Wide temperature zone hydrogen storage material low temperature hydrogen storage performance testing device

A hydrogen storage material and test device technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of no test device, etc., and achieve the effect of reducing the time required for the test, ensuring replacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

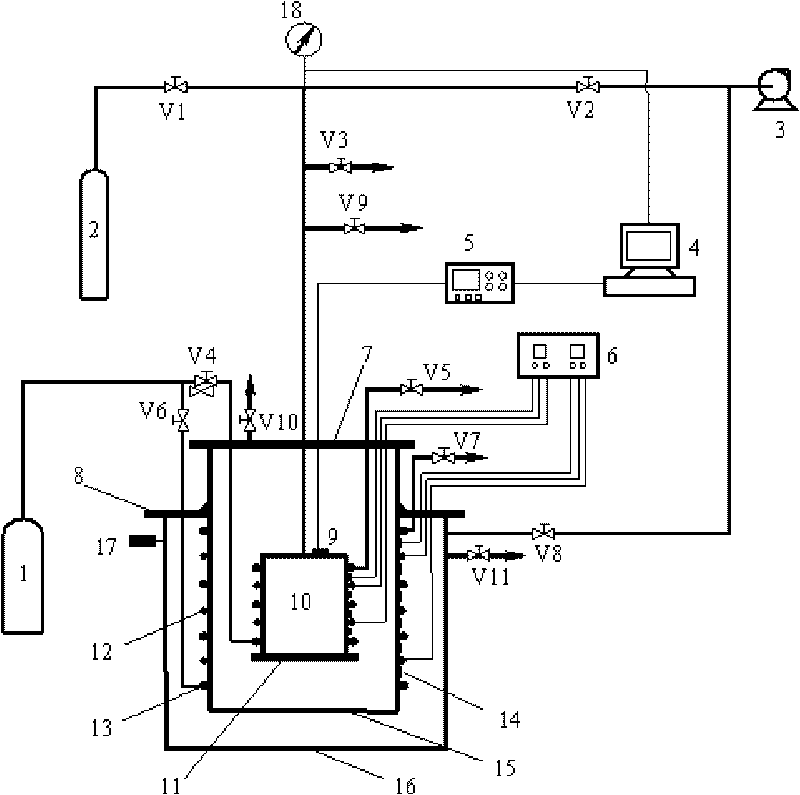

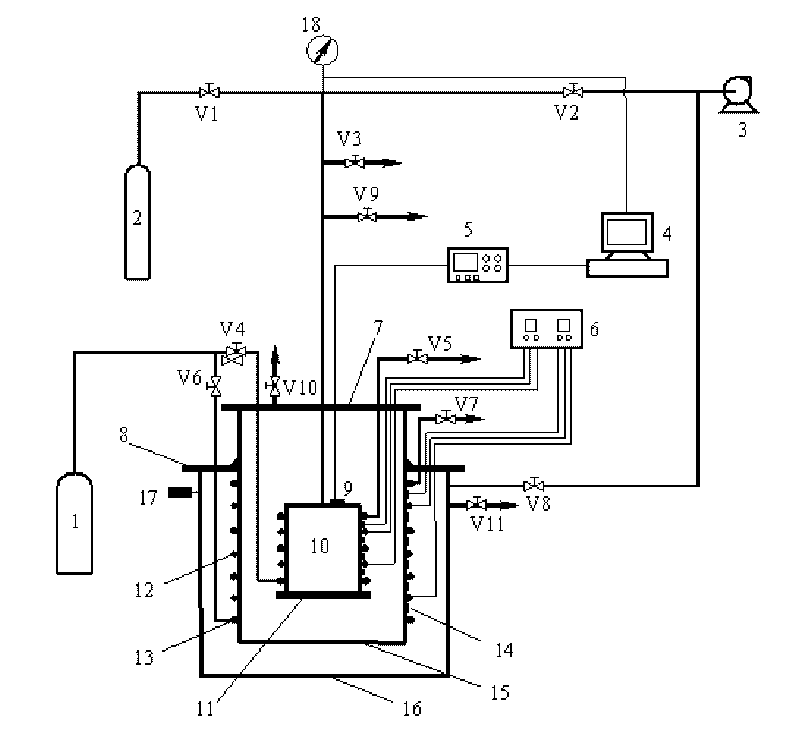

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] like figure 1As shown, the present invention includes a liquid nitrogen Dewar 1, a high-pressure hydrogen cylinder 2, a vacuum unit 3, a data acquisition computer 4, a temperature acquisition instrument 5, a PID temperature controller 6, an inner Dewar flange 7, and an outer Dewar flange 8 , platinum resistance thermometer 9, sample chamber 10, sample chamber flange 11, heating wire 12, cooling coil 13, thermocouple 14, inner Dewar 15, outer Dewar 16, vacuum gauge 17, pressure sensor 18, hydrogen filling Injection valve V1, first vacuum valve V2, hydrogen exhaust valve V3, first liquid nitrogen delivery valve V4, first liquid nitrogen discharge valve V5, second liquid nitrogen delivery valve V6, second liquid nitrogen discharge valve V7, second Two vacuum valves V8, the first safety valve V9, the second safety valve V10, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com