Gas low temperature heat exchanger capable of self eliminating stress and pollution proof

A low-temperature heat exchanger technology, applied in low-temperature engineering and low-temperature fields, can solve the problems of failing to meet the requirements of anti-pollution and self-stress relief, not considering the influence of thermal expansion and cold contraction heat exchanger sealing performance, etc., and achieve remarkable results. Economic and social benefits, smooth inner surface and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

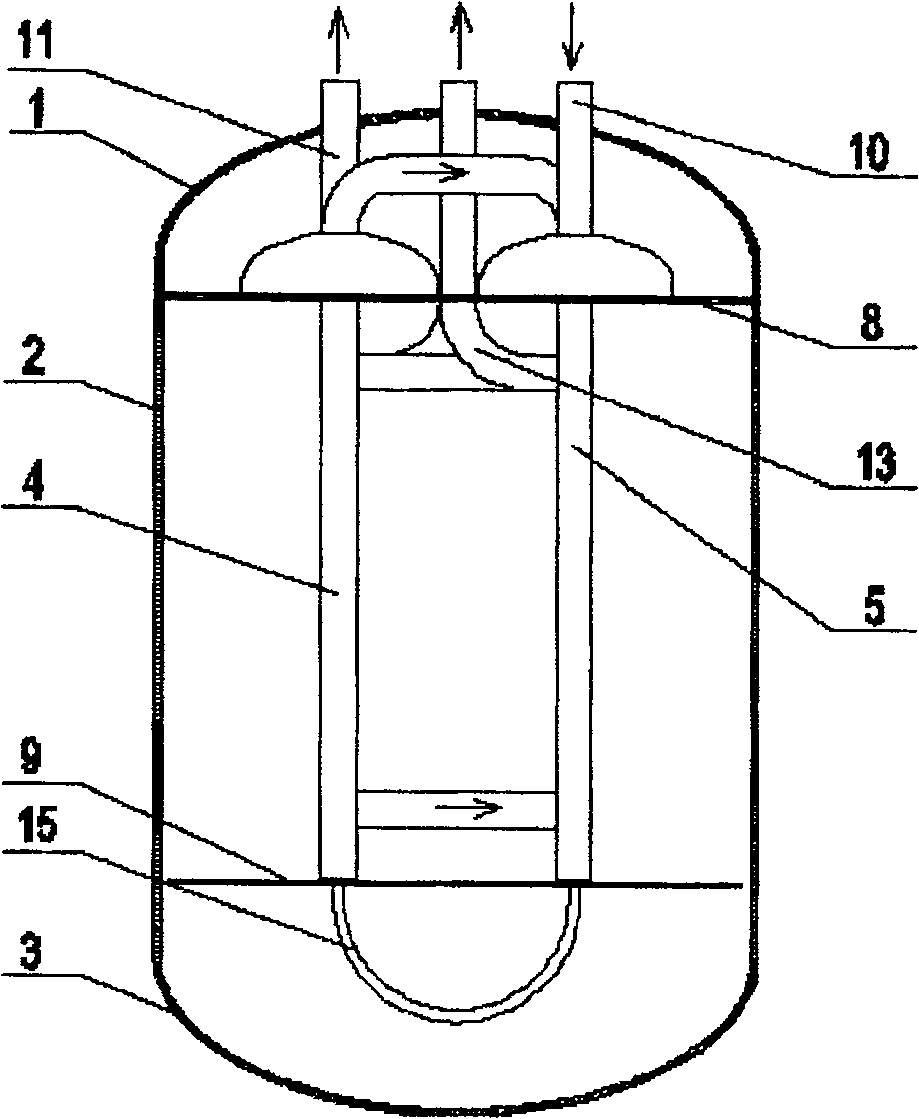

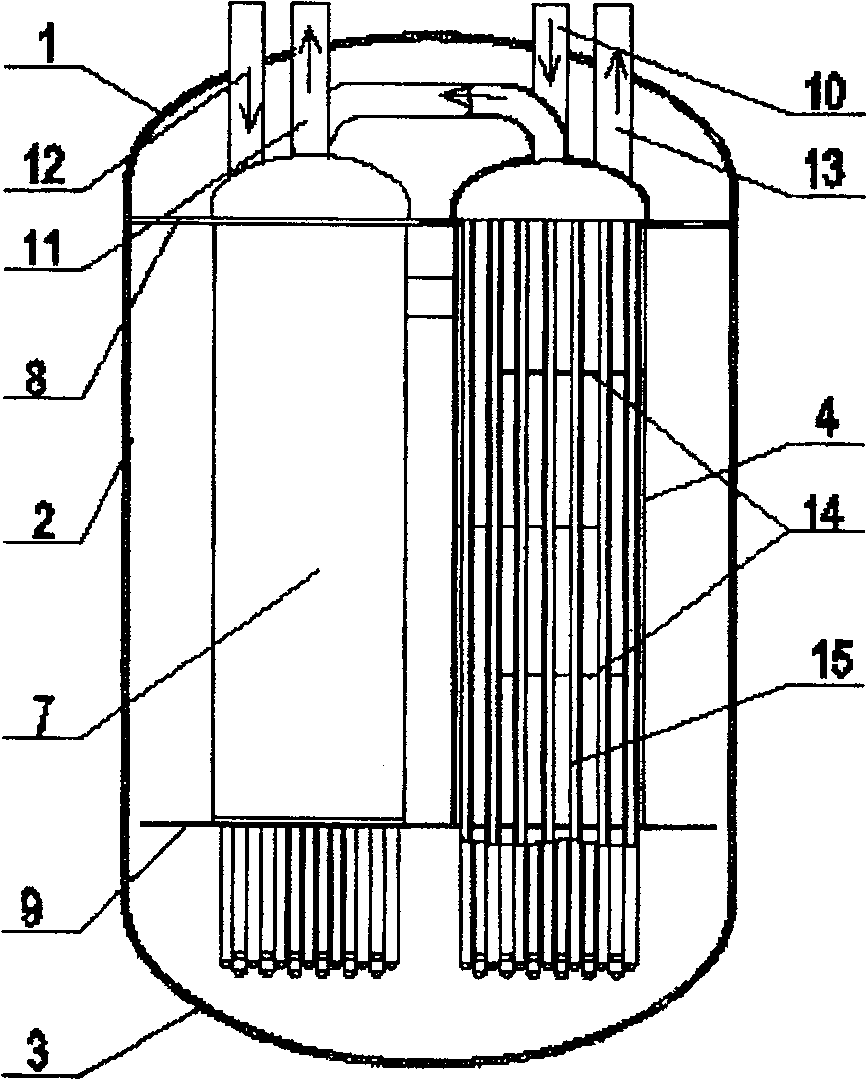

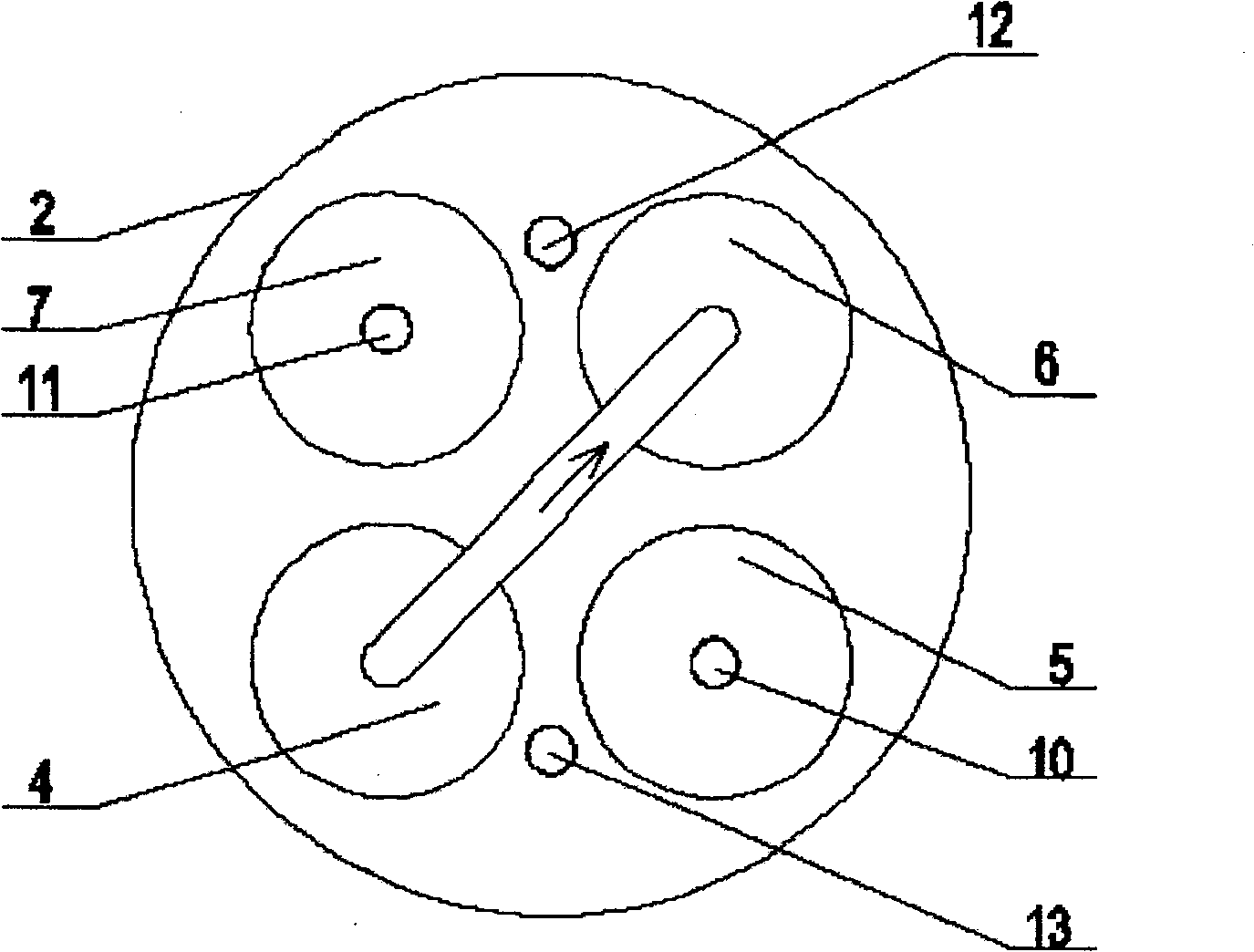

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes a low-temperature heat exchanger upper head 1, a low-temperature heat exchanger cylinder body 2, a low-temperature heat exchanger lower head 3, A shell-and-tube heat exchanger 4, B shell-and-tube heat exchanger 5, C shell and tube heat exchanger 6, D shell and tube heat exchanger 7, tube sheet 8, support plate 9, low temperature heat exchanger tube side inlet pipe 10, low temperature heat exchanger tube side outlet pipe 11, low temperature heat exchanger Shell side inlet pipe 12 and low temperature heat exchanger shell side outlet pipe 13. The tube sheet 8 is located at the upper end of the low-temperature heat exchanger cylinder 2, and the upper head 1 of the low-temperature heat exchanger and the upper end of the low-temperature heat exchanger cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com