Method for preparing continuous bulk of flame retardant and highly impact resistant acrylonitrile-chlorinated polyethylene-styrene resin

A technology of chlorinated polyethylene and styrene resin, which is applied in the field of preparation of polymer chemical materials, can solve problems such as limitation, impact resistance limitation, and complicated process, so as to facilitate the control of the preparation process, reduce equipment costs, simplify The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

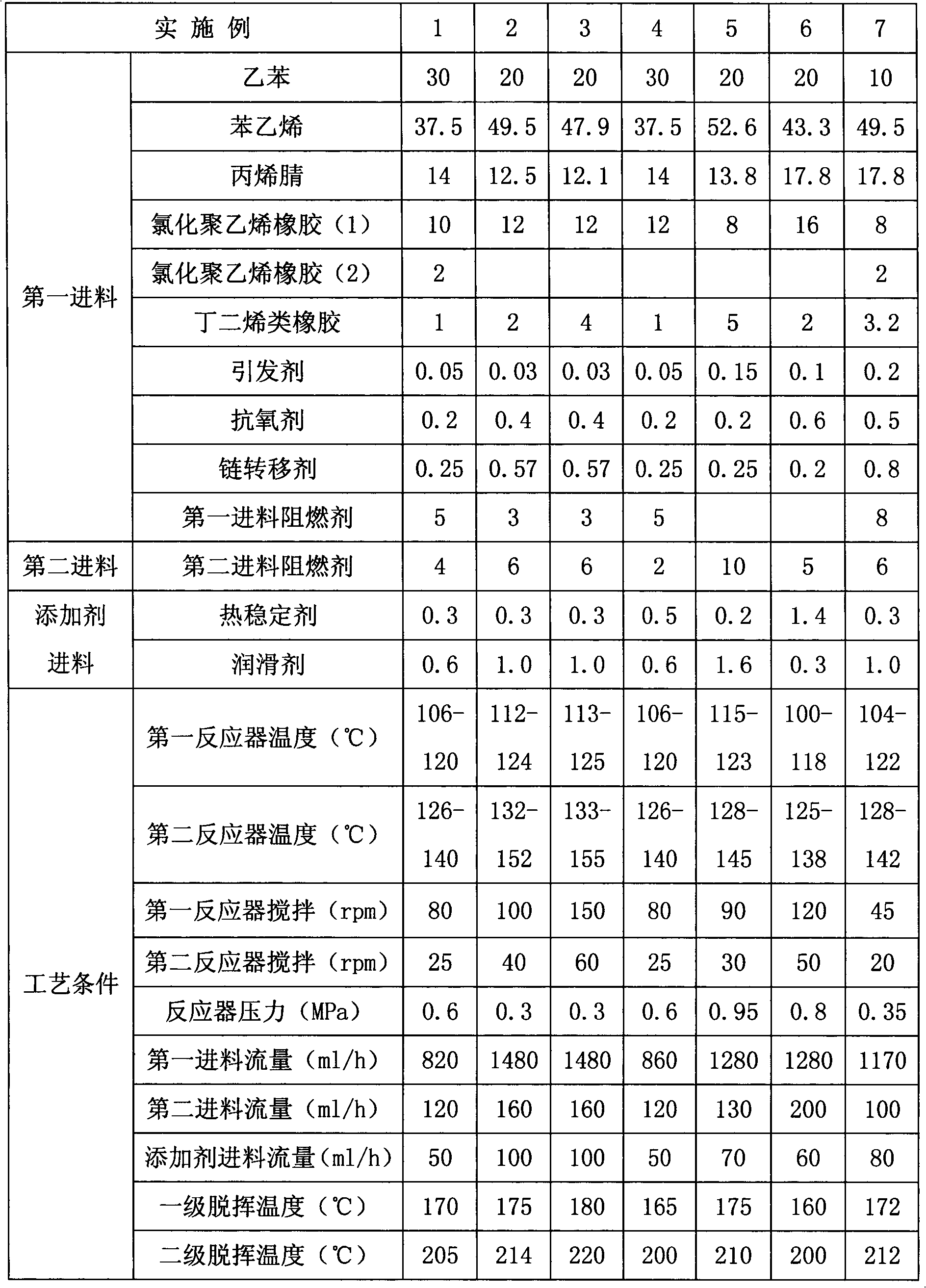

[0050] In the nitrogen-purged sol tank, add ethylbenzene, styrene, acrylonitrile, Haijing CPE135, Yaxing CPE2135, 35AE rubber, tert-butyl peroctoate, and antioxidant 1076 according to the parts by weight in Table 1. , dodecyl mercaptan, and tris(2-chloroethyl) phosphate are dissolved and stirred. After the sol is completed, the raw material glue enters two tower reactors connected in series. Add ethylbenzene and tris(2-chloroethyl) phosphate into the second feed tank, stir well to dissolve. Add methyl tin mercaptide and ethylene bis stearamide into the additive feed tank, and stir well to mix.

