Startup water feed pump for nuclear power station

A technology for starting feedwater pumps and nuclear power plants, applied to the components of pumping devices for elastic fluids, radial flow pumps, pumps, etc., can solve the problem of increasing system complexity and failure sources, mechanical seals cannot be replaced in a short time Complete, increase operating costs and other issues, to achieve the effect of ensuring rotation efficiency, simple structure, and reducing maintenance space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

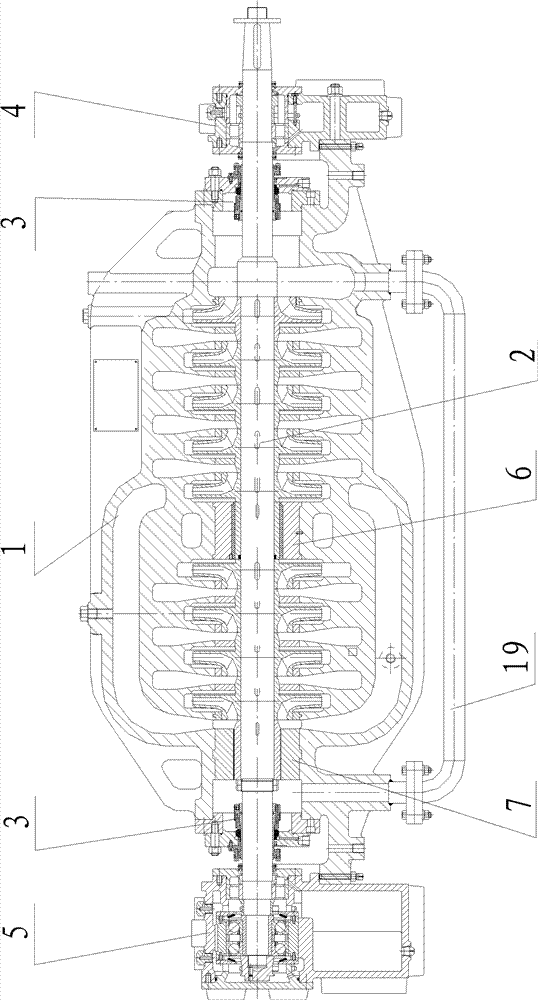

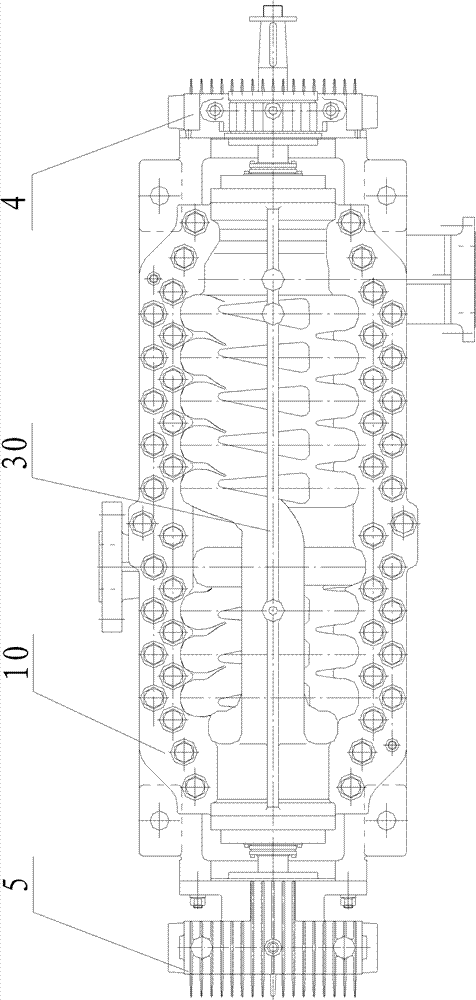

[0043] see figure 1 and figure 2 , a kind of start-up feedwater pump for nuclear power plants of the present invention comprises a stator part 1, a rotor part 2, two sets of mechanical seals 3, a mechanical seal flushing pipe 30 and bearing parts, wherein the two sets of mechanical seals 3 are of the same structure Cartridge single-end mechanical seals are installed opposite to the pump shaft 21 and located at the front and rear ends of the pump body respectively, mainly used to prevent the fluid medium from leaking outward along the gap between the pump body and the high-speed rotating pump shaft 21 ; The bearing components include the front bearing 4, the rear bearing 5, the middle throttling bushing 6 and the rear throttling bushing 7.

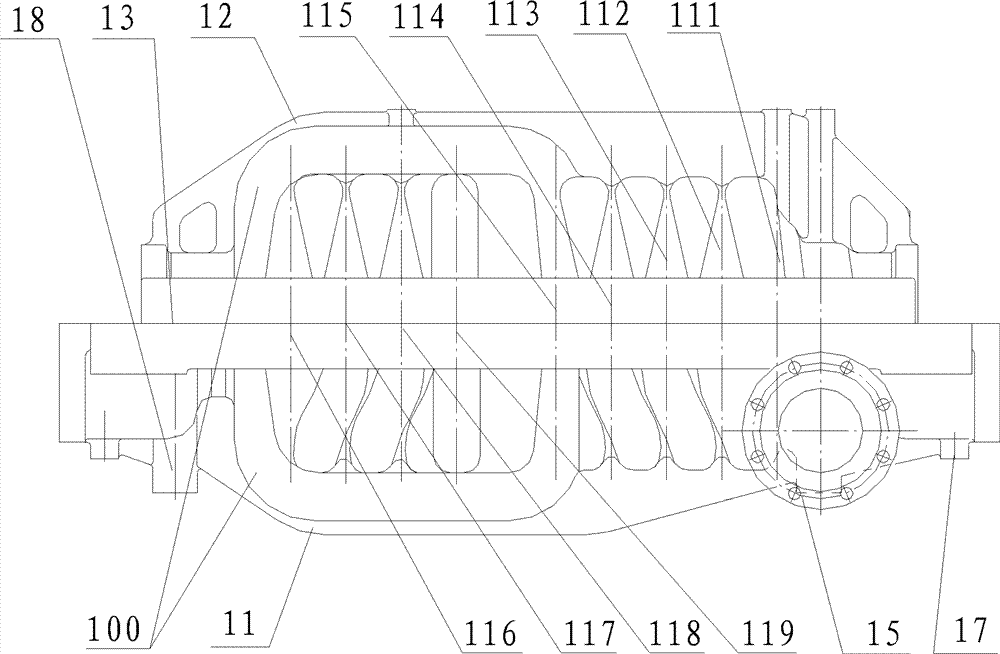

[0044] see again image 3 and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com