Glass fiber reinforced polycarbonate composite material with flame-retarding mobility and thermal endurance, and product thereof

A technology of polycarbonate and composite materials, applied in the field of polymer materials, can solve the problems of poor temperature resistance, unbalanced fluidity and temperature resistance of composite materials, poor fluidity, etc., and achieve excellent fluidity and temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

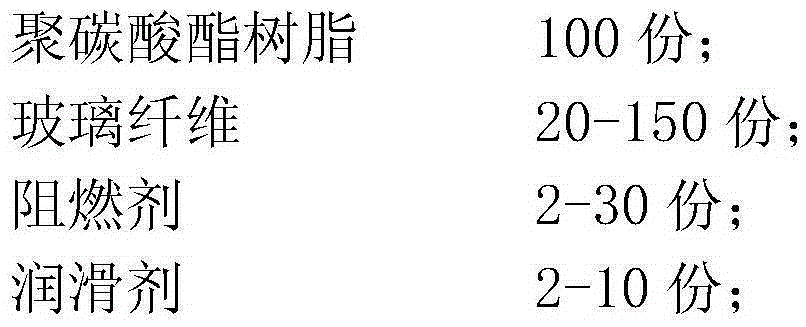

Method used

Image

Examples

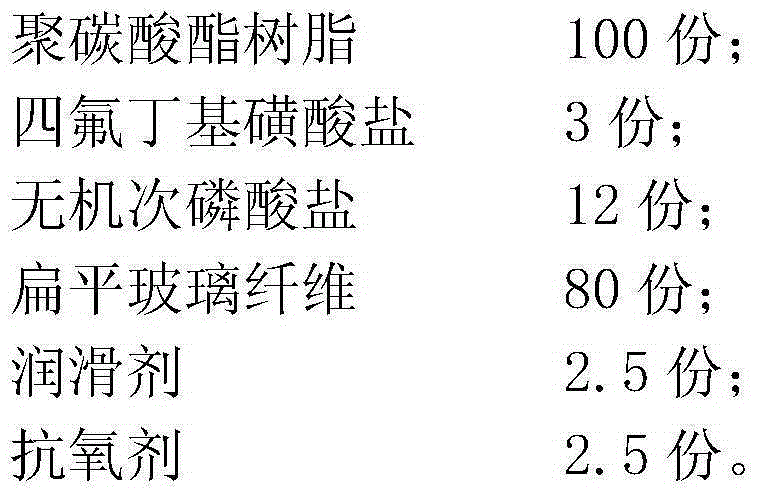

Embodiment 1

[0030]

[0031] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

Embodiment 2

[0033]

[0034] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

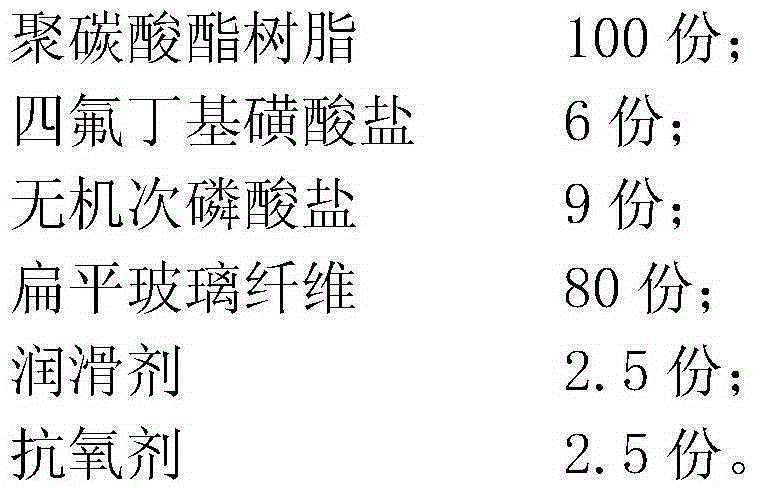

Embodiment 3

[0036]

[0037] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com