Flexible decorative wood veneer

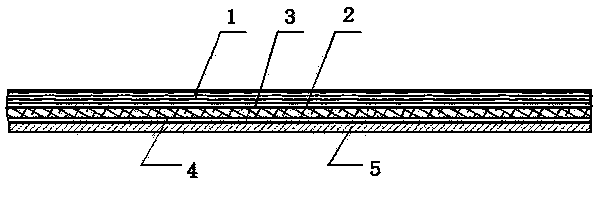

A decorative veneer and flexible technology, applied in the field of decorative veneer, can solve problems such as inability to bend veneer at a large angle, hinder the application of veneer products, and threaten life safety, and achieve the effects of avoiding damage or tearing, saving wood, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use non-woven fabric with a thickness of 0.15mm to reinforce natural black walnut veneer as the surface layer, and metal aluminum foil with a thickness of 0.02mm as the middle layer, with a surface density of 50g / m 2 The kraft paper is used as the bottom material, and the layers are made of hot-melt adhesive film paper by hot-pressing. The hot-pressing temperature is 130°C and the hot-pressing pressure is 1.5MPa.

Embodiment 2

[0031] The surface layer is reinforced with non-woven fabric (red sandalwood) with a thickness of 0.18mm, and the metal tin foil with a thickness of 0.02mm is used as the middle layer. The surface density is 60g / m 2 The kraft paper is used as the bottom material, and the layers are made of thermosetting adhesive film paper by hot pressing. The hot pressing temperature is 150°C and the hot pressing pressure is 1.8 MPa.

Embodiment 3

[0033] Use non-woven fabric with a thickness of 0.05mm to reinforce natural red cherry veneer as the surface layer, metal aluminum foil with a thickness of 0.08mm as the middle layer, and the surface density is 40g / m 2 The kraft paper is the bottom material, and the layers are formed by hot pressing with melamine adhesive. The hot pressing temperature is 160°C and the hot pressing pressure is 1.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com