Polyphthalamide reinforced material and preparation method thereof

A technology of polyphthalamide and reinforcing materials, which is applied in the chemical industry and can solve the problems of low flame retardant efficiency and unfavorable mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

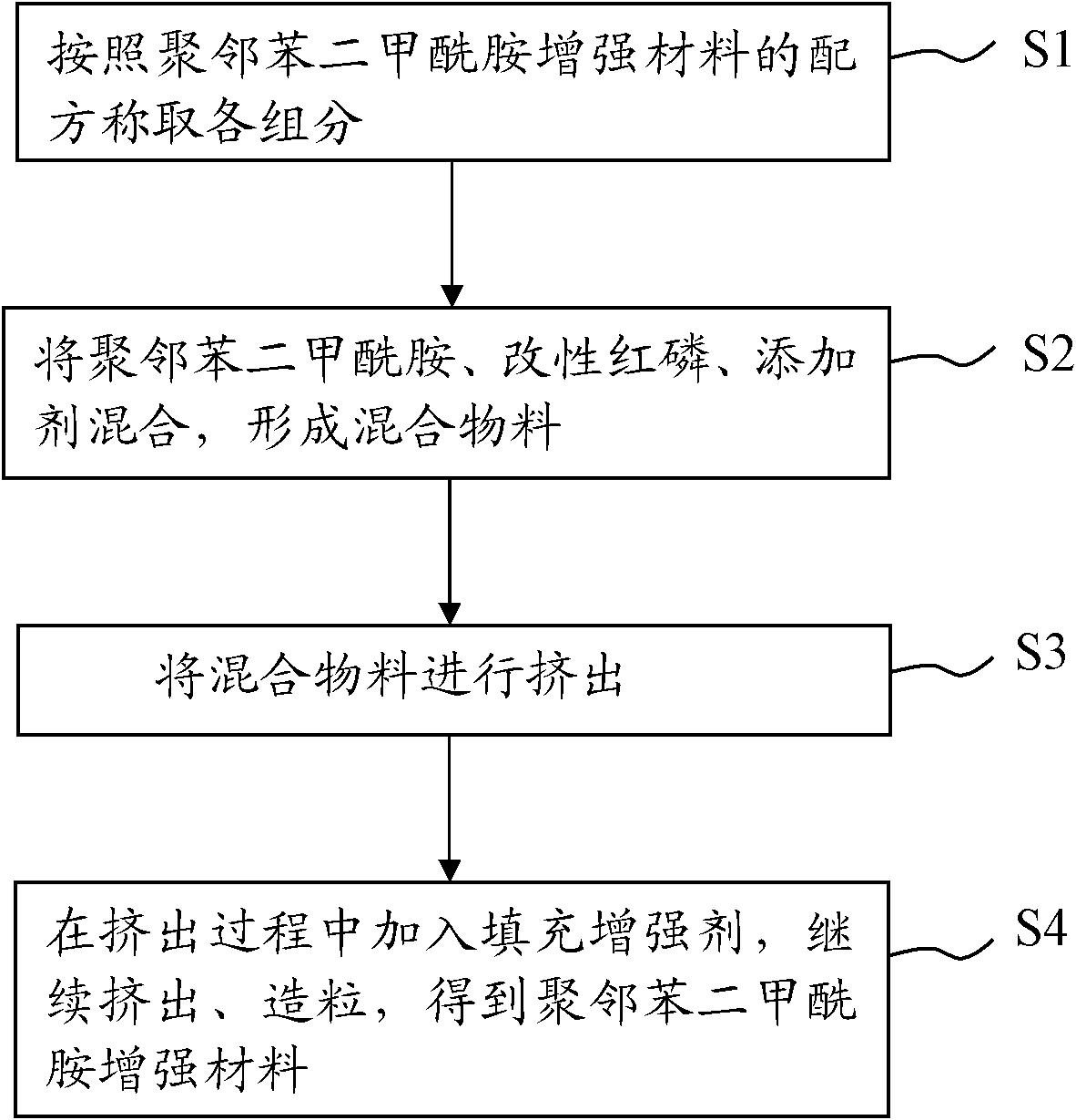

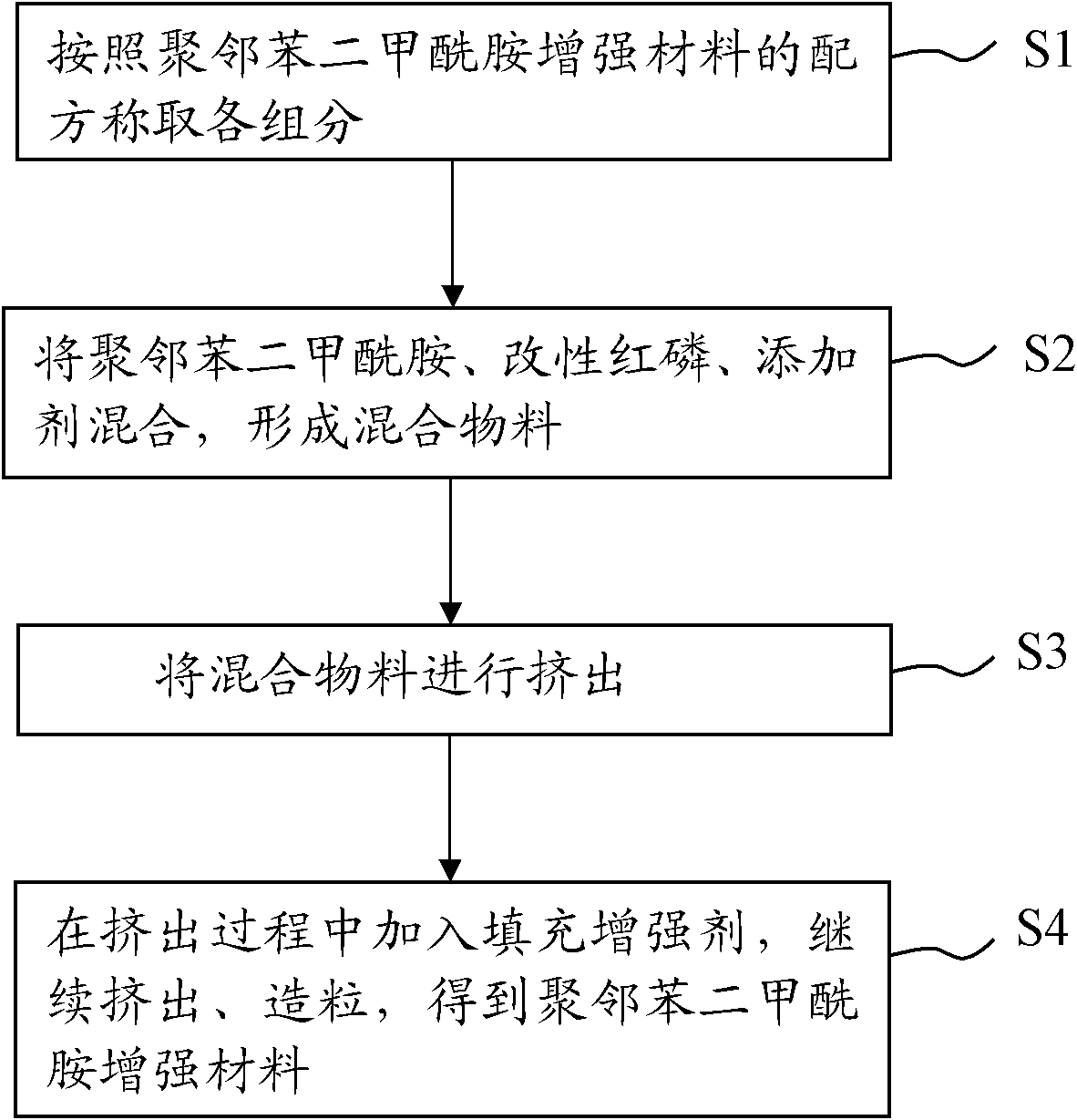

[0039] The present invention also provides the above-mentioned polyphthalamide reinforcing material preparation method, its technical process is as follows figure 1 shown. The method comprises the steps of:

[0040] S1: Weigh each component according to the formula of the above-mentioned polyphthalamide reinforcing material;

[0041] S2: mixing the polyphthalamide, modified red phosphorus, and additives to form a mixed material;

[0042] S3: extruding the mixed material;

[0043] S4: adding a filling reinforcing agent during the extrusion process, continuing to extrude and granulate to obtain the polyphthalamide reinforcing material.

[0044] Specifically, in the step S1 of the preparation method of the above-mentioned polyphthalamide reinforcing material, the formula components included in the polyphthalamide reinforcing material are:

[0045] Polyphthalamide 48~58%

[0046] Modified red phosphorus 6-15%

[0047] Filling enhancer 35~45%

[0048] Additive 1~2%.

[0049...

Embodiment 1

[0061] The formula composition of polyphthalamide reinforcing material mass percentage is as follows:

[0062] Polyphthalamide 48%, filling enhancer 45%, modified red phosphorus 6%, ester lubricant 0.3%, non-polar lubricant 0.3%, antioxidant 0.2%, coupling agent 0.2%.

