Low-temperature automobile expansion adhesive and preparation method thereof

An automotive and low-temperature technology, which is applied in the field of low-temperature automotive expansion rubber and its preparation, can solve the problems of low foaming ratio, poor storage stability, short storage period and the like of the expansion rubber, and achieves good high-temperature baking stability and storage stability. , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A kind of low-temperature automobile expansion rubber, described low-temperature automobile expansion rubber is made of each raw material comprising following weight parts:

[0066] 100 parts of high molecular polymer, 3-5 parts of peroxide vulcanizing agent, 0.5-3 parts of vulcanization aid (also known as auxiliary cross-linking agent), 5-15 parts of foaming agent, 0.5-8 parts of foaming activator, 1-10 parts of filler, 2-15 parts of tackifier, 0.5-3 parts of lubricant, 0-2 parts of antioxidant, 0-10 parts of flame retardant.

[0067] Wherein, the high molecular polymer is ethylene-vinyl acetate copolymer (EVA resin) with VA content of 26-28, ethylene-vinyl acetate copolymer (EVA resin) with VA content of 40, low-density polyethylene (LDPE), ethylene Methyl methacrylate copolymer (EMA), ethylene-ethyl acrylate copolymer (EEA), ethylene-butyl acrylate copolymer (EBA), butadiene rubber (BR), ethylene-propylene-diene rubber (EPDM) any one or a mixture of several.

[006...

