Method for regulating and controlling stable flow of liquid nitrogen jet flow state

A technology for stabilizing the flow rate and flow state, which is applied in the field of regulation and control of the stable flow rate of the liquid nitrogen jet state, and can solve the problem of not mentioning the regulation method of the stable flow rate of the liquid nitrogen jet state, not involving liquid nitrogen flow control, and insufficient cooling effect in the cutting area, etc. problem, to achieve stable liquid nitrogen jet state, compact structure, and reduce the effect of mass fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The thermal conductivity of the vacuum insulated pipe adopted in the embodiment is 2×10 -5 W / (m·K), the temperature difference between the inner and outer walls can withstand up to 270 degrees; the nominal pressure of the self-pressurized Dewar tank is 1.4Mpa.

[0020] The specific steps of the method are as follows:

[0021] The first step is to assemble the liquid nitrogen delivery device

[0022] The liquid nitrogen delivery device consists of a liquid nitrogen delivery pipeline system and a liquid nitrogen flow control unit.

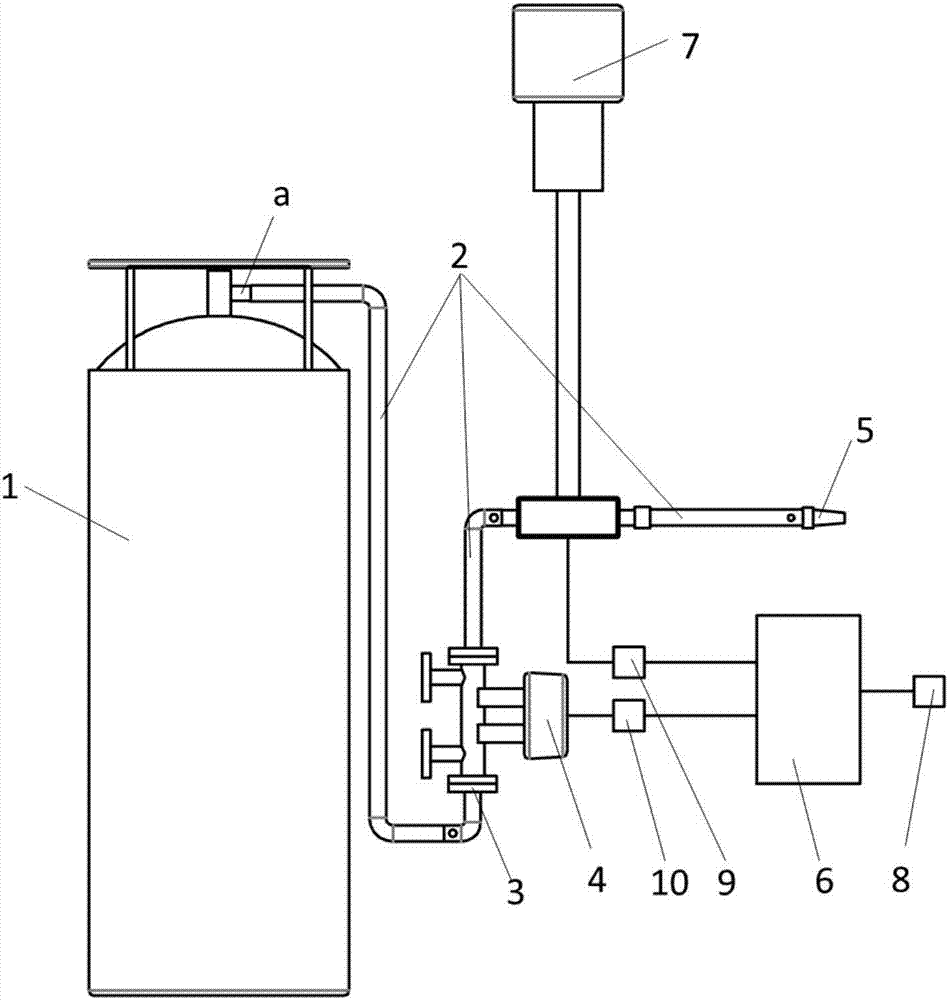

[0023] Assemble the liquid nitrogen delivery pipeline system first, such as figure 1 shown. The system consists of a self-pressurized Dewar tank 1, a vacuum insulation tube 2, a flange 3, a liquid nitrogen flow meter 4, a nozzle 5 and an ultra-low temperature regulating valve 7; The liquid port a is connected to the vacuum insulation pipe 2 through threads; the vacuum insulation pipe 2 is connected to the liquid nitrogen flowmeter 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com