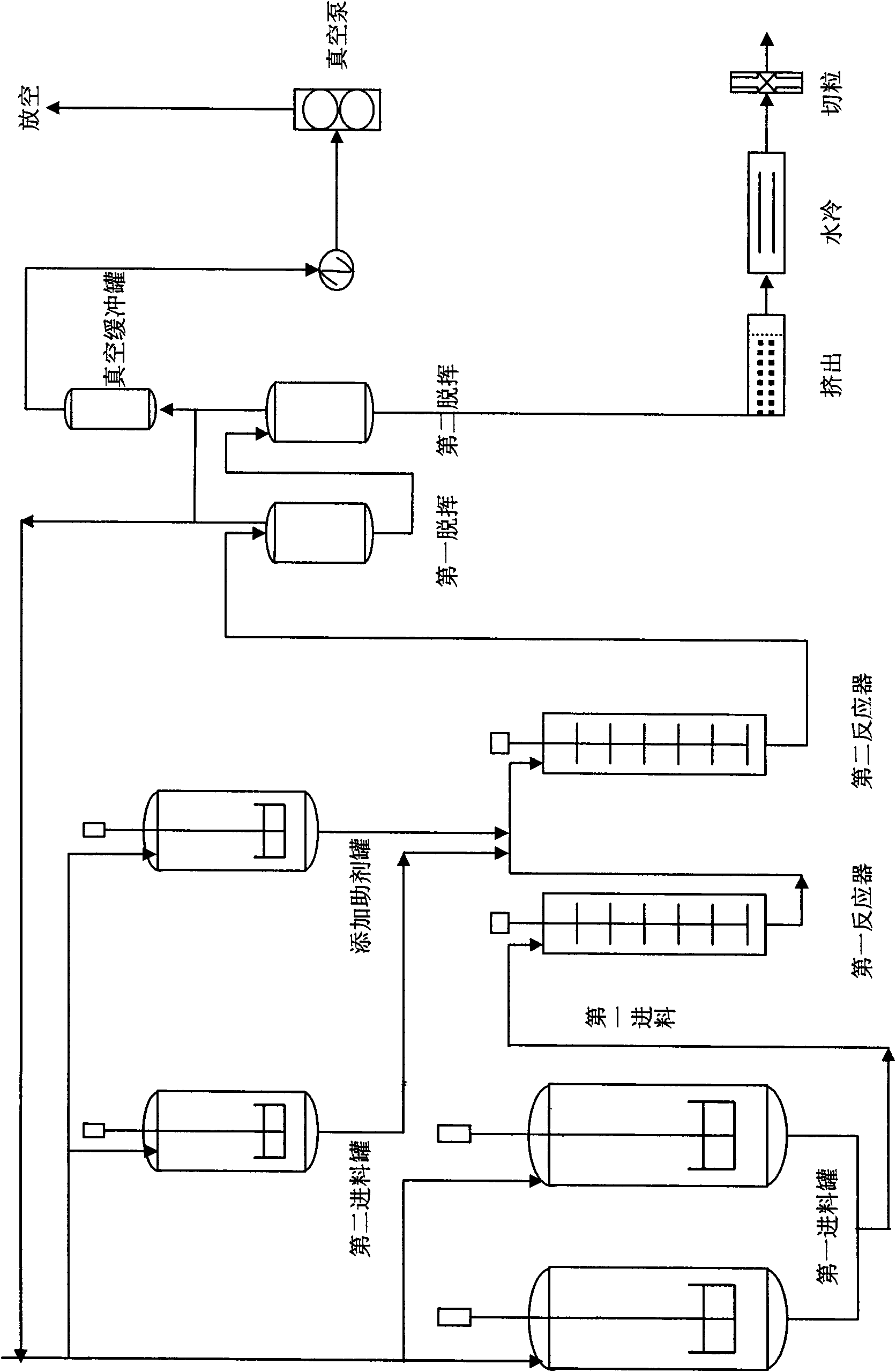

[0051] According to the conditions in Table 1 and figure 1 The said technological process carries out continuous polymerization reaction, and the generated polymerization product undergoes steps such as devolatilization, extrusion, granulation, etc. to obtain resin product granules.

