Double effect device being capable of gas boosting, transferring and recycling

A gas pressurization and gas cylinder technology, which is applied in fluid pressure converters, gas/liquid distribution and storage, equipment loaded into pressure vessels, etc., can solve the problems of high price, gas sample or working medium pollution, gas outlet and inlet pressure The ratio is small and other problems, to achieve the effect of simple structure, low production cost, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

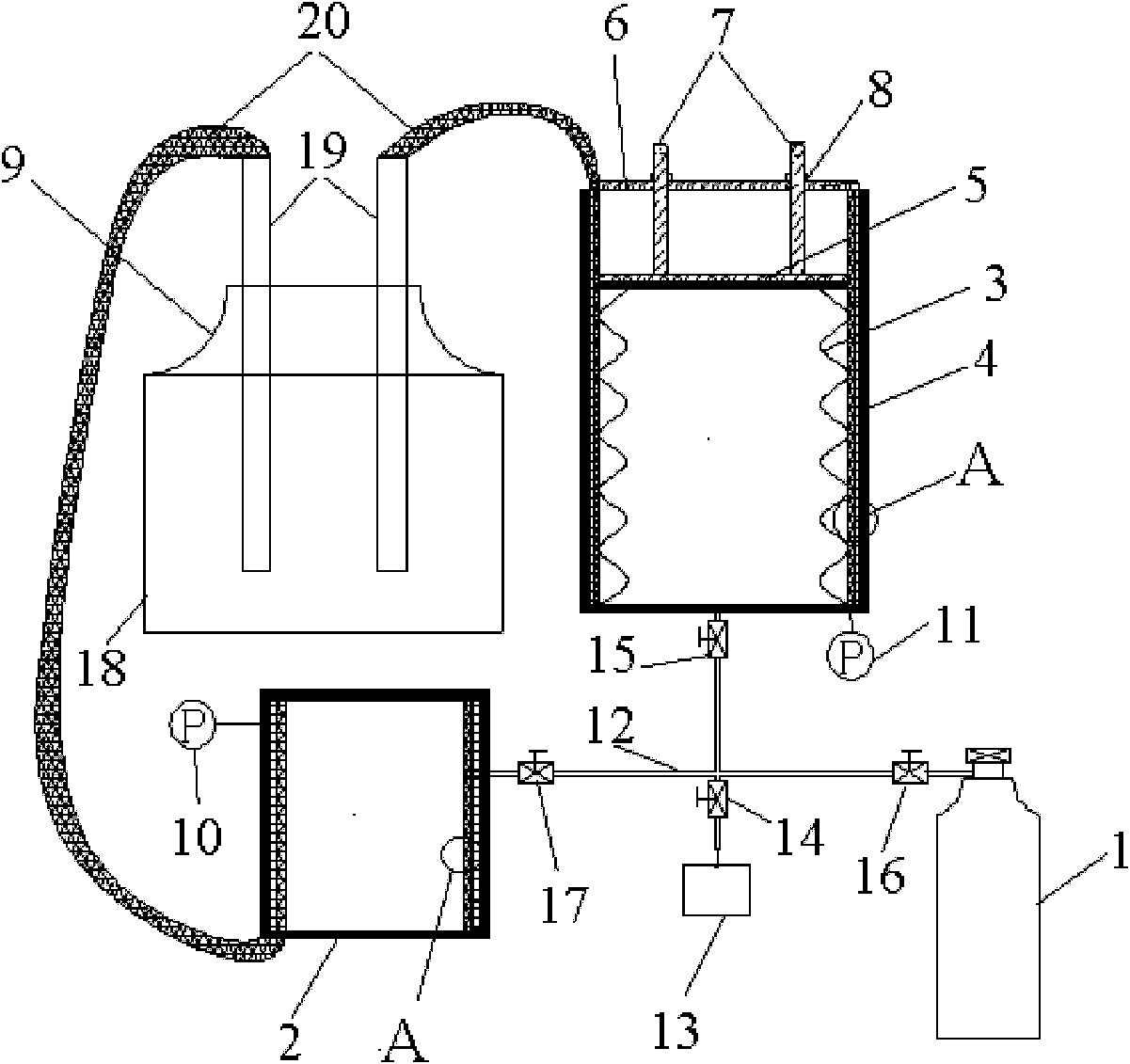

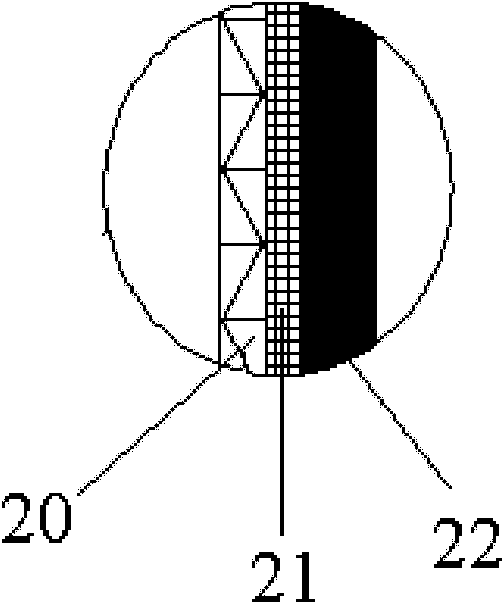

[0022] Such as figure 1 As shown, this embodiment includes: gas source gas cylinder 1, target gas cylinder 2, compressed gas cylinder 3, sleeve 4, flat plate 5, cover 6, adjusting rod 7, limiter 8, refrigerator 9, first Pressure gauge 10, second pressure gauge 11, pipeline 12, vacuum equipment 13, first valve 14, second valve 15, third valve 16 and fourth valve 17, wherein: the sleeve 4 is provided with a compressed gas cylinder 3. Both ends of the compressed gas cylinder 3 are sealed, one end of the compressed gas cylinder 3 is fixed on the bottom of the sleeve 4, and the other end is connected to the plate 5, the plate 5 is movable in the sleeve 4, and the cover 6 is fixed on the sleeve 4, the bottom end of the adjustment rod 7 is fixed on the flat plate 5, the top end of the adjustment rod 7 is socketed with the cover 6 and the top end is provided with a limiter 8, and the refrigerator 9 is connected with the target gas cylinder 2 and the sleeve 4 respectively. The target ...

