Thermal interface materials and manufacturing method thereof

A technology of thermal interface materials and manufacturing methods, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of limited types and components of thermal interface materials, unsatisfactory wettability between materials and chip substrates, etc., and achieve excellent Thermal properties and wetting properties, effective and convenient filling, and the effect of overcoming poor interface wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

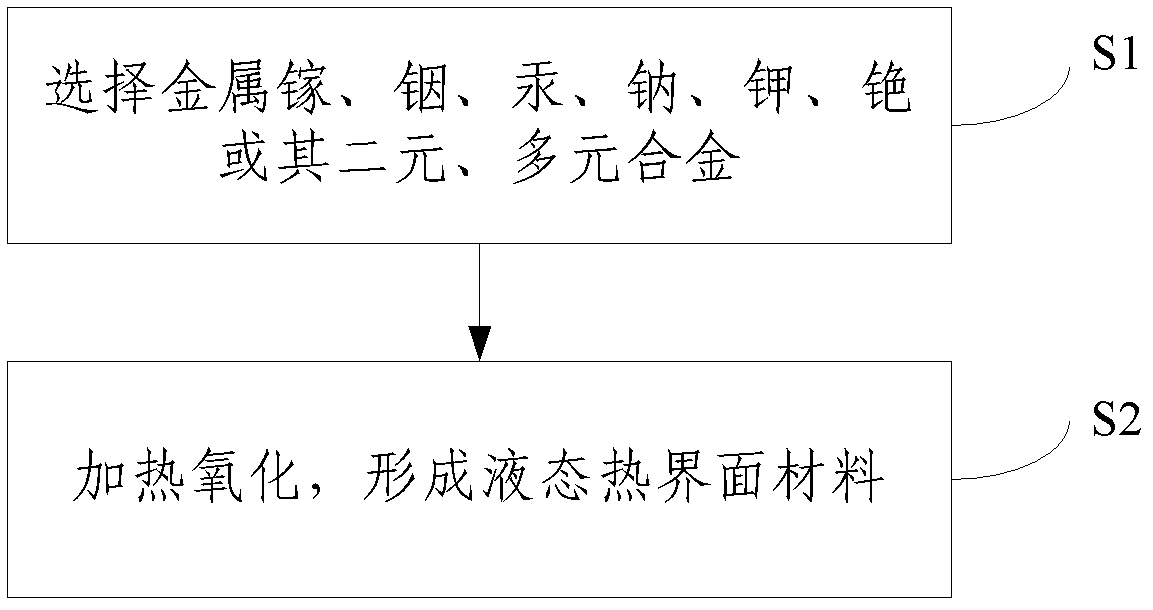

Method used

Image

Examples

Embodiment 1

[0037] Weigh 40 grams of gallium metal, heat it in a water bath to melt it into a liquid state, continue heating in the air, the heating temperature is 100 ° C, use a mechanical stirrer to stir evenly, and the stirring rate is 150 rpm, so that it gradually generates oxygen in the air. The oxidation reaction generates gallium oxide, which is uniformly dispersed in the liquid gallium metal, stirred for 3 hours, and then cooled to room temperature to obtain a liquid gallium metal-based thermal interface material with a certain viscosity.

Embodiment 2

[0039] According to the preparation method of example 1, just change air into high-purity oxygen environment.

Embodiment 3

[0041] According to the preparation method of Example 1, only the liquid metal gallium is replaced by a gallium-indium series alloy (such as 62.5% Ga, 21.5% In, 16% Sn).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com