[0063] Among them, the above-mentioned non-polar lubricant is siloxane; the ester lubricant is pentaerythritol stearate; the filling enhancer is alkali-free glass fiber; the antioxidant is N, N-hexamethylene-1,6-di[3 -(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide] 0.1% and tris(2,4-di-tert-butylphenyl)phosphite 0.1%; coupling agent is γ-aminopropyl base triethoxysilane; modified red phosphorus acquisition method is as follows:

[0064] SA1: Mix red phosphorus with ethanol solution of γ-glycidoxypropyltrimethoxysilane to form a solid-liquid mixture, wherein the mass ratio of red phosphorus to γ-glycidoxypropyltrimethoxysilane is 3:1 ;

[0065] SA2: Heat the solid-liquid mixture to 55°C and perform ultrasoni...

Embodiment 2

[0073] The formula composition of polyphthalamide reinforcing material mass percentage is as follows:

[0074] Polyphthalamide 51%, filling enhancer 40%, modified red phosphorus 7%, ester lubricant 0.5%, non-polar lubricant 0.5%, antioxidant 0.4%, coupling agent 0.6%;

[0075] Among them, the above-mentioned non-polar lubricant is siloxane; the ester lubricant is pentaerythritol stearate; the filling enhancer is alkali-free glass fiber; the antioxidant is N, N-hexamethylene-1,6-di[3 -(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide]0.2% and tris(2,4-di-tert-butylphenyl)phosphite 0.2%; coupling agent is γ-aminopropyl base triethoxysilane; modified red phosphorus acquisition method is as follows:

[0076] SA1: Red phosphorus is mixed with an acetone solution of γ-aminopropyltriethoxysilane to form a solid-liquid mixture, wherein the mass ratio of red phosphorus to γ-aminopropyltriethoxysilane is 3:1;

[0077] SA2: Heat the solid-liquid mixture to 45°C and perform ultrasonic tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com