Hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA (phenyl-propanolamine) material and preparation method thereof

An alcoholysis-resistant and hydrolysis-resistant technology, applied in the field of polymer materials, can solve the problems of failing to meet customer requirements, being easily eroded, and reducing mechanical properties, achieving high mechanical properties, excellent hydrolysis resistance, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

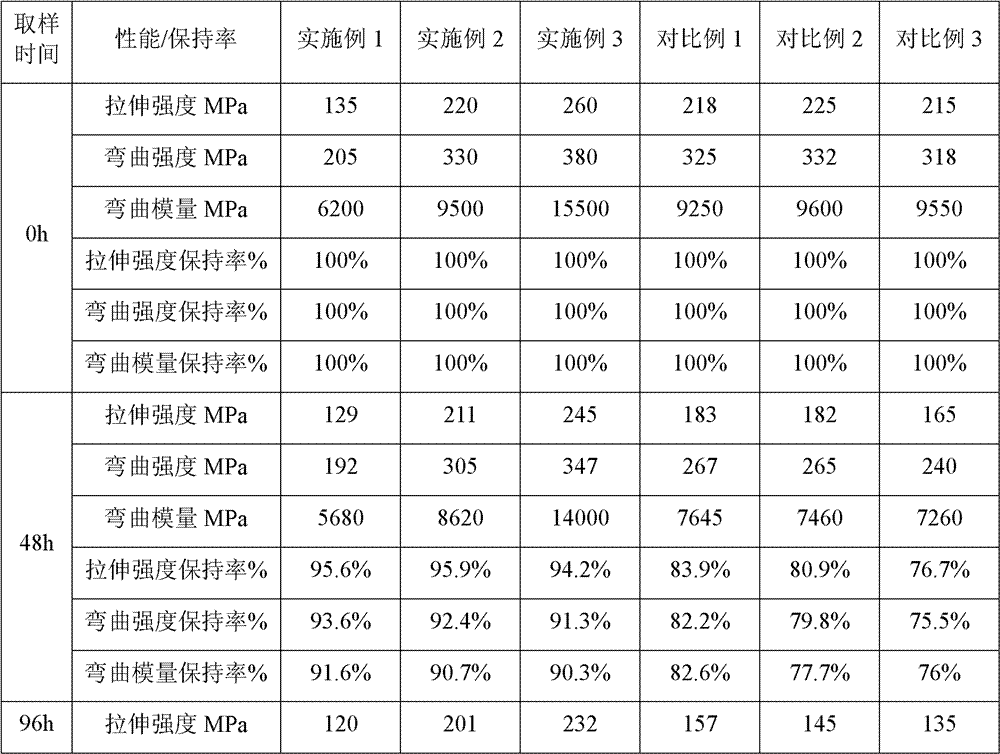

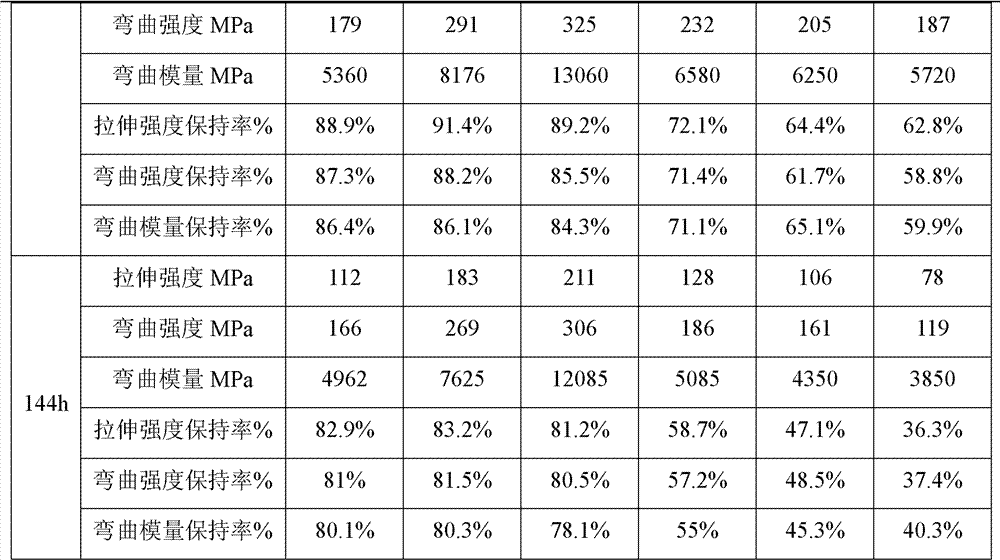

Embodiment 1

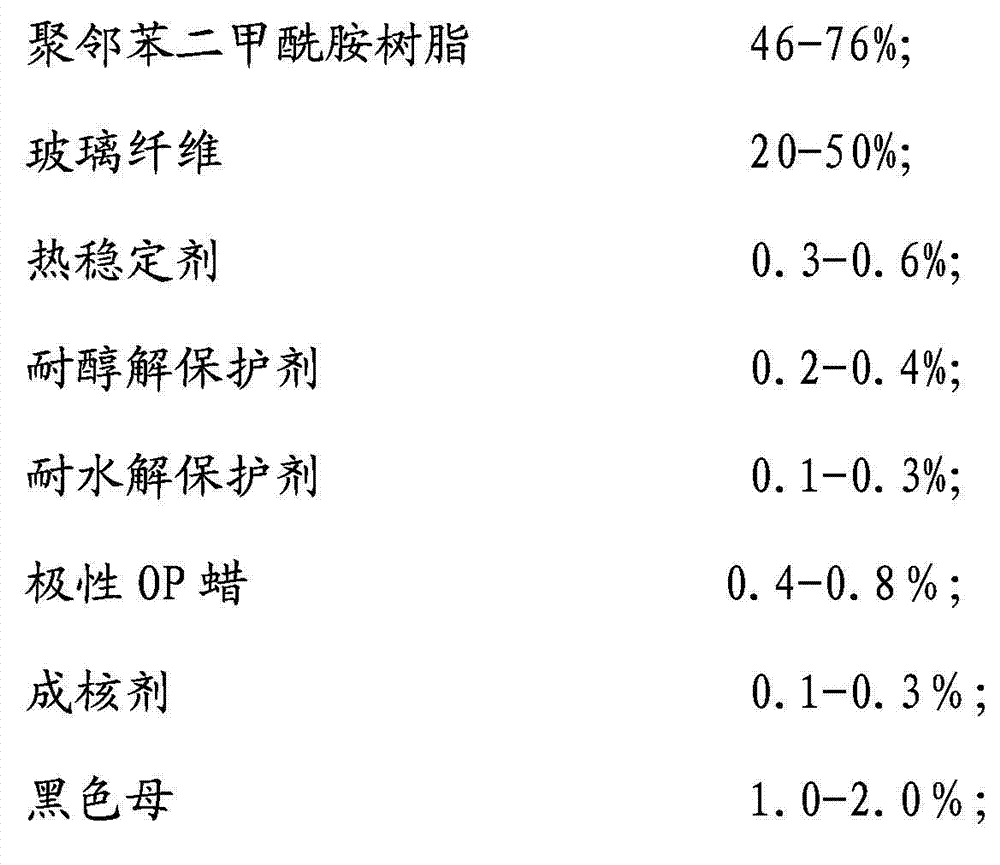

[0045] The PPA is 76.8% by weight percentage (below is weight percentage), heat stabilizer H1610.4%, alcoholysis-resistant protective agent 0.3%, hydrolysis-resistant protective agent 0.2%, OP wax 0.6%, nucleating agent 0.2%, Weigh the black mother N54 1.5%, pour it into a blender and stir evenly. The mixed materials are put into the hopper of the twin-screw extruder, and the glass fiber HP361020% is fed into the extruder through side feeding, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: the temperature of the first zone is 270°C; the temperature of the second zone is 290°C; the temperature of the third zone is 310°C; the temperature of the fourth zone is 300°C; 16MPa.

Embodiment 2