Embodiment 2

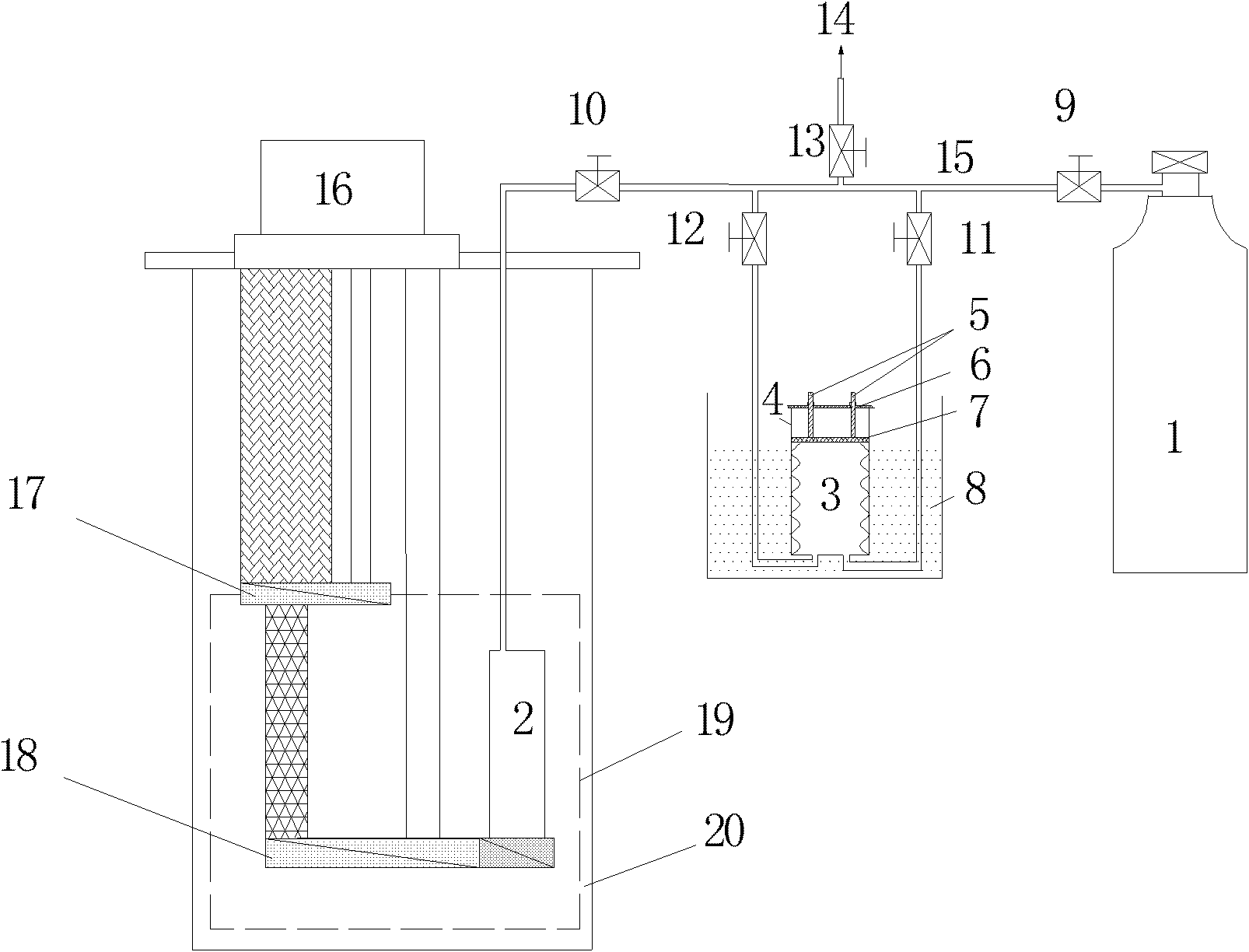

[0037] In this embodiment: a low-temperature refrigerator in the liquid helium temperature zone (such as a commercial GM refrigerator with 1W at 4.2K) is used as a cold source, and its cold head is used to directly cool the compressed gas cylinder and the target gas cylinder.

[0038] Such as image 3 As shown, this embodiment includes a source gas cylinder 1, a target gas cylinder 2, a compressed gas cylinder 3, a sleeve 4, an adjustment rod 5, a cover 6, a flat plate 7, a liquid nitrogen bath 8, a first valve 9, a second Valve 10, third valve 11 and fourth valve 12, fifth valve 13, vacuum equipment 14, pipeline 15, GM refrigerator 15, primary cold head 17, secondary cold head 18, low temperature screen 19, vacuum cover 20. Among them: the sleeve 4 is provided with a compressed gas cylinder 3, the two ends of the compressed gas cylinder 3 are sealed, one end of the compressed gas cylinder 3 is fixed on the bottom of the sleeve 4, the other end is connected with the plate 7, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com