High-temperature-resistant nylon composite material and preparation method thereof

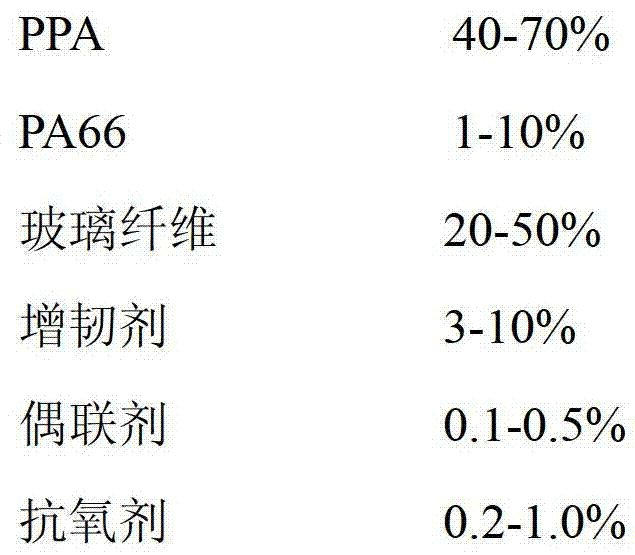

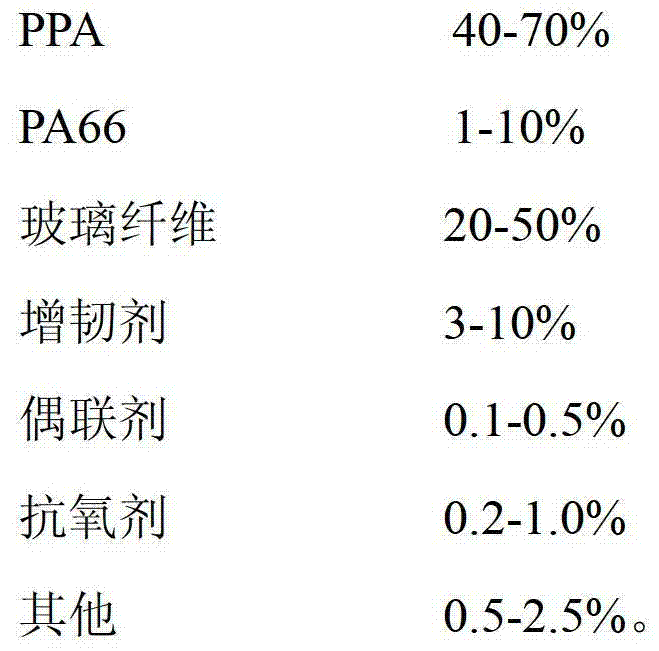

A nylon composite material and composite material technology are applied in the field of high temperature resistant nylon composite material and its preparation, which can solve the problems of difficult processing, limited use range, poor fluidity of PPA resin, etc., and achieve simple preparation process, good heat resistance and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The raw materials are calculated by weight percentage, PPA55% (pre-dried at 120°C for 3 hours), PA66 10% (pre-dried at 110°C for 3 hours), glass fiber 30%, grafted POE 3%, silane coupling agent 560 Add 0.5%, antioxidant 1098 1.0%, high-temperature lubricant PETS 0.5% into the mixer and mix for 10 minutes. Set the temperature of the extruder: Zone 1: 300°C; Zone 2: 300°C; Zone 3: 290°C; Zone 4 Zone: 285℃; Zone 5: 275℃; Zone 6: 270℃; Zone 7: 265℃; Zone 8: 285℃; After being cooled by water in a water tank, blown dry by a blower, it is pulled to a cutting machine to complete granulation, and the product is obtained. After testing, the heat distortion temperature is 290°C and the impact strength is 15.1kJ / m 2 .

Embodiment 2

[0026] The raw materials are calculated by weight percentage, PPA45% (pre-dried at 120°C for 4 hours), PA66 7% (pre-dried at 110°C for 4 hours), glass fiber 40%, grafted POE 5%, silane coupling agent 560 Add 0.5%, antioxidant 1098 0.5%, high-temperature lubricant PETS 2.0% into the mixer and mix for 20 minutes. Set the temperature of the extruder: Zone 1: 305°C; Zone 2: 300°C; Zone 3: 300°C; Zone 4 Zone: 290°C; Zone 5: 280°C; Zone 6: 270°C; Zone 7: 275°C; Zone 8: 285°C; Zone 9: 315°C. After being cooled by water in a water tank, blown dry by a blower, it is pulled to a cutting machine to complete granulation, and the product is obtained. After testing, the heat distortion temperature is 292°C and the impact strength is 15.5kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com