Full bridge type MMC direct current ice melting apparatus and control method therefor

A DC ice-melting, bridge-type technology, applied in overhead installation, cable installation, electrical components, etc., can solve the problems of limited application range, reduced comprehensive operation benefit, slow response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation will be described in detail below in conjunction with the accompanying drawings.

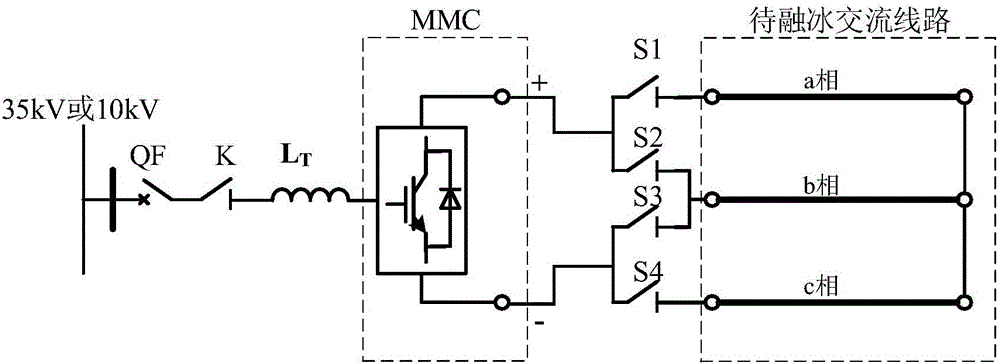

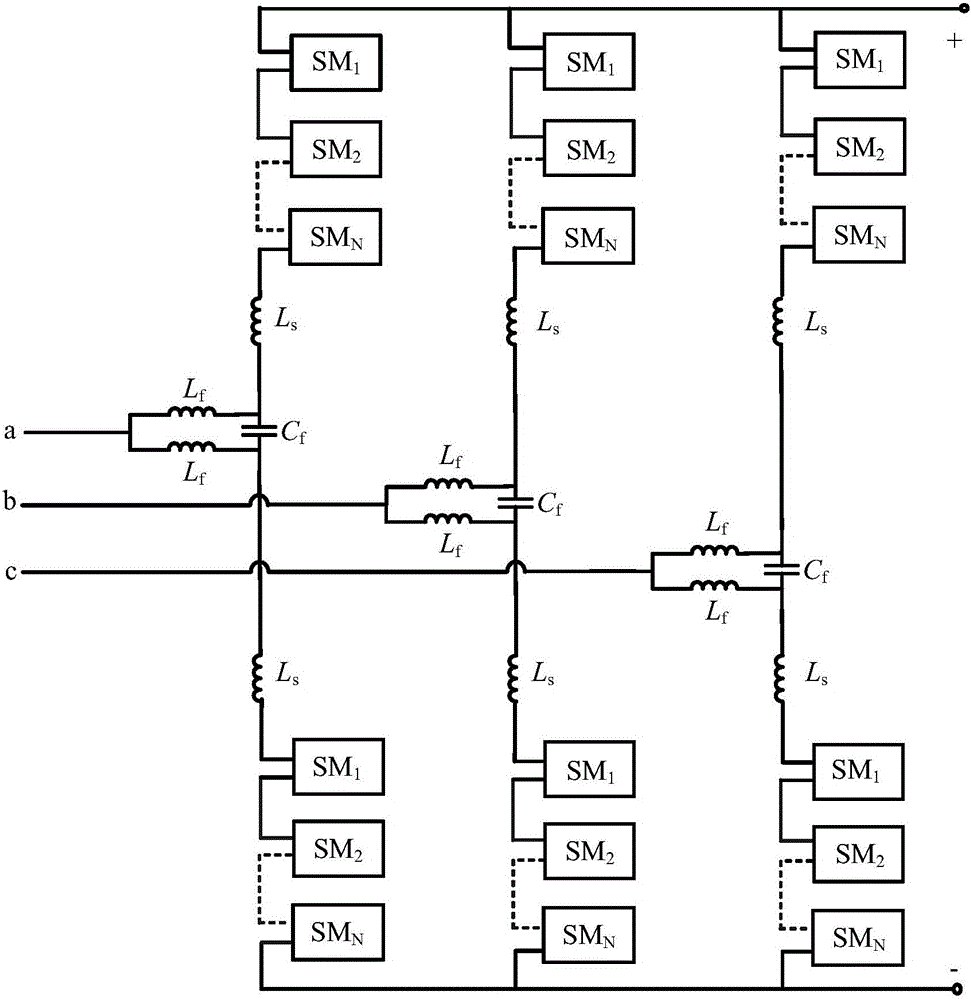

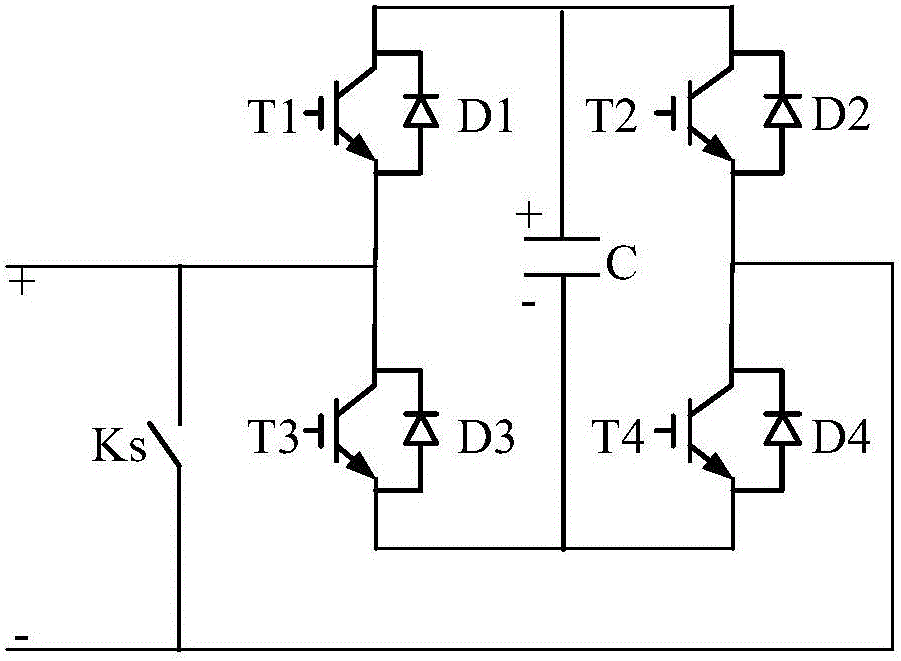

[0040] The structural diagram of a full-bridge type MMC DC ice-melting device of the present invention is as follows figure 1 shown, including: connect the reactor L T , full bridge type MMC, ice melting knife switch S1, S2, S3, S4; among them, the reactor L T One end of the terminal is connected to the 35kV or 10kV AC bus through the isolating switch K and the circuit breaker QF, and connected to the reactor L T The other end is connected to the AC side of the full-bridge MMC; one end of the ice-melting knife switch S1, S2 is connected to the positive pole of the DC side of the full-bridge MMC, and one end of the ice-melting knife switch S3, S4 is connected to the DC side of the full-bridge MMC. The negative pole is connected; the other end of ice-melting knife gate S1 is connected with one end of phase a of the AC line to be melted, the other end of ice-melting knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com