[0052] Table 1

[0053]

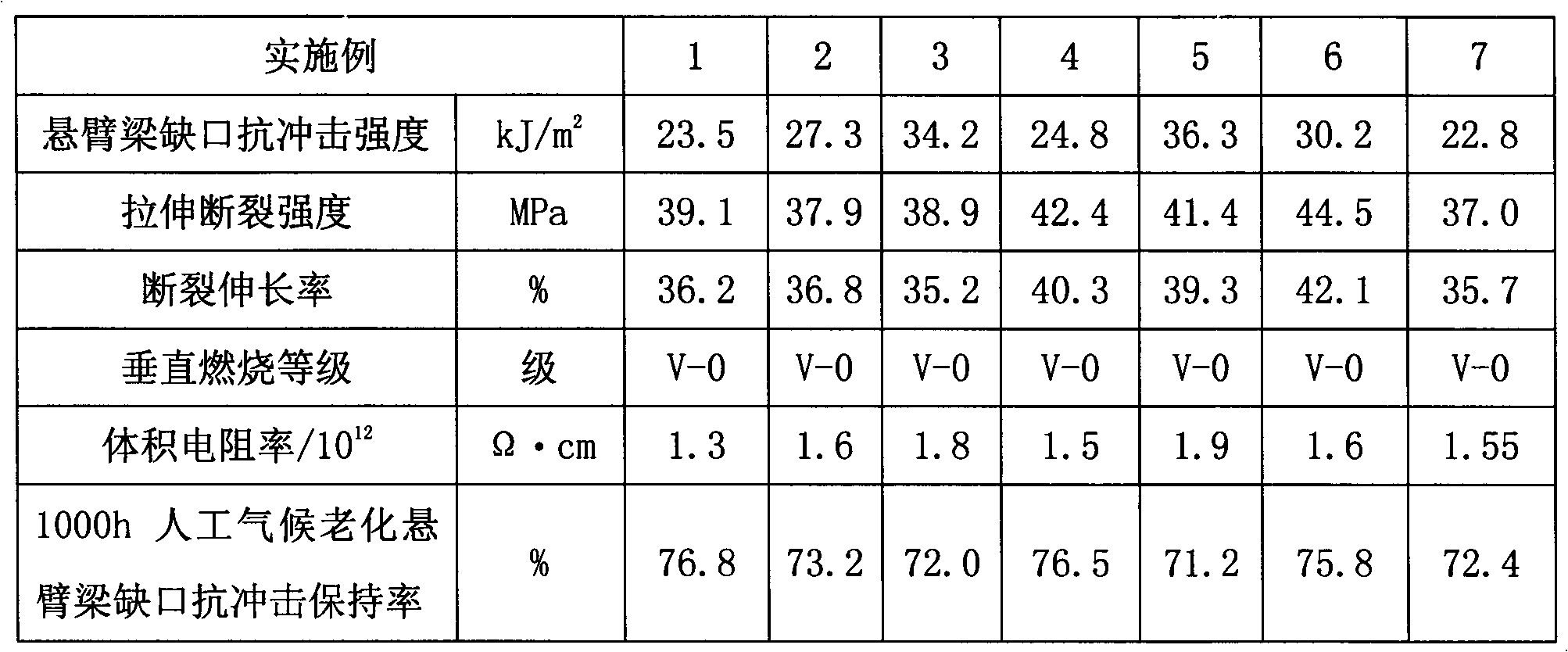

[0054] The obtained resin product is measured according to GB / T1843 fo...

Embodiment 2 and 3

[0059] In the nitrogen-purged sol tank, add ethylbenzene, styrene, acrylonitrile, Corley CPE135B, 35AE rubber, tert-butyl neodecanoate, antioxidant 1010, linear The dimer and triaryl phosphate are dissolved and stirred. After the sol is completed, the raw material glue enters two tower reactors connected in series. Add ethylbenzene and triaryl phosphate into the second feed tank, stir well to dissolve. Add dibutyltin laurate and polyethylene wax to the additive feed tank and stir well to mix.

[0060] The continuous polymerization reaction was carried out according to the conditions in Table 1, and the resulting polymerization product was subjected to steps such as devolatilization, extrusion, and granulation to obtain resin product granules. According to the same method as in Example 1, the results are shown in Table 2.

[0061] As can be seen from the measured data in Table 2, along with the gradual increase of the amount of butadiene rubber used in Examples 1, 2, and 3, t...

Embodiment 4

[0063] According to the steps in Example 1, various raw materials are added, wherein the chlorinated polyethylene rubber is Keli CM402, the butadiene rubber is SBR rubber, the initiator is tert-butyl perbenzoate, and the heat stabilizer is methyl mercaptan Base tin, all the other raw materials are identical with embodiment 1. The obtained resin product was measured according to the same method in Example 1, and the results are shown in Table 2.

[0064] As can be seen from the measured data in Table 2, due to the use of Corley CM402 with a chlorine weight percentage content of 42%, the resin product can still obtain the required flame retardant grade. In Example 4, we increased the amount of heat stabilizer used, and appropriately reduced the devolatilization temperature of the devolatilizer to ensure the thermal stability of the product.

[0065] In Example 4, we used SBR rubber. Due to the difference between butadiene rubbers, the physical and mechanical properties of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com