Device for inhibiting foundation soil from disturbing during removing of steel sheet piles and application method thereof

A technology of steel sheet pile and foundation soil, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve problems affecting application and development, foundation disturbance, surrounding environment impact, etc., to solve environmental impact problems, avoid disturbance, and structure reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

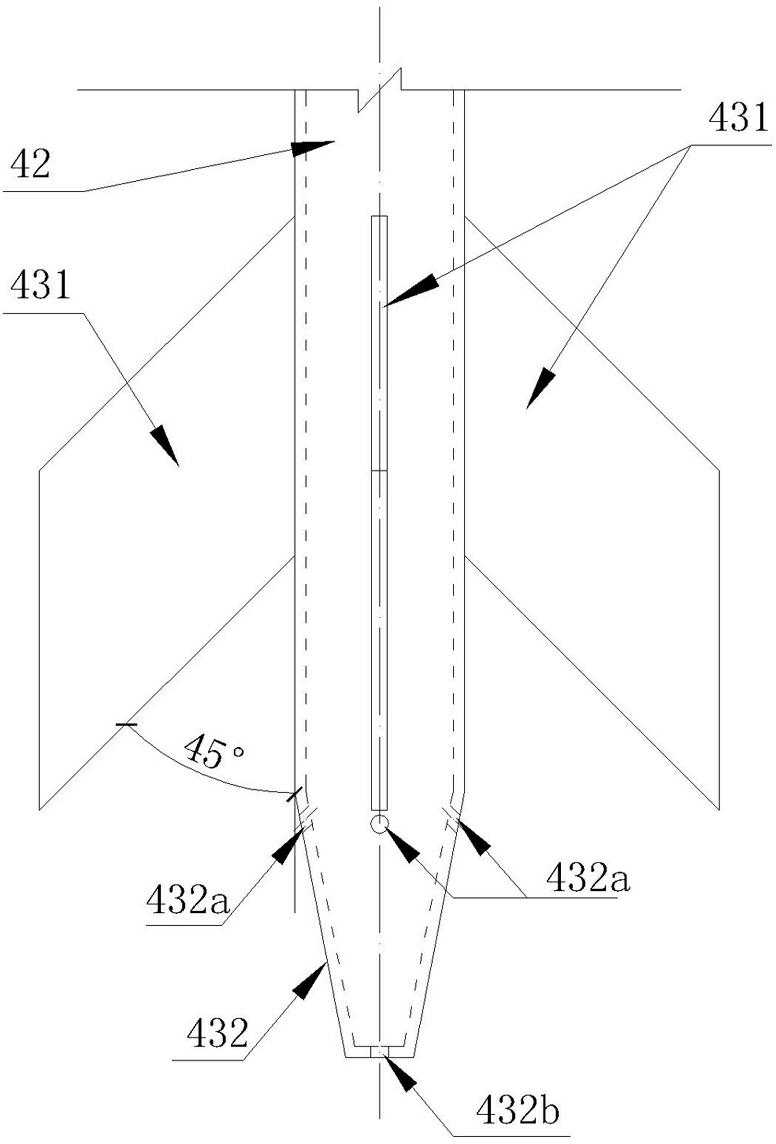

[0091] like image 3 As shown, the water jet holes are distributed according to 1+4, and one water jet hole 432b with a diameter of Ф8mm is set at the center of the bottom end of the conical tube 432, and the high-pressure water is sprayed vertically downward; the other four water jet holes 432a with a diameter of Ф6mm It is arranged on the upper end pipe wall of the tapered pipe 432, and its water jet direction is at an angle of 45° with the horizontal line or the axis of the water jet barrel 42 and the tapered pipe 432, and the high-pressure water is sprayed obliquely to the four sides.

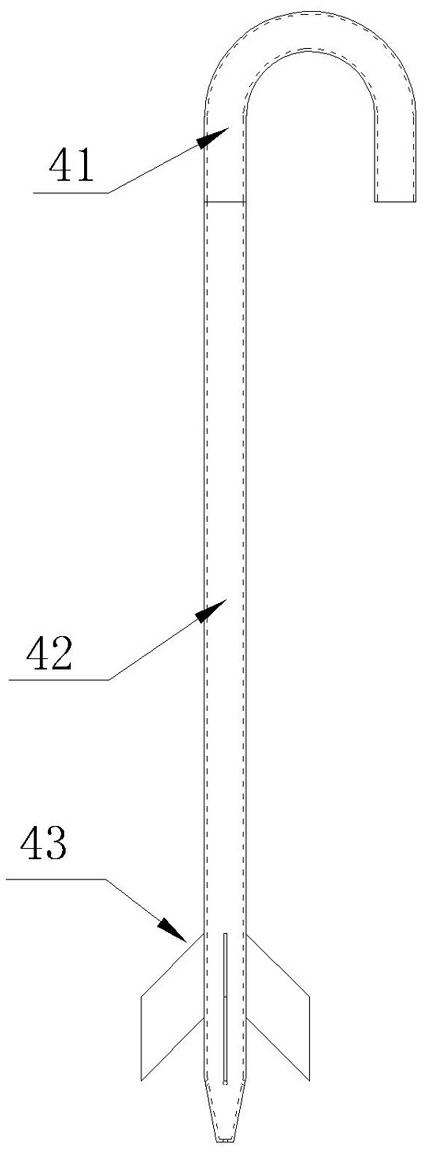

[0092] There are two pairs of welded on the water jet gun head 43 such as figure 2 or image 3 The "aperture-preserving" steel rib 431 shown has the specifications: 5mm×112.5mm×150mm, and the steel rib 431 is radially and evenly welded on the water jet gun barrel 42 with an outer diameter of ≥50mm and ≤100mm at the same height. on the outer wall. The peripheral dimensions of the two opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com