Method for evaluating influence on mechanical property of material by ultralow-temperature cooling

A technology of material mechanics and evaluation method, which is applied in the field of evaluation of the influence of ultra-low temperature cooling on the mechanical properties of materials, and can solve problems that do not involve the impact of ultra-low temperature cooling on the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

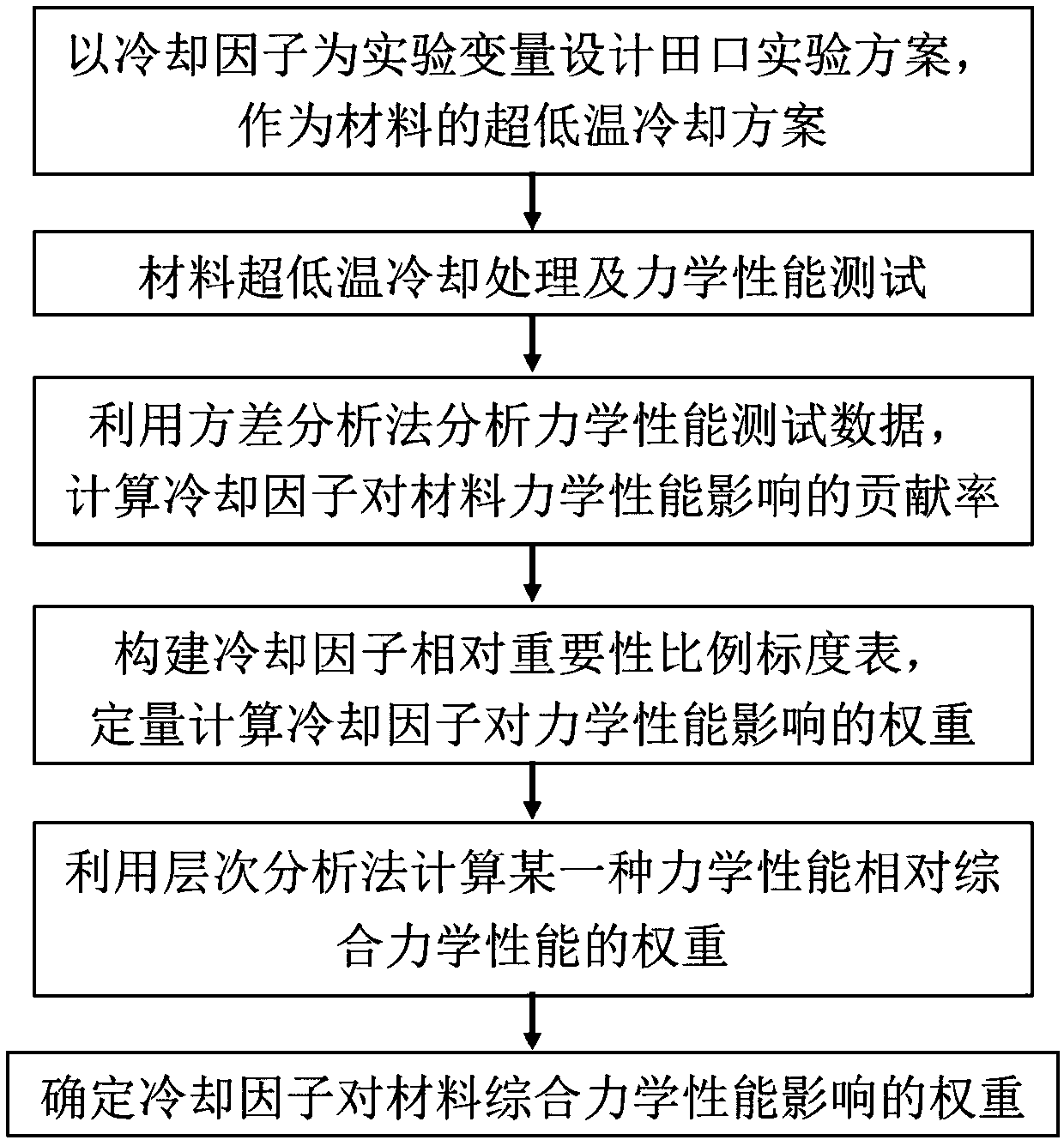

[0046] The detailed implementation of the present invention will be described in detail in conjunction with the drawings and technical solutions, and the evaluation process of using cooling factors to characterize the influence of ultra-low temperature cooling on the mechanical properties of materials will be described.

[0047] Select the material of the cylindrical test piece, the material is 1Cr18Ni9Ti stainless steel, the total length is 100mm, the end diameter is 15mm, the tensile section diameter is 10mm, the length is 50mm, the end is clamped, and the ultra-low temperature cooling of the test piece is carried out by spraying liquid nitrogen processing, the flow chart of the method is attached figure 1 shown. The specific steps of the method are as follows:

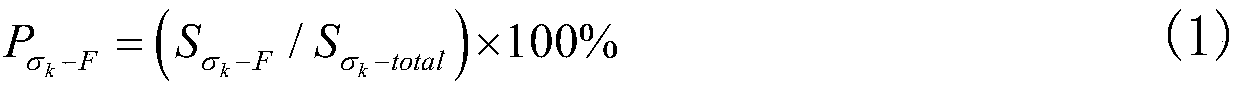

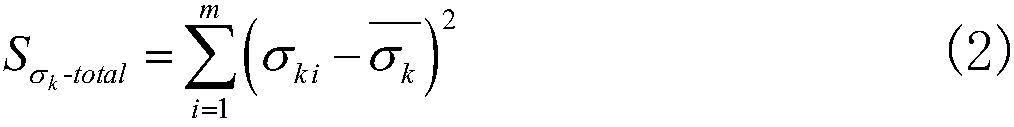

[0048] The first step is to design the Taguchi experiment scheme, implement ultra-low temperature cooling on the test piece, and test the mechanical properties of the material. Design the Taguchi experimental sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com