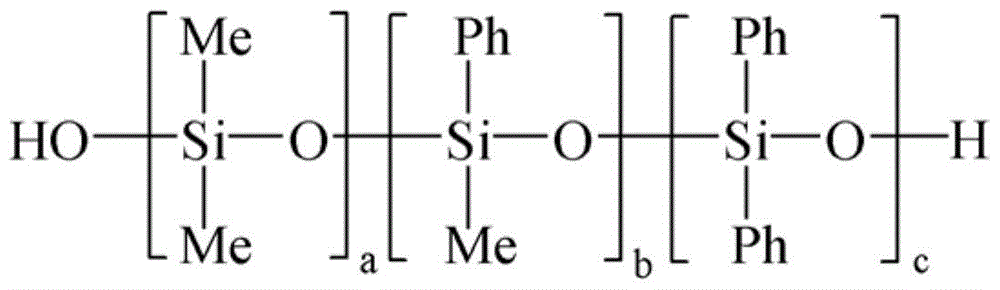

[0027] The 55.93g molecular formula is HO(MePhSiO) 5 H's phenyl hydroxy silicone oil, 11.82g 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 12.42g 3-methacryloxypropyltrimethoxysilane and 60g toluene were added with a thermometer, Mechanically stir and condense a 250mL three-neck flask with a reflux tube, stir evenly at room temperature, add 1.6g tetraisopropyl titanate, react at a temperature of 30°C for 8h, and then continue at a vacuum of 0.08MPa and a temperature of 80°C After reacting for 5 hours, adhesion promoter 1 was obtained with a refractive index of 1.529.

