Mechanical seal for starting water feeding pump

A technology for starting feed water pumps and mechanical seals, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. It can solve the problem that the replacement of mechanical seals cannot be completed in a short time, and achieve long-term reliability The effects of running capacity, prolonging life, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

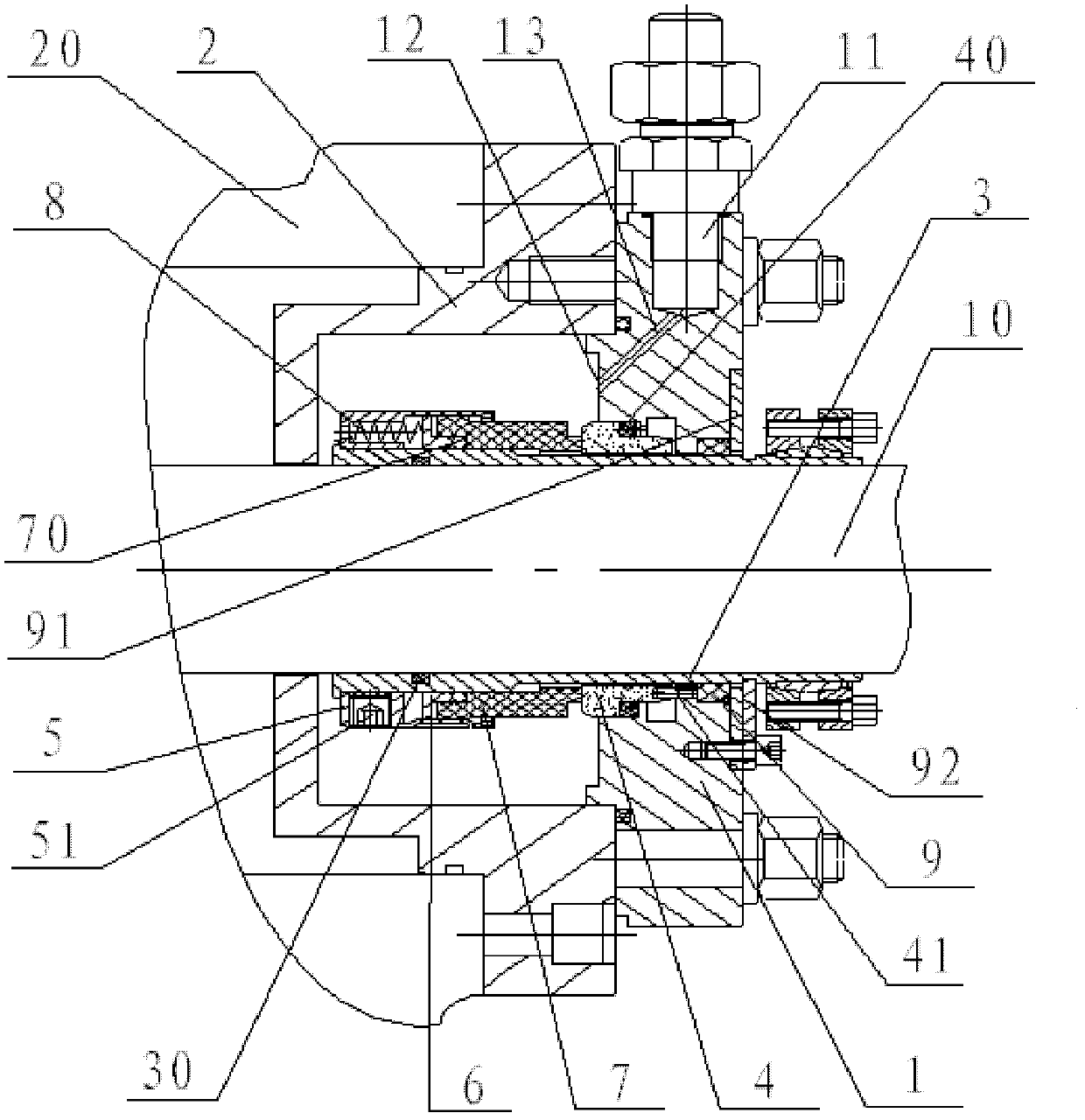

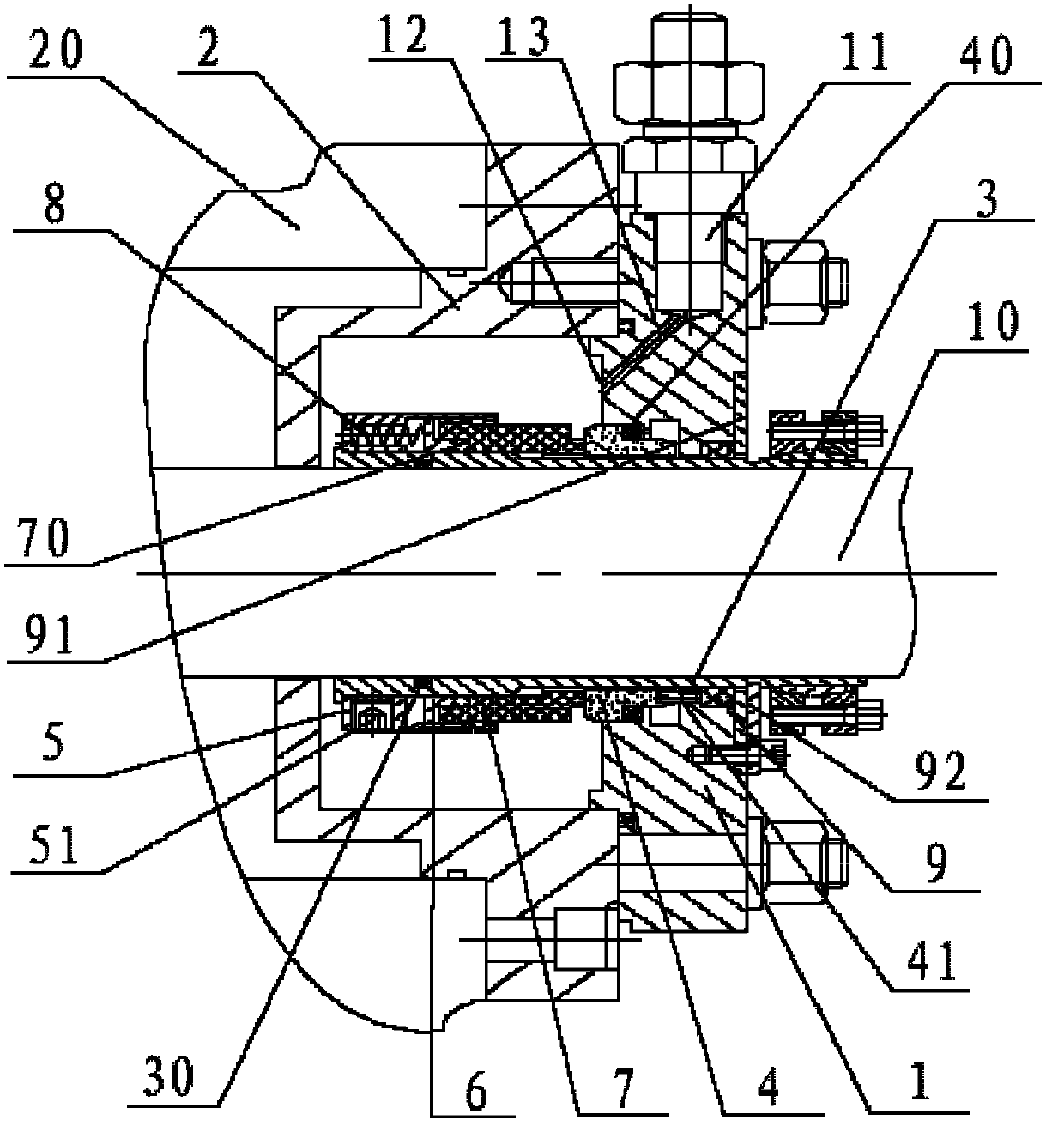

[0020] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

[0021] see figure 1 , a mechanical seal used to start the feed water pump of the present invention is a cartridge type single-end mechanical seal and is installed between the pump casing 20 and the high-speed rotating pump shaft 10, and is mainly used to prevent the fluid medium from passing along the pump casing 20 and the pump shaft 10. The gap between the pump shafts 10 rotating at high speed leaks outward. The mechanical seal includes a mechanical seal gland 1, a mechanical seal connecting ring 2, a mechanical seal sleeve 3, a static ring 4, a sleeve ring 5, a moving ring seat 6, a moving ring 7, a number of coil springs 8 and a throttle ring 9, of which:

[0022] The mechanical seal gland 1 is set on the pump shaft 10 for starting the water pump. The mechanical seal gland 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com