Laser formed polyphthalamide composition and preparation method thereof

A technology of polyphthalamide and composition, which is applied in the field of polyphthalamide composition and its preparation, can solve the problem of not meeting the special process requirements of laser direct forming, and achieves good bonding force, low price, and processing technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

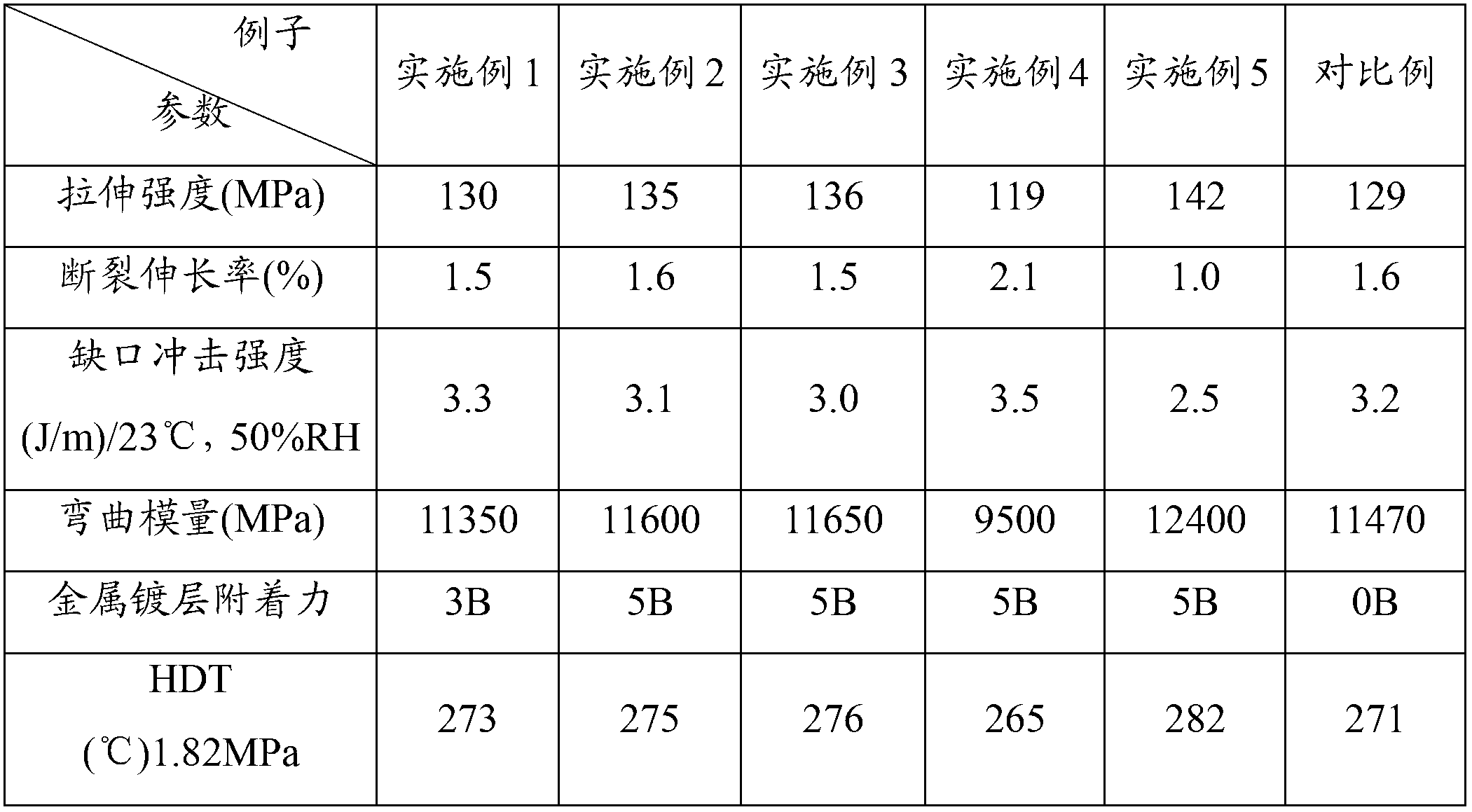

Examples

Embodiment 1

[0050] A polyphthalamide composition, its raw material composition and parts by weight are as follows: polyphthalamide, 63.8 parts; inorganic pigment, 5 parts; nucleating agent, 0.3 part; lubricant, 0.5 part; Oxygen agent, 0.2 parts; Phosphite antioxidant, 0.2 parts; Glass fiber, 30 parts.

[0051] The preparation method of above-mentioned polyphthalamide composition, comprises the steps:

[0052] (1) Dry polyphthalamide at 110-130°C for 3-5 hours, then mix the dried polyphthalamide with inorganic pigments, nucleating agents, hindered phenolic antioxidants, and phosphite antioxidants. The oxygen agent is placed in a mixer and mixed for 20 minutes to obtain a premix;

[0053] (2) Add the premixed material obtained in step (1) into the parallel twin-screw extruder through the feeder, melt and extrude, and add the glass fiber in the sixth zone of the parallel twin-screw extruder. The processing technology is as follows: Parallel The temperature of the twin-screw extruder zone 1...

Embodiment 2

[0056]A polyphthalamide composition, its raw material composition and parts by weight are as follows: polyphthalamide, 60.8 parts; inorganic pigment, 8 parts; nucleating agent, 0.3 part; lubricant, 0.5 part; Oxygen agent, 0.2 parts; Phosphite antioxidant, 0.2 parts; Glass fiber 30 parts.

[0057] The preparation method of above-mentioned polyphthalamide composition, comprises the steps:

[0058] (1) Dry polyphthalamide at 110-130°C for 3-5 hours, then mix the dried polyphthalamide with inorganic pigments, nucleating agents, hindered phenolic antioxidants, and phosphite antioxidants. The oxygen agent is placed in a mixer and mixed for 20 minutes to obtain a premix;

[0059] (2) Add the premixed material obtained in step (1) into the parallel twin-screw extruder through the feeder, melt and extrude, and add the glass fiber in the sixth zone of the parallel twin-screw extruder. The processing technology is as follows: Parallel The temperature of the twin-screw extruder zone 1 i...

Embodiment 3

[0062] A polyphthalamide composition, its raw material composition and parts by weight are as follows: polyphthalamide, 58.8 parts; inorganic pigment, 10 parts; nucleating agent, 0.3 part; lubricant, 0.5 part; Oxygen agent, 0.2 parts; Phosphite antioxidant, 0.2 parts; Glass fiber 30 parts.

[0063] The preparation method of above-mentioned polyphthalamide composition, comprises the steps:

[0064] (1) Dry polyphthalamide at 110-130°C for 3-5 hours, then mix the dried polyphthalamide with inorganic pigments, nucleating agents, hindered phenolic antioxidants, and phosphite antioxidants. The oxygen agent is placed in a mixer and mixed for 20 minutes to obtain a premix;

[0065] (2) Add the premixed material obtained in step (1) into the parallel twin-screw extruder through the feeder, melt and extrude, and add the glass fiber in the sixth zone of the parallel twin-screw extruder. The processing technology is as follows: Parallel The temperature of the twin-screw extruder zone 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com