Method for desalting seawater by utilizing cold energy of liquefied natural gas through direct contact refrigeration

A liquefied natural gas, direct technology, applied in the direction of chilled water/sewage treatment, seawater treatment, household refrigeration equipment, etc., can solve the problems of energy consumption, etc., achieve the effect of small loss in the heat exchange process, reduce energy consumption, and small device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

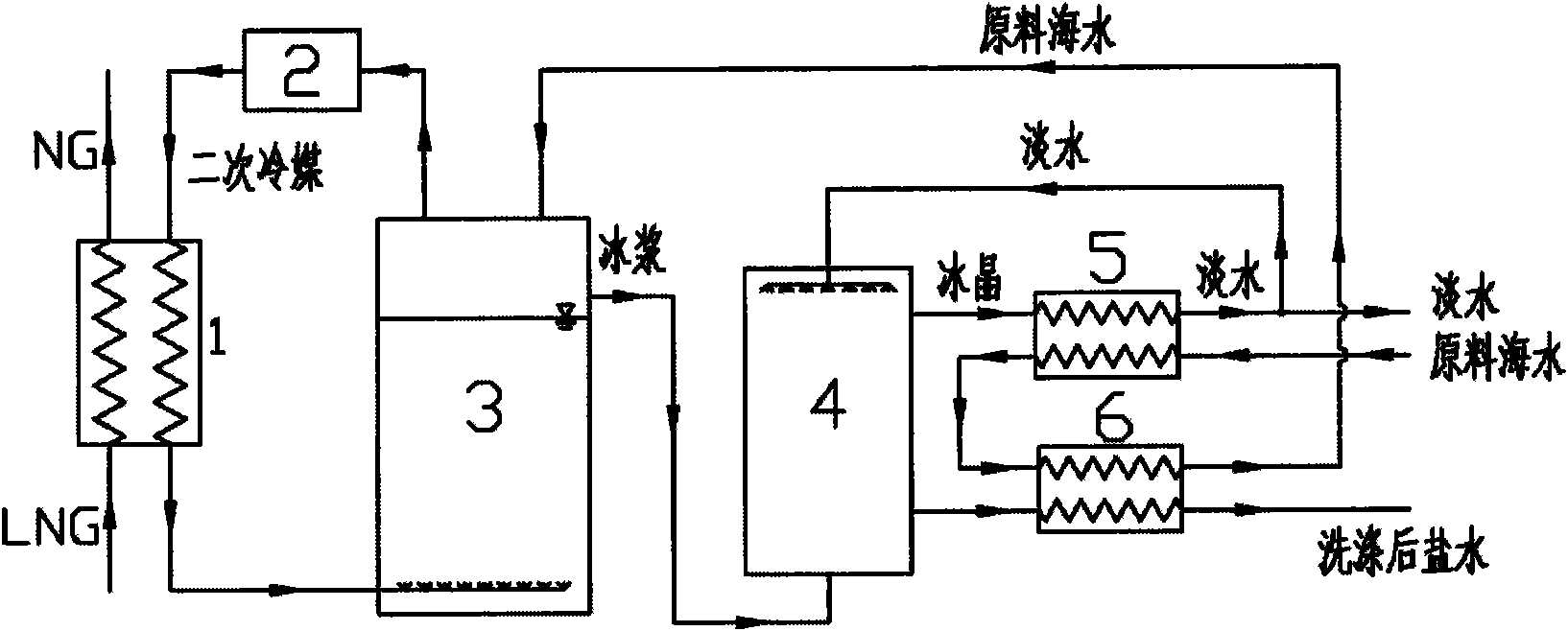

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 Shown, the inventive method comprises the following steps:

[0017] 1. The liquefied natural gas exchanges heat with the water-insoluble secondary refrigerant in the first heat exchanger 1 to evaporate and gasify the liquefied natural gas. The temperature of the secondary refrigerant is lowered and condensed. The secondary refrigerant used is n-butane or isobutane alkyl;

[0018] 2. After condensation, the water-insoluble secondary refrigerant n-butane or isobutane is directly sprayed into a large amount of seawater in the crystallizer 3, the secondary refrigerant droplets evaporate and absorb heat, and the surrounding seawater releases heat and freezes into ice crystals;

[0019] 3. The gasified secondary refrigerant is extracted from the crystallizer 3, and the water vapor entrained in the gas-phase secondary r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com