Resonant filter-based MMC DC deicing device and design method thereof

A DC deicing and filter technology, applied in cable installation, overhead installation, electrical components, etc., can solve the problems of large harmonics, limited application range, voltage stress, large valve loss, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation will be described in detail below in conjunction with the accompanying drawings.

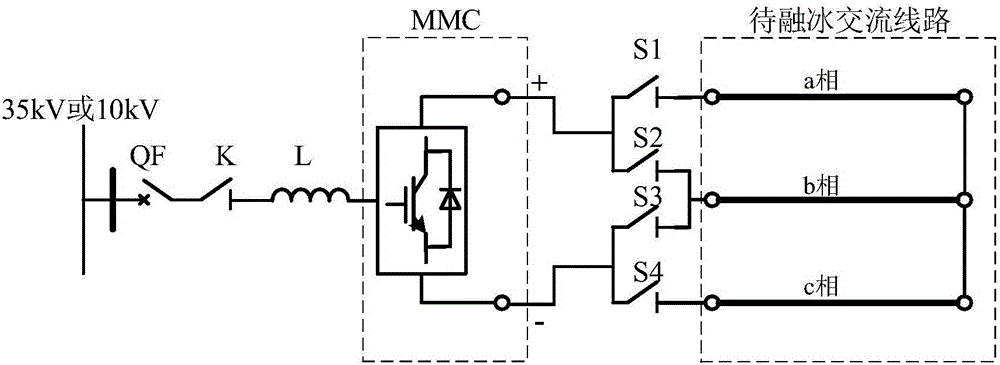

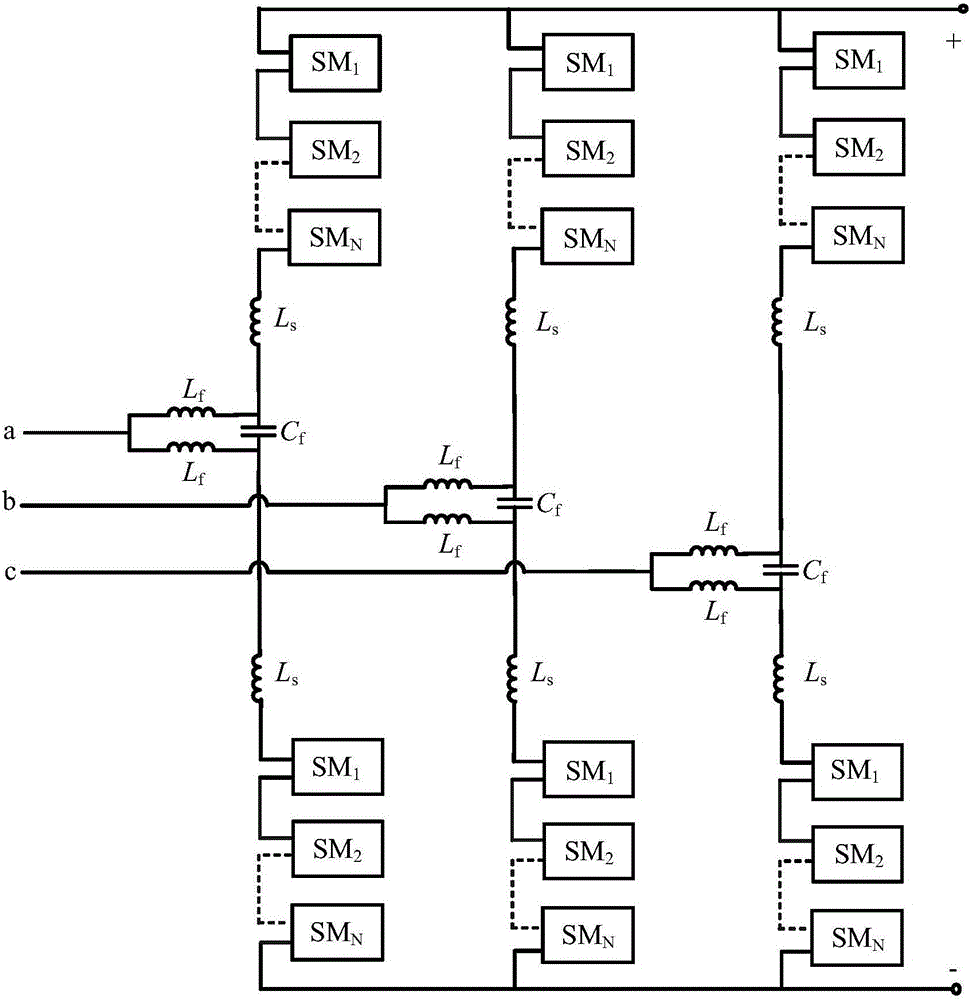

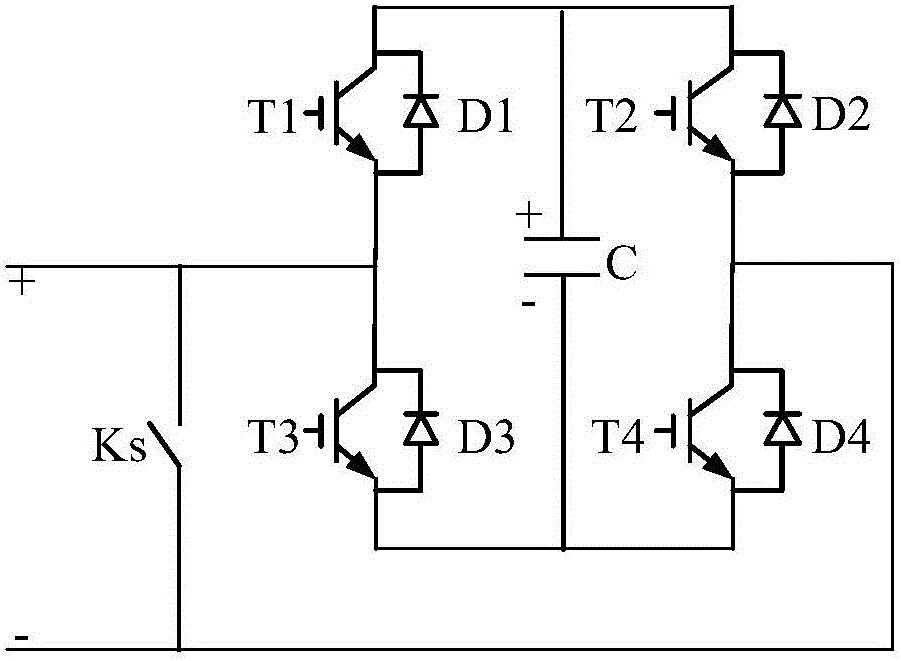

[0025] The structural diagram of a full-bridge type MMC DC deicing device based on a resonant filter of the present invention is as follows figure 1 As shown, it includes: connecting reactor L, full-bridge MMC based on resonant filter, ice-melting knife switch S1, S2, S3, S4; wherein, one end of connecting reactor L is connected to 35kV through isolating switch K and circuit breaker QF Or on the 10kV AC bus, the other end of the reactor L is connected to the AC side of the full-bridge MMC based on the resonant filter; one end of the ice-melting knife switch S1, S2 is connected to the DC side of the full-bridge MMC based on the resonant filter The positive poles are connected, and one end of the ice-melting knife gate S3 and S4 is connected to the negative pole of the DC side of the full-bridge MMC based on the resonant filter; the other end of the ice-melting knife gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com