Manufacturing method of 9% Ni steel ultra-large-specification cake-shaped forge piece for ultralow-temperature engineering

A technology with super-large specifications and manufacturing methods, which is applied in the field of metal thermal processing, can solve the problems of narrow deformable temperature range, high deformation resistance of forging billets, and easy cracks, etc., to eliminate the source of crack induction, improve surface plasticity, and avoid cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

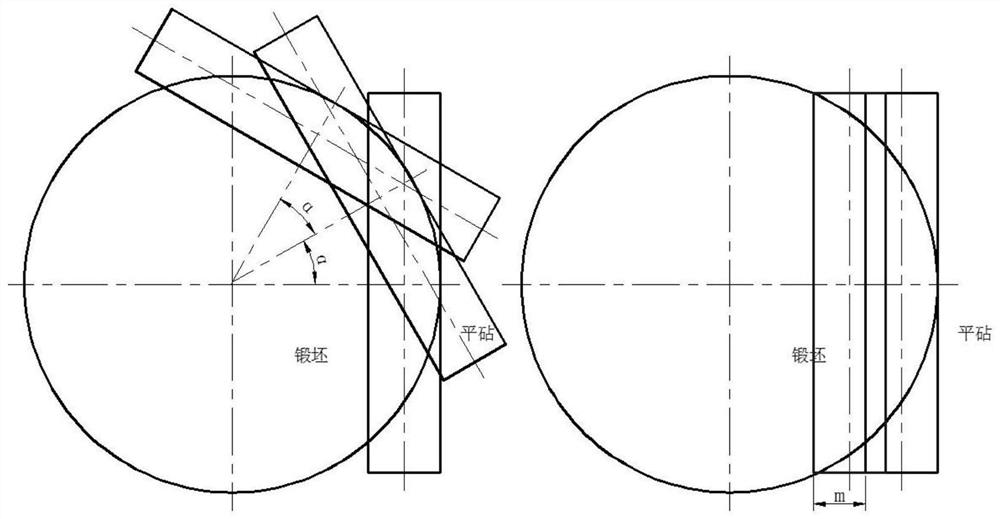

Method used

Image

Examples

Embodiment 1

[0071] The composition of the cylindrical steel ingot is preferably: C 0.02%, Si 0.08%, Mn 0.69%, S 0.002%, P 0.004%, Cr 0.09%, Ni 9.88%, Mo 0.09%, Cu 0.13%, Al 0.008% , As 0.0026%, Sn0.0020%, Sb 0.0010%, Pb 0.002%, Bi 0.0018%, H 0.6ppm, O 12ppm, N 32ppm, the balance is high-purity iron Fe;

[0072] The target size of 9% Ni steel super-sized pie-shaped forgings for ultra-low temperature engineering is 3500mm in diameter D and 450mm in height H;

[0073] Based on (H 圆柱形坯体 -H 9%Ni钢饼形锻件 ) / H 圆柱形坯体 =35.7% and the principle of constant volume, the height of the cylindrical blank is 700mm, and the diameter is 2806.2mm. After rounding, the diameter of the cylindrical blank is 2810mm.

[0074] After obtaining the size of the cylindrical green body, based on (H 圆柱形钢锭 -H 圆柱形坯体 ) / H圆柱形钢锭 =75.9% and the principle of constant volume, the height of the cylindrical steel ingot is 2904.6mm, and the diameter is 1379.5mm. After rounding, the height of the cylindrical steel ingot is 2900mm,...

Embodiment 2

[0090] The composition of the cylindrical steel ingot is preferably: C 0.05%, Si 0.11%, Mn 0.68%, S 0.002%, P 0.005%, Cr 0.13%, Ni 9.76%, Mo 0.12%, Cu 0.14%, Al 0.010% , As 0.0028%, Sn0.0018%, Sb 0.0009%, Pb 0.0021%, Bi 0.0020%, H 0.8ppm, O 15ppm, N 34ppm, the balance is high-purity iron Fe;

[0091] The target size of 9% Ni steel super-sized pie-shaped forgings for ultra-low temperature engineering is 3500mm in diameter D and 450mm in height H;

[0092] Based on (H 圆柱形坯体 -H 9%Ni钢饼形锻件 ) / H 圆柱形坯体 =35.7% and the principle of constant volume, the height of the cylindrical blank is 700mm, and the diameter is 2806.2mm. After rounding, the diameter of the cylindrical blank is 2810mm.

[0093] After obtaining the size of the cylindrical green body, based on (H 圆柱形钢锭 -H 圆柱形坯体 ) / H圆柱形钢锭 =75.9% and the principle of constant volume, the height of the cylindrical steel ingot is 2904.6 mm, and the diameter is 1379.5 mm. After rounding, the height of the cylindrical steel ingot is 2900...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com