DOPO-based silicon-phosphorus synergistic flame retardant as well as preparation method and application thereof

A synergistic flame retardant and silicon-based technology, applied in the field of flame retardants, can solve the problems of low limiting oxygen index, affecting material performance, and low flame retardant level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

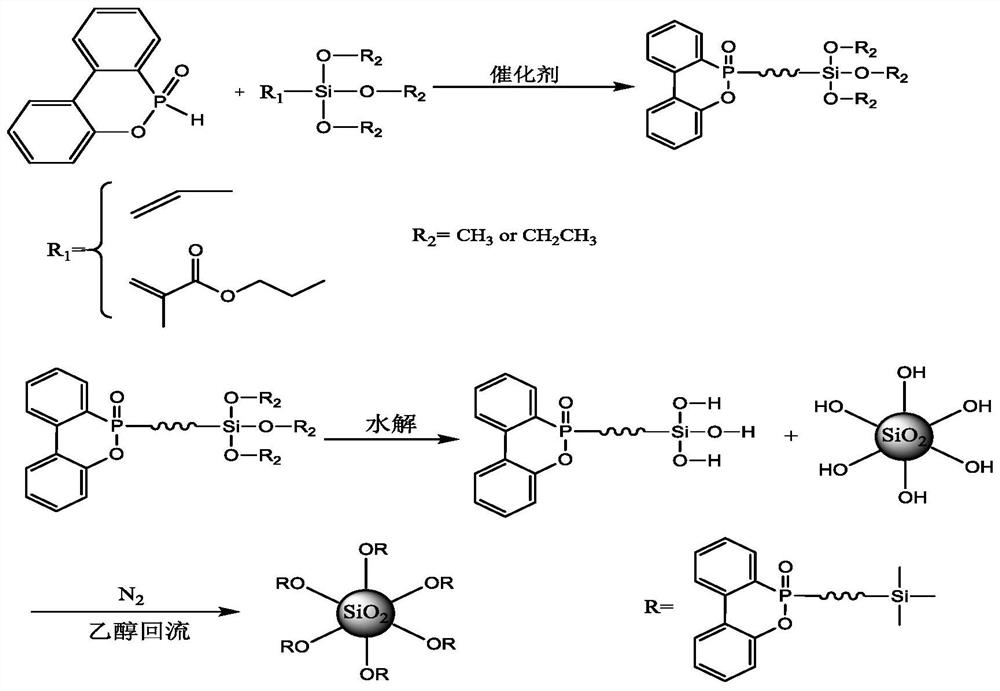

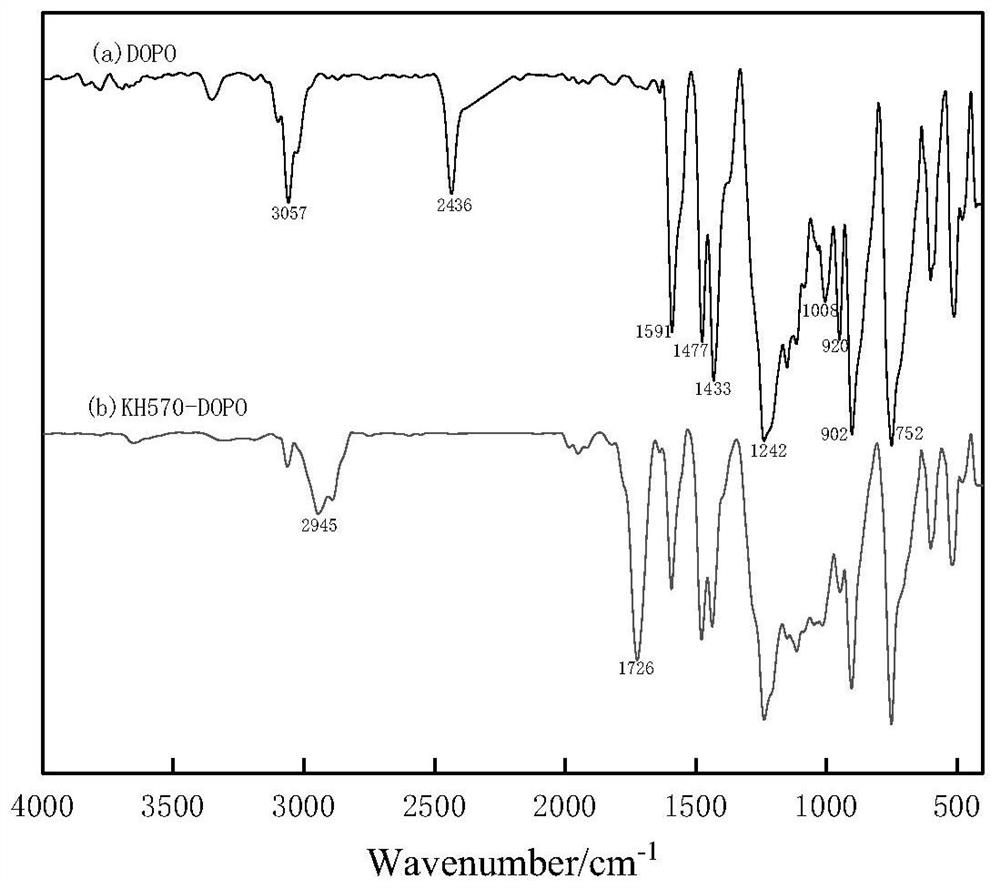

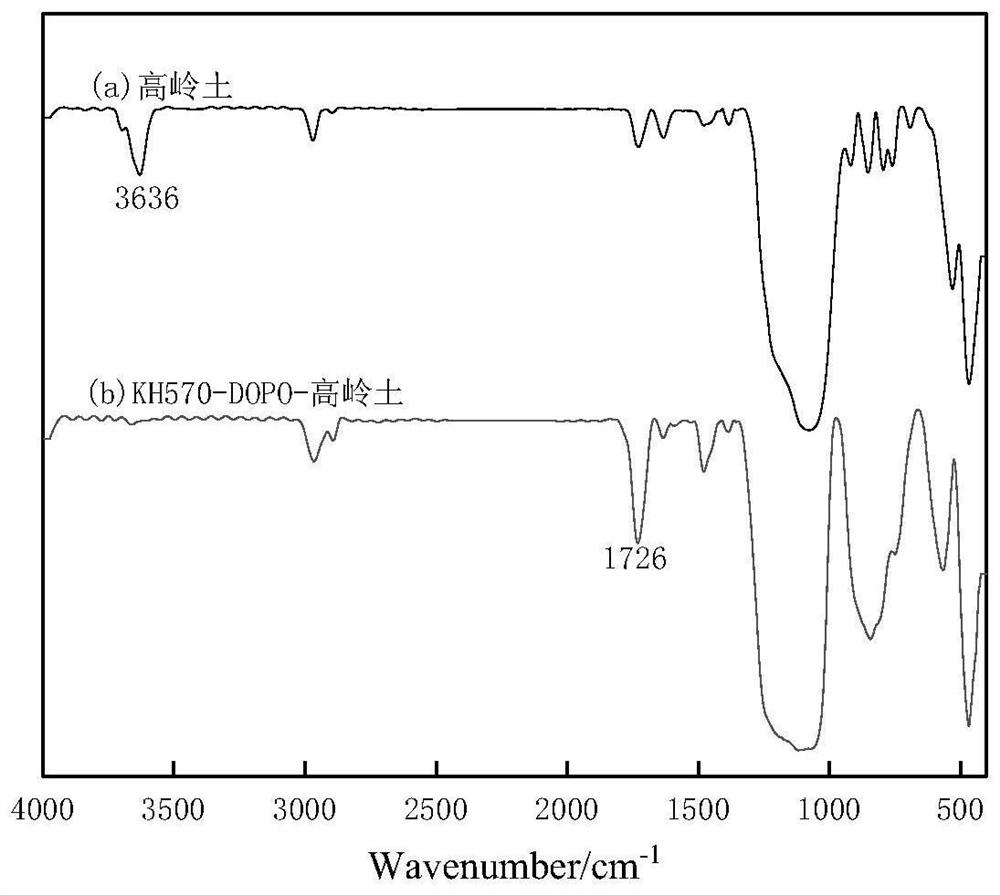

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of a DOPO-based silicon-phosphorus synergistic flame retardant, comprising the following steps:

[0052](1) Add 2.0g DOPO, 2.5g KH570 and 50.0g absolute ethanol into a three-necked flask filled with inert gas and mix to obtain solution A;

[0053] Dissolve 0.135g of azobisisobutyronitrile in 10.0g of absolute ethanol to obtain solution B;

[0054] Add solution B dropwise to solution A for 30 minutes, then react in an oil bath at 75°C for 12 hours to obtain a crude product, remove the solvent by rotary evaporation, and then dry it for 24 hours to obtain a flame retardant intermediate;

[0055] (2) Add 57.0 g of methanol and 3.0 g of deionized water to the flame retardant intermediate, add 0.14 g of acetic acid to adjust the pH to 4.0, and ultrasonically hydrolyze for 2 hours to obtain solution C;

[0056] (3) Transfer solution C into a three-necked flask with an inert gas, add 50.0 g of absolute ethanol and 2.0 g of kaolin, reflux at 75°C for 8 hour...

Embodiment 2

[0064] A preparation method of a DOPO-based silicon-phosphorus synergistic flame retardant, comprising the following steps:

[0065] (1) Add 2.0g DOPO, 3.0g KH570 and 50.0g toluene into a three-necked flask filled with inert gas and mix to obtain solution A;