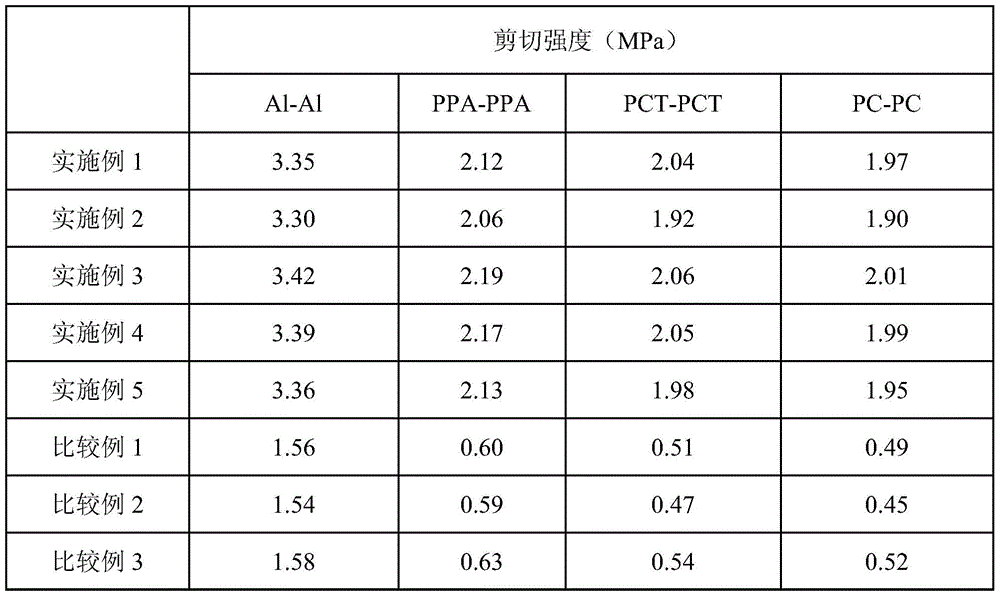

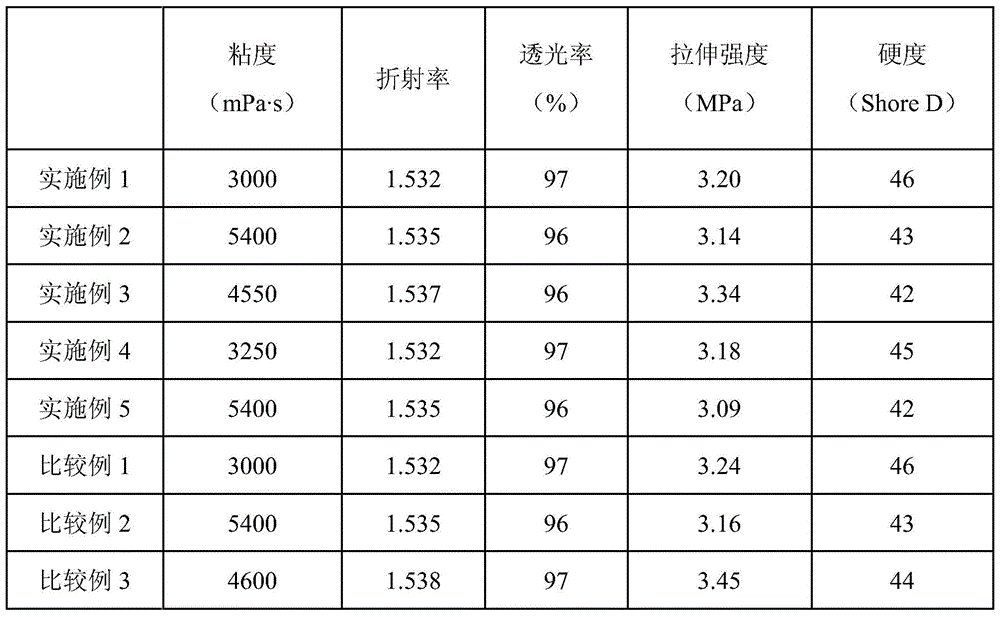

[0028] 100 parts by mass of vinyl phenyl silicone resin with a vinyl content of 4 wt%, 15 parts by mass of vinyl phenyl silicone oil with a viscosity of 500mPa·s, 30 parts by mass of phenyl hydrogen-containing silicone oil with an active hydrogen content of 0.45 wt%, 3 parts by mass of adhesion promoter 1 and 0.02 parts by mass of 1-ethynyl-1-cyclohexanol were mixed uniformly under the action of a high-speed mixe...

Embodiment 2

[0030] The molecular formula of 61.29g is HO(Ph 2 SiO) 3 H's phenyl hydroxy silicone oil, 11.14g 3-(2,3-glycidoxy)propyltriethoxysilane, 17.42g 3-methacryloxypropyltriethoxysilane and 150g xylene were added to the belt In a 500mL three-neck flask equipped with a thermometer, mechanical stirring and condensing reflux tube, stir evenly at room temperature, add 0.45g tetra-n-butyl titanate, react at a temperature of 50°C for 6h, and then vacuum at a degree of 0.06MPa and a temperature of 110 The reaction was continued for 3 hours at °C to obtain adhesion promoter 2 with a refractive index of 1.532.

[0031] 100 parts by mass of vinyl phenyl silicone resin with a vinyl content of 2 wt%, 6 parts by mass of vinyl phenyl silicone oil with a viscosity of 800mPa·s, 14 parts by mass of phenyl hydrogen-containing silicone oil with an active hydrogen content of 0.3 wt%, 2 parts by mass of adhesion promoter 2 and 0.01 parts by mass of 1-ethynyl-1-cyclohexanol were mixed uniformly under t...

Embodiment 3

[0033] The molecular formula of 143.92g is HO(MePhSiO) 4 (Ph 2 SiO) 2 H's phenyl hydroxy silicone oil, 19.71g2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 4.97g3-methacryloxypropyltrimethoxysilane and 350g toluene were added with A 1000mL three-necked flask with a thermometer, mechanical stirring and a condensing reflux tube was stirred evenly at room temperature. The reaction was continued for 2 hours to obtain adhesion promoter 3 with a refractive index of 1.538.

[0034]100 parts by mass of vinyl phenyl silicone resin with a vinyl content of 5 wt%, 30 parts by mass of vinyl phenyl silicone oil with a viscosity of 2000mPa·s, 25 parts by mass of phenyl hydrogen-containing silicone oil with an active hydrogen content of 0.6 wt%, 6 parts by mass of adhesion promoter 3 and 0.008 parts by mass of 1-ethynyl-1-cyclohexanol were mixed uniformly under the action of a high-speed disperser, and then 0.16 parts by mass of platinum-methylphenyl polysiloxane was added Mix the complex ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com