High-strength 9% Ni steel for ultra-low temperature engineering fasteners and its preparation method

An engineering fastener, high-strength technology, applied in the field of low-temperature metal materials, can solve problems such as unsatisfactory, and achieve excellent room/low temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

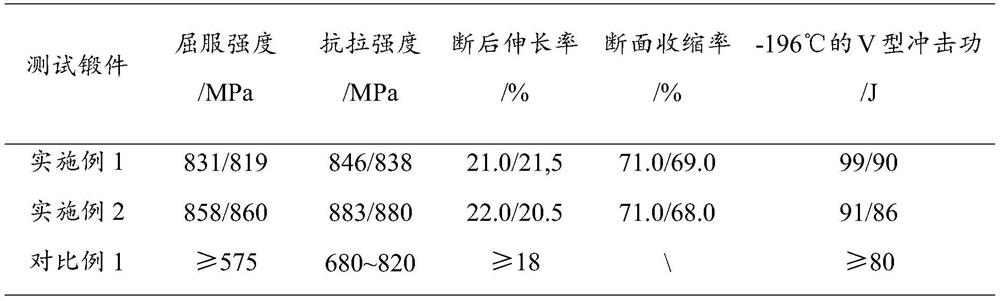

Examples

preparation example Construction

[0024] The invention provides a preparation method of high-strength 9% Ni steel for ultra-low temperature engineering fasteners, comprising the following steps:

[0025] The raw materials are smelted according to the vacuum induction-electroslag remelting process, and the resulting smelting liquid is cast to obtain steel ingots; in terms of element content, the raw materials are weighed according to the following weight percentages: C 0.02-0.06%, Si≤0.15%, Mn 0.30~0.80%, S≤0.005%, P≤0.008%, Cr≤0.10%, V 0.03~0.08%, Ni 9.50~10.0%, Mo0.12~0.16%, H≤1.0ppm, O≤0.01%, N ≤0.01%, the balance is high-purity Fe;

[0026] Forging the steel ingot to obtain a forging;

[0027] The forgings are sequentially quenched and tempered to obtain the high-strength 9% Ni steel for ultra-low temperature engineering fasteners.

[0028] The raw material of the present invention is smelted according to the vacuum induction-electroslag remelting process, and the resulting smelting solution is cast to ob...

Embodiment 1

[0059] According to: C: 0.029%, Si: 0.038%, Mn: 0.61%, Cr: 0.020%, Ni: 9.61%, V: 0.037%, Mo: 0.15%, S: 0.004%, P: 0.0068%, H: 0.8 ppm, O: 0.0086%, N: 0.0064%, and the balance is high-purity Fe.

[0060] Smelting through the process of "vacuum melting + electroslag remelting" and casting the obtained molten liquid to obtain steel ingots required for forging; the process parameters of the "vacuum melting + electroslag remelting" are: the parameters of vacuum induction melting include: chemical power The refining temperature is 1560℃, and the vacuum degree is 2 o 3 25%, CaO 15%; the melting rate is 11 kg / min; the atmosphere is dry air.

[0061] The steel ingot was forged at an initial forging temperature of 1200°C and a final forging temperature of 900°C, with a forging ratio of 7, and the forged piece obtained after forging was buried in sand and cooled to room temperature to obtain a forged piece with an effective thickness of 80mm;

[0062] Raise the temperature at 80°C / h t...

Embodiment 2

[0065] According to: C: 0.043%, Si: 0.12%, Mn: 0.71%, Cr: 0.015%, Ni: 9.97%, V: 0.044%, Mo: 0.15%, S: 0.003%, P: 0.003%, H: 0.5 ppm, O: 0.009%, N: 0.0053%, and the balance is high-purity Fe.

[0066] Through the process of "vacuum melting + electroslag remelting" melting, the resulting molten liquid is cast to obtain the steel ingots required for forging; the process parameters of the "vacuum melting + electroslag remelting" are:

[0067] The parameters of vacuum induction melting include: chemical power of 750kW, power-up rate of 200kw / h; refining temperature of 1570°C, vacuum degree 2 o 3 25%, CaO 15%; the melting speed is 12 kg / min; the atmosphere is dry air, and the content of H element is controlled during the remelting process.

[0068] The steel ingot was forged at an initial forging temperature of 1160°C and a final forging temperature of 850°C, with a forging ratio of 6, and the forged piece obtained after forging was buried in sand and cooled to room temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com