Detachable cryogenic liquid cavitation flow observational test section

A technology of cryogenic liquid and test section, which is applied in the fields of cryogenic engineering, aerospace engineering, and fluid mechanical engineering. It can solve problems such as inconvenient replacement, fragile disassembly, and damage to the glass test section, and achieves convenient disassembly, cost reduction, and synchronization. measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

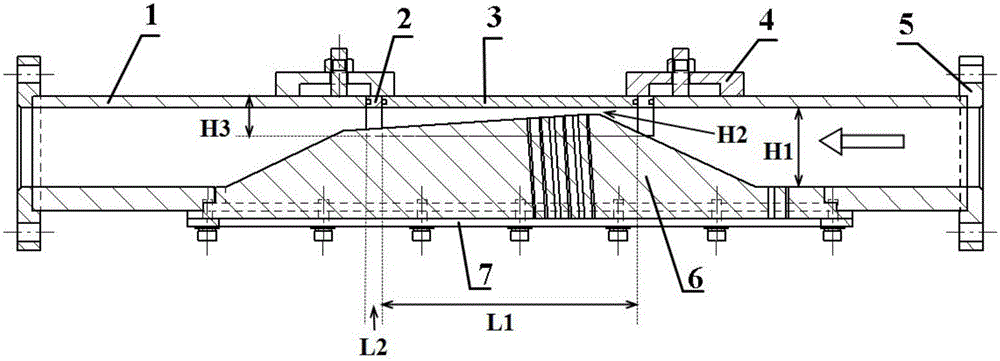

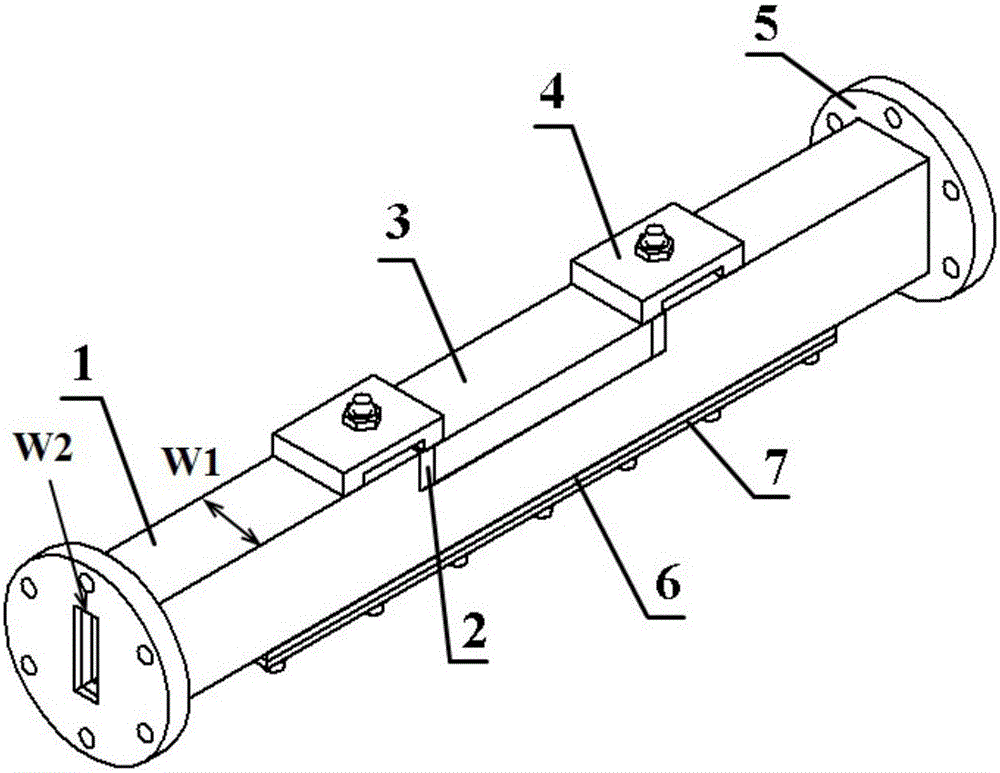

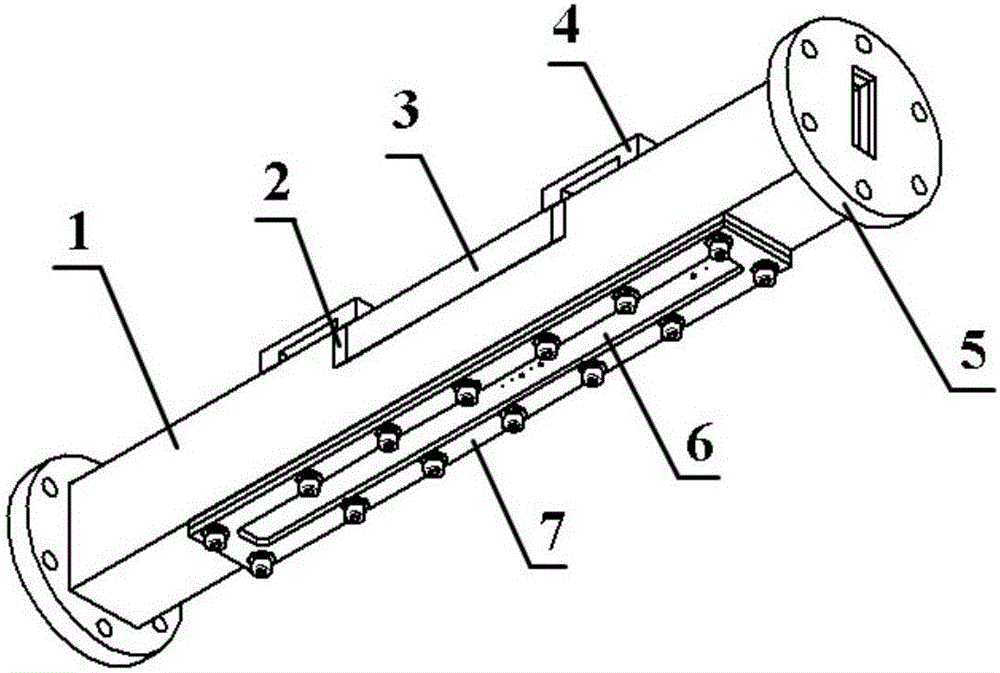

[0046] Such as Figure 1-3 As shown, a detachable cryogenic liquid cavitation flow observation test section consists of a basic flow channel 1, a flow channel lower panel 6, a visual observation window 3, a buffer gasket 2, a compression gasket 7, and a flange plate 5 , temperature sensor and pressure sensor.

[0047] Connection relationship: the temperature sensor and the pressure sensor are installed on the lower panel 6 of the flow channel through the mounting holes; the lower panel 6 of the flow channel is connected to the inner pipe of the basic flow channel 1 through the notch below the basic flow channel 1; and then through the compression gasket 7 is fixedly connected to the basic flow channel 1; the visual observation window 3 is placed at the notch above the basic flow channel 1, and two buffer gaskets 2 are respectively installed on both sides of the visual observation window 3; the connection bayonet 4 is fixedly connected to the basic Above the flow channel 1; fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com