[0066] Dissolve 0.15g of azobisisobutyronitrile in 10.0g of toluene to obtain solution B;

[0067] Add solution B dropwise to solution A for 30 minutes, then react in an oil bath at 120°C for 12 hours to obtain a crude product, remove the solvent by rotary evaporation, and then dry it for 24 hours to obtain a flame-retardant intermediate;

[0068] (2) Add 57.0 g of methanol and 3.0 g of deionized water to the flame retardant intermediate, add 0.14 g of acetic acid to adjust the pH to 4.0, and ultrasonically hydrolyze for 2 hours to obtain solution C;

[0069] (3) Transfer solution C into a three-necked flask with inert gas, add 50.0g toluene and 1.5g diatomaceous earth, reflux at 120°C for 8h, wash with ethanol three ti...

Embodiment 3

[0071] A preparation method of a DOPO-based silicon-phosphorus synergistic flame retardant, comprising the following steps:

[0072] (1) Add 1.5g DOPO, 2.0g KH570 and 50.0g toluene into a three-necked flask filled with inert gas and mix to obtain solution A;

[0073] Dissolve 0.105g of azobisisobutyronitrile in 10.0g of toluene to obtain solution B;

[0074] Add solution B dropwise to solution A for 30 minutes, then react in an oil bath at 120°C for 12 hours to obtain a crude product, remove the solvent by rotary evaporation, and then dry it for 24 hours to obtain a flame retardant intermediate;

[0075] (2) Add 76.0 g of methanol and 4.0 g of deionized water to the flame retardant intermediate, add 0.2 g of acetic acid to adjust the pH to 4.0, and ultrasonically hydrolyze for 2 hours to obtain solution C;

[0076] (3) Transfer the solution C into a three-necked flask with an inert gas, add 50.0 g of toluene and 3.0 g of kaolin, reflux at 75 ° C for 8 h, wash with ethanol thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com