Polyphthalamide (PPA) composite material with high temperature resistance and abrasion resistance and preparation method of PPA composite material

A technology of polyphthalamide and phthalamide, which is applied in the field of polyphthalamide composite materials and its preparation, can solve problems such as low lifespan and unstable mechanical properties, and ensure mechanical properties and durability Effect of thermal wear resistance, surface gloss and dimensional stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

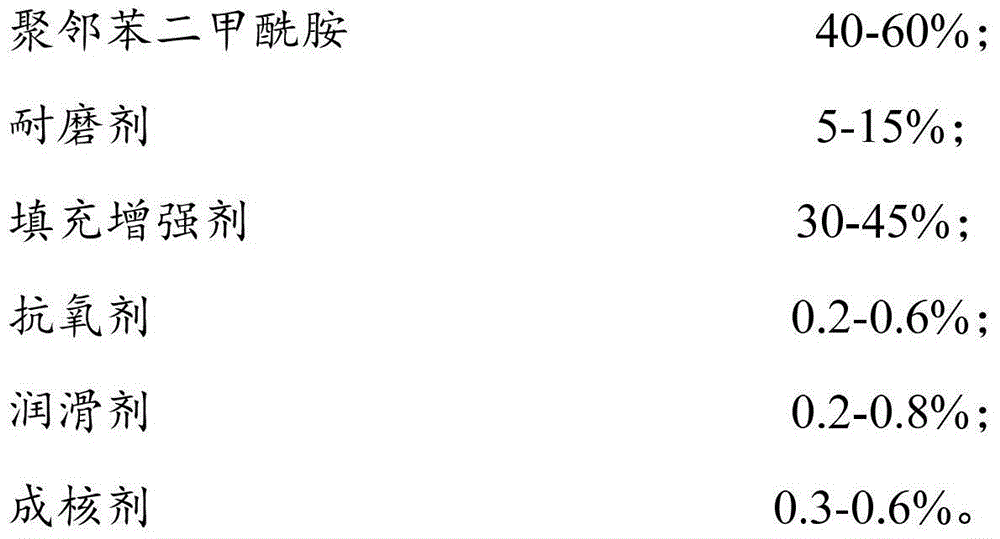

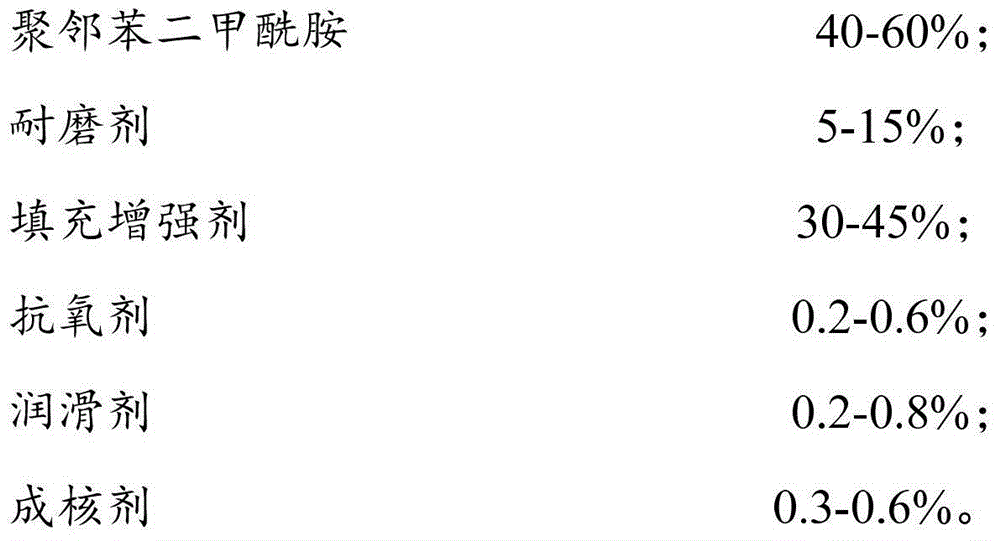

Method used

Image

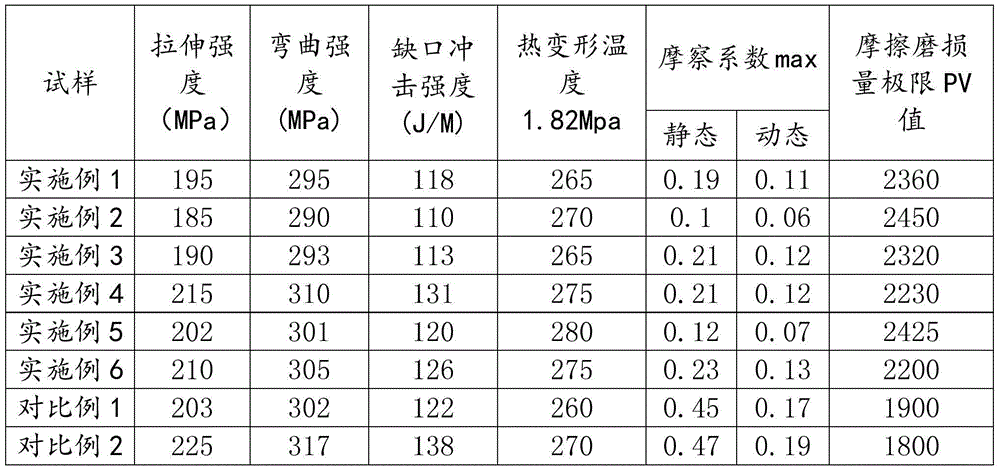

Examples

preparation example Construction

[0037] The preparation method comprises the steps of:

[0038] S101, the step of weighing raw materials. Each raw material is weighed according to the mass ratio of the raw materials of the high-temperature and wear-resistant polyphthalamide composite material.

[0039] S102, a drying treatment step. The raw materials taken symmetrically are dried.

[0040] S103, the initial mixing step. Put the dried polyphthalamide into the mixer, then add antioxidant, lubricant and nucleating agent, and mix thoroughly.

[0041] S104, a remixing step. Add the anti-wear agent into the mixer and mix thoroughly again. After the mixing is completed, the obtained material is put into a drying oven for drying treatment.

[0042] S105. Melting and granulating step. The dried material is put into a twin-screw extruder, melted and reacted, and glass fiber is added to carry out reinforced filling extrusion granulation, wherein the glass fiber is added from the fourth section of the twin-screw ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com