Desalting method with phase change for indirectly freeze seawater by using of liquefied natural gas refrigeration capacity

A liquefied natural gas, indirect technology, applied in the field of refrigeration and low temperature, can solve the problem of high energy consumption and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

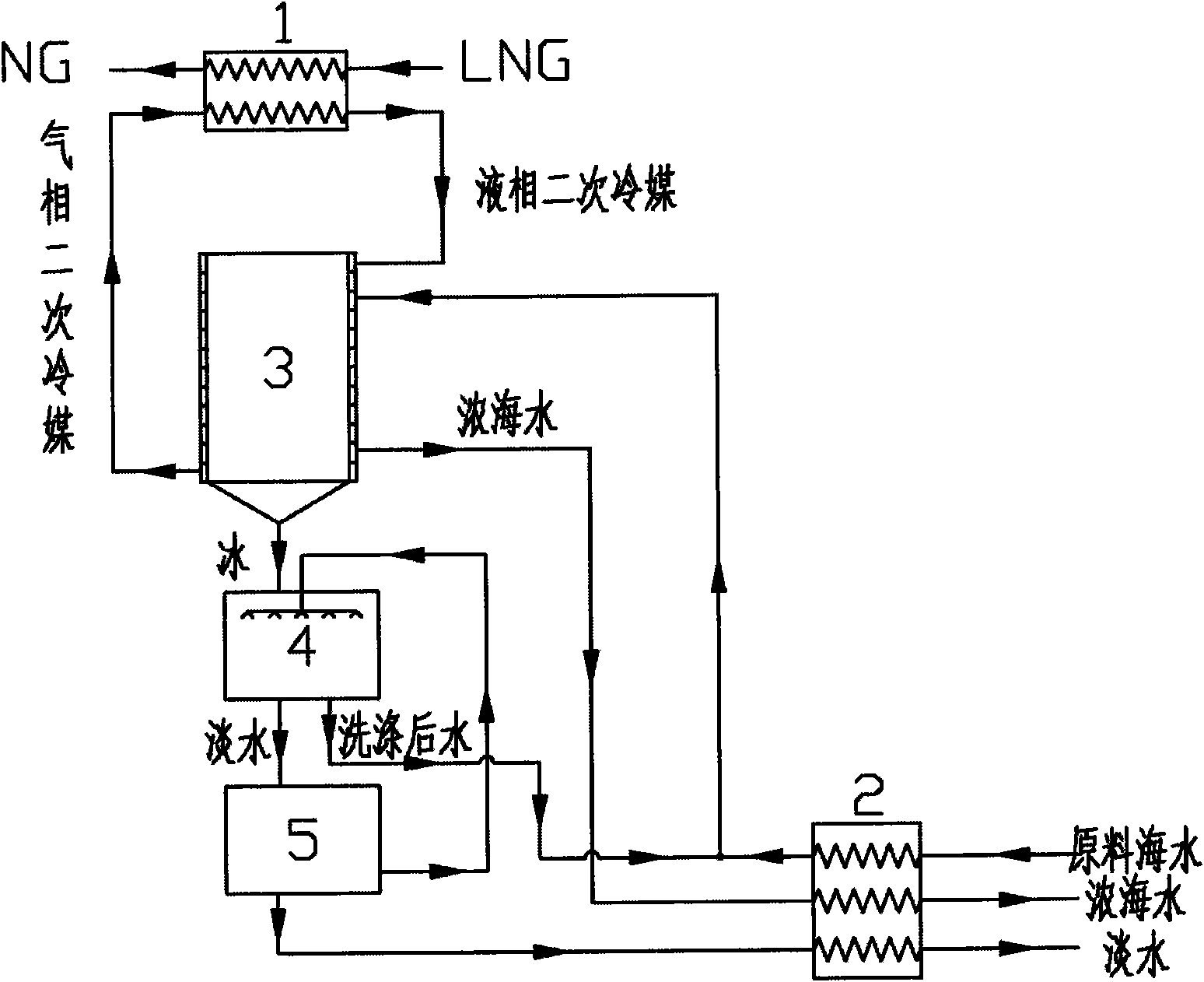

[0015] The specific implementation of the present invention using R410A as the secondary refrigerant will be further described below in conjunction with the accompanying drawings.

[0016] like figure 1 Shown, the inventive method comprises the following steps:

[0017] 1. The liquefied natural gas exchanges heat with the gas-phase secondary refrigerant R410A in the first heat exchanger 1, so that the temperature of the secondary refrigerant decreases and undergoes a gas-liquid phase transition to condense. Among them, the secondary refrigerant R410A is in the first heat exchanger 1 The inlet state parameters are -25°C, 0.33MPa, the outlet state parameters are -32°C, 0.28MPa, and the first heat exchanger 1 adopts a plate-fin low-temperature heat exchanger;

[0018] 2. The secondary refrigerant R410A after cooling and liquefaction enters the evaporation coil outside the crystallizer 3, and the raw seawater enters the inner side of the crystallizer 3 after being cooled by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com