Basalt fiber production method and wire drawing device thereof

A basalt fiber and basalt technology, which is applied in the field of basalt fiber production method and its wire drawing device, can solve the problems of inability to provide more reasonable cooling and cooling, reduce the temperature difference at the leak nozzle, etc., so as to solve the temperature difference and cooling rate difference. Adaptation, calm control, avoid the effect of pressure surges or dips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

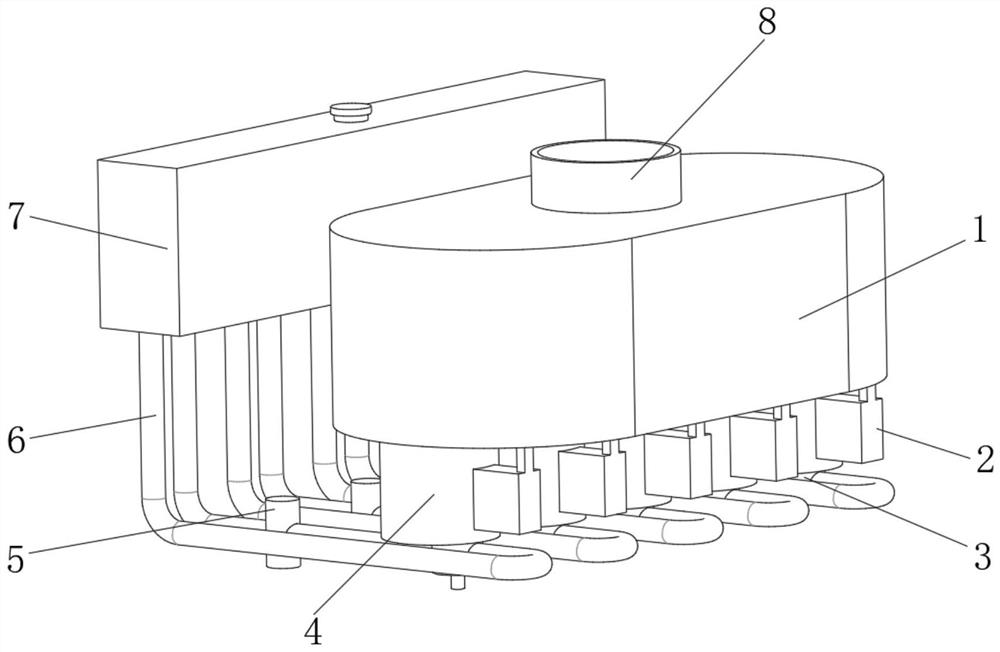

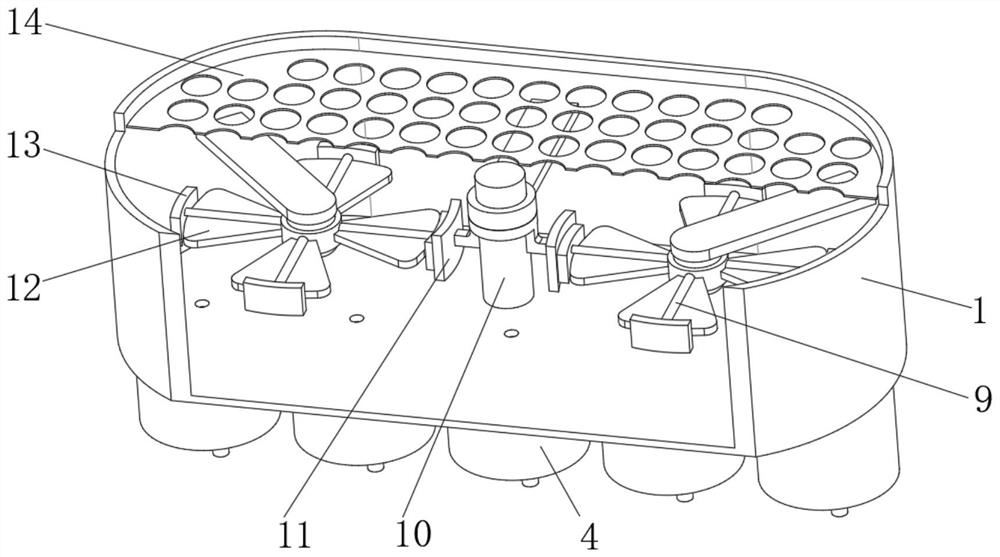

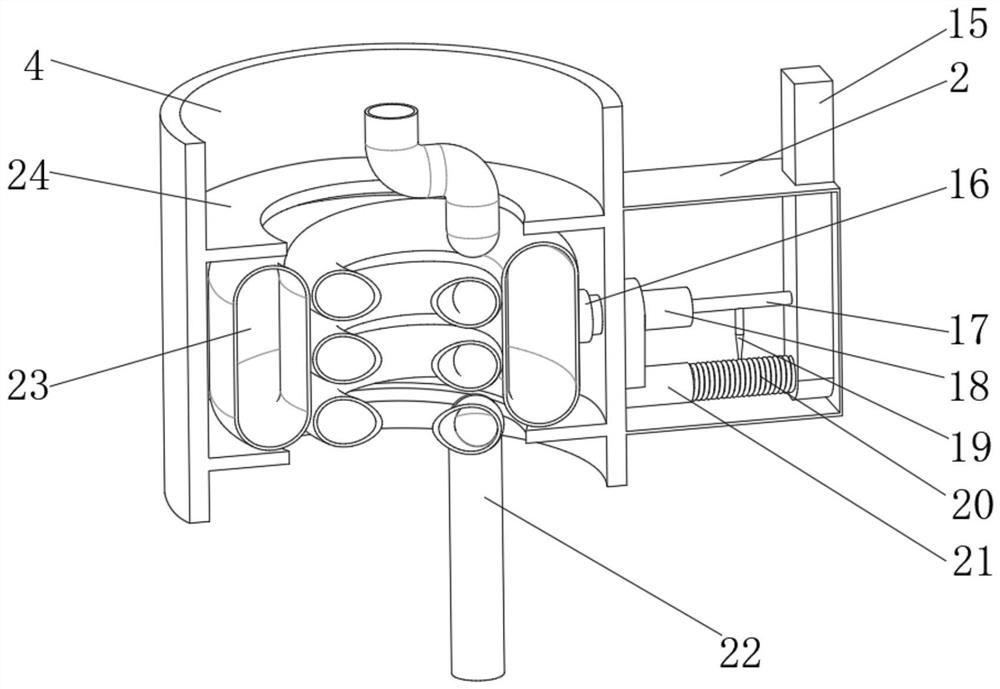

[0041] A kind of drawing device of basalt fiber, such as Figure 1-6 As shown, it includes a box body 1, a heating mechanism and a cooling mechanism. The heating mechanism is installed inside the box body 1. The outer wall of the bottom of the box body 1 is connected with evenly distributed leak nozzles 22 through flanges. The outer wall of the bottom of the box body 1 is connected by screws. The thermal induction chamber 4 adapted to the leak nozzle 22 is fixed. The top of the leak nozzle 22 is located inside the thermal induction chamber 4. The thermal induction chamber 4 is provided with an expansion bag 23 that expands with heat and contracts with cold. The expansion bag 23 is sleeved on the side wall of the top of the leak nozzle 22. The outer wall of one side of the thermal induction chamber 4 is fixed with the regulating chamber 2 by screws, and the inner wall of one side of the thermal induction chamber 4 is slidably connected with a push rod 18, which slides on the inn...

Embodiment 2

[0052] A kind of production method of the basalt fiber of drawing device according to embodiment 1, such as Figure 1-6 shown, including the following steps:

[0053] S1: Crushing and washing basalt ore;

[0054] S2: Add basalt ore to the melting pool of the melting furnace, and heat up to 1450°C to 1500°C to melt the basalt ore;

[0055] S3: Flow the basalt melt in the molten state into the feed tank, and wait for the temperature, viscosity, hydrostatic pressure and uniformity of the basalt melt to be stable;

[0056] S4: energize the heating electrode 10, and melt the basalt melt solidified in the feed tank and then add it to the box body 1 from the feed port 8;

[0057] S5: The basalt melt flows into the leak nozzle 22 after being heated by the heating mechanism in the box body 1;

[0058] S6: It flows out from the nozzle 22 and is simultaneously cooled by the cooling chamber 3. At the outlet of the nozzle 22, it is drawn into continuous basalt fibers by a high-speed rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com