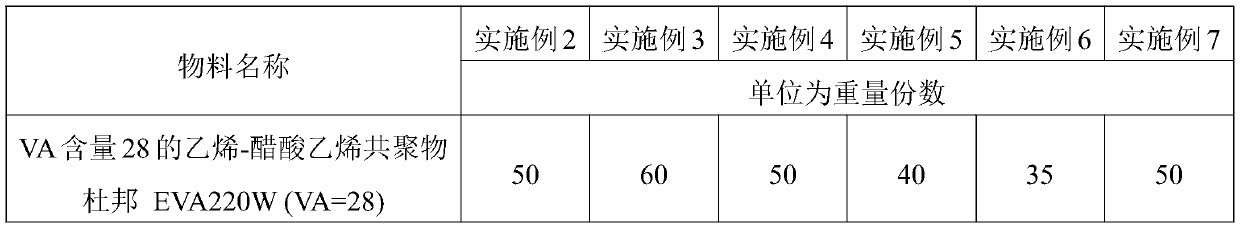

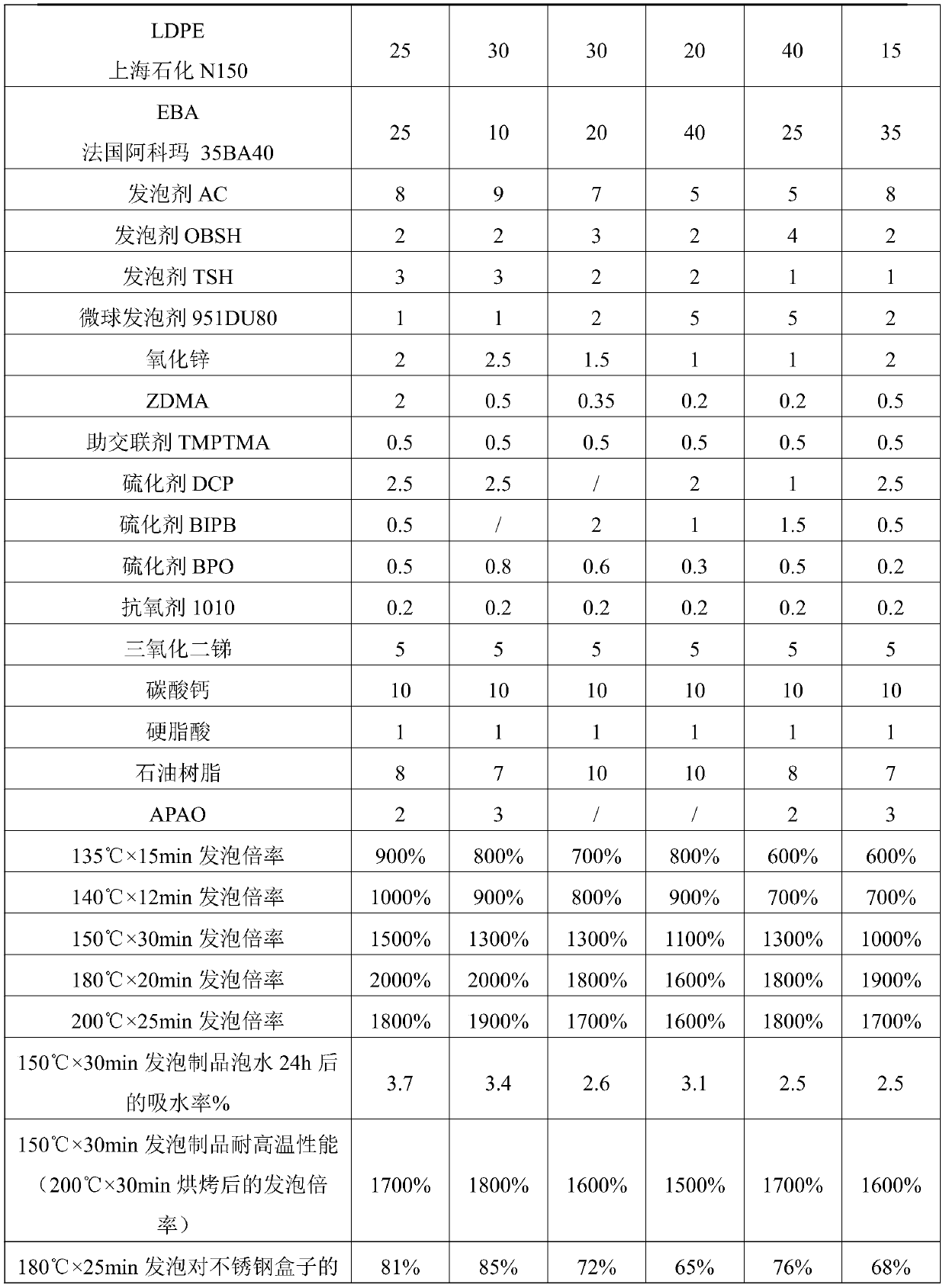

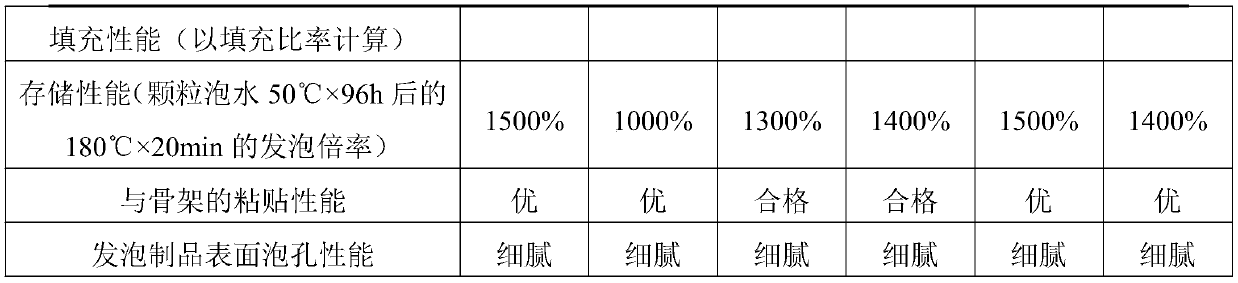

Embodiment 2 to 7

[0094] All adopt the preparation method of following a kind of described low-temperature automobile expansion glue, comprise the following steps:

[0095] (1) Add high molecular polymer in internal mixer and carry out pre-mixing;

[0096] (2) Add lubricant, foaming agent, antioxidant, filler, tackifier, flame retardant to the internal mixer in turn, and enter the next step after the materials are mixed into blocks;

[0097] (3) Continue mixing after adding vulcanizing agent, vulcanizing aid, and foaming activator; turn over the material during mixing and clean the material at the feeding port for more than 3 times;

[0098] (4) After mixing evenly, under the condition that the temperature of the material does not exceed 90°C, unload the material and enter the extruder for granulation;

[0099] (5) Packaging granular expansion rubber, which is the low-temperature automobile expansion rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com