Halogen-free flame-retardant resin matrix sandwich structure body and preparation method thereof

A technology of flame retardant resin and resin matrix, applied in the field of halogen-free flame retardant resin matrix sandwich structure and its preparation, to achieve the effects of excellent thermal stability, light weight, and good thermophysical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

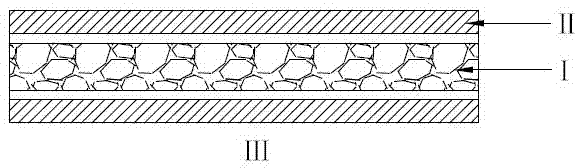

Image

Examples

Embodiment 1

[0052] The FR100 series PET structural foam (specific gravity of 100kg / m 3 ) cut into 3.0mm thickness and 320mm*250mm surface size (weight is 24g) as a foam with voids, the elastic modulus of the foam is 70MPa according to ASTM D 638 test, and the shear modulus is 35Mpa;

[0053] Cut the thermoplastic resin-based carbon fiber prepreg (CFR-2, Jinfa Carbon Fiber New Material Development Co., Ltd.) into a thickness of 0.25mm and a surface size of 320mm*250mm (each piece weighs 35g) as a resin matrix fiber reinforcement material; laminating a resin matrix fiber reinforcement material on both upper and lower surfaces of the foam to provide a laminate;

[0054] Prepare a steel flat mold with levelness and smoothness ranging from 5 to 13, and the steel flat mold has a concave-convex surface, and the thickness can be controlled from 1 to 10mm. Place the above-mentioned laminate in the rigid flat mold and heat the steel flat mold To 160°C, pressurize and maintain for 10-30s, quickly c...

Embodiment 2

[0057] Rohacell's 71WF type PMI structural foam (specific gravity 70kg / m 3 ) cut into 3.0mm thickness and 320mm*250mm surface size (weight 18g) as a foam with voids, the elastic modulus of the foam is 92Mpa according to ASTM D 638 test, and the shear modulus is 42Mpa;

[0058] Cut the P-N, FD / MFP epoxy resin-based carbon fiber prepreg sheet ((CFR-1), Jinfa Carbon Fiber New Material Development Co., Ltd.) into 0.26mm thickness and 320mm*250mm surface size (each piece weighs 34g ) as the resin matrix fiber reinforcement material; laminating the resin matrix fiber reinforcement material on the upper and lower surfaces of the foam to provide a laminate;

[0059] Prepare a steel flat mold with levelness and smoothness ranging from 5 to 13, and the steel flat mold has a concave-convex surface, and the thickness can be controlled from 1 to 10mm. Place the above-mentioned laminate in the rigid flat mold and heat the steel flat mold to 160°C, pressurize and maintain for 7-10 minutes, ...

Embodiment 3

[0062] A core material made of a modified thermoplastic resin matrix fiber reinforcement material, wherein the thermoplastic resin matrix and long fibers cross to form a void structure through fiber-impregnated resin, and the length of the fiber-impregnated resin is more than 10nm; the core The specific gravity of the material is 1.0, and the thickness is 3.0mm; cut into 3.0mm thickness and 320mm*250mm* (weight is 24g);

[0063] Cut the thermoplastic resin-based carbon fiber prepreg (CFR-2, Jinfa Carbon Fiber New Material Development Co., Ltd.) into a thickness of 0.25mm and a surface size of 320mm*250mm (each piece weighs 35g) as a resin matrix fiber reinforcement material; laminating a resin matrix fiber reinforcement material on upper and lower surfaces of said core material to provide a laminate;

[0064] Prepare a steel flat mold with levelness and smoothness ranging from 5 to 13, and the steel flat mold has a concave-convex surface, and the thickness can be controlled fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com