High-efficiency hydrogen removal device in high-vacuum multilayer heat-insulation cryogenic container

A low-temperature container, multi-layer insulation technology, applied in the direction of pressure vessels/vacuum containers, pressure vessels used in chemical processes, chemical instruments and methods, etc., can solve the problems of high price, low hydrogen absorption capacity of palladium, etc., and achieve low cost , fast adsorption speed, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

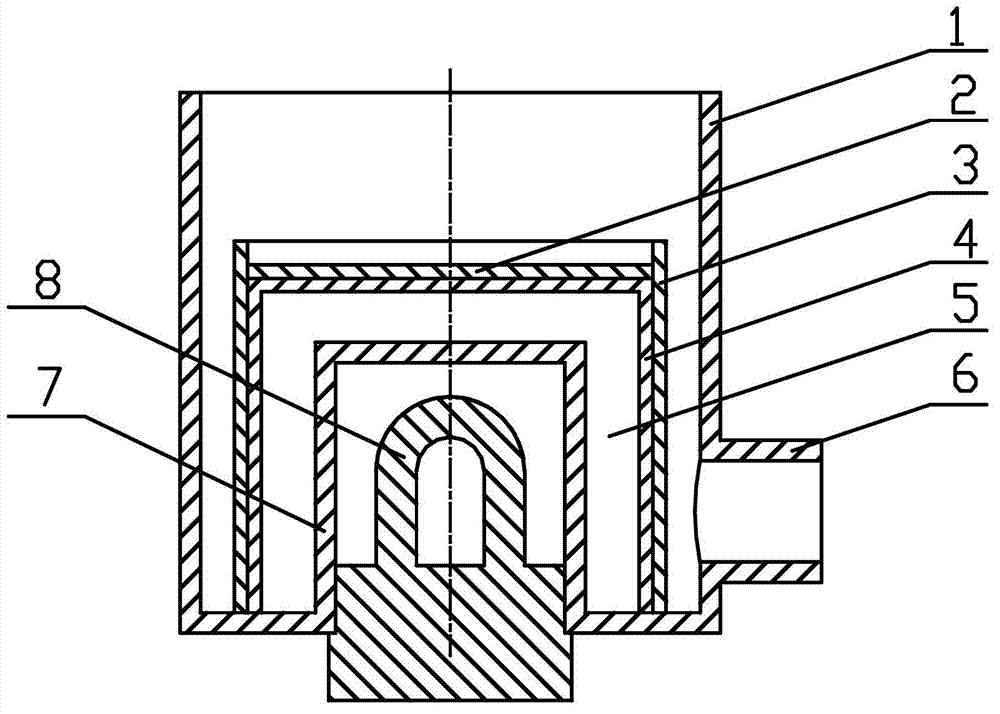

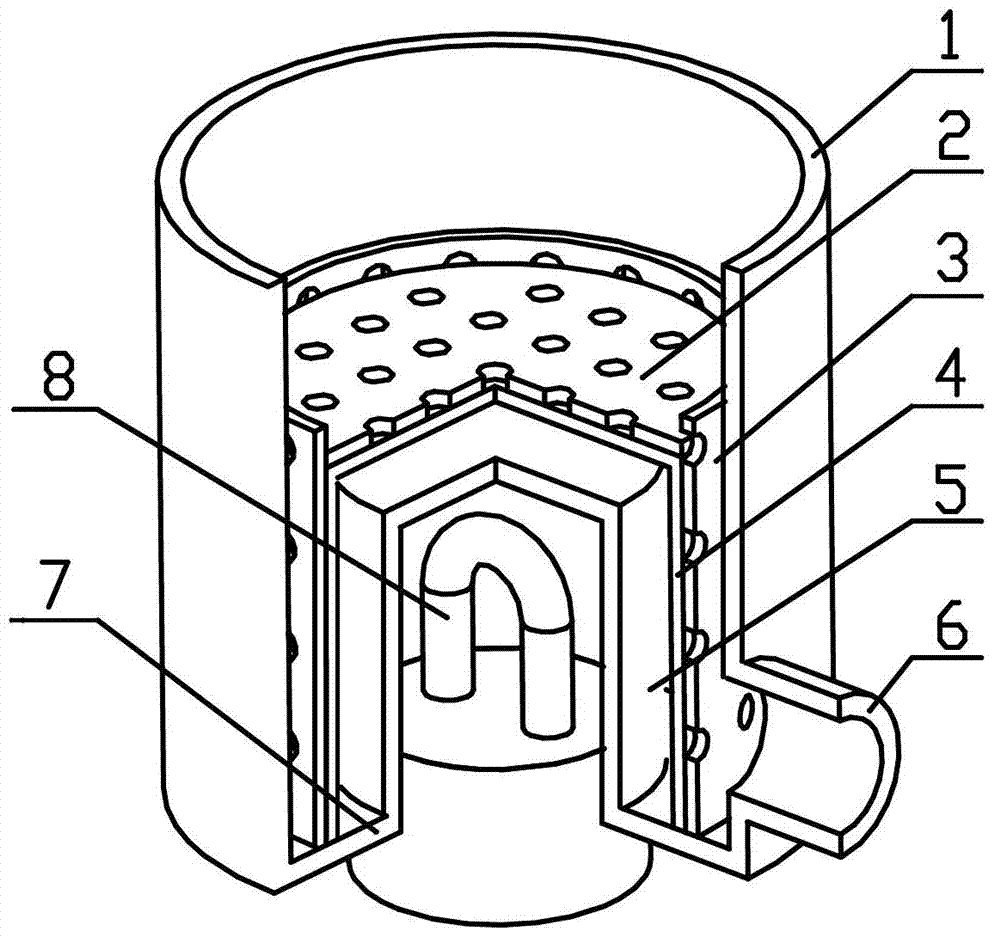

[0012] Such as figure 1 , figure 2 As shown, the device of the present invention includes an air outlet pipe 1, a cover net 2, a side net 3, a glass fiber cloth 4, an adsorption chamber 5, an air intake pipe 6, a concave bottom plate 7, an electric heater 8 and hydrogen absorbing agent copper oxide powder. Wherein the intake pipe 6 is vertically welded on the side of the outlet pipe 1 bottom, the concave base plate 7 is welded on the bottom of the outlet pipe 1, the electric heater 8 is placed in the groove of the concave base plate 7 and is threadedly connected with the concave base plate 7, The side net 3 wraps around the inner wall of the air outlet pipe 1, and its bottom end is welded on the concave bottom plate 7 with a gap between it and the inner wall of the air outlet pipe 1. The cover net 2 is placed on the top of the side net 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com