[0047] PPA is 61.8% by weight percentage (hereinafter all are percentage by weight), heat stabilizer H1610.4%, alcoholysis-resistant protective agent 0.3%, hydrolysis-resistant protective agent 0.2%, OP wax 0.6%, nucleating agent 0.2%, Weigh the black mother N54 1.5%, pour it into a blender and stir evenly. The mixed materials are put into the hopper of the twin-screw extruder, and glass fiber HP3610 35% is fed into the extruder through side feeding, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: the temperature of the first zone is 270°C; the temperature of the second zone is 290°C; the temperature of the third zone is 310°C; the temperature of the fourth zone is 300°C; 16MPa.

Embodiment 3

[0049]PPA is 46.8% by weight percentage (below all is weight percentage), heat stabilizer H1610.4%, alcoholysis-resistant protective agent 0.3%, hydrolysis-resistant protective agent 0.2%, OP wax 0.6%, nucleating agent 0.2%, Weigh the black mother N54 1.5%, pour it into a blender and stir evenly. The mixed materials are put into the hopper of the twin-screw extruder, and the glass fiber HP361050% is fed into the extruder through side feeding, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: the temperature of the first zone is 270°C; the temperature of the second zone is 290°C; the temperature of the third zone is 310°C; the temperature of the fourth zone is 300°C; 16 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com