Cooling liquid for battery constant temperature control and preparation method thereof

A technology of constant temperature control and cooling liquid, which is applied in the direction of secondary batteries, circuits, electrical components, etc., to achieve the effects of high thermal conductivity, optimized heat capacity, and high flame retardant grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw materials and their proportioning ratio are shown in Table 1.

[0021] The raw material of table 1 embodiment 1 and its proportioning

[0022] raw material paraffin NP100 AEO3 Carbomer 1342 water Ethylene glycol Proportion 40% 4% 4% 4% 16% 32%

[0023] Preparation method: Put the phase change material paraffin into a heated dispersion kettle, raise the temperature to 70°C until the paraffin is completely melted, start stirring to 2000rpm, add emulsifier NP100, AEO3, stir for 20min, slowly add Carbomer 1342 aqueous solution, Stir for 5 minutes, add water and ethylene glycol solvent, and accelerate to 4000rpm, fully homogeneously emulsify, and form a highly stable emulsion.

Embodiment 2

[0025] Raw materials and their proportioning ratio are shown in Table 2.

[0026] The raw material of table 2 embodiment 2 and proportioning thereof

[0027] raw material amino polyether NP100 SPAN80 Carbomer 934 water Propylene Glycol Proportion 40% 3% 4% 3% 25% 25%

[0028] Preparation method: Put the phase change material amino polyether into the heated dispersion kettle, raise the temperature to 80°C until the phase change material melts, start stirring to 2000rpm, add emulsifier NP100, SPAN80, stir for 20min, slowly add carbo M934 aqueous solution, stirred for 5 minutes, added water and propylene glycol solvent, and accelerated to 4000rpm, fully homogeneous emulsified, and formed a highly stable emulsion.

Embodiment 3

[0030] Raw materials and their proportioning ratio are shown in Table 3.

[0031] The raw material of table 3 embodiment 3 and proportioning thereof

[0032] project Block polyether NP100 OP100 AEO3 Carbomer 1342 water Ethylene glycol Proportion 45% 3% 3% 3% 6% 20% 20%

[0033] Preparation method: Put the phase change material block polyether into the heated dispersion kettle, raise the temperature to 80°C until the phase change material is melted, start stirring to 2000rpm, add emulsifier NP100, OP100, AEO3, stir for 60min, slowly Add carbomer 1342 aqueous solution, stir for 20 minutes, add water and ethylene glycol solvent, and accelerate to 4000rpm, fully homogeneously emulsify, and form a highly stable emulsion.

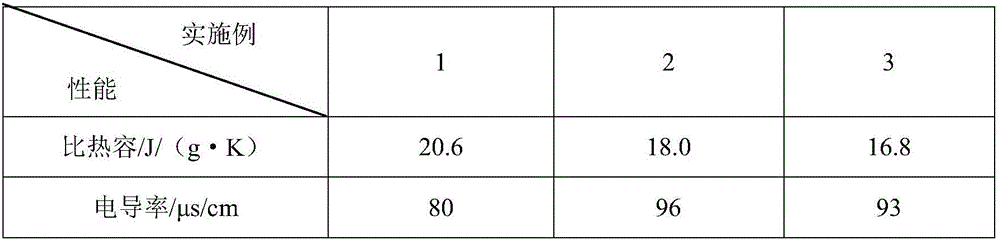

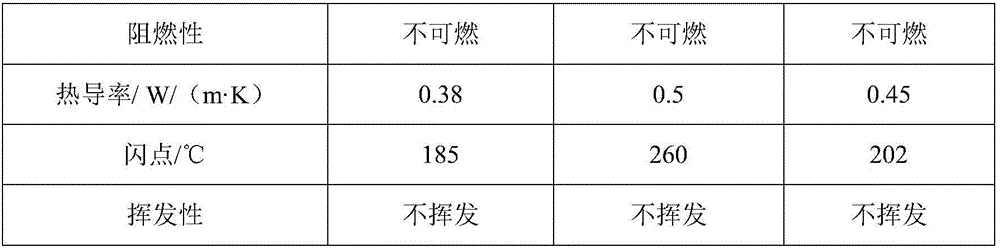

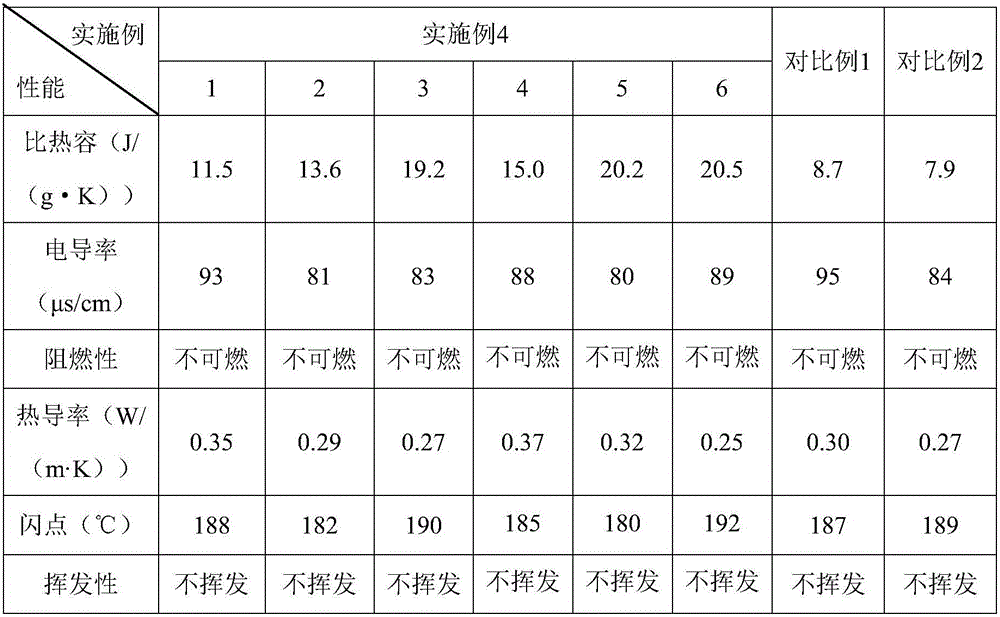

[0034] The cooling liquid prepared in Examples 1-3 was tested for performance, and the obtained results are shown in Table 4.

[0035] The performance comparison table of the cooling liquid prepared by the embodiment 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com